Structure of the surface layer of high-chrome steel nitridated in the elion regime in the plasma of a suspended arc discharge with a heated cathode

Автор: S.P. Eresko, Yu.F. Ivanov, I.V. Lopatin, A.A. Klopotov, A.V. Nikonenko

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 1 vol.24, 2023 года.

Бесплатный доступ

The purpose of this work is to reveal the patterns of formation of the structure of the surface layer of high-chromium steel subjected to nitriding in a low-pressure gas discharge plasma using a plasma genera-tor with a hot cathode "PINK". Heating of the samples to the nitriding temperature was carried out by the ionic component of the plasma, as well as by the electron and ionic components of the plasma (elion mode). The object of the study was heat-resistant corrosion-resistant steel of the austenitic class grade 20X23H18 (foreign analogue is AISI 310S). The relevance of research is due to the relatively low level of hardness and wear resistance of steels of this class. Nitriding of steel was carried out on the TRIO installation, retro-fitted with a switching unit for implementing the aelion (electronic and ionic) processing mode. It has been established that the thickness of the hardened layer is (55–60) μm and weakly depends on the method of nitriding, temperature (in the range of 793–873 K), and duration (3–5 hours) of the process. A nitriding regime has been revealed that makes it possible to form a surface layer with a microhardness of 13.7 GPa (ionic heating mode) and 10.8 GPa (elion heating mode). It has been revealed that the high strength and tribological properties of nitrided steel are due to the formation of a nanocrystalline structure in the surface layer, the main phases of which are iron nitrides Fe4N and chromium nitrides CrN. It is shown that heating the samples to the nitriding temperature in the aelion mode, which uses the electron and ion components of the plasma, leads to a significantly lower level of material roughness compared to the samples heated during nitriding by the ion component of the plasma.

Gas discharge plasma, aelion nitriding regime, high-alloy steel, roughness, structure, properties

Короткий адрес: https://sciup.org/148329683

IDR: 148329683 | УДК: 621.785.53 | DOI: 10.31772/2712-8970-2023-24-1-168-176

Текст научной статьи Structure of the surface layer of high-chrome steel nitridated in the elion regime in the plasma of a suspended arc discharge with a heated cathode

The use of low-pressure arc discharges with heated cathodes (plasma concentration of 1015-1018 m-3 in volume up to several m3) which allow generation of plasma gas streams without microdroplets, ion cleaning (etching) of the surface and heating of the treated part to the required temperature is promising for chemical-thermal treatment processes [1-3]. In this case, the ion energy and their average current are often excessive for ionic cleaning of the treated surface, which leads to its intense etching and a significant increase in the surface roughness of the part [4; 5]. In [6; 7], for effective heating of the substrate, it was suggested to use the electron component of the discharge plasma. Exposure of low-energy (tens of eV) electrons of discharge plasma with current densities of tens of А/cm2 does not produce etching but does not provide its cleaning. Therefore, to provide substrate heating and its effective cleaning it is necessary to alternate influence on it of electron and ionic components of discharge plasma. Such mode of products processing is called elionic, i.e. including influence of both electronic and ionic components of plasma of non-self arc discharge with heated cathode. A relatively low level of surface etching makes it possible to recommend the elion nitriding mode for parts and products of the rocket and space industry, for which an increasing of the level of surface roughness is unacceptable.

The aim of the present work is to compare the evolution of the structure of high-chromium steel subjected to nitriding in a non-self arc discharge plasma with a heated cathode under conditions of heating the samples to the nitriding temperature, first, by the ion plasma component and, second, by the electronic and ion plasma components.

Material and research methodology

Materials of research were the samples of high-chromium steel of grade 20Х23Н18 (foreign analogue is AISI 310S) (0,2С-1Si-2Mn-(17-20)Ni-(22-25)Cr-0.02S-0.035P, the rest - Fe, weight %). The steel nitriding was carried out on the TRIO unit retrofitted with a switching unit for the elion (electron and ion) treatment mode. Nitriding of steel in conditions of ion heating of samples was carried out simultaneously. Nitriding was performed at the temperatures 723 - 873 K for 1, 3 and 5 h. The sample temperature was controlled by the electron phase filling factor. The samples were fixed on a stationary holder in the center of the chamber on the axis of the plasma sources so that the holder was at an angle of 60° to each of them and the samples were on the front side of the holder. Study of structure, elemental and phase composition of modified steel was carried out by X-ray phase analysis and scanning electron microscopy methods, defective substructure of modified steel layer was studied by transmission electron diffraction microscopy methods.

Research results and discussion

It was shown in [8-11] that the optimal mode from the position of increasing the hardness of the surface layer of steel 20X23H18, regardless of the method of heating samples to the temperature of nitriding, is the following regime - the temperature 793 K, time 3 h. In this case the microhardness of samples is 13.7 (ionic heating mode) and 10.8 GPa (elionic heating mode). The hardness of the steel is maximum at the nitriding surface and decreases monotonically with increasing distance from the surface of the sample. The thickness of the hardened layer is 55-60 μm and is weakly dependent on the method of nitriding. Tribological tests on steel 20X23H18 subjected to nitriding have shown that under conditions of heating of samples by plasma ions the minimum value of the wear parameter (maximum wear resistance) is reached at the temperature of nitriding 873 K, 3-5 h and is k = 0.45 x 10-6 mm3/ N x m, which is less than the wear parameter of steel 20X23H18 in the initial state by 350 times. At nitriding in conditions of heating of samples in elion mode the minimum value of parameter of wear (maximum wear resistance) is reached at temperature of nitriding 793 K, 3 h and makes k = 0,86*10-6 mm3/ N x m, that less than parameter of wear of steel 20Х23Н18 in the initial condition by ≈200 times. Thus, the nitriding of steel in the conditions of ion heating of samples makes it possible to achieve higher values of microhardness and wear resistance as compared with the elion heating method. Reaching the maximum hardness at the ionic nitriding regime (793 K, 3 h) steel loses wear resistance, the wear parameter of samples for this regime k = 3,44 x 10-6 mm3/N x m that is 4 times higher than the wear parameter of steel at the comparable elionic nitriding regime (793 K, 3 h).

The level of surface roughness of the samples was determined. It is found that regardless of the method of sample heating, increasing the nitriding temperature in the range of 723-873 K leads to an increase in the surface roughness of steel [9]. It has been revealed that heating samples to the nitriding temperature in the elion mode leads to a significantly lower (2.2-3.5 times) level of material roughness as compared to the samples heated by the ionic component of the plasma during nitriding.

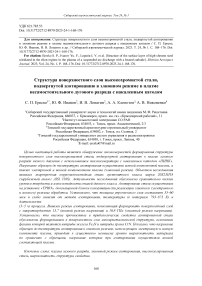

It is clear that the identified significant change in the microhardness and wear resistance of steel under nitriding conditions is due to the transformation of the elemental and phase composition, the state of the defective substructure of the surface layer of the material. Let us consider this question for a single nitriding regime of ~793 K, 3 h. The phase composition of the nitrided layer was determined by X-ray diffraction analysis. It was found that the main strengthening phases of steel are iron nitride composition Fe4N and chromium nitride composition CrN (Fig. 1). It was found that, given the same phase composition, the samples subjected to nitriding under the conditions of heating by the two above-mentioned methods differ in the number of strengthening phases. Namely, in steel nitrided with plasma ions heating, the relative total content of the hardening nitride phases amounts to 89.3 wt. %; in steel with elion nitriding it is about 79.8 wt. %. Thus, at the ionic method of nitriding the surface layer of steel contains 79 wt. % of the phase Y‘-Fe4N and 10.3 wt. % CrN (the rest is y-Fe); at the elion nitriding the ratio of nitride phases is different: 49.7 wt. % of the phase γ'-Fe4N and 30.1 wt. % CrN.

Рис. 1. Фрагменты рентгенограмм стали 20Х23Н18, подвергнутой азотированию в плазме газового разряда низкого давления:

а – элионное азотирование; б – ионное азотирование. Температура азотирования 793 К, время азотирования 3 ч

Fig. 1. Fragments of X-ray diffraction patterns of 20X23H18 steel subjected to nitriding in a low-pressure gas discharge plasma:

a – aelion nitriding; b – ion nitriding. Nitriding temperature 793 K, nitriding time 3 hours

In [12] it was shown that in the binary system Cr - N chromium nitride CrN with NaCl structural type (Pearson symbol cF8 ; spatial group Fm 3 m ) is formed. In the system Fe - N [12; 13] the presence of nitrides y '(Fe 4 N) (Pearson symbol cP 5; spatial group Pm 3 m ), e (Fe 3 N 1+x ) (Pearson symbol hP 10; spatial group P 6 з 22), ^ (Fe 2 N) (Pearson symbol oP12 ; spatial group Pbcn ) and metastable nitride Fe 16 N 2 (Fe 8 N) (nitrogen martensite) was established. On the state diagram of the binary system Fe - N there is an extensive region of existence of nitride e (Fe 3 N 1+x ) with hexagonal syngony. Whereas the solubility of nitrogen in a- Fe with a BCC lattice in equilibrium with y '(Fe 4 N) at 590 ° C is only 0.4% (at.).

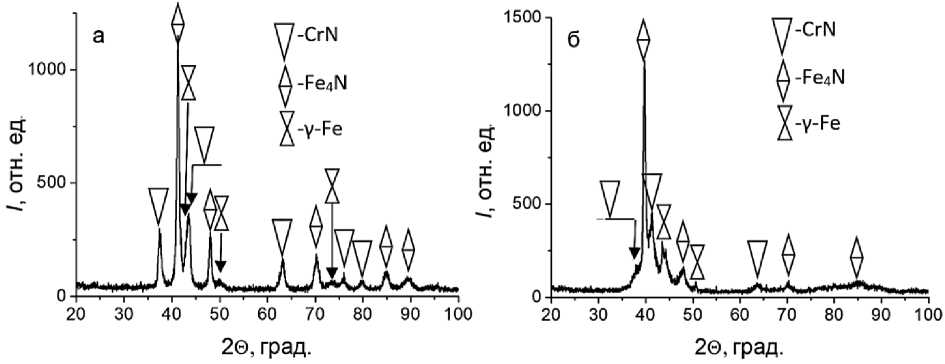

Fig. 2 shows isothermal cross sections of the ternary systems C - Cr - N and C - Fe - N, in which one alloy-forming element is a metal, the other element is not a metal, and the third element (nitrogen) is a gas. For the system C - Cr - N (Fig. 2, a ) is characterized by the existence of an extended area of homogeneity carbonitride Cr 2 (С,N) with a hexagonal structure (Pearson symbol hP9 ; spatial group P 3 1 m ). The presence of an extensive area of homogeneity of Cr 2 (С,N) carbonitride on the basis of Cr 2 N nitride reflects the high solubility of carbon in this nitride. At the same time the areas of existence of chromium carbides Cr 3 C 2 , Cr 7 C 3 , Cr 23 C 6 have very limited areas of homogeneity.

Рис. 2. Изотермические сечения тройных систем C - Cr - N в метастабильном состоянии при температуре 1100 °С и давлении P(N 2 )<0,10 МПа [14] ( а ), C - Fe - N при температуре 700 °С [15] ( б )

б

Fig. 2. Isothermal cross sections of C - Cr - N ternary systems in the metastable state at a temperature of 1100°C and pressure P(N 2 )<0.10 MPa [14] ( a ), C - Fe - N at a temperature of 700°C [15] ( b )

Fig. 2, b shows an isothermal cross section of the ternary system C - Fe - N. It can be seen that carbides θ(Fe 3 C), χ (Fe 5 C 2 ) have narrow and limited areas of homogeneity. At the same time, the extended homogeneity area of the three-component nitride ε(Fe 3 (С,N) 1+x ) in the system C - Fe - N can be clearly seen in the isothermal section. This nitride is formed on the basis of the two-component nitride Fe 3 N 1+x on the side Fe - N of the isothermal triangle. The existence of an extensive homogeneity region of the ε phase reflects the high solubility of carbon in this nitride. A characteristic feature of the Fe - C - N system is the presence of extensive two- and three-phase regions based on carbides and nitrides (Fig. 2, b ).

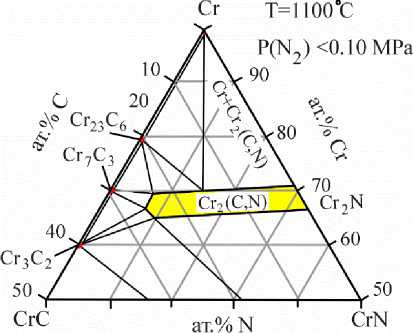

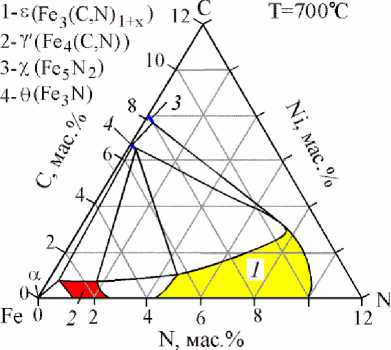

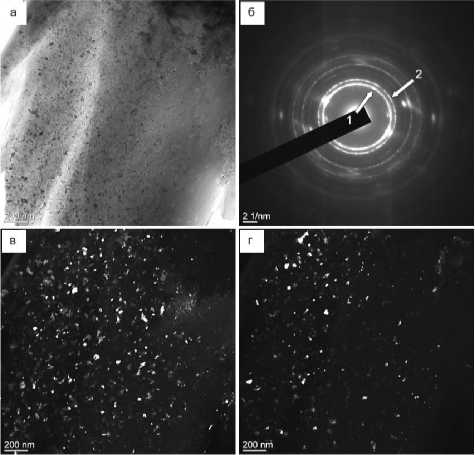

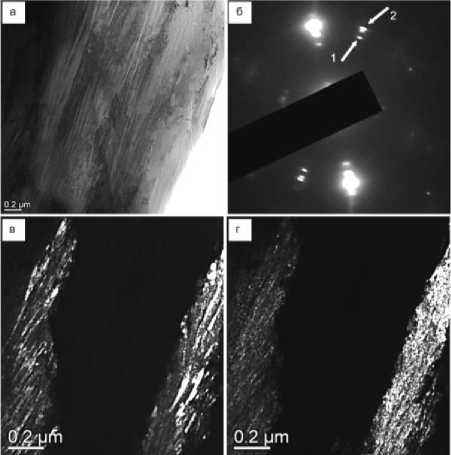

The morphology and mutual arrangement of the phases in the surface layer of nitrided steel were studied by transmission electron diffraction microscopy. It has been found that a nanocrystalline (crystallite size 20-27 nm) multiphase structure is formed in a surface layer 5-6 µm thick (regardless of the method of nitriding), the main phases of which are γ-Fe and nitrides of chromium CrN and iron Fe 4 N (Fig. 3). At greater distances, a lamellar-type structure is formed in a 30-37 μm thick layer (Fig. 4). The transverse dimensions of the plates vary from 15 to 32 nm. The analysis of microelectronograms made it possible to identify reflections belonging to the γ-Fe, CrN and Fe 4 N. These phases, in the form of plates, are arranged in an alternating manner γ-Fe / CrN or γ-Fe / Fe 4 N.

Рис. 3. Электронно-микроскопическое изображение структуры поверхностного слоя стали 20Х23Н18, подвергнутой азотированию в условиях нагревания образцов ионной составляющей плазмы: а – светлое поле; б – микроэлектронограмма, полученная с данного участка фольги; в , г – темные поля, полученные в рефлексах [111] γ-Fe + [200] CrN ( в ) и [200] γ-Fe ( г ). Стрелкой указаны рефлексы ( б ), в которых получены темные поля – рефлекс № 1 ( в ) и № 2 ( г )

Fig. 3. Electron microscopic image of the structure of the surface layer of steel 20X23H18 subjected to nitriding under conditions of heating of samples of the ionic component of the plasma:

a – bright field; b – microelectron diffraction pattern obtained from this section of the foil; ( c , d ) dark fields obtained in the [111] γ-Fe + [200] CrN ( c ) and [200] γ-Fe ( d ) reflections. In ( b ), the arrow indicates reflections in which dark fields were obtained reflection No. 1 ( c ) and reflection No. 2 ( d )

Рис. 4. Электронно-микроскопическое изображение структуры поверхностного слоя стали 20Х23Н18, подвергнутой азотированию в условиях нагревания образцов ионной составляющей плазмы: а – светлое поле; б – микроэлектронограмма, полученная с данного участка фольги; в , г – темные поля, полученное в рефлексах [111] CrN ( в ) и [111] γ-Fe + [111] Fe 4 N ( г ). Стрелкой указаны рефлексы ( б ), в которых получены темные поля– рефлекс № 1 ( в ) и № 2 ( г )

Fig. 4. Electron microscopic image of the structure of the surface layer of steel 20X23H18 subjected to nitriding under conditions of heating of samples of the ionic component of the plasma:

a – bright field; b – microelectron diffraction pattern obtained from this section of the foil; ( c , d ) dark fields obtained in ( c ) [111] CrN and ( d ) [111] γ-Fe + [111] Fe 4 N reflections. In ( b ), the arrow indicates the reflections in which dark fields were obtained reflection No. 1 ( c ) and reflection No. 2 ( d )

Conclusion

A comparative analysis of the evolution of the structure, mechanical and tribological properties of high-chromium steel subjected to nitriding in the plasma of a non-self arc discharge with a heated cathode under the conditions of heating the samples to the nitriding temperature, first, by the ion component of the plasma and, second, by the electronic and ion component of the plasma. It was found that, regardless of the method of heating the samples, the hardness of steel is maximum at the nitriding surface and decreases monotonically with increasing distance from the surface of the sample. It is shown that the thickness of the hardened layer is 55 - 60 μm and weakly depends on the nitriding method, temperature (in the range of 793 - 873 K) and the duration (3 - 5 h) of the process. It has been found that the hardness of the hardened layer (with the same layer thickness) is higher when the samples are heated by plasma ions as compared to the samples heated in the electron-ion mode.

It is shown that nitriding of steel in the conditions of ion heating of samples allows to achieve higher values of microhardness and wear resistance in comparison with the elion heating method. Reaching the maximum hardness at the ionic nitriding regime (793 K, 3 h) steel loses wear resistance, the wear parameter of samples for this regime k = 3.44*10-6 mm3/N*m, which is 4 times higher than the wear parameter of steel at the comparable elionic nitriding regime (793 K, 3 h). It was found that the high strength and tribological properties of the nitrided steel are due to the formation of a nanocrystalline structure in the surface layer, the main phases of which are iron nitrides Fe 4 N and chrome nitrides CrN. It was revealed that heating of samples to the nitriding temperature in the elion mode results in a significantly lower (by 2.2 - 3.5 times) level of material roughness as compared to the samples heated by the ionic component of the plasma during nitriding. The totality of the obtained results makes it possible to recommend the elion mode of nitriding steel for the case of modifying products, including rocket and space technology, which do not allow increasing the level of surface roughness.

Acknowledgements . The study was financially supported by the Russian Foundation for grant project №20-21-00111 Rosatom.

Список литературы Structure of the surface layer of high-chrome steel nitridated in the elion regime in the plasma of a suspended arc discharge with a heated cathode

- Wei R., Benn C. R., Cooper C. V. High Intensity Plasma Ion Nitriding of Aer Met 100 Marten-sitic Steel. Plasma Process. Polym, 2007, Vol. 4, No. 1, P. 700‒706.

- Meletis E. I. Intensified plasma-assisted processing: science and engineering. Surface and Coatings Technology. 2002, Vol. 149, No. 2‒3, P. 95‒113.

- Shanin P. M., Koval N. N., Goncharenko I. M. [Nitriding of structural steels in low pressure gas discharges]. Physics and Chemistry of Material Processing. 2001, No 3, P. 16‒19 (In Russ.).

- Yeo S., Lee C. M., Soo H. Synthesis of plasma-nitrided Cr coatings on HT9 steel for advanced chemical barrier property in a nuclear cladding application. Applied Surface Science. 2022, Vol. 579, P. 152133.

- Godec M. Ruiz-Zepeda F., Podgornik B. The influence of the plasma-nitriding temperature on the microstructure evolution and surface properties of additive-manufactured 18Ni300 maraging steel. Surface and Coatings Technology. 2022, Vol. 433, P. 128089.

- Akhmadeev Y. H., Ivanov Yu. F., Krysina O. V. Electron–ion–plasma modification of carbon steel. High Temperature Material Processes. 2021, No. 25(1), Р. 47–55.

- Ivanov Y., Lopatin I., Denisova Y. et al. Elion method of nitriding of high-chromium stainless steel: Structure and properties. 2020 7th International Congress on Energy Fluxes and Radiation Ef-fects, EFRE-2020. 2020, Р. 783–787.

- Ivanov Y., Lopatin I., Denisova Y. et al. Elion Method of Nitriding of High-Chromium Stainless Steel: Structure and Properties. IEEE. 2020, Р. 783–787.

- Ivanov Yu. F., Lopatin I. V., Petrikova E. A. et al. Azotirovanie vysokohromistoj stali v plazme nesamostoyatel'nogo dugovogo razryada s nakalennym katodom [Nitriding of high-chromium steel in plasma of a non-self-sustained arc discharge with a heated cathode]. Minsk, FTI NAN, 2022. P. 98–106.

- Eresko S. P., Ivanov Yu. F. et al. [Structure and properties of high-chromium steel subjected to nitriding in plasma of a non-self-sustained arc discharge with a heated cathode]. Reshetnevskie cht-eniya: materialy XXVI Mezhdunarodnoy nauchno-prakticheskoy konferentsii [Reshetnev Readings: Proceedings of the XXVI International Scientific and Practical Conference]. November 9–11, 2022, Krasnoyarsk, under the general. ed. Yu. Yu. Loginova; Sib. state aerospace un-t. Krasnoyarsk, 2022, P. 627–629.

- Eresko S. P., Ivanov Yu. F., Petrikova E. A. et al. [Formation of the structure, mechanical and tribological properties of high-chromium steel by electron-ion-plasma nitriding]. Siberian Aerospace Journal. 2021, Vol. 22, No. 4, P. 688‒699 (In Russ.).

- Lyakishev N. P. Diagrammy sostoyaniya dvoynykh metallicheskikh sistem 1996–2000 [Dual Metal System State Diagrams]. Moscow, Mashinostroenie Publ., 1996‒2000, Vol. 1‒3.

- Kubaschewski O. Iron – Binary Phase Diagrams. Berlin: Springer-Verlag. 1982, 184 p.

- Ettmayer P. Beitragzum System Chrom-Kohlenstoff-Stickstoff. Monatshefte für Chemie und verwandte Teileanderer. Wissenschaften. 1966, Vol. 97, Р. 1248‒1257.

- Du H. A Reevaluation of the Fe-N and Fe-C-N Systems. Journal of Phase Equilibria. 1993, Vol. 14, No. 6, P.682‒894.