Rigging material selection methodology for aircraft elements design

Автор: K.V. Faizullin, M.P. Danilaev, A.V. Polyaev, S.A. Semin, T.I. Rakipov

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.24, 2023 года.

Бесплатный доступ

The development of modern materials and technologies for manufacturing structural elements of aircraft from polymer compositions requires justification for the choice of technological rigging. The physical and technical characteristics of the material, ensuring the required accuracy of rigging manufacturing, as well as economic feasibility are the main criteria for choosing the material of technological rigging. The main criteria for choosing a rigging material are the physical and technical characteristics of the material, ensuring the required accuracy rigging manufacturing, as well as economic feasibility. The choice of rigging material depends on the technology for manufacturing structural elements from polymer composite materials. The paper presents a methodology for selecting rigging material for manufacturing details using the vacuum infusion method. The methodic of rigging materials selection for aircraft constriction elements production from polymer composition by vacuum infusion is considered in the paper. The results of a comparative analysis of typical rigging materials used in production are presented. It is shown that the main criteria for a comparative analysis are: temperature, resistance to solvents, resistance to mechanical stress; maintainability; the value of the coefficient of linear thermal expansion; the stability of the geometry of the rigging and its tightness. The results of the comparative analysis showed that metals and carbon fiber are the most appropriate for the manufacture of rigging, when using high temperatures in the technological process. The paper presents an algorithm for choosing the rigging material for manufacturing the details from polymer composite materials. It is noted that in the manufacture of structural elements based on fiberglass and carbon fiber, the rigging material should be chosen the same as that of the detail. This allows, firstly, to ensure the same CLTE, what is important when hot detail formation, and, secondly, to eliminate the warping of the detail during its cooling on the rigging. However, achieving the specified accuracy of such rigging requires taking into account the processing of the rigging with a gelcoat after its manufacture. The paper presents an approach to quantifying the economic feasibility of the choice of rigging material. It is shown that only a combination of technical, technological and economic factors makes it possible to justify the expediency of the rigging material used for the specific production of aircraft structural elements.

Infusion, rigging material, aircraft structural elements

Короткий адрес: https://sciup.org/148329703

IDR: 148329703 | УДК: 62.437 | DOI: 10.31772/2712-8970-2023-24-3-605-612

Текст научной статьи Rigging material selection methodology for aircraft elements design

Infusion technology has become widely used in the manufacture of structural elements of aircraft (AC) from polymer composite materials (PCM) [1-5]. Moreover, this technology is used for the manufacture of both a power set of aircraft (frames, small frames) [6], and for the manufacture of aircraft skinings and even interiors [2; 7]. This method of manufacturing the elements of aircraft structures allows to ensure the smallest number of defects (voids, pores) in the layers of PCM at a relatively low cost of technological equipment [1; 4; 5]. Increasing requirements to the accuracy of manufacturing details from PCM, the use of new PCM components (resins, woven and non-woven materials), as well as economic aspects, for example, in terms of the serialisation of products, require a revision of the methodology for selecting rigging materials when using infusion technology. Currently used rigging materials have different physical and technical characteristics. For example, riggings made from medium-density fiberboard (MDF) have good processability, but poor resistance to external factors (temperature, humidity, etc.). Riggings made of metals, for example, duralumin, have mirror-like characteristics: they are more difficult for processing, but are resistant to external influences [8–10].

Currently, there are no clear methodological recommendations for choosing rigging materials, taking into account economic feasibility and their physical and technical characteristics. When manufacturing the serial products, the impact of the cost of rigging is reduced depending on the increase in the volume of products manufactured on it [11; 12]. However, at the same time, the wearing of the equipment increases, what can result in a significant decrease in the accuracy of the aircraft’s structural elements. The purpose of this article is to develop a methodology for selecting rigging material for the manufacture of aircraft structural elements using the vacuum method infusion.

Research methodology

The choice of rigging material involves formalizing the criteria by which such a choice will be made. The main, practically important, criteria are: operating temperature, resistance to solvents, resistance to mechanical influences; maintainability; value of the coefficient of linear thermal expansion (CLTE); stability of the rigging geometry and its tightness [1, 13, 14]. The choice of these criteria is based, inter alia, on the following considerations.

Operating temperature of the rigging. The temperature conditions for the manufacture of aircraft structural elements using the vacuum infusion method are determined by the types of resins used and their polymerization technologies [1; 3; 4]. For example, when manufacturing products using the TO200 epoxy binder (TU 2257-055-59846689-2016, «Itekma» LLC, Russia), heating is carried out to 180 °C to polymerize the resin. In this case, the material of the rigging must not only withstand this temperature and not undergo destruction, but also maintain its shape with the given accuracy.

Chemical resistance. The rigging should not be damaged by solvents or specialized release agents. The rigging should be easily cleaned from resin residues and release agents using solvents recommended for resins.

Resistance to mechanical stress and maintainability . The rigging must be resistant to external mechanical influences. Moreover, the material of the rigging must allow repairing of the working surface in case of damage, for example, abrasion or chipping during its operation.

The requirement to a low CLTE value is due to the use of high-temperature polymerization processes of the finished product blanks. Moreover, the CLTE of the rigging material should be close to the CLTE of the polymer composite material of the product. It should be noted that taking into account the expansion of the rigging during the heating process does not guarantee the absence of warping of the part after molding [15].

Tightness. Vacuuming of a prepared product blank during its manufacture using the vacuum infusion method requires high tightness of the rigging material. The presence of pores in the rigging material can lead to the defects (bubbles, pores) in the final product.

Results and their discussion

The comparative analysis of commonly used rigging materials is presented in the table.

The following designations are used: «+» – the criterion is met; «±» – the criterion is partially met; «–» – the criterion is not met; k is the maximum number of details that can be manufactured on this rigging, taking into account its wear. The cost of rigging manufacturing is given relative to rigging made from MDF with dimensions 2×2×2 m.

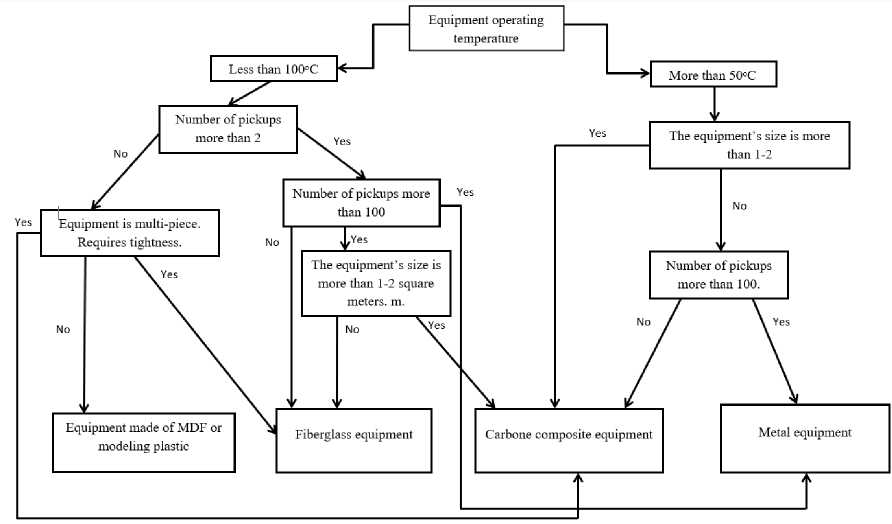

The analysis of the materials available on the market for the manufacture of rigging shows that when using high temperatures in the technological process, metals and carbon fiber are the most appropriate. The algorithm for selecting rigging material for manufacturing aircraft structural elements from PCM using the vacuum infusion method is presented in Fig. 1.

Comparative analysis of rigging materials

|

MDF |

Model plastic |

Duralumin (D16T) |

Alloy Invar |

Glassplastic |

Carbon fiber |

|

|

Temperature resistance |

– |

± |

+ |

+ |

– |

+ |

|

Solvent resistance |

± |

± |

+ |

+ |

± |

± |

|

Resistance to mechanical stress |

– |

– |

± |

+ |

± |

± |

|

Maintainability |

± |

+ |

± |

± |

+ |

+ |

|

CLTE |

± |

– |

– |

+ |

± |

+ |

|

Geometry stability |

– |

± |

+ |

+ |

± |

± |

|

Tightness |

– |

± |

+ |

+ |

± |

± |

|

Present cost of rigging manufacturing (E) |

1,0 |

2,5±0,3 |

10,0±1,0 |

20,0±2,0 |

7,0±0,7 |

10,0±1,0 |

|

k |

1 |

3 |

200 |

300 |

70 |

100 |

Рис. 1. Алгоритм выбора материала оснастки для изготовления элементов конструкции ЛА из ПКМ

-

Fig. 1. The algorithm for selecting the rigging material for the manufacture of aircraft structural elements from PCM

Nevertheless, it should be noted that the use of model plastic as a rigging material is promising. Infact, model plastic is a polymer composite material with dispersed filling. Polyurethanes of various brands are usually used as a binder in this material. By choosing the filler, its concentration, as well as the grade of polyurethane, it is possible to provide characteristics that meet the specified requirements of the technological process. Currently, the market presents mainly foreign brands of model plastic, which do not always meet production requirements. For example, a significant CLTE compared to carbon fiber and the presence of open cells (pores) (see the table) require additional costs for the manufacture of technological rigging. An example of manufacturing of rigging from model plastic is shown in Fig. 2

а

Рис. 2. Изготовление оснастки из модельного пластика:

а – заготовка мастер-модели на станке с ЧПУ; б – заготовка для изготовления мастер-модели из модельного пластика на каркасе из МДФ

б

-

Fig. 2. Production of rigging from model plastic:

a – blank of the master model on a NPC machine; b – blank for the production of a master model from model plastic on an MDF frame

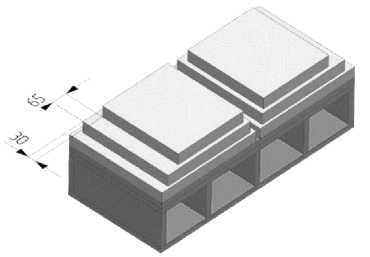

Separately, it should be noted that when manufacturing structural elements from fiberglass and carbon fiber, the rigging material should be chosen the same as that of the detail. This allows, firstly, to ensure the same CLTE, what is important when thermoforming a detail, and secondly, to eliminate warping of the detail during its cooling on the rigging. However, even in this case it is not always possible to ensure high accuracy of the specified dimensions of the details. For example, this may be due to the use of a «gelcoat» in the structure of such rigging, as opposed to the master model on which it is located (Fig. 3).

Рис. 3. Оснастка из углепластика

-

Fig. 3. Carbon fiber composite rigging

This, in turn, increases the requirements to the accuracy of rigging manufacturing, and, consequently, an increase in its cost should be expected.

Assessing the economic feasibility when choosing the material of the rigging, it is necessary to take into account not only its present value E (see the table), but also the cost (∑) of the batch of details, manufactured using it:

E = X • n +

k - n + 1 k

where X is the cost of one detail, Y is the cost of one rigging for the manufacture of such details, n is the number of details manufactured. For example, with the cost of an aircraft structural element X = 200,000 rubles, the cost of rigging made from model plastic Y МП = 50,000 rubles, from carbon fiber plastic Y УП = 150,000 rubles, the cost of a batch of details of 50 pieces will be:

£ УП = 10’076’500 rubles, ^ МП = 10’533’333 rubles.

Conclusion

The comparative analysis of rigging materials for the manufacture of details using the vacuum infusion method made it possible to formalize the methodology of the choice of the material that best satisfies the required criteria. It should be noted that only a combination of technical, technological and economic factors makes it possible to justify the feasibility of the rigging used for the specific production of aircraft structural elements.

Acknowledgements

This work was carried out by Russian Ministry of Science and Higher Education Grant No 1022041100774-3 / 1022041100496-8 of 03.06.2022.

Список литературы Rigging material selection methodology for aircraft elements design

- Dushin M. I., Chursova L. V., Khrul'kov A. V., Kogan D. I. [Peculiarities of production of polymer composites by vacuum infusion method]. Voprosy materialovedeniya. 2013, No. 3, P. 33–40 (In Russ.).

- Grigor'ev M. M., Khrul'kov A. V., Gurevich Ya. M., Panina N. N [Production of fiberglass liners by vacuum infusion using an epoxy-hydride binder and a semi-permeable membrane]. Trudy VIAM. 2014, No. 2, P. 4–8 (In Russ.).

- Donetskiy K. I., Usacheva M. N., Khrul'kov A. V. [Infusion methods for the production of polymer composites (review). Part 1]. Trudy VIAM. 2022, No. 6, P. 58–67 (In Russ.).

- Khrul'kov A. V., Donetskiy K. I., Usacheva M. N., Goryanskiy A. N. [Infusion methods for the manufacture of polymer composites (Review). Part 2]. Trudy VIAM. 2022, No. 7, P. 50–62 (In Russ.).

- Ushakov A. E., Klenin Yu. G., Sorina T. G. et al. [Composite bridge structures]. Kompozity i nanostruktury. 2009, No. 3, P. 25–37 (In Russ.).

- Ushakov A. E., Safonov A. A., Sergeichev I. V. et al. [Design and optimization of vacuum infusion process for manufacturing of hopper body made of polymer composites]. Problemy mashinostroeniya i nadezhnosti mashin. 2015, No. 3, P. 102–109 (In Russ.).

- Rudenko M. S., Mikheev A. E., Girn A. V. [Technology of honeycomb core production from polymer composites]. Sibirskiy aerokosmicheskiy zhurnal. 2021, Vol. 22, No. 2, P. 391–397 (In Russ.).

- Komarov V. A., Kurkin E. I., Kuznetsov A. S. [Research and modification of rigging and forming surface in order to improve the accuracy of parts manufacturing by vacuum infusion]. Izvestiya Samarskogo nauchnogo tsentra Rossiyskoy akademii nauk. 2013, Vol. 15, No. 6-3, P. 710–717 (In Russ.).

- Yanovich A. [Modern composite materials for rigging production]. Kompozitnyy mir. 2016, No. 6, P. 36–40 (In Russ.).

- Khrul'kov A. V., Dushin M. I., Popov Yu. O., Kogan D. I. [Research and development of autoclave and non-autoclave technologies for PCM molding]. Aviatsionnye materialy i tekhnologii. 2012, No. 5, P. 292–301 (In Russ.).

- Sharshin V. N., Kechin V. A., Sukhorukov D. V. et al. [Study of the properties of polymer composite material for the production of LGM molds]. Liteyshchik Rossii. 2011, No. 12, P. 40–42 (In Russ.).

- Dektyarev A. V., Morozov V. N. [Feasibility study on the implementation of additive technologies in the domestic shipbuilding industry]. Gipoteza. 2018, No. 3, P. 15–24 (In Russ.).

- Andreev A. V., Petropol'skiy V. S. [Optimization of material selection of master models for polymer composite products in the conditions of single and pilot production in the products of aeronautical engineering]. Voprosy proektirovaniya i proizvodstva konstruktsiy letatel'nykh apparatov. 2015, No. 2, P. 20–28 (In Russ.).

- Kozlov M. V., Sheshenin S. V., Makarenko I. V., Belov D. A. [Modeling the influence of rigging on the final shape of polymer composite products]. Vychislitel'naya mekhanika sploshnykh sred. 2016, Vol. 9, No. 2, P. 145–161 (In Russ.).

- Kartashova E. D., Muyzemnek A. Yu. [Technological defects in polymer layered composites]. Izvestiya vysshikh uchebnykh zavedeniy. Povolzhskiy region. Tekhnicheskie nauki. 2017, Vol. 42, No. 2, P. 79–89 (In Russ.).