Status of development orientations for mining titanium placers in Vietnam

Автор: Bui Xuan Nam, Ho Si Giao

Журнал: Горные науки и технологии @gornye-nauki-tekhnologii

Рубрика: Разработка месторождений полезных ископаемых

Статья в выпуске: 1, 2016 года.

Бесплатный доступ

Vietnam has potential reserves of titanium placers, located mainly along the coast of the Middle spreading across provinces from Thanh Hoa to Ba Ria - Vung Tau. Mining titanium placers deposits has gained considerable profit for localities and the country as a whole, but it has also given rise to significant environmental issues. The paper introduces the potential of titanium placers in Vietnam, current mining status and environmental issues faced, and then proposes a number of strategic orientations for sustainable development of the future titanium industry of Vietnam. These orientations are completely feasible with regard to the titanium placer mines of Vietnam in order to consider and apply effectively for suitable conditions. They also represent a useful reference for similar titanium placer mines in the world.

Vietnam, titanium placers, marine deposit, mining and processing technologies

Короткий адрес: https://sciup.org/140215859

IDR: 140215859 | DOI: 10.17073/2500-0632-2016-1-40-50

Текст научной статьи Status of development orientations for mining titanium placers in Vietnam

1. Potential of titanium placers in Vietnam

Sea-beach titanium placers are a mixture of heavy minerals such as ilmenite, rutile, zircon, monazite, sillimanite, garne, etc. The ratio of heavy minerals in ore is different from area to area because of their formations and economic values.

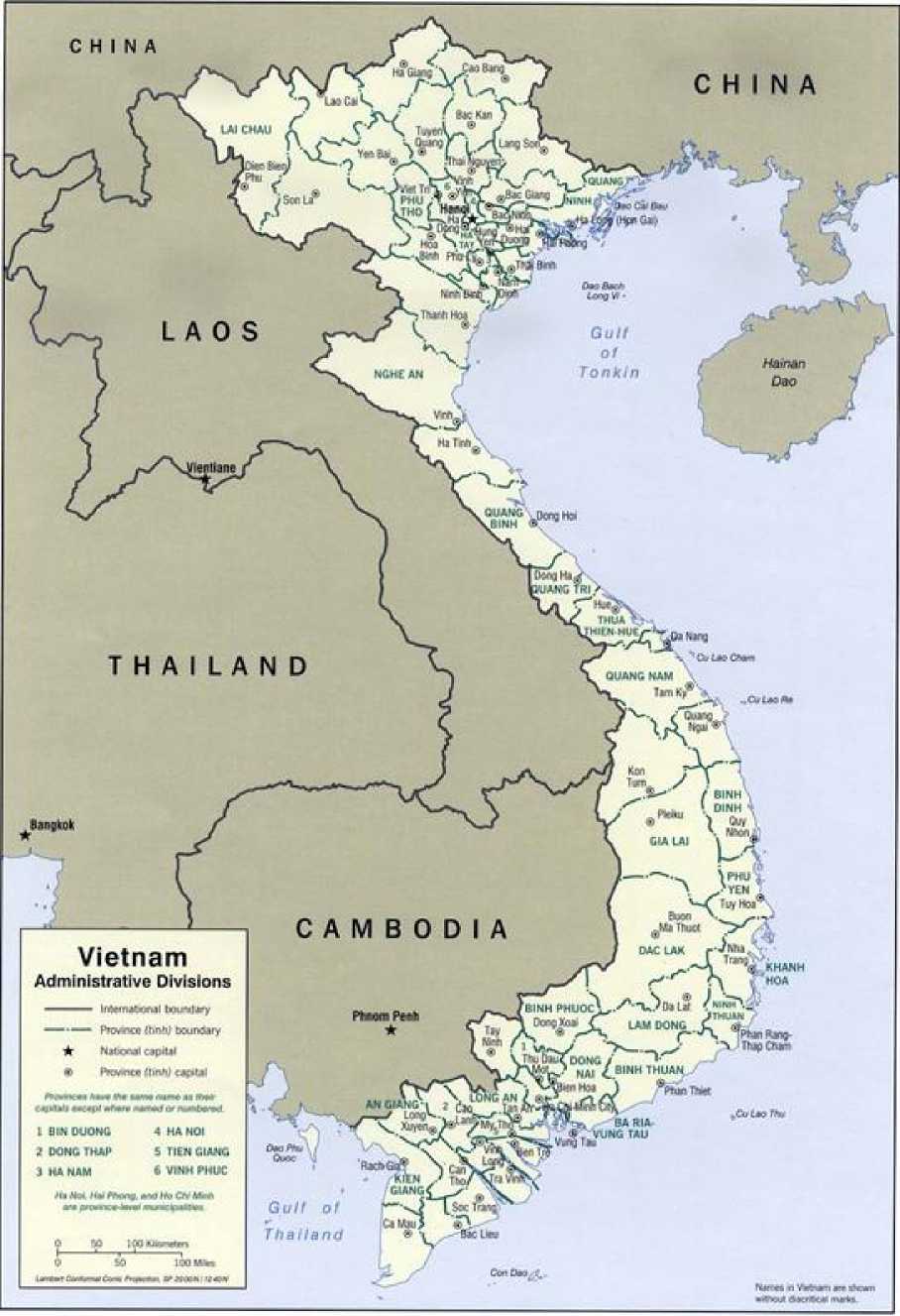

In Vietnam, titanium placers are discovered along the coast of the Middle, spreading across provinces from Thanh Hoa to Ba Ria – Vung Tau, concentrated at areas Ky Anh, Cam Xuyen (Ha Tinh province), Vinh Thai (Quang Tri province), Ke Sung, Vinh My (Thua Thien – Hue province), My Thanh – Phu My, De Gi – Phu Cat (Binh Dinh province), Ham Tan, Mui Ne (Binh

resources and reserves of Vietnam (calculated until 2008) is about 100 million tons.

Since 2008, the Ministry of Natural Resources and Environment of Vietnam has been implementing an exploration project of titanium placers in the red sand formation in Ninh Thuan, Binh Thuan and North of Ba Ria – Vung Tau over an area covering 1,460 km2. The research result over an area of 760 km2 out of the total of 1,460 km2 estimated the titanium resources and reserves at about 300 million tons. Therefore, over the total study area of 1,460 km2, it is estimated that there may be up to 500 million tons of potential titanium placers, increasing the total titanium – zircon resources of Vietnam to over 600 million tons.

Thuan province) – Figure 1. Total titanium

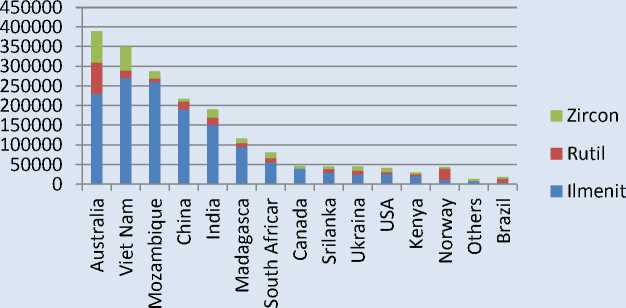

Unit: 1,000 ton/TiO 2 /ZrO 2

[correct the corresponding countries as follows: Vietnam, Madagascar, South Africa, Sri Lanka, Ukraine] [on right-hand side, change “Rutil” to “Rutile” and “Ilmenit” to “Ilmenite”]

Fig. 1: Titanium mineral reserves of some countries of the world ( Source: TZMI, USGS)

Fig. 2: Provinces with titanium placers in Vietnam

(Thanh Hoa, Nghe An, Ha Tinh, Quang Binh, Quang Tri, Thua Thien – Hue, Quang Nam, Quang Ngai, Binh Dinh, Phu Yen, Khanh Hoa, Ninh Thuan, Binh Thuan, Ba Ria – Vung Tau)

Since 2008, the Ministry of Natural Resources and Environment of Vietnam has been implementing an exploration project of titanium placers in the red sand formation in Ninh Thuan, Binh Thuan and North of Ba Ria – Vung Tau over an area covering 1,460 km2. The research result over an area of 760 km2 out of the total of 1,460 km2 estimated the titanium resources and reserves at about 300 million tons. Therefore, over the total study area of 1,460 km2, it is estimated that there may be up to 500 million tons of potential titanium placers, increasing the total titanium – zircon resources of Vietnam to over 600 million tons.

Sea-beach titanium placers in the Middle of Vietnam are similar to other titanium placer deposits in the world. They are synthetic placers, deposited by minerals with a density of 4.3–5.2 and grain size of 0.074–0.25 mm. There are many useful minerals, but including 4 main ones: ilmenite, rutile, zircon, and monazite, where ilmenite occupies 53.09–91.66%, zircon 3.56– 18.45%, rutile 0.69–2.65%. The concentrating ore quality of the titanium placers in the Middle of Vietnam meets all requirements for export.

According to the prospecting and exploration results on the titanium placers along the coast of Middle Vietnam, synthetic titanium placers are mainly located in the marine deposit and formed during the Late Pleistocene of the Quaternary period.

Deposits of titanium placers in the Middle of Vietnam explored before 2005 with the cut-off grade of ≥ 10 kg/m3 have shown: length of these deposits is from several meters to 20 km, width of 25–700 m, and thickness of 0.5–10 m.

There are two parts in the deposits of titanium placers in the Middle of Vietnam: nonore component is about 80.2–99.7%, and ore component is 0.3–18.8%.

– Non-ore component is mainly quartz (83.1–96.9%), sand (2.3–15.9%), and other minerals such as turmaline and distene (0.2– 3.2%).

– Ore component accounts for 0.3–5.2%, somewhere over 10%, where content of titanium and zircon is more than 98%; other minerals such as monazite, xenotime, granate are about 0.01– 2%. Minerals containing titanium comprise:

+ Ilmenite (FeTiO 3 ): is the main ore mineral with content from several kg/m3 to several hundred kg/m3, accounting for 50–90% of total useful heavy minerals. This mineral is black or grey black with ametallic luster. Grain size of ilmenite is from 0.02–0.4 mm, mainly 0.1–0.25 mm. Ilmenite consists of the following main components: TiO 2 (48.50–53.00%), FeO (39.96–44.78%), MnO (3.40–8.60%), SiO 2 (0.32–2.68%).

+ Zircon (ZrSiO 4 ): is also a mineral found often in ore. It can be colorless, light blue, pinkish, and transparent. The content of zircon ranges from 0.3–10 kg/m3. Grain size is from 0.02-0.2 mm. Zircon consists of the following main components: ZrO 2 (62.94–64.83%), HfO 2 (1.56–3.34%), SiO (32.15–33.58%).

According to Decision No. 104/2007/QD-TTg on Master Plans for investigation, exploration, processing and use of titanium ore in the 2007–2015 periods, orientation to 2025 of the Prime Minister, demand for products from titanium and zircon ores and estimated production of ilmenite concentration are shown in Tables 3 and 4.

Fig. 3: Marine deposit of Pleistocene (red sand) in Ninh Thuận

Fig. 4: Marine deposit of Halocene at Quang Xuong district in Thanh Hoa

Table 1

Chemical composition of ilmenite

|

Components (%) |

Areas |

||||

|

Mo Duc – Quang Ngai |

Phu My – Binh Dinh |

Phu Cat – Binh Dinh |

Quy Nhơn – Binh Dinh |

Tuy Hoa – Phu Yen |

|

|

TiO 2 |

52.00 |

53.00 |

50.79 |

48.84 |

50.14 |

|

FeO |

44.22 |

42.18 |

44.12 |

45.63 |

38.96 |

|

MnO |

2.87 |

2.21 |

2.95 |

4.03 |

8.60 |

|

SiO 2 |

0.31 |

2.17 |

1.37 |

0.88 |

1.95 |

|

Total |

99.40 |

99.56 |

99.59 |

99.38 |

99.65 |

Source: General Department of Geology and Minerals of Vietnam

Table 2

Chemical composition of zircon

|

Components (%) |

Areas |

||||

|

Mo Duc – Quang Ngai |

Phu My- Binh Dinh |

Phu Cat – Binh Dinh |

Quy Nhơn – Binh Dinh |

Tuy Hoa – Phu Yen |

|

|

ZrO 2 |

64.48 |

64.31 |

63.05 |

62.94 |

63.97 |

|

HfO 2 |

2.45 |

2.07 |

3.10 |

3.34 |

2.17 |

|

SiO 2 |

32.59 |

32.91 |

32.97 |

32.58 |

33.33 |

|

Tổng |

99.52 |

99.29 |

99.12 |

98.86 |

96.16 |

Source: General Department of Geology and Minerals ofVietnam

Table 3

Demand of products from titanium and zircon ores to 2025 (1,000 tons)

|

No. |

Demand |

2007 |

2010 |

2015 |

2020 |

2025 |

|

1 |

Pigment |

12 |

16 |

26 |

42 |

74 |

|

2 |

Artificial Rutile or titanium slag |

0 |

30 |

30 |

45 |

80 |

|

3 |

Ilmenite |

28 |

37 |

70 |

110 |

170 |

|

4 |

Fine zircon powder |

10 |

12 |

15 |

25 |

40 |

Table 4

Estimated production of ilmenite concentration to 2025 (1,000 tons)

|

Products |

2007 |

2010 |

2015 |

2020 |

2025 |

|

Concentration ore |

460 |

250 |

350 |

400 |

600 |

|

Concentration ore for deep processing |

40 |

250 |

350 |

400 |

600 |

|

Concentration ore for export |

420 |

0 |

0 |

0 |

0 |

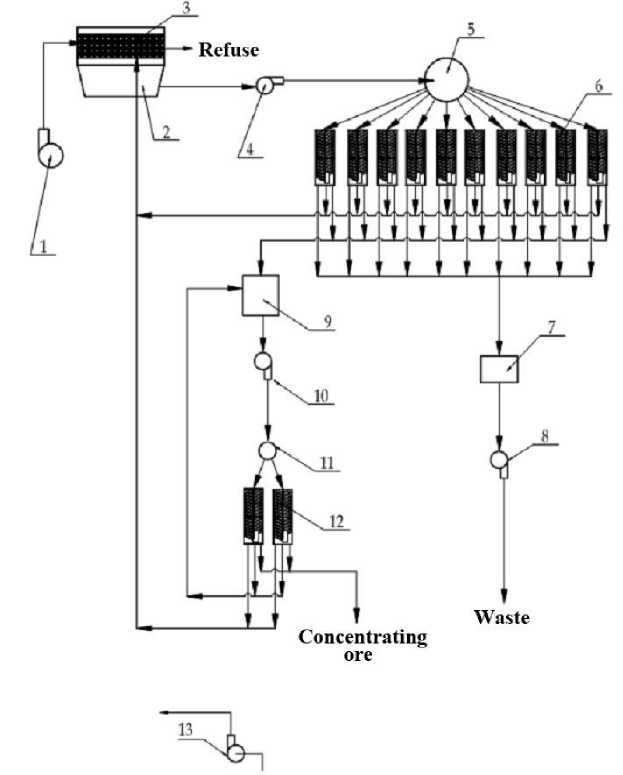

Fig. 5: Flow chart of the process scheme with fixed processing complex

(1 – Feed pump of run-off mine ores, 2 – Tank for collecting run-off mine ores, 3 – Screen for separating refuse, 4 – Pump supplying raw processing component, 5 – Tank for dividing into flows, 6 – Raw processing component, 7 – Tank for pumping waste sand, 8 – Pump for removing waste sand, 9 – Tank for pumping to the concentration processing component, 10 – Pump supplying for concentration processing component, 11 – Tank for dividing into flows, 12 – Concentration processing component, 13 – Water pump)

a) b)

Fig. 6: Ore is extracted and transported by excavator and truck (a), and fed to the fixed processing complex by pump machine (b)

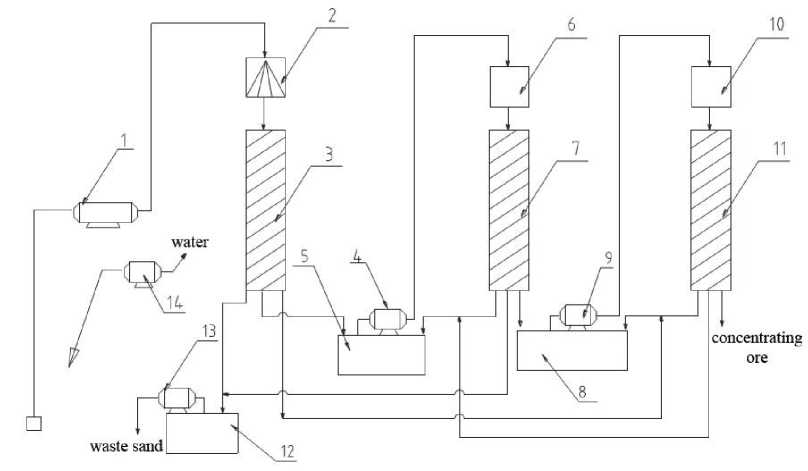

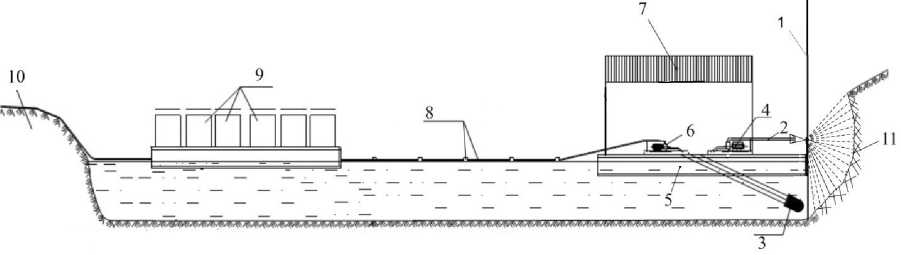

b. Mining with hydraulic monitor and sucker pump combined with the raft-mounted mobile processing complex (Figure 7):

Fig. 7: Flow chart of the process scheme with mobile processing complex

(1 – Pump for sucking ore sand, 2- Tank for dividing into flows with structure of separating refuse, 3 – Raw processing component, 4 – Pump for intermediate processing, 5 – Tank for pumping to the intermediate processing component, 6 – Tank for dividing into flows, 7 – Intermediate processing component, 8 – Tank for pumping to the concentration processing component, 9 – Pump supplying for concentration processing component, 10 – Tank for dividing into flows, 11 – Concentration processing component, 12 – Tank for pumping waste sand, 13 – Pump for removing waste sand, 14 – Water pump)

Fig. 8: Ore is exploited effectively with the mobile mining and processing system

(1 – anchor, 2 – nozzle, 3 – suction head, 4 – Pump for nozzle, 5 – raft, 6 – pump for mixture of titanium ore and sand, 7 – roof of the raft, 8 – pipeline to processing system, 9 – processing system, 10 – titanium ore)

Fig. 9: Mining titanium placers with the mobile mining and processing system at Phu My district, Binh Dinh province, Vietnam

-

2. Current mining of titanium placers in Vietnam and environmental issues

-

2.1. Mining and processing technologies

-

There are two mining and processing technologies applied for titanium placers in the Middle of Vietnam:

-

a. Mining with excavator (wheelloader) and truck combined with the fixed processing complex (Figure 5):

Ore is loaded by excavator or wheelloader to truck to transport to the fixed processing complex located in the center of the mine, then mixed with water to pump to the raw processing components. Concentration ore gained from the raw processing component is reprocessed at the concentration processing component to obtain the required concentration ore (approximately 85% of heavy minerals) – Figure 6.

The mining and processing scheme was applied quite commonly between 1995 and 2002 at the concentrated mines of large reserves in Ha Tinh, Binh Dinh, etc, but it is no longer popular. The scheme is high in output, but it involves

considerable investment capital, it is not well suited for small and complicated mines, and encounters many difficulties in land reclamation, especially when the distance between the fixed processing complex and mining face is considerable. For a deposit with a grade less than 2% of heavy minerals, this scheme is ineffective.

Ore is broken by hydraulic monitor (if necessary) and pumped for feeding to the raftmounted mobile processing complex in the mine in order to separate into 3 kinds of products (tailings, intermediate ore, and concentration ore). The intermediate ore gained from the raw processing component is pumped to the intermediate processing component in order to obtain concentration ore. The concentration ore that meets the quality requirement (>85% of heavy minerals) is pumped to the store. Waste sand is pumped to the waste dump at the mined-out areas (Figure 8).

The mining and processing scheme is flexible and suitable for deposits located under the underground water level. The process scheme

Fig. 10: Changing terrain of the area caused by mining and processing activities of titanium placers

is currently applied effectively for almost all titanium placers mines in the Middle of Vietnam.

-

2.2. Environmental issues caused by the mining and processing activities of titanium placers

Hazardous environmental impacts caused by the mining and processing activities of titanium placers can be listed as follows:

-

a. Changing terrain of the area: Over the time of the mining and processing, the terrain of the mine area has changed in altitude, slope, landscape, etc. These changes cause deformations of the coastline, depression of mine slope and beach, fly sand, etc.

-

b. Influence on the ecosystem of forest and land : Many protective forests have been cut down and overrun to create areas for ore exploitation. These have caused serious environmental pollution and soil depression. The key hazardous impacts of the mining and processing activities of titanium placers on the coastal soil environment are long and expansive land appropriation, a large volume of waste sand and areas of land reclamation that are limited in comparison with the mined-out regions.

-

c. Impact on the water environment: The rivers and lakes surrounding the mining areas are the sources of water supplying all mining and processing activities. Underground water in sand is used circularly. Mining and processing activities have lowered the local water level, and can cause salt incursion into water bearing aquifers.

Wastewater bearing sediment mud, heavy metals, lubricants, and so on is the reason for pollution of the running water for the people living in the areas surrounding the mine.

Mining and processing activities create a large volume of wastewater that is absorbed directly into the sand without treatment. This causes underground water pollution of the surrounding areas

-

d. Loss of mineral resources: Without the master plan for exploring and mining titanium placers, the area and mining sequence of licensed mines are not suitable. They lead to a loss of mineral resources and hamper the land reclamation process. Moreover, poorly developed mining and processing equipment is also a reason for mineral loss and low ore recovery.

Fig. 11: Areas of land reclamation are limited compared with the mined-out areas

Fig. 12: Loss of titanium placers in mining and processing activities

Fig. 13: Danger of radioactive pollution in mining, hauling, and processing of ilmenite

-

e. Radioactive pollution: Mining, hauling, and processing activities of ilmenite can disseminate radioactive substances with the sources are radioactive minerals going along such as zircon, monazite, etc, containing thorium, uranium, etc. In particular, concentration ores usually have a radioactive field in excess of radioactive safety norms.

-

3. Directions for future development of the titanium industry in Vietnam

-

3.1. A master plan for exploration, mining and processing of titanium placers

-

-

3.2. Improving the role of state management in licensing and ore consumption

Based on the demand for products from titanium placers for domestic consumption and export, and given the local potential of titanium placers, the government should have suitable master plans in place for the exploration, mining and processing of these kinds of minerals in provinces in the Middle of Vietnam.

To avoid the overlapping in the master plans of titanium ore exploitation, construction of an ecological resort, aquaculture, the construction of a coastal industrial park, and so on, which complicate the management process, the regulations of the Minerals Law should be observed, meaning that the areas containing titanium ore must be developed before conducting other works in these areas.

Additionally explore in particular the older titanium placer deposits in order to increase the reliability of ore quality and reserves, and to effectively justify investment and exploitation. At the same time, prospecting work should be performed for potential new deposits.

Areas for the mining and processing of titanium placers and the production there of should be planned in line with the development of industrial zones, export processing zones, meet all requirements of domestic consumption and export, and convenience for transportation, business, etc.

-

a. Licensing management

Although the Provincial People’s Committee is assigned to license artisan mining, in reality, its licensing power has not yet been executed properly. The “ask-and-give” mechanism still exists in the state management of mining licensing.

To avoid the above-mentioned problem, a new point, which is deemed a breakthrough of the Minerals Law of 2010, is a fundamental change in the mineral management mechanism, especially concerning regulations on finance, which are suitable for the market economy, such as regulations on payment for mining rights (Article 77); regulations on auctioning mining rights (Article 82), and regulations on licensing powers (Articles 77 and 78). These new regulations are transparent and in the public domain, helping abolish the “ask-and-give” mechanism, select technically and financially cabable investors, and avoid improper licensing as was the case in the past.

To guarantee the comprehensiveness between exploitation and processing, it is specifically stipulated in the Minerals Law of 2010 that mining licenses shall only be granted alongside commitments to build deep-processing plants to ensure added value for the mineral commodities.

-

b. Management and ore consumption

According to the Minerals Law, as amended in 2005, the export of raw minerals is limited by the state. In reality, however, this activity is still very much a work in progress. The deeper the processing of titanium ore, the higher the potential benefit. If the titanium ore is extracted and exported under the form of concentrates, its value is low and the revenue that the state can receive is not commensurate with the true value of the resources.

-

3.3. Investing in advanced mining and processing equipment and researching suitable process schemes

The Minerals Law of 2010 stipulated that it is forbidden to export crude ores. As regards the amount of titanium ore that had been extracted before the Minerals Law of 2010 came into effect, the Prime Minister released Directive No. 02/CT-TTg dated January 9, 2012, allowing for the export of in-stock ilmenite ore concentrates till June 30, 2012. This is an extremely important alternative that allows companies to release titanium ore concentrates from storage, ensuring are turn of capital to build deep-processing plants, registered in the provincial territories. Since July 1, 2012, the export of unprocessed mineral commodities has been forbidden, unless otherwise approved by the Prime Minister.

-

a. Investing in advanced mining and processing equipment

To increase productivity and ore recovery, and to decrease ore loss, investment into advanced mining and processing equipment is essential for titanium placer mines in Vietnam, especially for kinds of ores in the red sand formation.

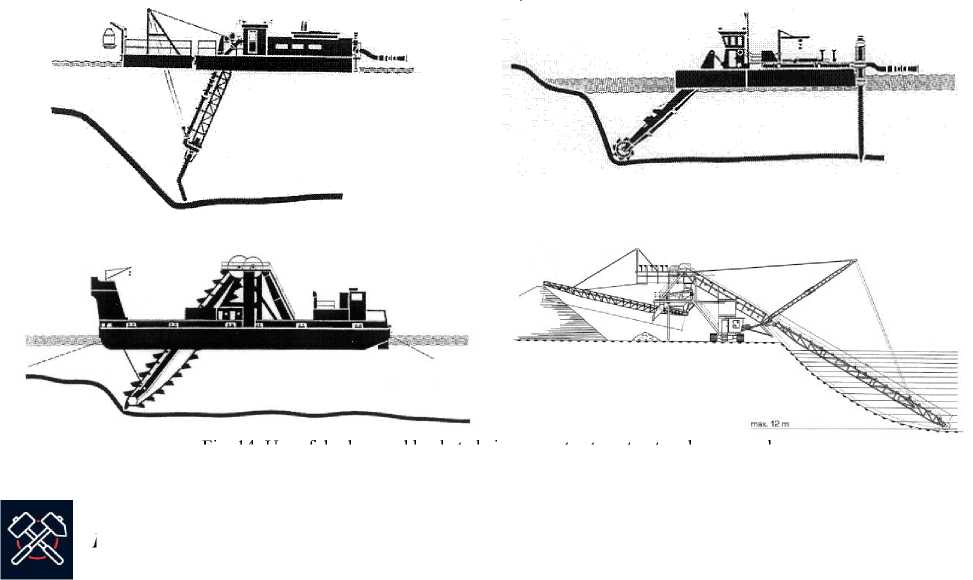

Dredgers and bucket chain excavators with a pipeline system and processing complex are options that should be considered carefully. The experience of Germany and other countries are useful lessons for application at titanium placer deposits in the Middle of Vietnam.

Fig. 14: Use of dredger and bucket chain excavator to extract and process placer ores

-

b. Researching suitable process schemes

-

4. Conclusions

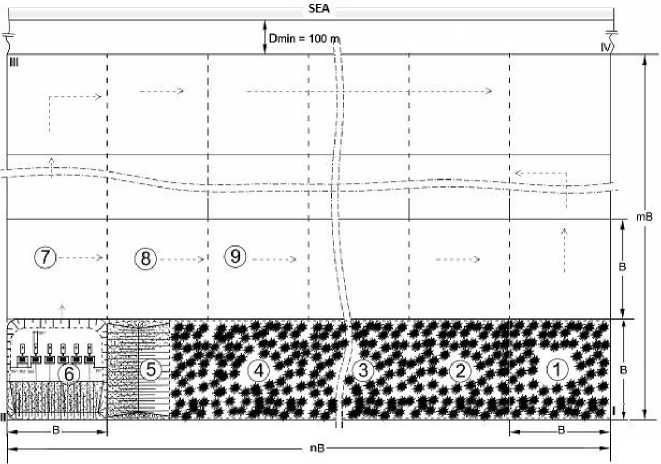

To decrease ore loss, increase the ratio of land reclamation and protect the environment, a suitable process scheme and mining sequence are very important for the titanium placer mines in Vietnam.

Suitable process schemes and mining sequences must facilitate all activities in mining, processing, waste dumping, and land reclamation, to be performed in sequence. In the process scheme, the area of the mine should be divided into blocks for mining periods, and developed in a specific direction.

In Figure 15, suitable process schemes and mining sequences are proposed for application at titanium placer mines in Vietnam. Here, blocks are square with B is the side of the square. D min is the minimum distance between the mine limit and the sea. The mining direction and sequence are shown by the number and arrows in Figure 15.

The above sequences of mining, processing, waste dumping, and land reclamation represent a truly environmental-friendly process scheme for titanium placer mines in Vietnam.

Vietnam has potential reserves of titanium placers, located mainly along the coast of the Middle, spreading over provinces from Thanh Hoa to Ba Ria – Vung Tau. There are two mining and processing technologies applied for titanium placers in the Middle of Vietnam: mining with excavator (wheelloader) and truck combined with the fixed processing complex, and mining with hydraulic monitor and sucker pump combined with a raft-mounted mobile processing complex.

Mining titanium placer deposits has generated considerable profit for localities and the country as a whole, but it has also caused significant environmental issues, such as a changing terrain, impact on the ecosystem of forestry and land, effect to water environment, loss of mineral resources, and radioactive pollution.

For sustainable future development of the titanium industry in Vietnam, this paper proposes a number of directions:

-

- there should be a master plan for titanium placer exploration, mining and processing;

-

- the role of state management in licensing and ore consumption should be improved;

-

- investment should be directed to state-of-the-art mining and processing equipment and to research into suitable process schemes and mining sequences.

It is completely feasible to consider and effectively apply under the right conditions these directions for titanium placer mines in Vietnam. They are also useful reference material for similar titanium placer mines around the world

Fig. 15: Proposed process scheme with model mining sequence

(1), (2), (3), (4) – mine-out blocks have been reclaimed; (5) – block for waste dumping; (6) – mining block; (7), (8), (9) -next mining blocks

Список литературы Status of development orientations for mining titanium placers in Vietnam

- V. Patzold, G. Gruhn, C. Drebenstedt (2008). "Der Nassabbau -Erkundung, Gewinnung, Aufbereitung, Bewertung". Springer-Verlag Berlin Heidenberg, 2008.

- Nguyen Van Thuan, Tran Van Thao (2008). "Industrial-scale titanium-zircon placer potential in the red sand dunes of the Phan Thiet formation in South Trung Bo coastlines" Journal of Geology, Series A, Issue No. 308, pages 18-24, Hanoi, Vietnam.

- Dang Trung Thuan, Bui Xuan Nam (2008). "Research of the process parameters and suitable mining sequence of ilmenite ore(Ti) in coastal sand dunes", Journal of Mining Industry, Issue No.6, pages 22-24, Hanoi, Vietnam.

- Quach Duc tin, Trinh Phuong Thao, Hoang Cao Phuong (2012). "Titanium placers in the red sand dunes in Binh Thuan province and measures for managing sustainable mining and processing", Proceedings of the 2nd International Conference on Advances in Mining and Tunneling, pages 15-156, Hanoi, Vietnam.