Стабилизация поливинилхлоридного пластиката соединениями 1,2,4-триазинового ряда

Автор: Маскова А.Р., Аминова Г.К., Каримов Ф.Ч., Сабитов И.Н., Тимофеев А.А., Мазитова А.К.

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Рубрика: Разработка новых полимерных материалов

Статья в выпуске: 6 т.10, 2018 года.

Бесплатный доступ

Пластикаты на основе поливинилхлорида (ПВХ) применяются в различных областях для изготовления широкого ассортимента материалов и изделий. Это обусловлено доступностью сырья, достаточно низкой стоимостью и широкими возможностями модификации их свойств. Целенаправленное изменение характеристик ПВХ достигается введением добавок различного функционального назначения – пластификаторов, стабилизаторов, наполнителей, антипиренов и др. Для пластификации наиболее приемлемыми являются сложноэфирные соединения. Одним из основных требований к сложноэфирным пластификаторам является их устойчивость к термоокислению. Устойчивость пластификаторов к окислению можно повысить использованием антиоксидантов ряда азотсодержащих гетероциклических соединений. Поэтому в данной работе изучена стабилизирующая активность соединений 1,2,4-триазинового ряда для пластифицированного поливинилхлорида методом хемилюминесценции. На основании проведенных экспериментов было установлено, что композиции, полученные с использованием новых добавок, а именно октилфеноксипропилфталатов и соединений 1,2,4-триазинового ряда, приобретают высокие эксплуатационные свойства, что приводит к увеличению срока их службы. Показано, что соединения 1,2,4-триазинового ряда понижают термоокислительную деструкцию пластифицированного поливинилхлорида. Таким образом, применение соединений 1,2,4-триазинового ряда в качестве стабилизаторов-антиоксидантов является целесообразным для повышения долговечности ПВХ-пластикатов.

Антиоксидант, метод хемилюминесценции, октилфеноксипропилфталат, ПВХ, пластификатор, соединения 1, 2, 4-триазинового ряда, стабилизатор, фталаты оксиалкилированных спиртов

Короткий адрес: https://sciup.org/142212323

IDR: 142212323 | УДК: 678 | DOI: 10.15828/2075-8545-2018-10-6-112-123

Текст научной статьи Стабилизация поливинилхлоридного пластиката соединениями 1,2,4-триазинового ряда

M achine - readable information on CC- licenses (HTML- code ) in metadata of the paper

is licensed under a ...

arious additives are used in the preparation of polyvinyl chloride plastic, that gives the necessary performance properties to it. The most part of additives is plasticizers, which are introduced to regulate the rheological properties of molten of PVC-compositions [1–5]. But plasticizers have a significant accelerating effect on the process of destruction of polyvinyl chloride during processing. Ester plasticizers participates in free-radical oxidation reactions in the presence of oxygen and activate the process of HCl elimination from polymer that leads to deterioration of physico-chemical properties of PVC-plasticates during their processing and exploitation [6–11].

DEVELOPMENT OF NEW POLYMER MATERIALS

The oxidation stability of plasticizers can be increased by using antioxidants from number of nitrogen-containing heterocyclic compounds [12– 17]. Outstanding characteristic of this group of stabilizers is their ability to echo-stabilization of PVC. In this case, nitrogen-containing stabilizers, which include amino groups, effectively inhibit free radical oxidation of esters [9-11]. For this reason we investigated compounds of the 1,2,4-tri-azine series as PVC stabilizers.

The present work studied the stabilizing activity of the 1,2,4-triazine series for plasticized polyvinyl chloride by the chemo luminescence method (CL).

We selected the following objects as stabilizers-antioxidants to study: PVC of C-70 brand, octylphenoxypropyl phthalate (OPOPP) as a plasticizer and compounds of 1,2,4-triazine specifically: 3-mercapto-6-furfuryl-1,2,4-triazinone-5 (compound I), 3-mercapto-4-amino-6-furfuryl-1,2,4-triazi-non-5 (compound II), 3-methylthio-4-amino-6-furfuryl-1,2,4-triazinon-5 (compound III).

Methods of preparation and physicochemical characteristics of the proposed chemical additives are given in the works [15-27].

Chemo luminescence in the process of thermo-oxidative destruction of PVC was recorded on the installation described in [9, 16, 17]. The high sensitivity of the CL-method makes it possible to quickly and efficiently measure even insignificant changes in the process of polymer destruction that occur with the introduction of various inhibitors into polymer. In our investigations an experimental chemo luminescent device containing a heating unit with transparent for emission heat-resistant container with a test sample, placed in a sealed chamber, a photomultiplier unit with a photocurrent amplifier, and a registration unit with matching and recording devices was used. The temperature change on the test sample was carried out with electronic unit that provides a temperature rise rate 2 ± 0.2оC/min.

An ampoule containing 50 ml of the test sample was placed in a thermostatically controlled furnace of the CL-installation. Then the difference in the CL-intensity at the reaction temperature was measured. The temperature in the thermostat and the level of its heating (2 ± 0.2оC/min) were maintained automatically by the electronic unit. The compositions were prepared by dissolving calculated amount of stabilizer (0.4% by mass) in the plasticizer.

DEVELOPMENT OF NEW POLYMER MATERIALS

Thermo-oxidative degradation of the samples was carried out in the stream of dry oxygen (O2), which was fed directly to the sample at the rate of 2.5 liters / hour. Investigations were performed in the temperature range of 100–200оC. Investigations were carried out in the temperature range of 100–200оC. The stabilizing effect was estimated by the difference in the intensity of chemo luminescence (Icl) emission of the test samples with additions relatively to the intensities Icl typical for the pure plasticizer.

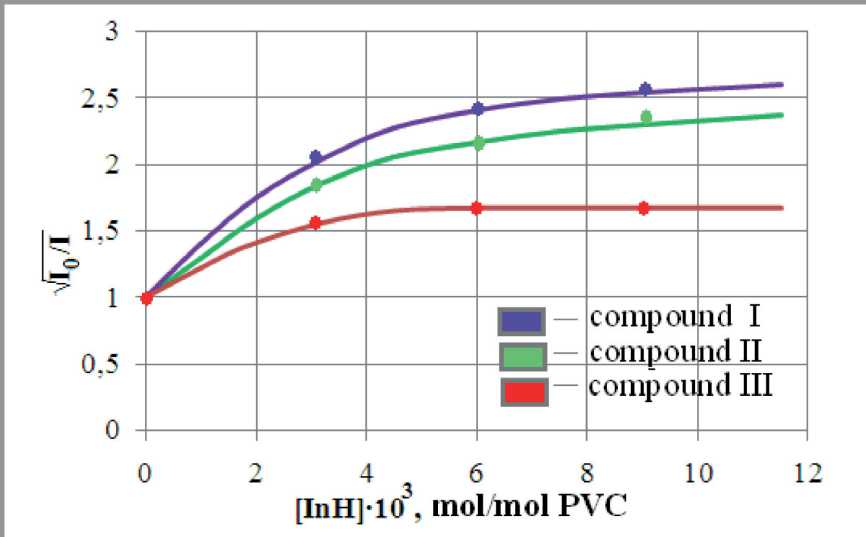

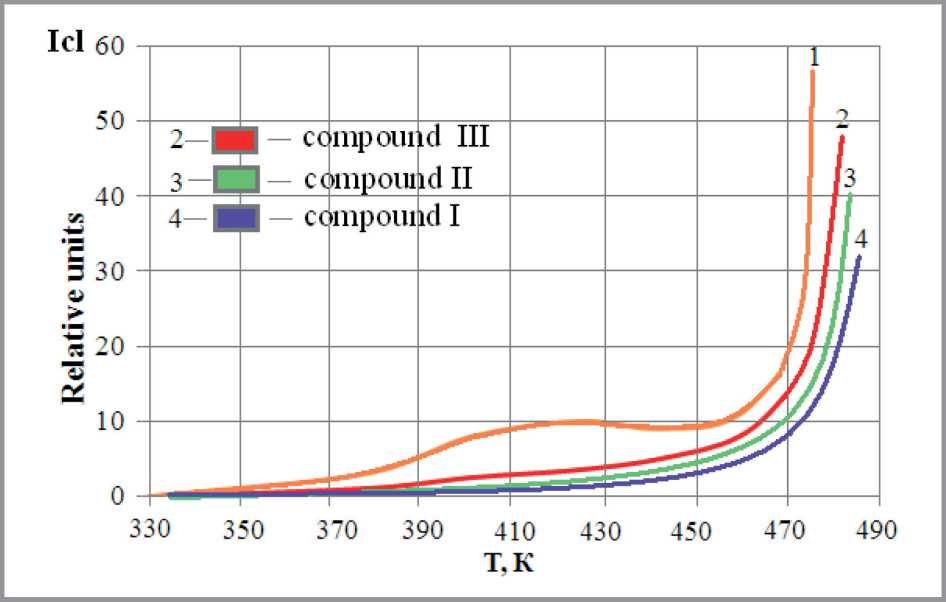

The experimental results of chemo luminescent studies of plasticized PVC are shown in Fig. 1–3.

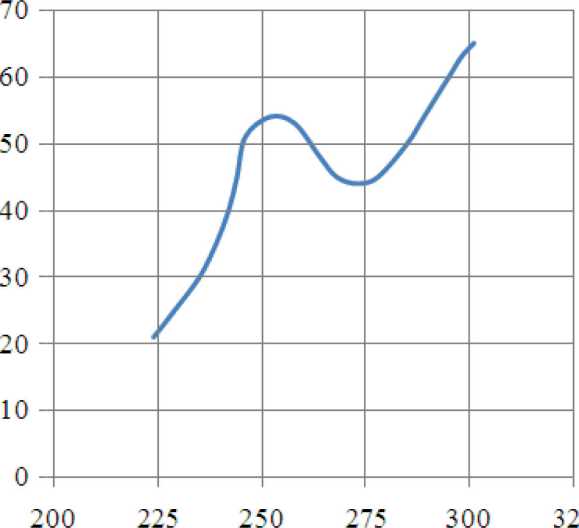

Experimental data demonstrate that of the 1,2,4-triazine series (Fig. 1) are weak UV stabilizers, but they exhibit a marked inhibitory effect on the thermo-oxidative destruction of plasticized PVC (Fig. 2), while the function of antioxidant stabilizer is manifested in a wide range of temperatures (from 375 K to 480 K and above) (Fig. 3).

According to the effectiveness of the inhibiting effect on the thermooxidative destruction of plasticized PVC, of the 1,2,4-triazine series are arranged in the following order: I > II > III. It is obviously that their effec-

X, nm

Fig. 1. UV-spectrum of the 1,2,4-triazine series

DEVELOPMENT OF NEW POLYMER MATERIALS

Fig. 2. The relative intensity change of chemo luminescence during the thermo oxidative (O2) degradation of plasticized PVC in the presence of the 1,2,4-triazine series (0.4% by mass)

Fig. 3. Temperature dependence of chemo luminescence during the thermo oxidative (O2) degradation of plasticized PVC (1) in the presence of the 1,2,4-triazine series (2–4) (0.4% by mass)

DEVELOPMENT OF NEW POLYMER MATERIALS tiveness as antioxidant stabilizers is influenced by the chemical structure of the substituent and their position in the heterocycle. The presence of the methylthio group in position 3 markedly reduces the effectiveness of the triazine derivatives as antioxidant stabilizers during thermo-oxidative degradation. Of the 1,2,4-triazine series is a more effective stabilizer in comparision with asymmetric triazine with the amino group in position 4, which is probably associated with an increase in basicity.

Thus, compounds of the 1,2,4-triazine series reduce the thermo-oxidative destruction of plasticized polyvinyl chloride. The suggested antioxidants were used in the formulation of PVC materials taken in an amount of not more than 0.4%. Therefore, we can confidently note that the nanoadditives that we used exhibit maximal efficiency.

The performed research has been funded through the government grant «Synthesis and investigation of the modern polyvinyl chloride plasticizers» according to the Decree of the Government of the Republic of Bashkortostan of 07.02.2018 №56 «On providing grants of the Republic of Bashkortostan to young scientists and groups of young researchers in 2018».