Scientific and practical approaches to the development of new-generation confectionery products

Автор: Dombrovskaya Y.P., Derkanosova A.A., Belokurova E.V., Kurchaeva E.E., Maksimov I.V., Kashirina N.A.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Пищевая биотехнология

Статья в выпуске: 4 (86), 2020 года.

Бесплатный доступ

A modern progressive direction in the development of confectionery production is the creation of new resource-saving technologies and the development of flour confectionery products with a reduced energy value based on the use of various types of non-traditional and local raw materials. The application of oilseed cake in the food industry makes it possible to enrich products chemical composition with proteins, lipids, dietary fiber, vitamins and minerals. The use of amaranth oil cake as a dry component allows the biological value increase, as it is characterized by a high content of easily digestible protein (18-20%) containing all essential amino acids in sufficient quantities. Recently, special attention has been paid to the introduction of animal fats to the food industry. Bone fat occupies a special place among them. It is produced from bones, regardless of the type of meat from which they were obtained. The application of bone fat allows to enrich foods with polyunsaturated fatty acids, as well as improve the ?-3 / ?-6 ratio of fatty acids in the diet. Taking into account the traditional technology, as well as the properties of amaranth cake and bone fat, the recipe for "Mayachok" gingerbread was developed to adjust chemical and fatty acid composition. The recipe for custard gingerbread with the addition of 15% amaranth oil cake and 11% bone fat to the flour mass in the dough improves organoleptic and physicochemical indicators; to increase their biological value (by 24.5%); to obtain products with the most balanced amino acid composition (amino acid rate for lysine is 44.5%); to balance the ?-3 / ?-6 ratio of fatty acids; to increase the calcium content in products and to normalize its ratio with magnesium and phosphorus - Ca: Mg: P - 1: 0.65: 1.65. The components added improve the structural and mechanical properties of the choux pastry, such as plasticity, elasticity, absorptivity.

A amaranth cake, bone fat, custard cakes, fatty acid composition, biological value

Короткий адрес: https://sciup.org/140257303

IDR: 140257303 | УДК: 640 | DOI: 10.20914/2310-1202-2020-4-60-68

Текст научной статьи Scientific and practical approaches to the development of new-generation confectionery products

A modern progressive trend in the development of confectionery production is the creation of new resource-saving technologies and the development of flour confectionery products with a reduced energy value based on the use of various types of non-traditional and local raw materials.

Using non-traditional raw materials in the production of flour confectionery, the following tasks are solved: reducing the consumption of expensive raw materials (sugar, flour) by replacing them with cheaper and less energy-intensive ones; increasing the nutritional and biological value of products by introducing protein-containing and other additives with unique properties and, on their basis, creating original formulations for functional products; improving the structural and mechanical properties of the dough, reducing losses, increasing the consumer properties of products; extension of shelf life; expansion of the range [2].

Food fortification is carried out based on scientifically grounded biomedical principles: we use those nutrients, the deficiency of which is manifested to a greater extent and which are widespread enough and safe for health; we enrich consumer products that are available to all groups of the population and are regularly used in daily diets.

The search for new sources of food protein, biologically active additives, as well as the development of technology for their processing to obtain products of increased biological and nutritional value with a functional focus is one of the urgent tasks of the food industry [3].

There are 65 general and about 900 species of amaranth known in the world, in Russia, where amaranth has another name – shiritsa, 17 species are known. Plants reach 2–3 m in height, with a stem thickness of 8–10 cm, plant weight – up to 30 kg. The leaves are large, oblong-elliptical with long petioles, wedge-shaped at the base, and sharp at the apex. Inflorescence is a lush panicle, 1.5 m long, of various shapes and density. Seeds are small, white, pink, brown and black, shiny like varnished.

a)

b)

Figure 1. The appearance of plants of the genus Amaranthus: a) A. hypochondriacus L . and b) A. caudatus L

A feature of amaranth is the small size of the grains (the weight of 1000 pieces is equal to 0.6 – 1.0 g) [8], covered with a hard shell of black, light orange or reddish color. In bread technology, grains of light orange color are most preferable (figure 2).

Figure 2. Amaranth seeds

For the preparation of bakery, confectionery and pasta, whole grain of amaranth, products of mechanical and thermal processing (wholeground flour, "puffed" amaranth grains, flour from thermally processed amaranth grain), products of deep biochemical processing (protein preparations, lipid-protein complexes, starch products, pectin substances) with high nutritional value and functional properties are used.

Currently, amaranth seeds are mainly used for oil production. After pressing the oil, oil cake accumulates as a by-product [4, 5].

Oil cake processing is one of the development directions of the vegetable oil industry, as it contains a residual fraction of oil and other nutritive and biologically active substances. The use of oilseed cake in the food industry makes it possible to enrich the chemical composition of products with protein, lipids, dietary fiber, vitamins and minerals [9–15].

It is a powdery mass with a particle size of 80.0 to 100.0 microns, with an insignificant inclusion of uncrushed shell particles, with a characteristic taste and smell. The use of amaranth cake as a dry component can increase the biological value of gingerbread, because it is distinguished by a high content of easily digestible protein (18–20% of DM), containing all essential amino acids in sufficient quantity. The cake contains 62.74% of starch; 5.10% of lipids; 2.86% of fiber; 0.61% of ash, macro – and microelements (calcium, magnesium, phosphorus, iron), vitamins (thiamine, riboflavin, tocopherols). The composition of amaranth cake is shown in table 1.

The cake contains a residual oil content of 5–8% with a high concentration of polyunsaturated fatty acids. Triglycerides of amaranth oil are represented by a complex of unsaturated fatty acids (linoleic, oleic, linolenic), and their content is 75%, of which 50% is linoleic acid, from which arachidonic acid is synthesized. Particularly valuable is linolenic acid,

Dombrovskaya Ya.P. et al. Proceedings of VSUET, 2020, vol. 82, no. 4, pp. 60-68

which belongs to the family of polyunsaturated acids ω-3, which in the human body turns into eicosopen-taenoic (C20:5) and docosahexanoic (C22:6) – precursors of leukotrienes with various properties that play an important role in the formation of immunity and differentiation of lymphocytes.

Table 1.

The chemical composition of amaranth cake

|

Name of indicators, units |

Value of indicators |

|

Amaranth cake |

|

|

Moisture, % |

8,0 |

|

Protein, % |

19,8 |

|

Fat, % |

5,1 |

|

Fatty acids, % of the total: oleic |

22,6 |

|

linoleic |

49,9 |

|

α – linolenic |

1,0 |

|

γ – linolenic |

0,35 |

|

Fiber, % |

2,9 |

|

Ash, % |

0,6 |

|

Vitamins: В 1 , mg/kg |

2,8 |

|

В 2 , mg/kg |

0,9 |

|

Е, mg/kg |

54,0 |

|

Minerals: iron, mg/kg |

112,3 |

|

magnesium, mg/kg |

348,7 |

|

calcium, mg/kg |

458,6 |

|

phosphorus, mg/kg |

698,7 |

Amaranth oil has the best ratio of PUFA and antioxidants, which prevent aging of liver cells, strengthen them and protect them from destruction, since the liver performs up to 500 vital functions: neutralizes toxins, regulates cholesterol and blood sugar levels, produces hormones, and participates in digestion.

In turn, amaranth oil is a well-known source of squalene. Depending on the extraction technology, it can contain from 5 to 15% of this substance. The gross formula of squalene is C30H80, belongs to triterpenes, being an intermediate in cholesterol biosynthesis.

Squalene carries the required amount of oxygen to the tissues and organs, has a pronounced antimicrobial and fungicidal effect, is a powerful antioxidant, and acts as a regulator of lipid and steroid metabolism in the body. In the course of biochemical studies of the properties of squalene, it was found that it is a derivative of vitamin A, and during the synthesis of cholesterol it is converted into its biochemical analogue 7-dehydrocholesterol, which transforms into the form of vitamin D when exposed to sunlight, thereby providing radioprotective properties. Vitamin A is involved in the work of the retina and is necessary for the body as a growth factor. With a lack of vitamin A, the work of the organs

Squalene is also a natural component of the secretion of the sebaceous glands of human skin (up to 12–14%), due to which it is easily absorbed into the body and accelerates the penetration of substances dissolved in it.

It also acts as a precursor in the synthesis of steroid hormones. It was noted that the consumption of amaranth oil lowers blood cholesterol levels, which reduces the risk of atherosclerosis.

The next most important component of amaranth oil is tocopherols (vitamin E), their total content can reach 2%. Vitamin E is the main fatsoluble natural antioxidant that normalizes the redox process in the body, prevents the destruction of other fat-soluble vitamins, promotes their better absorption, and lowers blood cholesterol levels.

Table 2.

The composition of essential amino acids of amaranth oil cake

|

Amino acid |

Content |

|

|

Oil cake |

||

|

g per 100 g of protein |

% to protein |

|

|

Lysine |

0,740 |

6,4 |

|

Threonine |

0,420 |

3,8 |

|

Valine |

0,505 |

4,5 |

|

Methionine |

0,277 |

2,4 |

|

Leucine |

0,470 |

4,0 |

|

Isoleucine |

0,651 |

5,6 |

|

Phenylalanine+ tyrosine |

0,400 0,477 |

3,6 4,1 |

|

Tryptophan |

0,18 |

1,6 |

The amino acid composition of amaranth cake has a balanced composition of basic amino acids, and the cake can be used in many branches of the food industry to increase the biological value of products, including confectionery and bakery production.

Taking into account the chemical composition of amaranth cake (table 1), the high biological value of its components, the composition of essential amino acids (table 2), we can conclude about the prospects of its use in the production of food products to give them a functional orientation.

Many experts believe that approximately 80% of the population of our country consumes an insufficient amount of essential fatty acids (EFA). In the composition of EFA, there are 5 polyunsaturated fatty acids (PUFA) – linoleic, linolenic, arachidonic, eicosapentaenoic and docosahexaenoic. The daily requirement for them is equal to 10–20% of the total calories received. Deficiency of these nutrients is a serious health threat.

EFAs have many different functions in the body. They are used to form fat, which covers and protects internal organs. Breaking down, fatty acids release energy. But the most important thing is that they are involved in the formation of cell membranes in the body. Fatty acids affect the synthesis of prostaglandins, leukotrienes and thromboxanes. These compounds regulate important bodily functions such as blood pressure, individual muscle contraction, body temperature, platelet aggregation, and inflammation. To control all of these functions, the body synthesizes specific compounds from fatty acids (prostaglandin, leukotriene or thromboxane) found in the dietary fats we consume. Fatty acids also:

─ improve the structure of the skin and hair, lower blood pressure, help prevent arthritis, lower cholesterol and triglyceride levels, and reduce the risk of blood clots;

-

─ have a positive effect on diseases of the cardiovascular system, candidiasis, eczema and psoriasis;

-

─ promote the transmission of nerve impulses;

-

─ are required for the normal development and functioning of the brain.

The ratio of linoleic (ω-6) and linolenic (ω-3) acids is important, which, according to the recommendations of the Institute of Nutrition of the Russian Academy of Medical Sciences, should be from 3: 1 to 6: 1. Most fatty foods contain linoleic and linolenic acids in a ratio that is far from ideal. Particularly valuable is linolenic acid, which belongs to the family of polyunsaturated acids ω-3, which in the human body turns into eicosopentaenoic (С 20:5 ) and docosahexanoic (С 22:6 ) acids – precursors of leukotrienes with various properties that play an important role in the formation of immunity, differentiation of lymphocytes. The addition of amaranth meal enriches products with essential fatty acids, but the ratio of ω-6:ω-3 fatty acids is far from the one recommended by the Institute of Nutrition of the Russian Academy of Medical Sciences.

The massive industrial processing of fats, oils and foods containing them has significantly reduced the content of essential fatty acids in our diet. What's more, there has been a huge increase in the amount of unnatural fats added to the diet in the form of trans fatty acids and partially hydrogenated oils. Well-known margarine also belongs to such products. In the production of margarine, during the hydrogenation process, liquid oils are converted into solid, pasty products. By hardening oils, this reaction also changes their chemical structure, converting some unsaturated fatty acids into their trans isomers, which have the same effect on the body as saturated fats. They increase cholesterol levels, and research results show a clear link to heart diseases [6–8].

Recently, attention has been paid to the introduction of animal fats into the food industry, among which bone fat occupies a special place. It is produced from bones, regardless of the type of meat from which they were obtained.

In accordance with the current regulatory documents, edible bone fat must meet the requirements of the highest and first grade (table 3).

The use of bone fat allows you to enrich foods with polyunsaturated fatty acids, as well as improve the ratio of ω-3 / ω-6 fatty acids in the diet. The fatty acid composition of bone fat is shown in table 4.

Table 3.

Bone fat quality indicators (according to GOST 8285 – 91)

|

Indicator |

Highest grade |

First grade |

|

Colour at 15–20 °С |

From white to yellow |

From white to yellow, grayish and greenish shades are allowed |

|

Smell and taste |

Typical for this type of fat produced from fresh raw materials |

Typical for this type of fat, produced from fresh raw materials, a pleasant toasty smell is allowed |

|

Transparency in the molten state |

Transparent |

|

|

Consistency at a temperature of 15–20 °С |

Liquid, pasty or solid |

|

|

Moisture content, %, no more |

0,25 |

0,3 |

|

Acid number, mg KOH, no more |

1,2 |

2,2 |

Table 4.

Fatty Acid Content of Bone Fat, %

|

Fatty acids, % |

Value |

|

|

Bone fat |

Margarine |

|

|

Oleic |

51,7 |

43,0 |

|

Linoleic |

2,7 |

8,0 |

|

Linolenic |

Traces |

Traces |

The use of bone fat for the production of various food products is due to its high digestibility (97%) by the human body.

Thus, the indicators of the quality of bone fat, the content of ω-6 fatty acids in it makes it a promising fat product for functional items. We have carried out calculations to determine the dosage of bone fat, which makes it possible to achieve the recommended ratio of fatty acids ω6 / ω3 = 5: 1.

In accordance with the objectives of the research, baking was carried out in laboratory conditions. The recipe for gingerbread “Russkiye” was taken as control.

Gingerbread cookies “Russkiye” have good taste and a pleasant aroma, have sufficient porosity

Dombrovskaya Ya.P. et al. Proceedings of VSUET, 2020, vol. 82, no. and a smooth streamlined surface. However, according to the obtained data on the biological and energy value, chemical composition, these products have a high energy value, the ω-6 / ω-3 fatty ratio is far from the optimal 9: 1, the Ca: Mg: P trace element ratio also does not correspond to the recommended 1: 0.5: 1.5 and is 1: 0.9: 7.4.

Taking into account the above, the new product was developed on the basis of traditional technology, while taking into account the properties of the introduced components in order to adjust the chemical and fatty acid composition of the new “Fantasy” gingerbread.

Table 5.

Amino acid composition of gingerbread products, g/100g protein

|

Amino acids |

Ideal protein, mg / 1g protein |

Product name |

|||

|

1 “Russkiye” |

2 “Fantasy” |

||||

|

Content |

Score, % |

Content |

Score, % |

||

|

Threonine |

40 |

24,0 |

60,0 |

29,4 |

73,5 |

|

Valine |

50 |

34,9 |

69,8 |

43,10 |

86,2 |

|

Methionine + cystine |

35 |

30,0 |

85,7 |

37,24 |

106,4 |

|

Isoleucine |

40 |

39,5 |

98,75 |

49,0 |

122,5 |

|

Leucine |

70 |

60,9 |

87,0 |

75,5 |

107,9 |

|

Phenylalanine + Tyrosine |

60 |

8,14 |

13,6 |

65,8 |

109,7 |

|

Lysine |

55 |

20,4 |

31,7 |

24,5 |

44,5 |

|

Tryptophan |

10 |

9,4 |

94,0 |

11,8 |

118,0 |

|

CDAAS, % |

- |

58,35 |

33,80 |

||

|

BV, % |

41,65 |

66,20 |

|||

Table 6.

The chemical composition of gingerbread products per 100 g of product

|

Indicators |

Product name |

|

|

1 “Russkiye” |

2 “Fantasy” |

|

|

Proteins, g |

4,9 |

5,0 |

|

Fat, g |

4,6 |

5,6 |

|

Carbohydrates, g: mono – and disaccharides starch |

48,2 30,9 |

48,4 27,8 |

|

Ash, g |

0,18 |

0,22 |

|

Mineral substances, mg: Са |

7,0 |

8,0 |

|

Mg |

6,4 |

5,2 |

|

Р |

52,0 |

13,2 |

|

Ratio Ca: Mg: P |

1:0,9:7,4 |

1:0,65:1,65 |

|

Recommended ratio Ca: Mg: P |

1:0,5:1,5 |

|

|

Viamins: μg/ml |

||

|

В 1 |

0,06 |

0,06 |

|

В 2 |

0,02 |

0,05 |

|

Energy value, kJ |

323,9 |

245,7 |

From the data given in table 6, it can be seen that the biological value of gingerbread " Fantasy " exceeds the biological value of the control sample by 24.5%. The biological value of the protein of gingerbread “Russkiye” is 41.65% due to the extremely low content of the limiting amino acid lysine (31.7% of the content in the ideal protein), and the biological value of the protein of gingerbread “Fantasy” is 66.20% due to the compensation of the limiting amino acids of wheat flour: lysine and threonine. The limiting amino acids for gingerbread “Fantasy” are lysine and threonine.

Table 7.

Fatty acid composition of finished products

|

Acid name |

Content, g per 100 g of product |

|

|

Gingerbread “Russkiye” |

Gingerbread “Fantasy” |

|

|

Monounsaturated: oleic (С 18:1) |

0,04 |

0,64 |

|

Polyunsaturated: linoleic acid (С18:2) linolenic acid (С18:3) |

0,173 0,011 |

0,68 0,147 |

|

Ω-6/ω-3 ratio of unsaturated fatty acids |

16:1 |

4,6:1 |

As can be seen from tables 7–8, the addition of 17% amaranth cake and 13% bone fat to the flour mass in the dough allows you to improve the organoleptic and physicochemical characteristics of finished products; to increase their biological value (by 24.5%); to obtain products with the most balanced amino acid composition (amino acid score for lysine is 44.5%, and in control sample – 48.7%); to balance the ratio of ω-6: ω-3 fatty acids (it is 4.6: 1 versus 16: 1 in the control sample), which corresponds to that recommended by the Institute of Nutrition of the Russian Academy of Medical Sciences for medical nutrition (from 4: 1 to 6: 1); to increase the calcium content in products and normalize its ratio with magnesium and phosphorus – Ca: Mg: P = 1: 0.65: 1.65, in the control sample – 1: 0.9: 7.4, and the recommended ratio: Ca: Mg: P = 1: 0.5: 1.5.

The appearance of gingerbread products is shown in figure 3

Figure 3. Appearance of finished products 1 – Gingerbread “Russkiye”, 2 – Gingerbread “Fantasy”

As can be seen from figure 3, “Fantasy” gingerbread products slightly differ from the control samples in terms of organoleptic and physicochemical indicators, but the biological value of the products increases.

The effect of amaranth cake and bone fat on the structural and mechanical properties of gingerbread dough was studied.

The dough is a kind of heterogeneous colloidal system. The formation of mechanical and rheological characteristics of the dough is most influenced by the properties of the raw material. Fats introduced into the dough reduce the swelling ability of flour colloids. By adsorptively binding to starch and proteins, fats block possible points of adhesion of colloidal particles, weaken their interconnection and thereby prevent moisture penetration, as a result, the dough becomes more plastic.

Considering that the structural and mechanical parameters that determine the technological properties of the dough are plasticity and elasticity, we studied the effect of component dosages on these dough indicators.

Ultimate shear stress, as one of the important rheological characteristics of a material, serves to assess the strength of its structure. Food materials under the action of shear stresses have the ability not to start movement (flow) as long as the applied stress is less than a certain value which is typical for the given material and is called the ultimate shear stress τ0.

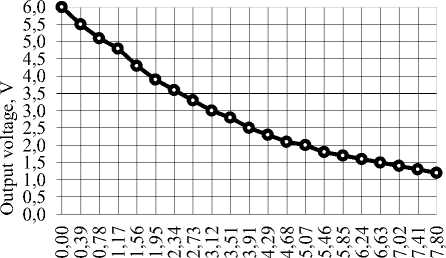

To calculate the ultimate shear stress on a conical rheometer according to the method of S.A. Titov, the dependences of the output voltage on the square of the distance between the light source and the diode were determined (figure 4). The dependences of the ultimate shear stress of gingerbread dough on the dosage of amaranth cake are shown in figure 4.

Distance between light source and diode, mm

Figure 4. Dependence of the output voltage on the distance between the light source and the diode

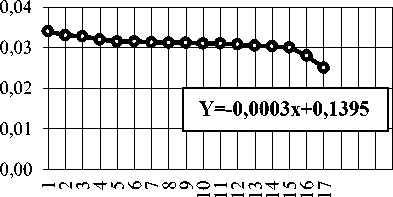

Amaranth cake dosage,% by weight of flour

Figure 5. Dependence of the ultimate shear stress of the gingerbread dough on the dosage of amaranth cake

Figure 5 shows that in the absence of amaranth cake in the gingerbread recipe, the ultimate shear stress of the dough for the "Fantasy" gingerbread is 0.033 MPa, and at dosages of 14 and 15%, the ultimate shear stress decreases to 0.030 MPa, which makes it possible to obtain a gingerbread dough with good shape-holding ability and elastic properties.

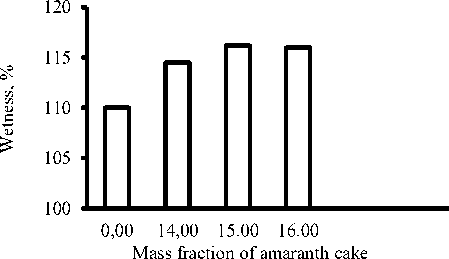

The introduction of amaranth cake up to 16% and bone fat up to 5% to the mass of 1st grade wheat flour also leads to an increase in the wetness and specific volume of products (figures 6, 7).

(% by weight of wheat flour)

Figure 6. Diagram of the change in the wetness of the "Fantasy" gingerbread depending on the mass fraction of amaranth cake (% to the mass of wheat flour)

M

S

о

220,00 210,00 200,00 190,00 180,00 170,00 160,00 150,00 140,00 130,00 120,00 110,00 100,00

0 14 15 16

Mass fraction of amaranth cake (% by weight of wheat flour)

Figure 7. Diagram of changes in the specific volume of the "Fantasy" gingerbread depending on the mass fraction of amaranth cake (% to the mass of wheat flour)

The increase in the wetness of the products is explained by a decrease in the gluten content in the gingerbread dough due to the replacement of a part of the wheat flour with amaranth cake, which does not contain gluten in its composition; in this case, it is easier for chemical leavening agents to break the gluten framework, as a result of which the product is more porous and friable.

Under the action of digestive enzymes, protein substances are broken down into separate fragments (amino acids and peptides), which penetrate the intestinal wall and are assimilated by the body. Bioactivity characterizes the ability of a product to stimulate internal metabolic processes, secretory function. Thus, the relative relationship between the biological value of proteins and their

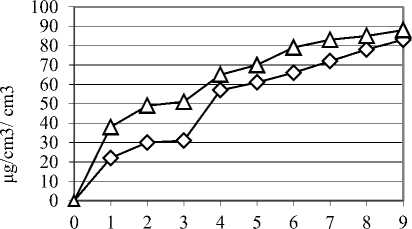

Dombrovskaya Ya.P. et al. Proceedings of VSUET, 2020, vol. 82, no. 4, pp. 60-68 amino acid composition can be valid only under the condition of sufficiently high rates of digestion by enzymes of the digestive tract, assimilation of components and their bioactivity. Figure 8 shows graphic dependences of protein digestibility in gingerbread by the pepsin-trypsin system.

Duration of hydrolysis, h

Figure 8. Digestibility of proteins of the "Fantasy" gingerbread system by the trypsin-pepsin system ▲ – Gingerbread “Russkiye” (control) Y=0,003x+0,9541 ◊ – Gingerbread “Fantasy” (experiment) Y=-0,0003x+0,1395

Under the influence of pepsin and trypsin on the substrate, hydrolysis proceeded more intensively in experimental samples. At the end of the 9th hour, the concentration of hydrolysis products was higher in the experimental sample – 88.2 μg/cm3 of tyrosine for the “Fantasy” gingerbread compared to the control one – 84.3 μg/cm3 for the “Russkiye” gingerbread. An increase in the degree of hydrolysis of gingerbread proteins in the experimental sample is apparently due to an improvement in the structural and mechanical properties of the product,

As a result of research, a new type of product has been developed – custard gingerbread "Fantasy" containing amaranth cake and bone fat, allowing to expand the range of functional flour confectionery.

Industrial testing of a new type of gingerbread was carried out at the enterprise of the Belgorod region, IE Bocharova A.A. – production test act dated 29.0.32008. Drafts of technical conditions TU 9113–114–02068108–2008 "Gingerbread Fantasy", TI and Recipes have been developed.

The developments were exhibited at the 23th interregional exhibition "Voronezhagro-2018" (November 14–15, 2018), the 6th interregional exhibition " Production and processing of agricultural products" (Voronezh, 10-11 october 2019) and a diploma was received.

The conducted tasting of the developed flour confectionery products in the conditions of LLC "Sanatorium named after tsuryupa" showed a clear positive advantage of the proposed technical solutions over the control sample. Based on the results obtained, a conclusion was made about the prospects for introducing the proposed products into the assortment group of products recommended for enriching the diets of all population groups.

Список литературы Scientific and practical approaches to the development of new-generation confectionery products

- Kolomnikova Ya.P., Tefikova S.N., Pashchenko V.L. New technologies of flour culinary products of improved nutritional value for public catering enterprises. Proceedings of VSUET. 2014. no. 2 (60). pp. 112-118. (in Russian).

- Kolomnikova Ya.P., Pitaikina E.A. Doctrine of food security in the field of food products. Modern technologies for civil defense and emergency response. 2014. no. 1 (5). pp. 41-42. (in Russian).

- Paschenko L.P., Ostroborodova S.N., Kolomnikova Ya.P., Ilyina T.F. New functional product in the catering sector. International Journal of Applied and Fundamental Research. 2010. no. 2. pp. 37-42. (in Russian).

- Uazhanova R.U., Alimardanova M.K. The use of amaranth cake in bread as a source of dietary fiber. Scientific perspective. 2010. no. 8. pp. 103-105. (in Russian).

- Pashchenko L.P., Pashchenko V.L. Secondary plant raw materials - a biologically active component for creating a new generation of food products. Proceedings of VSUET. 2012. no. 1 (51). pp. 100-106. (in Russian).

- Alekseeva T.V., Sokolova O.A., Zyablov M.M., Kalgina Yu.O. Development of the component composition of the plant complex food system for use in the field of healthy nutrition of the population. Economics. Innovation. Quality control. 2013. no. 4 (5). pp. 49. (in Russian).

- Matiyaschuk E.V., Furmanova J.P., Pynih S.K. Use amaranth flour in the sponge semi-finished production technologies. A scientific look into the future. 2017. vol. 2. no. 6. pp. 52-58.

- Kulushtayeva B., Rebezov M., Igenbayev A., Kichko Yu.S. et al. Luten-free diet: positive and negative e ect on human health. Indian Journal of Public Health Research and Development. 2019. vol. 10. no. 7. pp. 906-909.

- Shishkina A.N., Sadygova M.K., Belova M.V., Astashov A.N. et al. Use of secondary raw material of animal products in the technology of production of bakery products based on wheat-amaranth mixture. Scientific Study and Research: Chemistry and Chemical Engineering, Biotechnology, Food Industry. 2019. vol. 20. no. 2. pp. 303-311.

- Derkanosova N., Stakhurlova A., Pshenichnaya I., Ponomareva I. et al. Amaranth as a bread enriching ingredient. Foods and Raw Materials. 2020. vol. 8. no. 2. pp. 223-231.

- Derkanosova N.M., Vasilenko O.A., Shurshikova G.V. Prediction of probability of positive reaction of consumers to new types of enriched food. Smart Innovation, Systems and Technologies. 2020. vol. 172. pp. 891-897.

- Komiljonovna J.S., Babadjanovich I.I. Priority areas for improving the range of confectionery. Austrian Journal of Technical and Natural Sciences. 2019. no. 1-2.

- Zhabbarova S.K. et al. Analysis of food value of non-traditional sugar substitutes for flour confectionery goods. Asian Journal of Multidimensional Research (AJMR). 2020. vol. 9. no. 4. pp. 162-171.

- Chernenkova A.A., Leonova S.A., Nikiforova T., Zagranichnaya A. et al. The Usage of Biologically Active Raw Materials in Confectionery Products Technology. OnLine Journal of Biological Sciences. 2019. vol. 19. no. 1. pp. 77-91.

- Vitola V., Ciprovica I. The effect of cocoa beans heavy and trace elements on safety and stabil ity of confectionery products. Rural Sustainability Research. 2016. vol. 35. no. 330. pp. 19-23.