Structural-phase state and properties of hypereutectic silumin treated with a pulsed electron beam

Автор: Ivanov Yu. F., Eresko S. P., Klopotov A. A., Rygina M. E., Petrikova E. A., Teresov A. D.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.22, 2021 года.

Бесплатный доступ

Hypereutectic silumin composition are promising modern materials of wide application (mechanical engineering, aviation, instrumentation, medicine, etc.). Disadvantages of hypereutectic silumin, significantly limiting their scope of application, are pores and cavities, large (about 100 µm) inclusions of lamellar and needle-shaped second phases. As a result of the studies carried out in this work, the possibility of forming structural-phase states in the surface layer of silumin, the size and morphology of which can purposefully change in the range from tens of micrometers to tens of nanometers, is demonstrated. The irradiation modes that allow more than 5 times to increase the microhardness (15 J/cm2, 150 µs, 0.3 s–1, 5 imp.) and more than 3 times to increase the wear resistance (50 J/cm2, 150 µs, 0.3 s–1, 5 imp.) of silumin were revealed.

Hypereutectic silumin, pulsed electron beam, structure, wear resistance, hardness.

Короткий адрес: https://sciup.org/148321811

IDR: 148321811 | УДК: 669/713-048/25 | DOI: 10.31772/2587-6066-2021-22-2-371-382

Текст научной статьи Structural-phase state and properties of hypereutectic silumin treated with a pulsed electron beam

Silumins belong to a class of aluminum-based materials that are widely used in the aerospace industry. Silumin is an alloy of aluminum and silicon.. This alloy is distinguished by its low cost, high corrosion resistance, and good casting properties. The state diagram of the Al-Si system is eutectic. There are hypoeutectic (<12 wt% Si), eutectic (≈12 wt% Si), hypereutectic (> 12 wt% Si) silumins. The structure of hypereutectic silumin is represented by eutectic, primary silicon grains and intermetallic compounds based on iron, aluminum and silicon. Hypereutectic silumin has a number of macro- and microdefects arising during casting and crystallization of the alloy: pores and cavities caused by high gas saturation. Most often these defects can be corrected either by using modifying additives or by changing the casting method. Various alloy casting technologies are currently under development that employ intensive cooling [1], quenching [2], as well as alloying [3-5]. These methods require costly additives; casting methods have limitations in shape and size.

Irradiation of silumin with a pulsed electron beam makes it possible to modify the structure and properties of the surface layer without using expensive additives [6–8].In a number of works [9; 10], performed on silumins of eutectic composition, it is shown that the interaction of an electron beam with the surface of metallic materials due to ultrahigh heating and cooling rates forms a multiphase structure of the nano- and submicrosize range. This contributes to an increase in hardness and wear resistance, fatigue life and many other properties of the material.

The aim of this work is to discover and analyze the regularities of the transformation of the structure and properties of hypereutectic silumin exposed to an intense pulsed electron beam of submillisecond duration of exposure.

Material and research technique

The study material was silumin of hypereutectic composition (Al-22 wt.% Si) in cast condition. The alloy was prepared in a shaft-type laboratory electric resistance furnace with silicon carbide heaters in a painted stainless steel crucible. As a charge, we used commercially pure aluminum A7 (GOST 11069-2001 [11]) and silicon Kr0 (GOST 2169-69 [12]). The alloy was made without modifying and refining the liquid metal. The technological process of alloy preparation included the following main operations: loading into the furnace and melting the calculated amount of aluminum, introducing a silicon sample into liquid aluminum (step- wise) and dissolving it, settling the melt, removing slag, pouring. The melt preparation temperature was 800– 850 °С. The melt was poured into a cold aluminum chill mold painted with a fire-resistant paint at a temperature of 820 °C. To measure the temperature of the melt, a chromel-alumel thermocouple (CA) and a direct current potentiometer of the PP type (class 0.5) were used. The resulting castings were rectangular plates 55 × 120 × 20 mm in size (excluding feeding head), from which specimens 15 × 15 × 5 mm in size were cut out for processing with a pulsed electron beam in order to analyze the structural-phase state and properties of silumin. The samples were irradiated with an intense pulsed electron beam on a “SOLO” setup [13]. Irradiation mode: the energy of accelerated electrons is 18 keV, the energy density of the electron beam is 15–50 J/cm2, the pulse repetition rate is 0.3 s –1, the duration of the action of the electron beam is 150 µs, the number of irradiation pulses is 3; irradiation was carried out in a residual argon atmosphere at a pressure of 0.02 Pa. The irradiation mode was selected according to thermal calculations [14].

The samples were examined by optical (μVizo-MET-221), scanning (SEM-515 Philips) and transmission (JEM-2100F) electron microscopy. Measuring of microhardness was carried out on the device PMT-3 at a load on an indenter of 0,2 N. Parameter of wear and coefficient of friction were determined on tribometer TRIBOtechnic (condition of dry friction at room temperature, counterbody - ball ШХ15, diameter 6 mm, track diameter 4 mm, sample speed 2.5 cm/s, indenter load 10 N, number of revolutions 8000).

Research results and their discussion

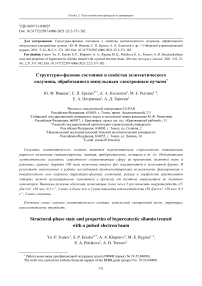

The structure of the initial hypereutectic silumin is typical for this group of alloys and is characterized by the presence of primary silicon grains up to 100 µm in size, grains of Al-Si eutectics and inclusions of intermetallic phase (Fig. 1).

Рис. 1. Структура исходного заэвтектического силумина

-

Fig. 1. Structure of the initial hypereutectic silumin

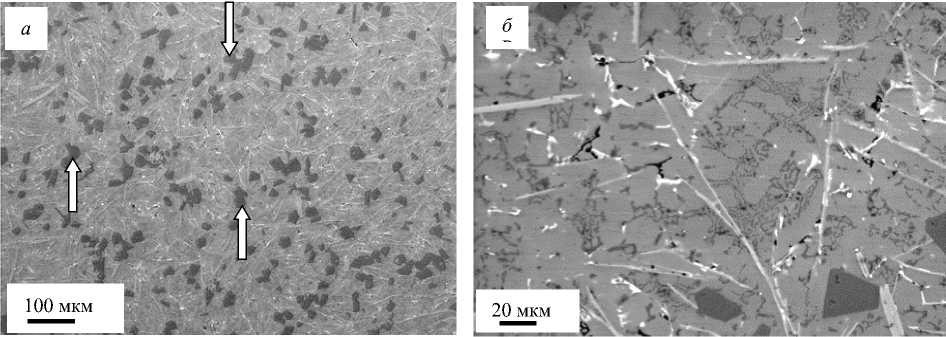

The micro-X-ray spectral analysis performed by the "point-by-point" method revealed a substantially heterogeneous distribution of the alloy elemental composition. Silicon grains (Fig. 2, а , marked «1»), grains of Al-Si eutectics (Fig. 2, а , marked «2»), intermetallic inclusions of different element composition and shape (Fig. 2, б ) were revealed.

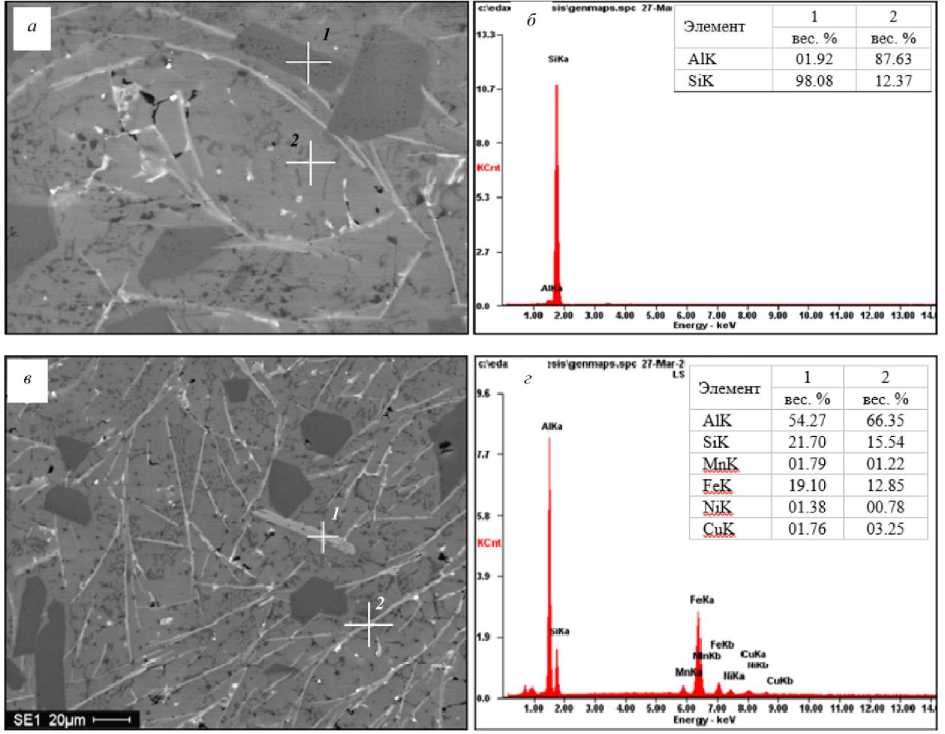

Irradiation of silumin with a pulsed electron beam leads to a significant transformation of the structure of the surface layer of the alloy. Shown in Fig. 3 electron microscopic images illustrate the state of the surface layer of the alloy irradiated in the regime of partial (Fig. 3, а, б) and complete (Fig. 3, в, г) dissolution of inclusions of intermetallic compounds and silicon grains. It is clearly seen that in the second case, a homogeneous structure is formed with crystallite sizes varying within a few micrometers. Irradiation of silumin with a pulsed electron beam in the indicated range of energy densities does not lead to a significant change in the elemental composi- ror.

tion of the surface layer; the concentration of alloying and impurity elements varies within the measurement er-

Рис. 2. Электронно-микроскопические изображения структуры силумина в литом состоянии ( а, в ); энергетические спектры ( б, г ), полученные с участков, обозначенных значком «+» и цифрой «1» ( а, в). В таблицах ( б , г) , показан элементный состав анализируемых участков силумина

Fig. 2. Electron microscopic images of the structure of silumin in the cast state ( a , в ); ( б , г ) show the energy spectra obtained from the areas indicated in ( a , в ) with a “+” and the number “1”. The tables given in ( б ) and ( г ) show the elemental composition of the analyzed sections of silumin

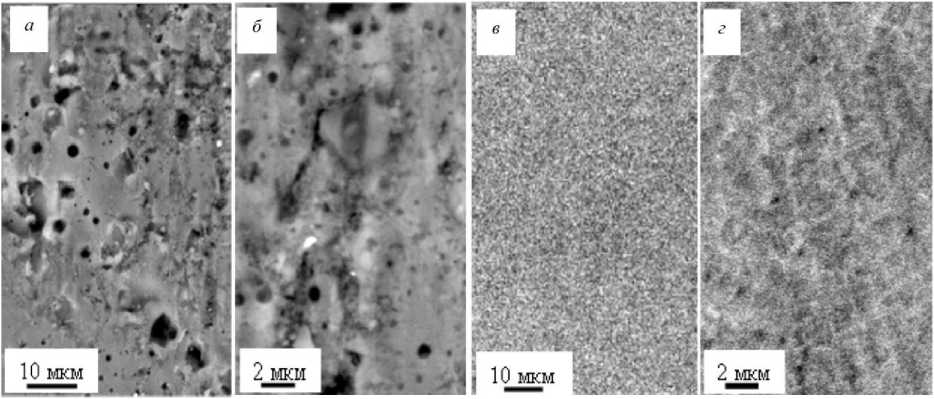

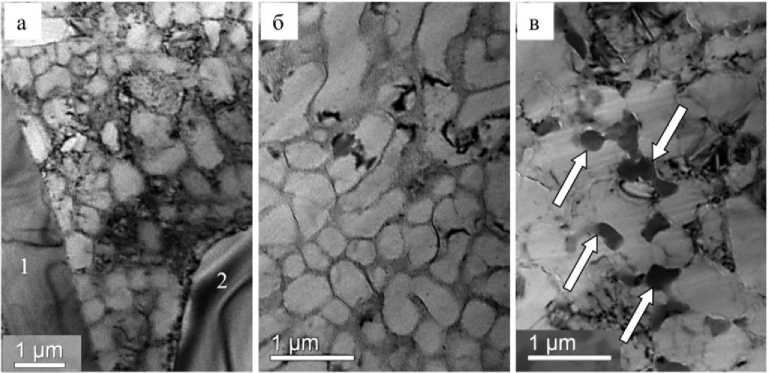

The structural-phase state of silumin at the submicro-nanodimensional level was analyzed by transmission electron microscopy. It was found that the pulse electron-beam treatment leads to a radical transformation of the structure of the surface layer of silumin. The high-speed mode of heating, melting, crystallization and cooling, which is realized during pulse electron-beam irradiation [15], leads to the formation of a cellular crystallization structure in the surface layer of the samples (Fig. 4). The size of crystallization cells varies in the range from 200 to 650 nm. The thickness of the modified layer increases with increasing energy density of the electron beam and can reach hundreds of micrometers. Along the boundaries of crystallization cells, inclusions of the second phase are located that form (at an electron beam energy density of up to 30-35 J/cm2) extensive interlayers (Fig. 4, а, б) with a thickness of 30-85 nm. At high values of energy density of electron beam in the surface layer of silumin rounded (globular) particles of the second phase are formed at the borders of cells (Fig. 4, в, arrows indicate the particles). Size of such particles is 100-180 nm. It is important to note that at the energy densities of the electron beam not exceeding 20 J/cm2, in the surface layer of silumin, along with cells of high-speed crystallization, there are primary inclusions of the second phase, formed in the material during casting (Fig. 4, а, inclusions are designated by numbers 1 and 2). The sizes of such inclusions can reach tens of micrometers.

Рис. 3. Структура заэвтектического силумина, облученного импульсным электронным пучком (150 мкс, 0,3 с–1, 3 имп): а , б – 15 Дж/см2; в , г – 50 Дж/см2

Fig. 3. Structure of hypereutectic silumin irradiated with a pulsed electron beam

(150 μs, 0.3 s–1, 3 impulses): a , б – 15 J/cm2; в , г – 50 J/cm2

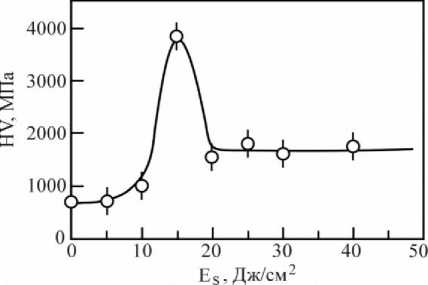

It is obvious that such a significant transformation of silumin structure that takes place during irradiation with a pulsed electron beam will lead to changes in mechanical and tribological properties of the material. Indeed, studies of mechanical properties performed by determination of microhardness showed that irradiation of silumin with a pulsed electron beam contributes to hardening of the material (Fig. 5). The best result providing increase of hardness of samples more than in 5 times in comparison with cast state was reached at irradiation of silumin by electron beam with energy density of electron beam 15 J/cm2.

Analysis of the structure and phase state of the modified silumin layer gives grounds to conclude that the main factors providing the revealed multiple increase in the microhardness of the samples are the presence of partially dissolved inclusions of silicon and intermetallic compounds of the initial state, as well as the formation of crystallization cells that increase the strength of aluminum grains. and Al-Si eutectics. Complete dissolution of the initial inclusions of the second phase is accompanied by a decrease in the microhardness of silumin.

Рис. 4. Электронно-микроскопическое изображение структуры поверхностного слоя образцов силумина, облученных импульсным электронным пучком (150 мкс, 0,3 с–1, 3 имп.): а – 15 Дж/см2; б – 25 Дж/см2, в – 40 Дж/см2. На ( а ) цифрами обозначены включения второй фазы микронных размеров, образовавшиеся в процессе литья; на ( в ) стрелками указаны частицы второй фазы субмикронных размеров, образовавшиеся в результате облучения силумина электронным пучком. Просвечивающая электронная микроскопия

Fig. 4. Electron microscopic image of the structure of the surface layer of silumin samples irradiated with a pulsed electron beam (150 μs, 0.3 s–1, 3 pulses): a - 15 J/cm2; б - 25 J/cm2, в - 40 J/cm2. On ( a ) the numbers indicate inclusions of the second phase of micron dimensions, formed during the casting process; in ( в ), arrows indicate the particles of the second phase of submicron sizes, formed as a result of irradiation of silumin with an electron beam. Transmission electron microscopy

Рис. 5. Зависимость микротвердости силумина, облученного электронным пучком, от плотности энергии пучка электронов (150 мкс, 3 имп., 0,3 с–1)

Fig. 5. Dependence of the microhardness of silumin irradiated with an electron beam on the energy density of the electron beam (150 μs, 3 pulses, 0.3 s–1)

The microhardness of the modified layer exceeds the microhardness of the cast state by more than 2 times (Fig. 5).

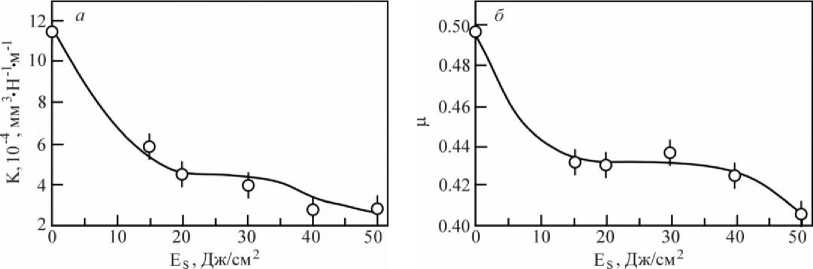

Облучение силумина сопровождается существенным преобразованием трибологических свойств материала. Установлено, что при увеличении плотности энергии пучка электронов происходит снижение износа (повышение износостойкости) (рис. 6, а) и уменьшение коэффициента трения (рис. 6, б). Основываясь на результатах структурно-фазового анализа силумина, рассмотренных выше, можно заключить, что увеличение износостойкости силумина обусловлено, во-первых, растворением зерен первичного кремния, являющегося хрупкой фазой, которая в процессе трения выкрашивается и приводит к дополнительному изнашиванию материала. Во-вторых, повторным выделением частиц второй фазы субмикро- наноразмерного диапазона. В-третьих, формированием структуры ячеистой кристаллизации, упрочняющей зерна алюминия и эвтектики Al-Si.

Irradiation of silumin is accompanied by a significant transformation of the tribological properties of the material. It was found that with an increase in the energy density of the electron beam, there is a decrease in wear (increase in wear resistance) (Fig. 6, а ) and a decrease in the friction coefficient (Fig. 6, б ). Based on the results of the structural-phase analysis of silumin discussed above, it can be concluded that an increase in the wear resistance of silumin is due, first, to the dissolution of grains of primary silicon, which is a brittle phase, which crumbles during friction and leads to additional wear of the material. Second, it is due to the repeated separation of particles of the second phase of the submicro-nanoscale range and, third, to the formation of a cellular crystallization structure that strengthens the grains of aluminum and Al-Si eutectic.

Рис. 6. Зависимость параметра износа ( а ) и коэффициента трения ( б ) силумина, облученного импульсным электронным пучком, от плотности энергии пучка электронов (150 мкс, 3 имп., 0,3 с–1)

Fig. 6. Dependence of the wear parameter ( a ) and the friction coefficient ( б ) of a silumin irradiated with a pulsed electron beam on the energy density of the electron beam (150 μs, 3 pulses, 0.3 s–1)

Ternary systems Al-Cu-Si, Al-Cu-Fe, Al-Fe-Si and Cu-Fe-Si

On the basis of the literature data, an analysis of the structural features of the ternary diagrams of the Al-Cu-Si, Al-Cu-Fe, Al-Fe-Si and Cu-Fe-Si systems has been carried out.

In the Al-Cu-Si ternary system inside the isothermal triangle, the existence of only one ternary compound based on the k -phase was found (prototype Mg, Pearson's symbol hP 2). A ternary solid solution with a wide homogeneity region based on Cu (Al, Si) is formed in the region of the copper corner [16; 17]. Also in this system, the existence of a phase with a noticeable size homogeneity region based on the γ 1 -phase (Cu 9 Al 4 ), in which the third component Si is well dissolved, is observed. Only on one side of the Al-Cu isothermal triangle is the formation of ternary compounds with narrow regions of homogeneity based on binary compounds.

In [18] the formation of a ternary solid solution with a wide area of homogeneity based on Cu(Al,Fe) in the ternary system Al-Cu-Fe in the area of the copper angle was revealed. The β - Fe x Cu y Al z (CsCl, cP 8) (0 < x < 1, 0 < y < 1, 0,23 < x < 0,7) phase occupies a significant area in the isothermal triangle [18; 19]. Also within the isothermal triangle, the formation of about six ternary compounds has been established: Ψ -FeCu 2 Al 6 (prototype Mg 23 (Al,Zn) 49 , Pearson’s symbol cI 62 ω -FeCu 2 Al 7 (Al 7 Cu 2 Fe, tP 40), Ф-FeCu 10 Al 10 ( δ -Ni 2 Al, hP 5), τ 2 -FeCu 2 Al 7 (Al 7 Cu 2 Fe, tP 40), τ 3 -FeCu 10 Al 7 (Al 7 Cu 2 Fe, tP 40), τ i -Fe 12,5 Cu 25,5 Al 62 (Mg 23 (Al,Zn) 49 , cI 62). In addition, on the sides of the Al-Cu and Cu-Fe isothermal triangle up to 9 compounds based on binary compounds with small areas of homogeneity are formed [18; 19].

Basing on the data presented, it can be concluded that in a ternary solid solution with a wide range of homogeneity based on Cu(Al, Si), good dissolution of the fourth component Fe should occur.

In the Al-Fe-Si ternary system in the Fe region of the isothermal triangle angle, there are two regions of a ternary solid solution based on a disordered bcc lattice α -(Fe, Al, Si) and on the basis of a disordered fcc lattice γ -(Fe, Al, Si) [20–22]. The two-component compound FeSi ( P 2 1 3, cP 8) dissolves the third component Al well and, as a result, an extended region of homogeneity of the ternary compound FeSi 1 - х Al х is created. A characteristic feature of this system inside the isothermal triangle is the formation of about 10 intermetallic ternary compounds with narrow regions of homogeneity: τ 1 /τ 1 , Fe 3 Al 2 Si 3 (Fe 3 Al 2 Si 3 , aP 16), τ 2 γ -Fe 2 Al 5 Si 2 ( mC *), τ 3 , Fe 5 Al 9 Si 5 (FeAl 2 Si, oC 128), τ 4 , δ -FeAl 3 Si 3 (PdGa 5 , tI 24), τ 5 , Fe 2 Al 7.4 Si (Fe 2 Al 7.4 Si, hP 245), τ 6 , β -Fe 2 Al 9 Si 2 (Fe 2 Al 9 Si 2 , C 2/ c ), τ 7 ,Fe 22 Al 40 Si 38 (Fe 2 Al 3 Si 3 , P 2 1 / c ), τ 8 , Fe 3 Al 2 Si 4 (Fe 3 Al 2 Si 4 , oC 36), τ 10 , Fe 5 Al 12 Si 3 (Mn 3 Al 10 , hP 26).

In the ternary system Cu-Fe-Si, no ternary intermetallic compounds were found inside the isothermal triangle. Only in the region of the Fe angle of the isothermal triangle there is a region of a ternary solid solution based on α -(Fe,Cu,Si) phase [23].

The presented data show that as a result of high-energy exposure in the mode of high-speed melting in the surface layer of the alloy under study, it is possible to form a large number of double, ternary (possibly four-component) compounds based on copper Cu (Al, Si, Fe).

Conclusion

It is shown that irradiation of samples of hypereutectic silumin with a pulsed electron beam makes it possible, depending on the energy density of the electron beam, to form structural-phase states in the surface layer, the crystallite size of which can purposefully vary from tens of micrometers to tens of nanometers. The irradiation mode (15 J/cm2, 150 µs, 0.3 s –1, 3 impulses) was revealed, which makes it possible to increase the hardness of the modified material many times (more than 5 times). It was concluded, based on structural and phase studies of silumin, that the condition for a multiple increase in the microhardness of samples is the presence of partially dissolved inclusions of silicon and intermetallic compounds of the initial state, as well as the formation of crystallization cells that increase the strength of aluminum grains and Al-Si eutectic. It was found that an increase in the energy density of the electron beam in the range of 15–50 J/cm2 (150 μs, 0.3 s –1, 3 pulses) promotes an increase in wear resistance and a decrease in the friction coefficient of silumin irradiated with a pulsed electron beam. This is due, firstly, to the dissolution of grains of primary silicon, which is a brittle phase, which crumbles during friction and leads to additional wear of the material; secondly, to the repeated separation of particles of the second phase of the submicro-nanoscale range and, thirdly, to the formation of a cellular crystallization structure that strengthens the grains of aluminum and Al-Si eutectic.

Список литературы Structural-phase state and properties of hypereutectic silumin treated with a pulsed electron beam

- Władysiak R., Kozuń A. Dębowska K., Pacyniak T. Analysis of Crystallization Process of Intensive Cooled AlSi20CuNiCoMg Alloy. Archives of foundry engineering. 2017. Vol. 17(2). Р. 137–144.

- Marukovich E. A. Stetsenko V. Yu. Poluchenie-otlivok-iz-zaehvtekticheskogo-silumina-metodom-litya-zakalochnym-zatverdevaniem [Production of castings from hypereutectic silumin by quenching solidification casting]. Casting and metallurgy. 2005. Nо. 2(34). Р. 142–144.

- Piаtkowskia J., Wieszałab R. Tribological Properties of AlSi17Cu5Mg Alloy Modified with CuP Master Alloy with Various Speeds of Friction. Archives of foundry engineering. 2016. Vol. 16. Р. 45–48.

- Szymczak T., Gumienny G., Pacyniak T. Effect of Sr and Sb Modificationon the Microstructure and Mechanical Properties of 226 Silumin Pressure Casts. Archives of foundry engineering. 2015. Vol. 15(1). Р. 105–108.

- Roik T. A., Gavrysh O. A., Vitsiuk Y. Y. The Functional Properties Acquired by Antifriction Composites Produced from Silumin Grinding Waste. Powder metallurgy and metal ceramics. 2019. Vol. 57, Nо. 9-10. Р. 526–532.

- Qinglin Li, Binqiang Li, Jianjun Liu, Jinbao Li, Dexue Liu, Yefeng Lan, and Tiandong Xia Modification of hypereutectic Al–20 wt%Si alloy based on the addition of yttrium and Al–5Ti–1B modifiers mixing melt// International Journal of Metalcasting. 2019. Vol. 13. Р. 367–383.

- Afanasyev V. K., Prudnikova A. N. Vliyanie obrabotki rasplava na strukturu i prochnost’ promyshlennogo zaevtekticheskogo silumina [Effect of melt treatment on the structure and strength of industrial hypereutectic silumin]. Bulletin of TSU. 1998. Т. 3(3). P. 314.

- Martyushev N. V., Zykova A. P., Bashev V. S. Modificirovanie splava marki AK12 chasticami ul’tradispersnogo poroshka vol’frama. [Modification of the AK12 alloy with ultrafine tungsten powder particles] Metal processing (technology, equipment, tools). 2017. Nо. 3 (76). P. 51–58.

- Modifikaciya struktury i svojstv evtekticheskogo silumina elektronno-ionno-plazmennoj obrabotkoj [Modification of the structure and properties of eutectic silumin by electron-ion-plasma treatment] / edited by A. P. Laskovnev. Minsk, Belarus. navuka, 2013, 287 с.

- Elektronno-ionno-plazmennaya modifikaciya poverhnosti cvetnyh metallov i splavov [Electron-ion-plasma modification of the surface of non-ferrous metals and alloys]. Ed. N. N. Koval and Yu. F. Ivanov. Tomsk, NTL, 2016, 312 p.

- GOST 11069–2001. Alyuminij pervichnyj. Marki [GOST 11069–2001. Primary aluminum. Stamps]. Moscow, Standartinform Publ., 2008, 6 р.

- GOST 2169–69. Kremnij tekhnicheskij. [GOST 2169–69. Technical silicon.] Moscow, Standartinform Publ., 2001, 6 p.

- Koval N. N., Ivanov Yu. F. Nanostructuring of surfacesof metalloceramic and ceramic materials byelectron-beams. Russian Physics. Journal. 2008. Vol. 51. P. 505–516.

- Ivanov Yu. F., Petricova E. A., Ivanova O. V. and et. al. Numerical Simulation of the Temperature Field of Silumin. Russian Physics. Journal. 2015. Vol. 58. P. 478–484.

- Rotshtein V. P., Proskurovsky D. I., Ozur G. E., Ivanov Yu. F. Modifikaciya poverhnostnyh sloev metallicheskih materialov nizkoenergeticheskimi sil’notochnymi elektronnymi puchkami. [Modification of the surface layers of metallic materials by low-energy high-current electron beams]. Novosibirsk, SB RAS, Nauka, 2019, 348 p.

- Ponweiser N., Richter K. W. New investigation of phase equilibria in the system Al-Cu-Si. J. Alloys and Compound. 2012. Vol. 512. P. 252–263.

- He C. Y., Du Y., Chen H. L. and et. al. Experimental investigation and thermodynamic modeling of the Al-Cu-Si system. CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry. 2009. Vol. 33. P. 200–210.

- Bannykh O. A., Budberg P. B., Alisova S. P. and et. al. Diagrams of the state of dual and multicomponent systems based on iron: Reference [Diagrammy sostoyaniya dvojnyh i mnogokom-ponentnyh sistem na osnove zheleza: Spravochnik]. Moscow, Metallurgy, 1986, 440 р.

- Zhang L. M., Lück R. Phase diagram of the Al-Cu-Fe quasicrystal-forming alloy system. III. Isothermal sections. International Journal of Materials Research. 2003. Vol. 94. P. 108–115.

- Du Y., Schuster J. C., Liu Z. K. and et. al. A thermodynamic description of the Al-Fe-Si system over the whole composition and temperature ranges via a hybrid approach of CALPHAD and key experiments. Intermetallics. 2008. Vol. 16. P. 554–570.

- Dons A. L. AlFeSi – particles in commercial pure aluminum. Zeitschrift für Metallkunde. 1984. Vol. 75. P. 170–174.

- Miyazaki T., Kozakai T., Tsuzuki T. Phase decomposition of Al-Si-Fe ordered alloys. J. Materials Science. 1986. Vol. 21. P. 2557–2564.

- Wang C. P., X. J. Liu, I. Ohnuma and et. al. Phase equilibria in FeCu-X (X: Co, Cr, Si, V) ternary systems. J. Phase Equilibria. 2002. Vol. 23. Nо. 3. P. 236–245.