Strength and durability of concrete using quarry dust as a substitute for sand

Автор: Obeid Mahmoud Abdelsalam, Aref Abu-Mahadi Mohammed Ibrahim, Nasrat Nasratullah Abdul Ghafoor

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 3 (117), 2025 года.

Бесплатный доступ

The object of research is quarry dust as a sustainable alternative to natural sand in M40-grade concrete, addressing the environmental and resource challenges caused by sand depletion in Russia. The study examines the effects of replacing fine aggregate with quarry dust (10% to 40%) on concrete's compressive strength, split tensile strength, and durability Method. The concrete mixes were designed following IS 10 262−2019 guidelines, with materials hand-mixed and each component precisely weighed. The mix was placed in cubic molds, compacted, and cured in water for 28 days. A total of 45 specimens were prepared and tested for compressive strength and split tensile strength at 7, 14, and 28 days using a universal testing machine C040PN, adhering to IS 516−1959 standards. Results. Replacing up to 20% of fine aggregate with quarry dust enhances compressive strength, achieving a peak strength of 46.35 MPa at 28 days, slightly below the control mix's 47.23 MPa. And up to 20% enhances tensile strength of concrete achieving a peak strength of 3.95 MPa at 28 days. However, beyond this threshold, performance declines, with strengths dropping to 35.21 MPa at 30% replacement and 34.04 MPa at 40%. making 20% the recommended limit for quarry dust substitution in M40-grade concrete. This approach enables sustainable use of quarry dust without sacrificing the structural qualities essential for construction.

M40 Concrete Mix, Quarry Dust, Fine Aggregate Replacement, Sustainable Construction, Compressive Strength, Split tensile strength

Короткий адрес: https://sciup.org/143184931

IDR: 143184931 | УДК: 69 | DOI: 10.4123/CUBS.117.7

Текст научной статьи Strength and durability of concrete using quarry dust as a substitute for sand

Concrete, a composite material made of cement, fine aggregate, coarse aggregate, and water [1], [2], is fundamental for all types of construction due to its unparalleled strength, durability, and versatility. However, the rapid depletion of natural sand resources, driven by its extensive use as a fine aggregate, has led to severe environmental concerns, including habitat destruction, groundwater depletion, and resource scarcity.

According to Anwar’s experimental results confirm that stone dust effectively replaces natural sand in concrete, demonstrating superior strength characteristics while maintaining workability. The optimal 40-60% replacement ratio enhanced compressive strength by 29-40% and flexural strength by 32-53% compared to conventional sand concrete, exceeding M25 grade requirements. Physical and chemical analyses verified the material's compliance with ASTM standards, with slump tests (27-74mm) confirming adequate workability [3].

Azhagarsamy and his group of researchers investigate the suitability of quarry dust as a 60% replacement for natural sand in high-strength M60 grade concrete, incorporating silica fume (10-20% cement weight) and steel fibers (0.5-1.5%) to enhance performance. Experimental results demonstrated that the quarry dust concrete achieved comparable or improved properties to conventional concrete, with silica fume significantly boosting compressive strength and steel fibers (optimally at 1%) enhancing tensile strength [4] .

The effective use of supplementary cementitious materials (SCMs) has been demonstrated by [5], specifically bentonite clay (5–20%) and quarry dust, in enhancing concrete performance. Experimental results revealed a 7.31% increase in compressive strength, a notable 19.7% improvement in flexural strength, and superior acid resistance compared to conventional concrete. The optimized mix exhibited substantial strength gains (18.08% compressive, 33.60% flexural, and 11.15% tensile) while maintaining durability, proving these locally sourced SCMs as sustainable, high-performance alternatives for concrete production. While Vamsi found that partial replacement of sand with quarry dust enhances compressive strength, with optimal performance at 15% replacement (significant strength increase) and viable application up to 35-45% [6].

On the other hand, the sustainable utilization of quarry dust and waste plastic (LDPE) in concrete to optimize resource efficiency while minimizing environmental impact. Experimental mixes replaced river sand with quarry dust (25%, 50%, 75%, and 100%) combined with LDPE fibers, revealing enhanced structural properties in strength and crack resistance [7].

Ravi and Chenab [8] found that blending local fine river sand with normalized quarry dust significantly improved concrete performance while reducing costs. By replacing 40–60% of river sand with quarry dust, the mixture met ASTM requirements, enhancing the compressive strength by 10–25% and flexural strength by 9–17% for 28 MPa concrete compared to costly imported pit sand. Additionally, the optimized sand mixes reduced material costs by 8.6%, offering a sustainable and economical alternative for construction in Lahore, Pakistan.

Rosstat [9] reported that Russia produced 77.3 million m³ (108.1 million tons) of crushed stone, an 8.8% decline compared to the same period in 2024. Screenings (dust)—a byproduct typically accounting for 20–30% of total processed rock mass-were estimated at 25% of production volume, resulting in approximately 19.3 million m³ (27 million tons) of output.

In the recent years the demand for natural sand is increased, there is a crucial need to explore alternative materials for natural sand as a partial replacement for fine aggregate especially in Russia, and quarry dust has been determined as one of the viable options to use as a part of concrete’s aggregate as an alternative material for natural sand. Over the past five years, numerous prestigious research papers have been published worldwide on the increasing demand for natural sand and the use of quarry dust as a partial replacement for fine aggregate. However, in Russia, there is limited information available on this topic. The aim of this is to guide the construction industry in adopting quarry dust as a feasible alternative to natural sand, potentially alleviating environmental concerns related to sand extraction.

Quarry dust not only offers a sustainable resource by utilizing waste by-product but also supports the circular economic approach in construction. This research, therefore, holds promise for advancing eco-friendly practices in concrete production while ensuring the durability and strength required for structures.

-

2 Materials and Methods

The experimental procedure involved uniformly blending cement, sand, coarse aggregates, and quarry dust with a controlled water-cement ratio of 0.44. The fresh concrete was systematically placed into steel molds—pre-treated with a releasing agent—in three layers, each compacted 25 times to ensure proper consolidation. After demolding at 24 hours, specimens were water-cured for 28 days as shown in the figure 1. A total of 45 specimens were prepared and tested (figure 2) for compressive strength at 7, 14, and 28 days using a universal testing machine (figure 3), post-curing, compressive strength, flexural strength, and splitting tensile strength tests were conducted to evaluate mechanical performance. This standardized methodology ensured reliable comparison of strength characteristics across quarry dust replacement levels.

Fig. 1 – Specimens of concrete water-cured for 28 days

Fig. 2 – Specimens of concrete

Fig. 3 – Testing machine C040PN

Materials. The materials used in this experimental study were carefully selected to ensure consistency and reliability in the results. The key components include :

Cement. Ordinary Portland Cement (OPC) grade 53 (Table 1), conforming to relevant standards (ASTM C150) , was used as the primary binding material. Cement provides the necessary adhesive properties to bind all the constituents of concrete together.

Table 1. Properties of cement grade 53

|

Property |

Value/Requirement |

|

Soundness |

≤10 mm (Le Chatelier test) |

|

Specific Gravity |

~3.15 |

|

Normal Consistency |

~30–35% |

|

Fineness |

≥225 m²/kg (Blaine test) |

|

Initial Setting Time |

≥45 minutes |

|

Final Setting Time |

≤375 minutes |

|

Compressive |

≥27 MPa (3 days) |

|

Strength |

≥53 MPa (28 days) |

Water. Potable water, free from harmful chemicals and impurities, was used for mixing and curing the concrete samples. The water-cement ratio (w/c=0.44) was maintained as per mix design requirements to achieve the desired workability and strength.

Coarse Aggregates. Crushed stone aggregates with a maximum nominal size of 20 mm were used. The coarse aggregates were well-graded, ensuring optimal packing density and workability of the concrete mix.

Fine Aggregate: Natural River sand (control) is a preferred fine aggregate for concrete due to its rounded grains, smooth texture, and well-graded particle size (0.075mm–4.75mm), which enhance workability and reduce water demand. It has low clay/silt content (<3%), ensuring strong bonding with cement, and its chemically inert quartz composition improves durability. Quarry dust “Granite Dust” obtained from crushing granite rocks, is a fine, angular, and coarse-textured byproduct with particle sizes typically below 4.75mm. It exhibits high strength and durability due to its hard mineral composition (primarily quartz and feldspar), making it suitable for concrete mixes, road bases, and soil stabilization at 10%, 20%, 30%, and 40% replacement by weight Table 3.

Table 2. Normal concrete [M40 grade]

|

Materials (kg) |

Cement |

Fine aggregate |

Coarse aggregate |

|

14.34 |

22.61 |

36.68 |

Table 3. Replacement Materials

|

Include material |

Replaced material |

Replaced amount (kg), % |

|

Quarry dust |

Fine aggregate |

|

|

2.26 |

20.35 |

10 |

|

4.52 |

18.08 |

20 |

|

6.78 |

15.82 |

30 |

|

9.04 |

13.56 |

40 |

-

3 Results and Discussion

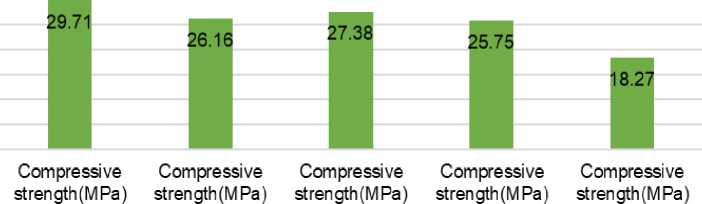

Average of Compressive strength(MPa) at 7 days

(7 days) 0% (7 days) 10% (7 days) 20% (7 days) 30% (7 days) 40%

Percentage of quarry dust %

Fig. 4 - Average Compressive strength (MPa) at 7 days

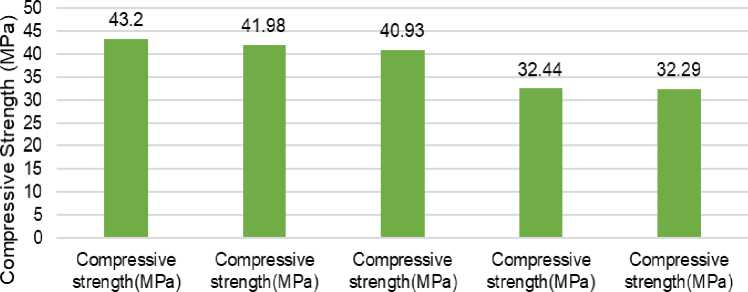

Average of Compressive strength(MPa) at 14 days

Fig. 5

(14 days) 0% (14 days) 10% (14 days) 20% (14 days) 30% (14 days) 40%

Percentage of quarry dust %

Average Compressive strength (MPa) at 14 days

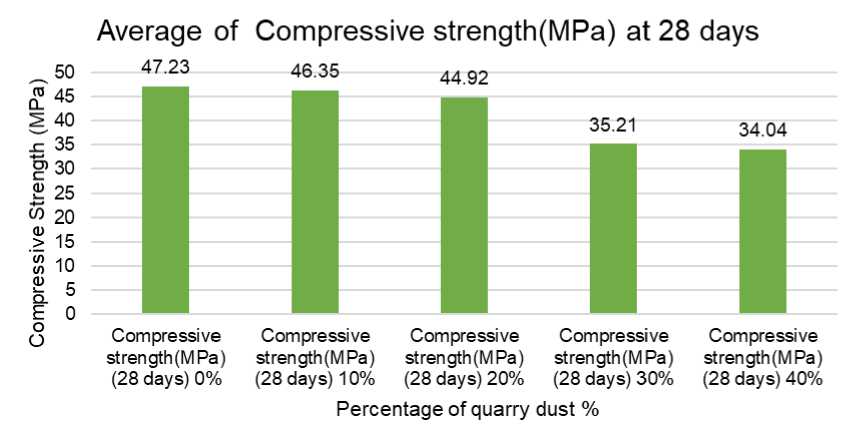

Fig. 6 - Average Compressive strength (MPa) at 28 days

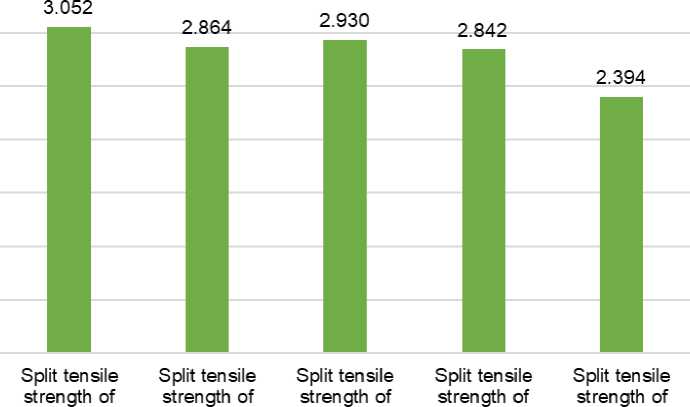

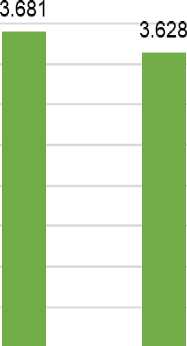

Split tensile strength of concrete (MPa) (7 days)

_ 3.500

CL §,3.000

CD

О 2.500 c о

2.000

-C

c 1.500

СЛ

^ 1.000

СЛ

- 0.500

° 0.000

concrete (MPa) concrete (MPa) concrete (MPa) concrete (MPa) concrete (MPa) (7 days) 0% (7 days) 10% (7 days) 20% (7 days) 30% (7 days) 40%

Percentage of the quarry dust %

Fig. 7 -

Average Split tensile strength of concrete (MPa) (7 days)

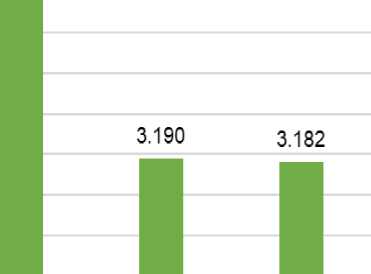

Split tensile strength of concrete (MPa) (14 days)

3.800

ш

3.700

5 ф L-o c о

3.600

3.500

3.400

о

3.300

0) c Ф

tn

Ф in

Ф

3.200

3.100

3.000

2.900

3.583

CL

GO

Split tensile strength of concrete (MPa) (14 days) 0%

Split tensile Split tensile

strength of strength of

concrete (MPa) concrete (MPa) (14 days) 10% (14 days) 20%

Split tensile strength of concrete (MPa) (14 days) 30%

Split tensile strength of concrete (MPa) (14 days) 40%

3.849 3.813

Percentage of the quarry dust %

Fig. 8 -

Average Split tensile strength of concrete (MPa) (14 days)

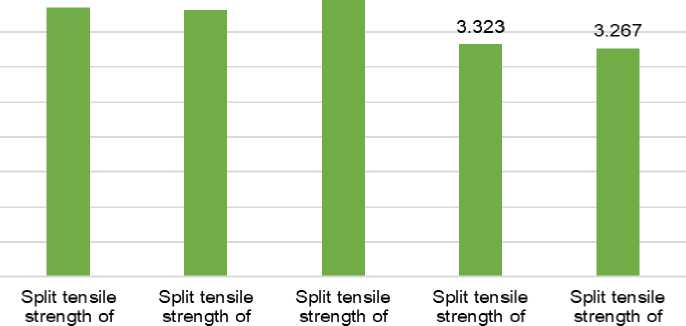

Split tensile strength of concrete (MPa) (28 days)

_ 4.500 CO

concrete (MPa) concrete (MPa) concrete (MPa) concrete (MPa) concrete (MPa) (28 days) 0% (28 days) 10% (28 days) 20% (28 days) 30% (28 days) 40%

Percentage of the quarry dust %

^ 4.000

«2 3.500 ф g 3.000 о

“ 2.500

О

% 2.000 С £ 1.500

^ 1.000

ф 0.500

И 0.000 со

Fig. 9 - Average Split tensile strength of concrete (MPa) (28 days)

Table 4. Characteristics of Included Studies

|

Study Focus |

Key Findings |

Citation |

|

Compressive Strength |

Improved compressive strength with up to 25% quarry dust replacement |

Laxmana Reddy et al. 2023 |

|

Flexural and Split Tensile Strength |

Enhanced flexural (19.7%) and split tensile strengths with quarry dust and bentonite clay |

Umar et al. 2025 Chandramouli et al. 2022 |

|

Durability |

Improved resistance to sulfate attack and degradation with quarry dust |

Muhammad Shahzad Aslam et al. n.d. |

|

Optimal Replacement Levels |

Effective replacement levels of 30-40% for improved strength and durability |

Nagaraju 2023 Sree Kumar et al. 2024 |

|

Role of Admixtures |

Enhanced strength and durability with SCMs and admixtures |

Charan et al. 2023 Benjamin et al.2021 |

|

Cost and Environmental Benefits |

Cost savings and reduced environmental impact with quarry dust |

Imran et al. 2018 Elseknidy et al. 2020 |

Table 5. Effects of Quarry Dust Replacement Mechanical Properties

|

Study |

Replacement level |

Compressive strength |

Workability |

Optimal Range |

|

Aginam et al. 2021 |

0-25% |

Increased up to 20%, then decreased |

Increased with increasing quarry dust |

20% |

|

Ajamu et al. 2020 |

0-100% |

Increased up to 20%, then decreased |

Increased with increasing quarry dust |

50% |

|

Alli et al. 2018 |

0-100% |

Increased with increasing quarry dust |

No mention found |

100% |

|

Balamurugan et al. 2013 |

0-100% |

Increased with increasing quarry dust |

No mention found |

50% |

|

Sundaralingam et al. 2022 |

0-100% |

Improved with 100% replacement |

No mention found |

100% |

-

- 0% Quarry Dust (Control Sample): The standard concrete mix achieved compressive strength values of 29.71 MPa at 7 days, 43.2 MPa at 14 days, and 47.23 MPa at 28 days, serving as the benchmark for evaluating alternative mixes.

-

- 10% Quarry Dust Replacement: The compressive strength results from our study (26.16 MPa at 7 days, 41.98 MPa at 14 days, and 46.35 MPa at 28 days) consistently outperform those reported by Umar et al. 2025, who recorded significantly lower values of 16.69 MPa at 7 days and 29.09 MPa at 28 days, with no data available for 14 days. Similarly, our results surpass those ofvamsi et al. 2020, which were 27.11 MPa, 28.55 MPa, and 29.65 MPa at 7, 14, and 28 days, respectively.

-

- 20% Quarry Dust Replacement: At a 20% replacement level, the compressive strengths achieved in our study—27.38 MPa at 7 days, 40.93 MPa at 14 days, and 44.92 MPa at 28 days—demonstrate favorable performance despite being slightly lower than the control. In comparison, Umar et al. 2025 reported significantly lower values of 15.55 MPa at 7 days and 26.40 MPa at 28 days, with no intermediate data provided. Umar et al. 2025 observed higher strengths of 31.48 MPa, 32.88 MPa, and 33.92 MPa at 7, 14, and 28 days, respectively, while Siddiqui et al. 2023 reported much lower strengths of 14.95 MPa, 16.67 MPa, and 25.00 MPa at the same intervals. Although our results show a minor reduction in strength compared to the control, they remain close to the target strength, confirming 20% quarry dust replacement as an optimal and viable level for maintaining structural integrity.

-

- 30% and 40% Quarry Dust Replacement: Higher replacement levels exhibited notable declines in compressive strength. At a 30% replacement level, our study recorded a 28-day compressive strength of 35.21 MPa, while the 40% replacement mix declined further to 34.04 MPa, highlighting the unsuitability of higher additive levels for structural applications demanding sustained load-bearing capacity. In comparison, vamsi et al. 2020 achieved compressive strengths of 35.70 MPa, 36.95 MPa, and 37.85 MPa at 7, 14, and 28 days, respectively, with a 30% replacement, and 27.78 MPa, 29.20 MPa, and 30.10 MPa with a 40% replacement. Notably, Azhagarsamy et al. 2018 reported significantly higher strengths of 31.86 MPa, 42.67 MPa, and 63.48 MPa at 3, 7, and 28 days for a 60% replacement mix, while Akmal et al. 2023 achieved a compressive strength of 36.7 MPa at 28 days with a 50% replacement. These findings emphasize that replacement levels beyond 20–30% may compromise structural performance, depending on mix proportions and conditions.

The optimal mix design identified through Response Surface Methodology (RSM) consisted of 10.29% bentonite clay, 7.20% quarry dust, and 8.19% fine aggregate replacement, leading to notable strength improvements: an 18.08% increase in compressive strength, 33.60% in flexural strength, and 11.15% in tensile strength compared to reference concrete Umar et al. 2025. Additionally, at a 20% replacement level, the study recorded a 28-day compressive strength of 3.95 MPa, which declined to 3.26 MPa at a 40% replacement. Incorporating quarry dust as a fine aggregate substitute in rice husk ash-based concrete significantly impacted its strength and durability. A 40% replacement yielded a 0.65% increase in compressive strength and a 1.77% enhancement in splitting tensile strength after 28 days of curing. However, higher quarry dust percentages initially reduced strength, with optimal performance observed at 40% replacement, demonstrating its potential for sustainable concrete applications Sadaf et al. 2023

-

4 Conclusion

This study investigated quarry dust as a sustainable partial replacement for natural sand in M40-grade concrete, employing experimental methods to evaluate its mechanical and environmental feasibility. The research process involved:

-

1. Preparing concrete mixes with 10–40% quarry dust replacement (by weight of fine aggregate) following IS 10262-2019 standards.

-

2. Testing compressive strength, split tensile strength, and workability at 7, 14, and 28 days per IS 516-1959.

-

3. Comparing results with conventional concrete to identify optimal replacement thresholds.

New Scientific Contributions

Optimal Replacement Threshold:

-

• 20% quarry dust replacement maximizes compressive strength (46.35 MPa at 28 days), achieving 97% of control mix performance (47.23 MPa).

-

• 10% replacement optimizes tensile strength (3.95 MPa), demonstrating quarry dust’s efficacy in enhancing concrete’s resistance to cracking.

Performance Degradation Beyond Thresholds:

-

• Replacements >20% reduce compressive strength by 25–28% (35.21–34.04 MPa), while >10% compromises tensile capacity, limiting suitability for high-load structural applications.

Microstructural Advantage:

-

• Quarry dust’s finer particle size and angular morphology (inferred from strength data) improve packing density at ≤20% replacement, though SEM validation is recommended for future work.

Sustainability Validation:

-

• The 20% replacement threshold aligns with circular economy principles, reducing natural sand demand by ~1.5 tons per 10 m³ of concrete while repurposing industrial byproducts.

5 Acknowledgements

The authors would like to acknowledge the technical support by the concrete laboratory in the Civil Engineering Department at the Faculty of Engineering Technology, RUDN University.

-

6 Conflict of Interests

The authors declare no conflict of interest.