Results of experimental testing of agricultural combined aggregate for processing and fine seed crops before sowing in the soil

Автор: Turdaliev V., Asqarov N., Yigitaliyev J.

Журнал: Экономика и социум @ekonomika-socium

Рубрика: Основной раздел

Статья в выпуске: 6-1 (85), 2021 года.

Бесплатный доступ

This article provides information on the results of the experimental-testing in the field conditions of a new effective prototype of a combined unit for sowing small seeds of agricultural crops.

Combined unit, soil, compactor, milling drum, blade, seeder, drum

Короткий адрес: https://sciup.org/140259523

IDR: 140259523 | УДК: 631.31

Текст научной статьи Results of experimental testing of agricultural combined aggregate for processing and fine seed crops before sowing in the soil

РЕЗУЛЬТАТЫ ЭКСПЕРИМЕНТАЛЬНЫХ ИСПЫТАНИЙ

СЕЛЬСКОХОЗЯЙСТВЕННОГО КОМБИНИРОВАННОГО АГРЕГАТА ДЛЯ ПЕРЕРАБОТКИ И МЕСТОРОЖДЕНИЯ СЕМЕННЫХ КУЛЬТУР ПЕРЕД

Турдалиев Вохиджон доктор технических наук, профессор, Наманганский инженерностроительный институт

Аскаров Нодиржон исследовательский стажер, Наманганский инженерностроительный институт Йигиталиев Джалолиддин

Студент, Наманганский инженерно-строительный институт

In addition, most farms have 40 ... 70% of the fractional composition of the soil (at a depth of 10 ... 20 cm) during the planting season, which is difficult to grind (diameter 10 cm and above) [1]. The presence of such cuttings has a negative impact on the agro-technical performance of soil preparation for sowing and sowing operations of small-seeded crops. [2].

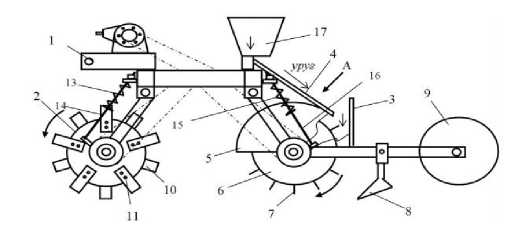

The combined aggregate consists of the following. Frame 1, pre-sowing milling drum 2, seed hopper 17, seed hopper 4, seed hopper 3, paddle drum 6, which mixes with the seed spread from the seed hopper 4 8 and a cylindrical compactor-leveling roller 9. In this case, the milling drum 2 is fastened to the drum 6 by a blade 10 s bolts 11 s, the blade 7 s are mounted vertically to the drum 6. The upper part of the drum 6 is covered with a P-shaped arched shell 5 so that the soil does not scatter. A seed barrier 3 is installed at the end of the trough 4 to prevent the seeds from falling and scattering. In Seed No. 4, a spreading plate 12 is installed on its surface to ensure good spreading and distribution of seeds. After the drum 6, the eagle is formed by means of an opener 8 mounted on the frame 1, and the uncompressed soil is compacted and leveled by means of a cylindrical compactor-leveling roller 9 attached to the end of the frame 1.

The sowing unit works in the following way: during the sowing process, the milling drum receives 2 movements from the tractor's power shaft (QOV) by means of a star-shaped chain drive [3].

The machining depth of the milling drum 2 is adjusted using a screw 14 equipped with a pressure spring 13. The crushed fine soil is taken through the drum 6 paddle 7s and thrown back. The depth of immersion of the blade drum 6 into the ground is adjusted by means of a screw 16 equipped with a pressure spring 15. After the seeds from the seed trough 4 hit the seed barrier 3 and return, the paddle drum 6 falls to the field surface mixed with the falling soil. When falling to the ground, the seeds are buried in the soil to a depth of 2 .... 3 cm. This is the basis for ensuring that the seeds germinate evenly on their own. After the seeds are mixed with the soil and buried, the field is opened using a field opener 8. When the seed is opened, the cylindrical compactor-leveling roller 9 flattens the area where the seeds are sown, and concentrates at the required level.

Figure 1. Combined aggregate scheme

A prototype of the combined unit was prepared and tested on the experimental field plot of the Namangan regional branch of UzPITI (Figure 2).

Figure 2. A combined unit with a star-shaped chain drive in the transmission mechanism

Soil moisture in the cultivated field was tested at the Namangan regional limited liability company "Agrokimyo" by taking samples from nine places on the diagonal of the field in special cylindrical boxes (Fig. 3).

Figure 3. Determination of the sample mass obtained to determine soil moisture

In determining the moisture content, soil samples taken from the experimental plot were dried at 105 ° C for 6 h using a thermostatic dryer, and the results are given in Table 1.

Table 1

Results of soil moisture testing at the experimental site.

|

Beaux net weight, g |

Weight by soil. g |

The net weight of the soil. g |

Dry for 3 hours at 105°C. g |

Dry for 2 hours at 1050C. g |

Dry for 1 hour at 105oC. g |

Humidity, % |

|

|

1 |

23,585 |

60,7014 |

37,1164 |

54,9868 |

54,969 |

54,968 |

15,4 |

|

2 |

30,9572 |

68,2566 |

37,2994 |

62,267 |

62,267 |

62,267 |

16,1 |

|

3 |

31,184 |

68,415 |

37,231 |

62,606 |

62,602 |

62,6 |

15,6 |

|

4 |

31,177 |

70,8648 |

39,6878 |

64,2264 |

64,2251 |

64,225 |

16,7 |

|

5 |

31,4752 |

70,5162 |

39,041 |

65,0078 |

65,0076 |

65,0076 |

14,1 |

|

6 |

31,0656 |

67,5428 |

36,4772 |

60,6026 |

60,6 |

60,5808 |

19,1 |

|

7 |

31,0674 |

71.1054 |

40,038 |

64,5878 |

64,587 |

64,586 |

16,3 |

|

8 |

30,495 |

65,4848 |

34,9898 |

59,485 |

59,435 |

59,432 |

17,3 |

|

9 |

30,9572 |

68,2566 |

37,2994 |

62,267 |

62,267 |

62,267 |

16,1 |

|

Average |

16.3 |

||||||

In order to improve the planting quality, the milling drum was tested before planting in the soil. Tests are performed on milling drums with a diameter of 340 mm, the number of blades is 3, 4, 5. The analysis of the obtained results shows that the number of fractions of 25 mm, 10 mm and less than 10 mm with a number of milling drum blades is 3, 73.8% 13.9%, 12.3%, respectively, the number of blades 4 is 78.5%, 13 , 8% was 7.7%, the number of blades was 81.6%, 11.5%, 6.9% when there were 5 (Table 2). The figures show that with the increase in the number of blades, the proportion of fractions less than 10 mm increased, while the proportion of fractions of 25 mm and 10 mm decreased.

Table 2

The erosion quality of the treated soil on the experimental field plot

|

Number of blades in the cutter, pcs |

The amount of soil fractions of the following dimensions, % |

||

|

10 mm and smaller |

10-25 mm |

25 mm and bigger |

|

|

3 |

73.8 |

13,9 |

12,3 |

|

4 |

78.5 |

13,8 |

7.7 |

|

5 |

81.6 |

11,5 |

6.9 |

The density of 4 layers of soil, ie 12 cm, was measured. When the number of milling drum blades is 3, 1 (0-3 cm), 2 (3-6 cm) and 3 (6-9 cm) - soil density in layers 1.3 g / cm3, 4 (9-12 cm) - in layers while 1.4 g / cm3, when the number of blades is 4 and 5, 1 (0-3 cm), 2 (3-6 cm) and 3 (6-9 cm) - 1.2 g / cm3 in layers, 4 (9- 12 cm) - 1.4 g / cm3 in the layer was determined (Table 3).

Table 3

Density of cultivated soil on the experimental field plot.

|

Number of blades in the cutter, pcs |

3 Sample layer density, g/mc3 |

|||

|

1st layer 0-3 cm |

2nd layer 3-6 sm |

3rd layer 6-9 sm |

4th layer 9-12 sm |

|

|

3 |

1,3 |

1,3 |

1,32 |

1.4 |

|

4 |

1,2 |

1.2 |

1,2 |

1.4 |

|

5 |

1,2 |

1.2 |

1,2 |

1,4 |

This can be explained by the fact that the combination of pre-sowing tillage and sowing processes allows sowing seeds in the first place without evaporating the natural moisture of the soil. At the same time, the dynamics of seed germination improves, as the number of blades increases, the soil concentration and the blades become more flexible.

Список литературы Results of experimental testing of agricultural combined aggregate for processing and fine seed crops before sowing in the soil

- Мамахонов А., Джураев А., Мухамедов Ж. Тупроққа экишдан олдин ишлов бериш агрегатининг ишчи органларини такомиллаштириш. Республика илмий - амалий анжумани. Жиззах. Гулистон, 2009.

- Патент Узб. Pec., № FAP20150012, Комбинациялашган агрегат. Джураев А., Турдалиев В. Ва бошк. 03.02.3015.

- Патент Рее. Узб. №FAP00595. Джураев А., Мухамедов Ж., Мамахонов А., Цепная передача, Бюлл. - №12, 2010.