Simulation of waste heat recovery from ship boiler exhaust gas

Автор: Zhou Yingzhen, Liu Zuncheng, Golyanin Anton

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 4 т.6, 2020 года.

Бесплатный доступ

The heat pipe type waste heat recovery system can effectively reduce energy consumption when the ship is sailing in a polar region, so it has great engineering application value. In order to improve the design of the heat pipe waste heat recovery system and ensure that the design parameters meet the design requirements, this project has carried out a three-dimensional simulation analysis of the internal flow field of the heat pipe waste heat recovery system. Through reasonable model processing, application of boundary conditions, and the assignment of physical attributes the flow field characteristics of the key positions of the heat pipe type waste heat recovery system were obtained scientifically and effectively. The model was simulated and calculated, and the flue gas temperature distribution in the evaporator heat exchange tube, the overall temperature distribution of the waste heat recovery system, and the temperature change curve from the cold water entering the condenser to the steady state were obtained. The change curve of the thermal efficiency of the system during the temperature of the flue gas from the evaporator to the steady state.

Flue gas heat recycling, heat pipe heat exchanger, simulation

Короткий адрес: https://sciup.org/14116210

IDR: 14116210 | УДК: 621.432 | DOI: 10.33619/2414-2948/53/27

Текст научной статьи Simulation of waste heat recovery from ship boiler exhaust gas

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 621.432

The operating temperature of surface ships in polar navigation is low, and daily heating equipment of ship personnel needs to consume a large amount of energy. About 50% of the diesel engine’s thermal energy is lost, and about 25% of the heat is taken away by the exhaust gas. This part accounts for 10% of the fuel plutonium. It has a high taste and great potential for recycling. Therefore, there is great potential for recovering the thermal energy in the diesel exhaust gas. In order to reduce the ship’s overall energy consumption, the waste heat of the ship’s boiler exhaust gas can be used as auxiliary energy for ship’s daily heating, gas supply, power supply, and power. This solution can effectively improve the total utilization of thermal energy, reduce fuel consumption indicators, and reduce power consumption, thereby achieving higher economic benefits. In order to demonstrate the reliability of the heat pipe type waste heat recovery system, the project used the fluid calculation software FLUENT to carry out a simulation calculation of the internal flow field of the heat pipe type waste heat recovery system based on “three evaporators”. Through the simulation calculation of the internal flow field of the equivalent scale model under 6 working conditions, the temperature, pressure, and flow rate of the working fluid, flue gas, water, and other fluids in the evaporator, condenser, and pipeline under each working condition are obtained. And other physical parameters. So as to provide theoretical proof for the implementation of the project plan [1–14].

Material and research methods

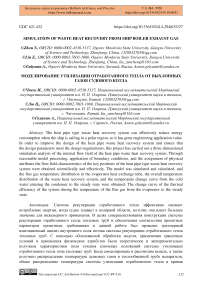

This article takes the heat pipe type waste heat recovery system as the research object, and based on the FLUENT software platform, simulates the physical situation of the internal flow field of the key components such as the evaporator and the condenser during the system work. The specific research goals are mainly divided into five steps. First, a three-dimensional geometric model for finite element calculation is established. The heat pipe waste heat recovery system involves more than 5,000 parts and the system is relatively complicated. Some of these components have a small impact on the simulation calculations, but adversely affect the mesh division and loading of boundary conditions. Without affecting the reliability of the calculation, in order to improve the calculation efficiency, the geometric model of the actual system needs to be simplified to meet the applicability of the finite element software. Secondly, a flow field simulation calculation scheme for the heat pipe type waste heat recovery system is proposed. During the grid division test of the heat pipe waste heat recovery system, it was found that if the overall system model is directly meshed, the total number of units will exceed 100 million. The existing calculation conditions cannot achieve the finite element calculation of this order of magnitude model. To this end, a calculation method of “local + whole” is proposed, in which the local model is an evaporator model, and the overall model includes a condenser and related pipes. The evaporator is used as the input and output of the flue gas and the output device of the heat exchange working medium. The calculation of a single evaporator can obtain the flue gas and working medium outflow parameters under the corresponding working conditions. Then obtain the overall model input parameters. Establish a local finite element simulation calculation model, complete the local model calculation, and provide calculation input parameters for the overall model. Complete the overall simulation calculation. The overall calculation model is established and combined with the local calculation model; the flow field calculation of the heat pipe waste heat recovery system is completed. Finally, a variety of operating conditions were substituted into the calculation model to obtain relevant simulation results. The calculation scheme in this paper will adopt the “local + whole” thinking to realize the flow field simulation of the heat pipe waste heat recovery system. The specific technical route is shown in Figure 1.

Figure 1. Simulation Computing Technology Route.

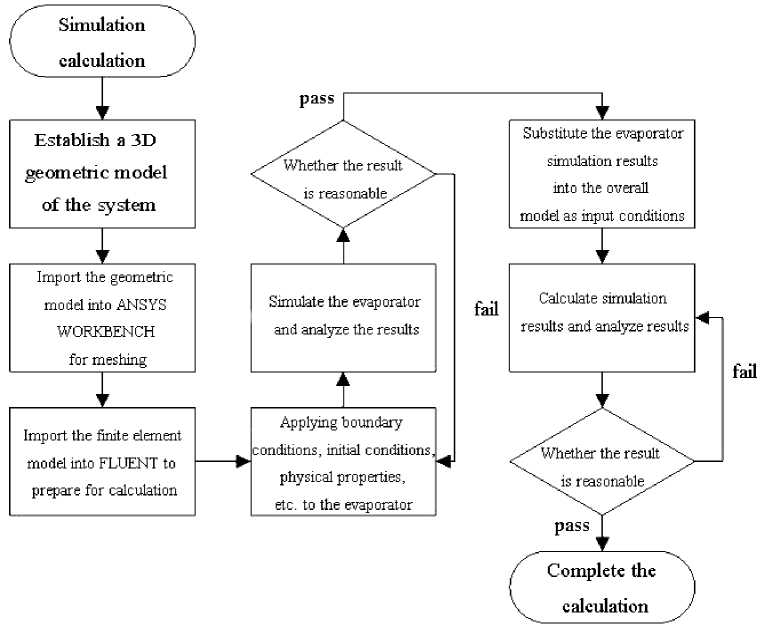

The heat pipe type waste heat recovery system mainly includes components such as an evaporator, a condenser, and a working fluid pipeline. The schematic diagram of the system is shown in Figure 2. The evaporator and the condenser are both tube-and-tube heat exchangers. The shell side of the evaporator is the working medium, the tube side is the flue gas, the condenser pipe is the cooling water, and the shell side is the working medium. After the flue gas enters the tube side of the evaporator, the flue gas heats the working medium in the shell side of the evaporator through the heat conduction of the tube wall. The working medium is heated to evaporate into a gaseous state and is collected in the vapor cavity of the evaporator. Driven by the gas phase working fluid pipeline into the condenser’s steam cavity, the steam is then distributed into the shell and heat is transferred to the cooling water in the condenser tube through tube wall heat exchange. The working fluid in the tube is condensed into heat. The liquid returns to the evaporator through the condensate line under the effect of gravity.

High, temperature flue gas inlet

Figure 2. Structure diagram of heat pipe type waste heat recovery system.

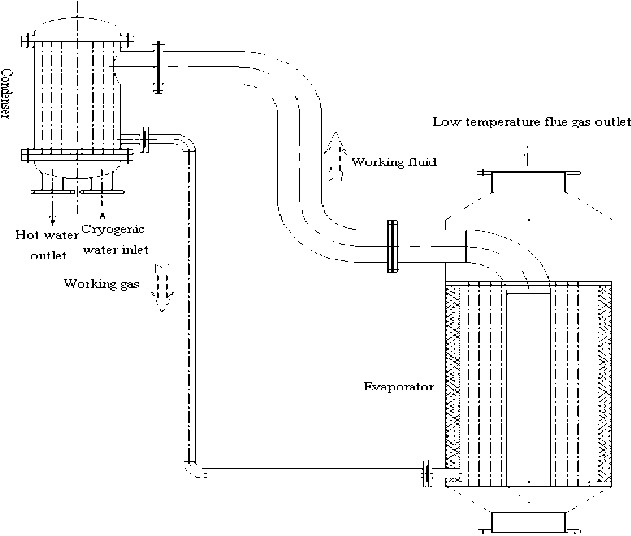

SOLIDWORKS software is used to model the relevant components of the heat pipe type waste heat recovery system and achieve system assembly. The 3D geometric model of the system was imported into ICEM in ANSYS WORKBENCH software platform for finite element mesh division, and the finite element model was submitted to FLUENT software for calculation. The overall assembly model of the heat pipe waste heat recovery system is shown in Figure 3.

Figure 3. Overall assembly model of heat pipe type waste heat recovery system.

Through the pulsation boosting heat transfer experiment, the change curves of the pressure increase value of the diaphragm supercharger with time at different pulsation frequencies were obtained. The change curves of the pipe pressure before and after the boost were compared [8]. The pressure was obtained by analyzing the experimental data Change as a function of time.

The project needs to carry out simulation calculations for the model under five operating conditions. The relevant operating conditions are shown in Table 1.

Table 1.

FIVE OPERATING CONDITIONS

|

Condition number |

1 |

2 |

3 |

4 |

5 |

|

Power /[Kw] |

0 |

798 |

1596 |

2394 |

3990 |

|

Load factor |

0 |

20% |

40% |

60% |

100% |

|

Post-vortex temperature /[°C] |

364 |

425 |

476 |

512 |

537 |

|

Exhaust flow/[m 3 /s] |

4.5 |

5.6 |

7.3 |

9.6 |

15.2 |

|

Exhaust flow /[Kg/s] |

2.7 |

3.1 |

3.8 |

4.7 |

7.2 |

|

Intake flow /[m 3 /s] |

2.4 |

2.8 |

3.4 |

4.2 |

6.5 |

|

Intake flow /[Kg/s] |

2.6 |

3 |

3.6 |

4.6 |

7 |

Results and discussion

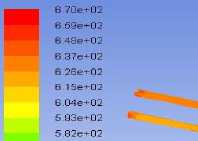

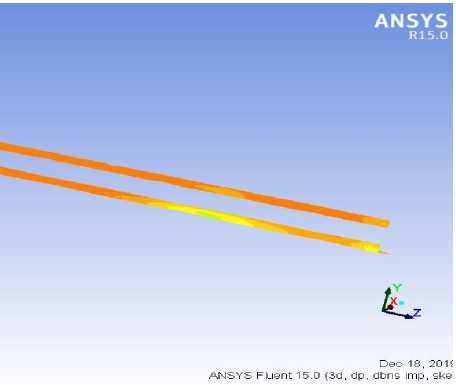

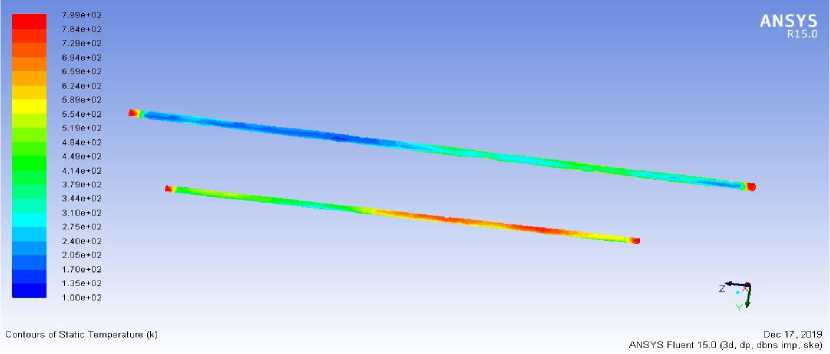

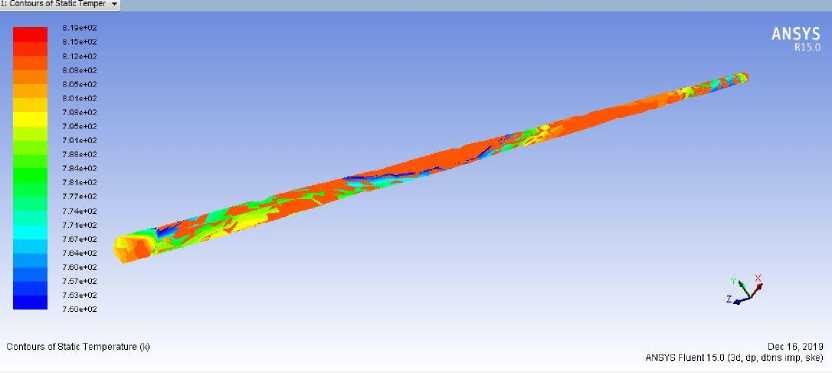

The model was imported into FLUENT software for iterative solution. The resulting cloud diagrams are shown in Figures 4-8. Among them, Figures 4 to 8 are cloud diagrams of surface temperature changes of the heat exchange tubes in evaporators 1 to 5.

5.71e+02

5.60e+02

5.49e+02

5.3Be+02

5.27e+02

5.1Be+02

5.05e+02

4.94e+02

4.83e+02

4.72e+02

4.61e+02

4.50e+02

Contours of Static Temperature (k)

Figure 4. Temperature map of the internal pipeline of the evaporator under operating condition 1.

Figure 5. Temperature map of the internal pipeline of the evaporator under operating condition 2.

Contours of Static Temperature (k) Dec 17,2019

ANSYS Fluent 15.0 pd, dp, dbns imp, ske)

Figure 6. Temperature map of the internal pipeline of the evaporator under operating condition 3.

Figure 7. Temperature map of the internal pipeline of the evaporator under operating condition 4.

Figure 8. Temperature map of the internal pipeline of the evaporator under operating condition 5 .

It can be seen from Figures 4 to 8 that after the flue gas enters, the internal temperature of the evaporator rises rapidly, and the temperature at the flue gas inlet is the highest. As the flue gas gradually exchanges heat with the working fluid outside the pipe in the evaporation pipe, the smoke gradually decreases the temperature at the gas outlet is the lowest. Because the evaporation tubes are very densely arranged, the temperature field inside the evaporator is relatively uniform. Only at the center of the evaporator, the temperature difference is obvious, and the overall temperature difference of the flue gas in the pipeline is not large.

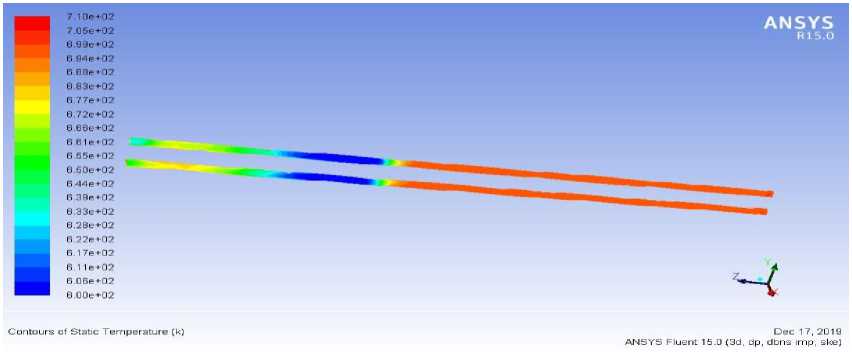

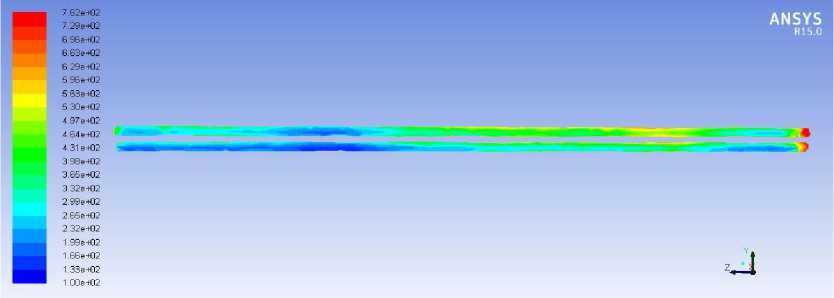

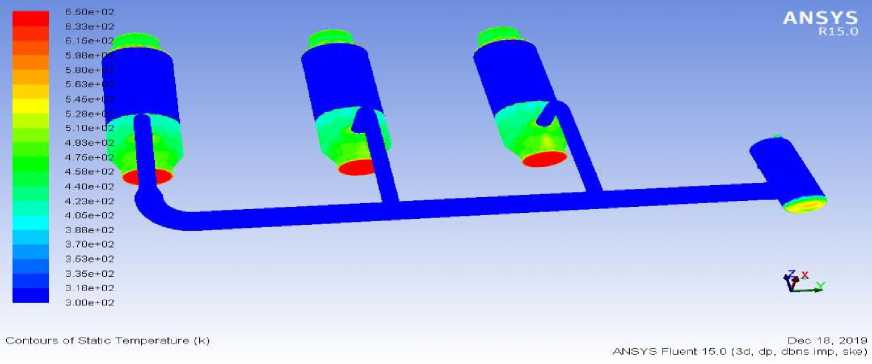

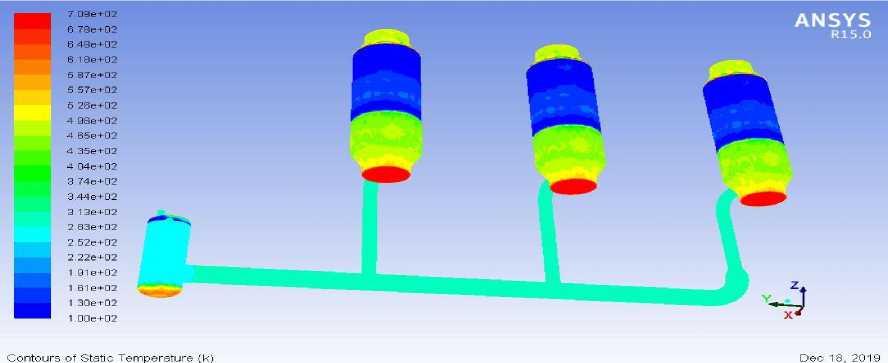

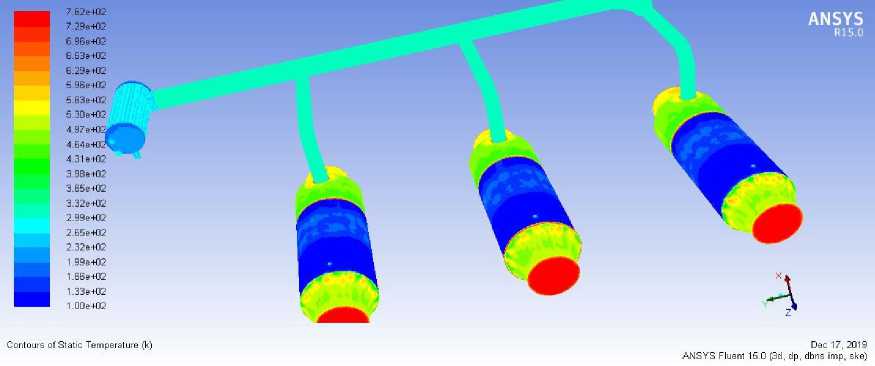

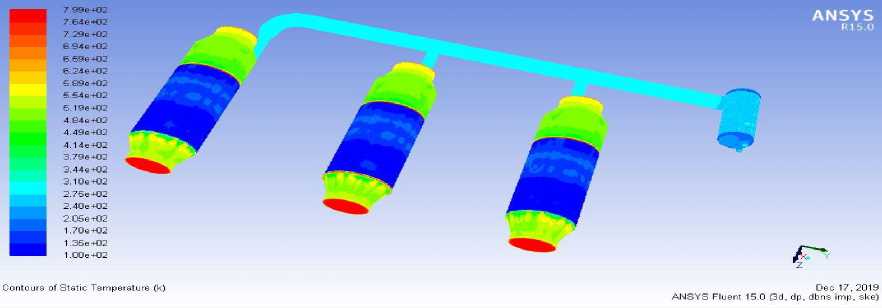

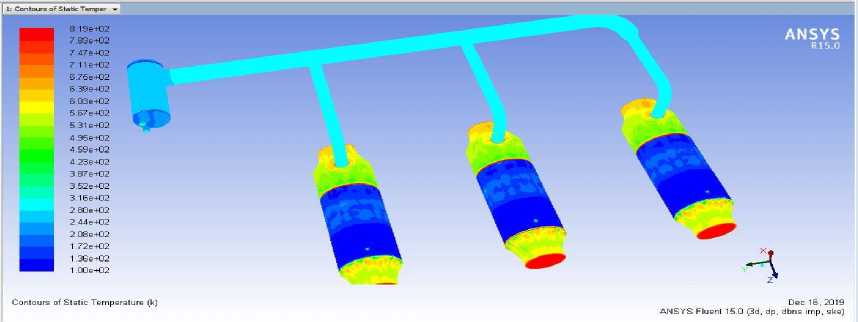

The overall model was imported into FLUENT software for iterative solution, and the resulting cloud diagrams are shown in Figures 9-13. The overall model temperature change under working conditions 1~5.

Figure 9. Temperature model of the overall model under operating condition 1.

ANSYS Fluent 15.0 (3d. dp, dbns imp, ske)

Figure 10. Temperature model of the overall model under operating condition 2.

Figure 11. Temperature model of the overall model under operating condition 3.

Figure 12. Temperature model of the overall model under operating condition 4.

Figure 13. Temperature model of the overall model under operating condition 5.

It can be seen from Figures 9-13 that the steam generated by the evaporator enters the condenser through the large three-way pipe. Due to the large effective thermal resistance of the external insulation material of the pipe, the steam temperature changes little, and the temperature difference between the hot and cold surfaces after entering the condenser is obvious. The upper temperature of the condenser is significantly higher than the lower temperature. When the steady state is reached, the heat transfer of the condenser tube is uniform, and the temperature difference is not large.

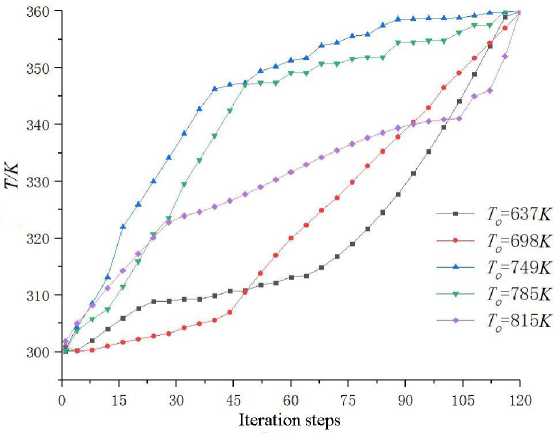

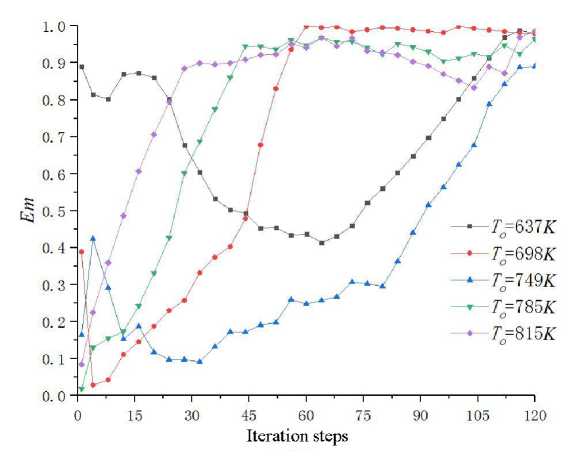

Figure 14. Condenser hot water outlet temperature as a function of calculation steps.

Figure 15. Thermal efficiency of waste heat recovery system.

According to Figures 14 and 15, it can be seen that the higher the flue gas temperature in the waste heat recovery system, the better the thermal efficiency of the system, and the more obvious the hot water temperature rises in the condenser. The simulation results show that the heat pipe type waste heat recovery system can effectively reduce energy consumption when the ship is sailing in polar regions, and thus has great engineering application value.

Conclusion

Aiming at the flue gas side of the heat pipe heat exchanger, the influence of flue gas inlet temperature on the resistance of flow heat transfer was analyzed. Increasing the temperature of the flue gas inlet can enhance the heat transfer performance and the flue gas temperature difference will increase accordingly. It is more appropriate to use an inlet speed of 6.5 m / s ~ 8.5 m/s.

Based on the design parameters of the heat pipe heat exchanger, the flow heat transfer in the flue gas is simulated and analyzed. The velocity, temperature and pressure fields of the flue gas side of the heat exchanger were obtained. The smoke exhaust temperature and pressure drop data of the simulated flue gas proved the reliability of the simulation and the feasibility and accuracy of the phase-change heat exchanger design.

Список литературы Simulation of waste heat recovery from ship boiler exhaust gas

- Zhang N., Shao X. Numerical simulation of the influence of different forms of liquid distributors on the internal flow field in a horizontal tube falling film evaporator // Energy Conservation. 2012. V. 31. №5. P. 19-24.

- Jin R., He X. Numerical simulation of shell-side flow field in profiled tube bundle evaporator // Mechanical Design and Manufacturing. 2010. №9. 193-195.

- Lu L. Q., Yu J. & al. Numerical simulation of flow field characteristics of thin film evaporator // Science and Technology of Food Industry. 2008. №11. P. 209-210.

- Feng M., Chen W. Research on Numerical Simulation of Flow Field in Reciprocating Condenser // Thermal Power Engineering. 2005. V. 20. №1. P. 45-47.

- Xi L. Flow field analysis and design optimization of large-scale brick-ice ice trough. Hengyang: Nanhua University, 2016.

- Deng X. Design of EAF Furnace Waste Heat Recovery and Utilization System // Industrial Boiler. 2010. №3. P. 36-38.

- Yang, Zhang H., Song et al. Organic Rankine Cycle Recovery System for Exhaust Heat of Vehicle Diesel Engines under Variable Operating Conditions // Chinese Journal of Chemical Industry. 2010. №3. P. 103-110.

- Mao Z. Research on Recycling of Waste Heat from Gas Units // Low Carbon World. 2019. №9. P. 89-95.

- Jia B., Li A., Shi Q. et al. Analysis of transient heat transfer characteristics of passive waste heat removal heat exchanger based on FLUENT and analysis of thermal fluid behavior in water tank // Nuclear Science and Engineering. 2019. V. 39. №2. P. 216-223.

- Han Y., Chai B., Wang Z. et al. Selection and experimental research of medium temperature heat pipe working medium // Science and Technology Innovation Herald. 2019. №13. P. 775-780.

- Tong J., Ke H. Study on the Thermodynamic Properties of High-temperature Carrier-Heat Conductor // Natural Gas Chemical Industry (C1 Chemistry and Chemical Industry). 2000. V. 25. №3. P. 59-62.

- Li J., Zhu Z., An H. et al. Influence of microchannel cross-section shape on condensation heat transfer characteristics // Journal of Nanjing University of Technology (Natural Science Edition). 2018. V. 40. №06. P. 54-58.

- Chai Y., Chen H., Jia Y. et al. Super-hydrophobic surface enhanced vapor droplet condensation heat transfer of PVDF hollow fiber heat exchanger tubes // Chinese Journal of Chemical Industry and Engineering. 2019. V. 70. №04. P. 96-104.

- Luo L. Numerical simulation of heat transfer characteristics of finned tube heat exchanger. Changsha: Central South University, 2010.