Study of effect of nickel and rare-earth metals on the structure and properties of cast and deformed semi-finished products made of aluminum alloys

Автор: Sidelnikov Sergey B., Baranov Vladimir N., Lopatina Ekaterina S., Trifonenkov Leonid P.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 1 т.5, 2012 года.

Бесплатный доступ

Technology for making electrical aluminum alloys with different contents of rare-earth metals and nickel was developed. Cast and deformed semi-finished products made of new alloys were obtained as a result of experimental studies. The structure and mechanical properties of metal were studied as well as electrical resistivity measurements of rods and wires were carried out. The effect of nickel and rare-earth metals on these characteristics was found out and alloy compositions with the most favorable combination of strength and electrical properties were determined.

Aluminum, nickel, rare earth metals, alloy, mechanical properties, electro conductivity, structure, casting parameters

Короткий адрес: https://sciup.org/146114626

IDR: 146114626 | УДК: 671.03

Текст научной статьи Study of effect of nickel and rare-earth metals on the structure and properties of cast and deformed semi-finished products made of aluminum alloys

a

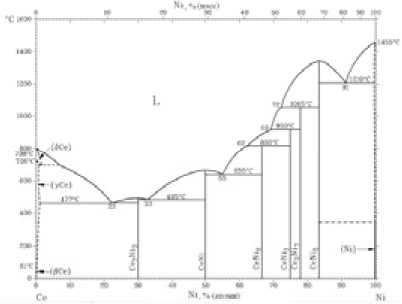

Fig. 1. Diagrams of phase equilibrium in aluminum – nickel (a) and nickel – cerium (b) systems

b

alloys can lead to equipment failure and defective products. Therefore it is reasonable to use the continuous technologies of combined casting, rolling and pressing (CCRP) for these alloys [1]. These technologies are characterized by low energy consumption and high productivity and allow the final product to be obtained in one or two technological steps, which is important in modern manufacturing.

Thus the combination of the highest specific strength and electrical conductivity (minimal electrical resistance equates to aluminum wire) of electrical wire rod made of low-alloyed aluminum alloys with optimum complex alloying can be achieved through the use the author’s CCRP method for producing of long-length semi-finished products and subsequent drawing with a given degree of deformation and annealing.

The efficiency of hardening effects of the alloying at the expense of complicating the structure of the hardening phases such as through additional alloying by transition metals was evaluated in this study. These transition metals are slightly soluble in aluminum like REM otherwise they can form intermetallic phases with aluminum and REM as well as with iron and silicon, which are the main impurities in aluminum. This further reduces the content of such impurities in the solid solution and leads to an increase in hardening while maintaining the electrical resistivity. Typical representative of such transition metals is nickel. Diagram of phase equilibrium with aluminum (Fig. 1 a) shows the possibility of such an influence of nickel on the phase state of electrical alloys.

According to the data provided by the phase equilibrium diagram the maximum solubility of nickel at the eutectic temperature (640 ºC) is 0,05 % (atomic), but it sharply decreases to 0.01% at the temperature of 500 ºC (Table 1). Nickel as well as REM forms intermetallic compound Al3Ni which is in equilibrium with the aluminum solid solution, whose particles are practically insoluble in aluminum at the temperatures below 500 ºC. The presence of nickel in aluminum alloy in conjunction with REM can lead to the interaction between nickel and these components, as double diagram indicates (Fig. 1 b).

According to [2] nickel in the presence of iron (in equal amounts) in aluminum-based alloy interacts with it forming a ternary compound FeNiAl9. This phase is practically insoluble during the heating and do not adversely affect the mechanical properties of the alloy.

Table 1. Features of dual diagrams Al-Ce, Al-La, Al-Ni

|

Metal |

Metal solubility limit in aluminum, mass % (at the eutectic temperature) |

Eutectic concentration, mass % |

Eutectic temperature, ° С |

Phase |

|

Ce |

0,05 |

12,0 |

637 |

Al 4 Ce (Al 11 Ce 3 ) |

|

La |

0,05 |

12,0 |

642 |

(Al 11 La 3 ) Al 4 La |

|

Ni |

0,05 |

6,0 |

640 |

Al 3 Ni |

Table 2. Casting modes and chemical compositions of Al-REM and Al-REM-Ni alloys

|

Sample № |

Ni concentration, |

Relative content |

Heat temperature, |

Pouring |

|

mass % |

of REM in alloy |

° С |

temperature, ° С |

|

|

1 |

- |

Very low |

||

|

2 |

- |

Low |

||

|

3 |

- |

Medium |

||

|

4 |

- |

High |

750-800 |

740 ± 10 |

|

5 |

0,15-0,20 |

Very low |

||

|

6 |

0,20-0,25 |

Low |

||

|

7 |

0,25-0,30 |

Medium |

||

|

8 |

0,30-0,35 |

High |

Analysis of phase equilibriums in alloys based on aluminum showed that it is possible to create semi-finished products of the Al-REM-Ni alloy for electrical purpose with the correct iron and silicon content in amounts corresponding to the content of these components in the commercial grade aluminum.

In order to experimentally verify the analytical conclusions the new aluminum alloys with different contents of rare-earth metals (cerium based) and nickel were developed in the laboratory of Siberian State University as well as the technological parameters of their preparation and casting were studied. Al-Ni and Al-REM waffle alloys made by KBM Company were used to prepare electrical purpose alloys. Primary aluminum melt was prepared in graphite crucibles in a high-frequency melting furnace and heated to a temperature of 750-800 °C. Then the preheated Al-Ni alloy with calculated composition and mass (in amount of 0,15-0,35 mass%) was injected directly into the crucible and held for 3-5 minutes and after that Al-REM alloy was added into the crucible. The melt was poured into a specially prepared mold and technological sample to determine the chemical composition. Casting modes and chemical compositions of studied alloys are shown in Table 2.

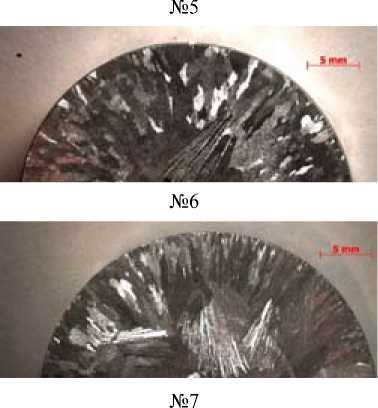

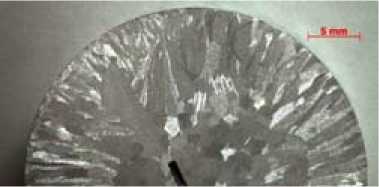

The macrostructure of the alloys, which was studied using Stemi 2000-C stereoscopic microscope, mainly consist of columnar crystals zone located on the periphery of the ingot and the zone of large equiaxed crystals in the center of the ingot. The adverse fan structure is observed in alloys with small, medium and high REM content and the higher total concentration of alloying elements, the greater area occupied by fan crystals (Fig. 2).

Research of microstructure of the alloys with different contents of rare-earth metals and Ni was carried out using light and scanning electron microscope EVO 50 with energy-dispersion microanalyzer Inca Energy 350. The microstructure of the alloys is shown in Fig. 3. It was found that the dendritic cells size reduces with increasing concentrations of rare-earth elements and there are Al 4 Me eutectic

№1

№2

№3

№4

№8

Fig. 2. Macrostructure of Al-REM alloys (samples №1-4) и Al-REM-Ni alloys (samples №5-8)

phases along the boundaries of dendritic cells in the low-alloyed alloys (sample №1). The amount of eutectic component increases with increasing concentration of REM and eutectic colonies (a+Al 4 Me) form the volume of dendritic cells (samples № 2-4).

Alloying of Al-REM alloys with small additions of Ni from 0.15 to 0.35 % (samples № 5-8) has no significant effect on the microstructure of the alloys.

Hot-deformed semi-products with circular cross-section in the form of 9 mm rod were produced from these alloy ingots using combined casting, rolling and pressing process [1]. Then the wire 2 mm in diameter was produced from this rod by cold-drawing and the samples obtained were researched in relation to their structure, mechanical properties and electrical resistance.

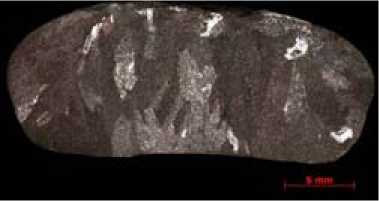

Typical distribution of constituents throughout the cross-section of the samples occurs when producing the rods from Al-REM and Al-REM-Ni alloys by CCRP process which leads to both macro- and microheterogeneity. In low-alloyed alloys (samples № 1, № 5) there are some areas

№1

№5

№2

№6

№3

№7

№4

№8

Fig. 3. Microstructure of Al-REM alloys (samples № 1-4) and Al-REM-Ni alloys (samples № 5-8), x 200

with an increased number of eutectic component in the form of lines oriented in the direction of deformation.

An increase in concentration of rare-earth metals in the alloys leads to significant heterogeneity throughout the cross-section of the rod (samples № 2 – 8). Areas containing eutectic colonies of crystals are located along the boundaries of deformed grains. Eutectic colonies generate the areas in the form of clusters with a high content of alloying elements. Microheterogeneity of alloying elements throughout the cross section of the rod is confirmed by the presence of large intermetalloids predominantly of platelet shape in the eutectic structure.

Electron probe microanalysis of intermetalloids (samples № 3, 4) shows the presence of Al, Ce, La and Si. The rods high-alloyed with rare-earth metals have Ce content higher than La and it reaches 4.5% in Al-REM alloys and 7.9% in Al-REM-Ni alloys. Microheterogeneity of the rods appears in the form of areas with a low amount of eutectic constituent (Table 3, Fig. 4).

Table 3. Microhardness of deformed semi-finished products made of Al-REM and Al-REM-Ni alloys

|

Rod microhardness HV, kgf/mm2 |

Wire microhardness HV, kgf/mm2 |

||||||

|

№ |

Al-REM |

№ |

Al-REM-Ni |

№ |

Al-REM |

№ |

Al-REM-Ni |

|

1 |

38,4±2,7 |

5 |

42,2±1,3 |

1 |

52,7±2,3 |

5 |

57,0±1,1 |

|

2 |

42,7±1,8 |

6 |

40,7±3,4 |

2 |

54,0±2,6 |

6 |

51,1±1,2 |

|

3 |

41,7±1,6 |

7 |

46,7±2,0 |

3 |

54,4±1,0 |

7 |

61,5±1,5 |

|

4 |

45,5±1,0 |

8 |

45,7±2,0 |

4 |

61,6±2,3 |

8 |

67,4±2,1 |

№1

№2

№5

№3

№6

№7

№4

№8

Fig. 4. The microstructure of the rods made of Al-REM (Samples № 1-4) and Al-REM-Ni (samples № 5-8) alloys produced by CCRP process, x 200

Wire drawing out of studied rods did not eliminate the macro- and microheterogeneity of the rods. The structures of the rods and wires with different compositions are similar and differs by presence more expressed streaked structure for cold deformation. It should be noted that plastic properties of the developed alloys provide cold deformation without annealing and ruptures with a total degree of deformation up to 70-80 %.

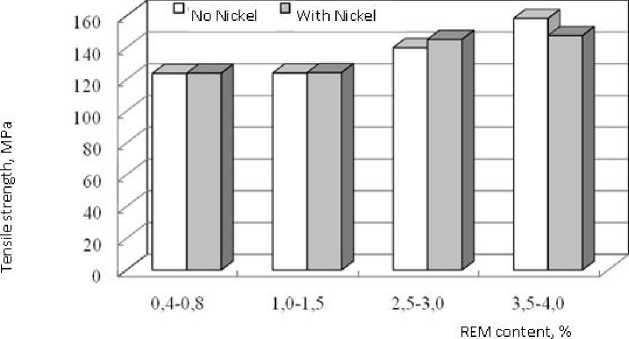

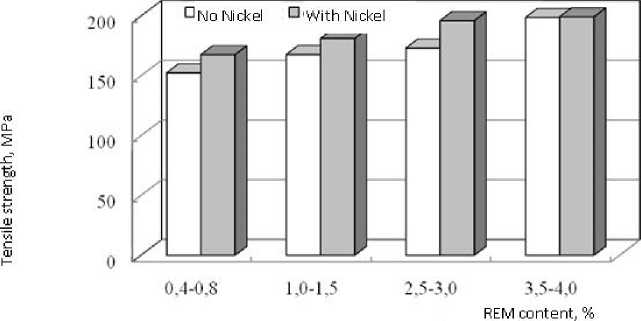

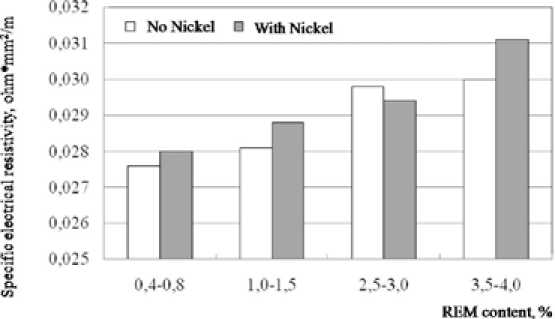

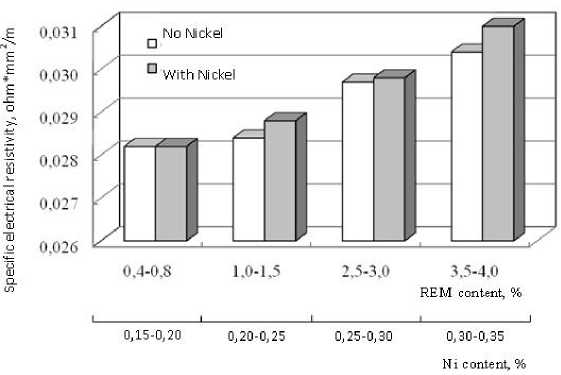

Studies of tensile strength of the test rods and wires were carried out using the universal electromechanical machine LFM 400 (400 kN) which can record the main parameters of the process on a computer. The research results are shown on Fig. 5-6. Results of specific electrical resistivity measurements of obtained rods and wires are presented in Fig. 7-8.

I_____________________________________________________________________________I_______________________________________________________________________________I__J______________________________________________________________________________I

0,15-0,20 0,20-0,25 0,25-0,30 0,30-0,35

Ni content, %

Fig. 5. Tensile strength of the rods made of Al-REM and Al-REM-Ni alloys produced by CCRP process

i__________________________________________________________i____________________________________________________________i__________________________________________________________,______________________________________________

0,15-0,20 0,20-0,25 0,25-0,30 0,30-0,35

Ni content, %

Fig. 6. Tensile strength of the wires made of Al-REM and Al-REM-Ni alloys

0,15 ОДО

0.20-0 Д5

0.25-0,30

0.30 0.35 Nt content, %

Fig. 7. Specific electrical resistivity of the rods made of Al-REM and Al-REM-Ni alloys produced by CCRP process

Fig. 8. Specific electrical resistivity of the wires made of Al-REM and Al-REM-Ni alloys

The results of studies of the mechanical properties of rods and wires of the alloys shows that their strength properties reach values up to 150 MPa for rods and up to 200 MPa for the wire, what is much higher than tensile strength according to the standard requirements for deformed semi-finished products made of electrotechnical grade aluminum. But on the other hand resistivity has the same level in case if the content of rare-earth metals and nickel in the alloy decreases.

The made studies shown that in principle it is possible to obtain a new aluminum alloys with additions of rare-earth metals and nickel with the required level of mechanical and electrical properties and fine structure. Developed technical solutions in addition to an increase in production efficiency of long-length semi-finished products of aluminum alloys [3] enable to get most favorable combination of specific strength and electrical conductivity due to the optimal complex alloying.

The obtained quantitative assessment of mechanical and electrophysical properties and regularities of their changes depending on process parameters were used to create equipment design and develop operating practices for producing of long-length products made of the investigated aluminum alloys.