Study of the influence of alphanizing on the structure and properties of the alloy BT6

Автор: Lekarev A.V., Yurchuk L.I., Merkulova G.A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.24, 2023 года.

Бесплатный доступ

The paper considers the influence of two technologies of alphanizing (oxidation) on the structure and properties of the deformable titanium alloy BT6, which is used, in particular, in the aviation and space industries. The application of oxide coating by methods of chemical-thermal treatment (CTO) allows to compensate for the main drawback of the alloy – low wear resistance of the surface. The initial set of properties increases. The objects of research are titanium alloy BT6 and its oxide coatings. Two samples of the part with oxide coatings obtained by different technologies were compared. The first technology is alphanizing in finegrained graphite, the second one is alphanizing in a vacuum. The aim of the work is to find out the influence of two technologies of alphanizing on the structure and properties of the BT6 alloy. Alphanizing was carried out: 1) in fine-grained graphite at a temperature of 800 ± 10 ° C with exposure for 8 hours; 2) in an electric furnace at a temperature of 760–780 ° C in a vacuum of 10-1 – 10-3 mm Hg. for 1.5–2 hours. A study of the microstructure (light and electron microscopy) was performed. We used a microscope type Carl Zeiss Axio Observer A1m using a digital camera, adapter devices for converting an optical signal, a computer. Statistical processing was carried out according to the SIAMS700 program. Electron microscopic studies were performed using a scanning electron microscope (SEM) EVO 50 with an energy-dispersive microanalyzer INCA Energ 350. X-ray phase analysis was carried out using an X-ray diffractometer Shimadzu XRD7000, Japan (CuKa radiation, monochromator), in the following mode: range from 5 to 70 ° on a scale of 2θ, increments of 0.03°, scanning speed of 1.5 ° / min. Powders obtained from two types of coatings were investigated. The microhardness of the samples was measured on the DM8 microhardometer according to GOST 9450–76. The wear resistance of the alloy was assessed at a special laboratory installation. The phase composition and structure of the BT6 alloy after alphanizing were clarified. In the diffusion layer, the following points were detected: after alphanizing in graphite – TiO2 phases; Ti3O; TiN. After carbonation in vacuum – TiO2; Ti6O11. In the alphad layer, after processing in graphite, grains of α – solid solution, intermetallics Ti–Al-V, Ti–V and Ti–Al were detected; the alphanized layer contains more titanium after treatment in vacuum, and areas with 100% (at.) titanium have also been identified; the region of solid solution (α) and the intermetallics Ti–Al-V, Ti–V and Ti–Al are visible. The thickness of the oxidized layer is on average 103.6 μm (graphite), and in a vacuum – 66.8 μm. The average grain size in the layer is 17.2 μm (graphite); 6.0 μm (vacuum). It has been established that chemical-thermal treatment (alphanizing) contributes to a significant increase in microhardness in the diffusion layer. The hardness of HV580 (vacuum) and HV724 (graphite) was obtained on the surface. Alphanizing in graphite and in vacuum ensures the wear resistance of the product, but the best result is obtained after alphanizing in a vacuum. Both technologies improve the properties, but it is more profitable to carry out alphanizing in a vacuum, since in this case the process is carried out within 2 hours instead of 8 hours in graphite. Alphanizing (oxidation) provides wear resistance of the BT6 alloy, which contributes to the reliable operation of the product during operation.

Alphanizing, titanium alloy BT6, microstructure, microhardness, wear resistance, X-ray phase analysis

Короткий адрес: https://sciup.org/148329702

IDR: 148329702 | УДК: 621.785.539 | DOI: 10.31772/2712-8970-2023-24-3-589-604

Текст научной статьи Study of the influence of alphanizing on the structure and properties of the alloy BT6

The advantages of titanium are known: low density (4.5 g/cm 3 ), high specific strength, corrosion resistance, manufacturability during pressure treatment and weldability, cold resistance, high resistance to solar radiation, non-magneticity and other valuable physical and mechanical characteristics.

Titanium alloys are used in rocket and space technology, shipbuilding, and transport engineering. The creation of high-strength titanium alloys led to the emergence of supersonic aircraft. It is believed that titanium alloys are promising for use in the food industry. They are used in refrigeration and cryogenic technology, medicine, and construction (Japan).

The structure and properties of titanium alloys are given in [1–9]. Alloys have low wear resistance. To increase antifriction properties, parts made of titanium alloys are subjected to alphanizing (oxidation), i.e. the surface of titanium alloys is saturated with oxygen at elevated temperatures. Oxidation leads to the formation of an oxide film and a layer of solid solution of oxygen in titanium on the surface (alphanized layer). Alfanizing technologies are given in [10–16]. Chemical-thermal treatment takes place. Alfanizing is performed, in particular, in fine-grained graphite [12] and vacuum [13].

The purpose of this work is to find out the effect of two alfanizing technologies on the structure and properties of the BT6 alloy.

Materials and research methods

Titanium deformable alloy BT6 was chosen for the study. It is alloyed with aluminum (from 5.3 to 6.8 % wt.) and vanadium (from 3.5 to 5.3% wt.) [17]. The structure and properties of the BT6 alloy are described in sources [1–9].

Chemical-thermal treatment was carried out for a sleeve made of BT6 alloy. Alphanizing (oxidation) was carried out using two technologies:

-

1) in fine-grained graphite at a temperature of 800±10 °C with exposure for 8 hours [12];

-

2) in electric furnaces at a temperature of 760–780 °C in a vacuum of 10–1–10–3 mm Hg. for 1.5–2 hours [13].

Metallographic studies of samples cut from the sleeve were carried out on an optical-computer metallography installation, which includes a Carl Zeiss Axio Observer A1m microscope using a digital camera, optical signal conversion adapters, and a computer. Structure studies were performed at magnifications ×200, ×500, ×1000.

SIAMS700 software was used for quantitative analysis of the obtained images.

Electron microscopic studies were performed using an EVO 50 scanning electron microscope (SEM) with an INCA Energу 350 energy-dispersive microanalyzer.

X-ray phase analysis was carried out using a Shimadzu XRD7000 X-ray diffractometer, Japan (CuKa radiation, monochromator), in the following mode: range from 5 to 70° on a 2θ scale, step 0.03°, scanning speed 1.5°/min. Powders obtained from two types of coatings were studied.

The microhardness of the samples was measured using a DM8 microhardness tester according to GOST 9450–76 [18]. The measurement was carried out at a load of 100 gf (980.665 mN) from the edge of the sample to the center. The distance between the centers of two adjacent prints is 70 µm, the distance between two adjacent rows of prints is 70 µm. Between the rows of prints there is also a 10 µm offset from the edge to the center of the sample. The microhardness of alphanized coatings obtained using two technologies was assessed. 60 measurements were made on each sample. The arithmetic averages of the obtained microhardness values were calculated.

Tests for wear resistance of the samples were carried out using a special device. Belts of sanding paper with a grain size of P120 (abrasive grain size 100–125 µm) were passed through the slot, onto which the sample was placed. Next, the sample was pressed with a load weighing 1 kgf and the tape was pulled through. The piece of tape that abrases the surface has a length of 1 m and a width of 1 cm. After pulling, the sample was cleaned of abrasive dust and weighed on a VLTE-150 scale with an accuracy of 0.001 g, after which the test was repeated. As a result, the wear path of each sample was 10 m.

Research results and discussion

Metallographic analysis . BT6 alloy belongs to the titanium – aluminum (6%) – vanadium (4%) system. This is a deformable two-phase α+ β alloy, where α is a solid solution of aluminum (and vanadium) in α-Ti with an hcp lattice; β – is solid solution of aluminum (and vanadium) in β-Ti with a bcc lattice. Titanium is a polymorphic metal. Alloying the BT6 alloy with aluminum strengthens and stabilizes the α-phase, increases the Ac 3 temperature, and reduces the specific gravity of the alloy. Vanadium is a β -stabilizer. It reduces the temperature of the α+ β → β -transition, which for the BT6 alloy is 960–1000 °C [1; 4]. The work [9] presents a state diagram of the titanium-aluminum system.

In the titanium-rich region, two intermetallic compounds Ti 3 Al (α 2 -phase) and TiA1 (γ-phase) are formed. The α 2 phase (Ti 3 A1) has an hcp crystal structure, close to the lattice of the α phase, but differs from it in the ordered arrangement of titanium and aluminum atoms. The γ (TiAl) phase has an ordered tetragonally distorted face-centered structure, similar to the CuAu superstructure, in which layers packed with titanium atoms alternate with layers occupied by aluminum atoms.

In the titanium-rich region, two peritectic transformations occur: (l + β) → α (at 1475 ºС) and (l + α) → γ (at 1447 ºС). At a lower temperature (1118 ºС) it is observed eutectoid decomposition of the α-phase according to the scheme α → α 2 + γ. The solubility of aluminum in α-Ti decreases with decreasing temperature and is 10, 9 and 7% (by weight) at temperatures of 900, 800 and 600 °C respectively.

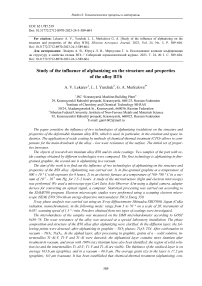

Oxygen is an α-stabilizer, i.e. it expands the region of the α-phase. The state diagram of the tita-nium-oxygen system is shown in Fig. 1.

Oxygen significantly dissolves in α-Ti and sharply increases the temperature of the polymorphic transformation of titanium [19]. At 1720 °C the peritectic reaction L + (α-Ti) → ( β -Ti) occurs. The maximum solubility of oxygen in ( β -Ti) is 8% (at.) at 1720±25 °C. The melting point (α-Ti) reaches a maximum of 1885±25 °C at a content of approximately 24% (at.) oxygen. With a further increase in oxygen content, the melting point of the alloys decreases slightly. At temperatures below 600 °C, there are two oxides Ti 3 O and Ti 2 O with a hexagonal crystal lattice. At these temperatures, Ti 6 O suboxide may form in alloys with higher titanium content.

In the titanium-oxygen system, the following intermediate phases may be present: Ti 3 O, Ti 2 O, Ti 3 O2, γ TiO, αTiO, αTi 2 O 3 , αTi 3 O 5 , β Ti 3 O 5 , TiO 2 (TiO 2 – rutile; TiO 2 – anatase; TiO 2 – brockite) [19].

Fig. 1. Diagram of the state of the titanium-oxygen system [19; 20]

Рис. 1. Диаграмма состояния системы титан-кислород [19; 20]

The studied microstructures and the results of their processing are shown in Fig. 2–12.

а

б

в

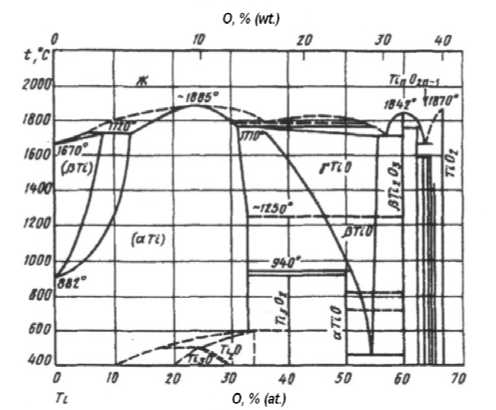

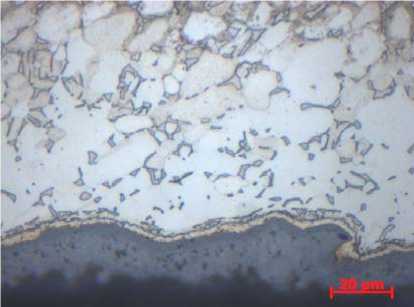

Fig. 2. Microstructures of BT6 alloy after alfanizing in graphite: а–г – is the surface layer; д , е – is the center of the sample; а – ×200; б – ×500; в , г – ×1000; д – ×500; е – ×1000 (Start)

г

Рис. 2. Микроструктуры сплава ВТ6 после альфирования в графите: а–г – поверхностный слой; д , е – центр образца; а – ×200; б – ×500; в , г – ×1000; д – ×500; е – ×1000 (Начало)

д е

Fig. 2. Completion

Рис. 2. Окончание

а

б

в

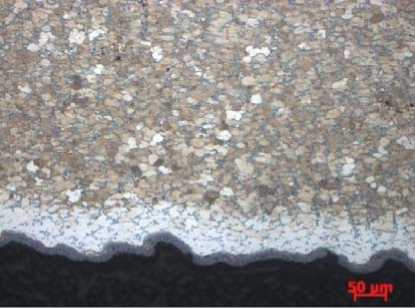

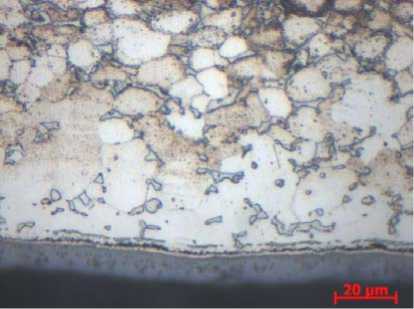

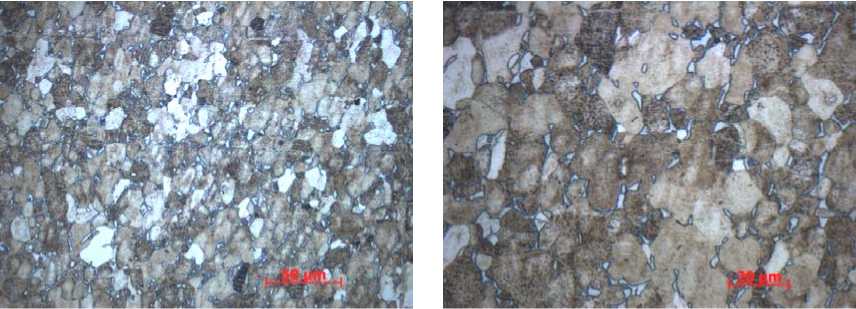

Fig. 3. Microstructures of BT6 alloy after alphanizing in vacuum: а , б – surface layer; в , г – the center of the sample; а , в – ×500; б , г – ×1000

г

Рис. 3. Микроструктуры сплава ВТ6 после альфирования в вакууме: а , б – поверхностный слой; в , г – центр образца; а , в – ×500; б , г – ×1000

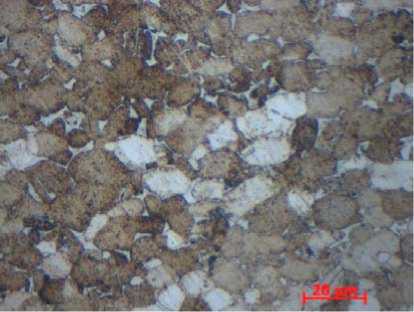

The study showed that in the center of the sample there are two phases of the globular (equiaxed grains) type α+ β : α – light; β – dark (see Fig. 2, 3).

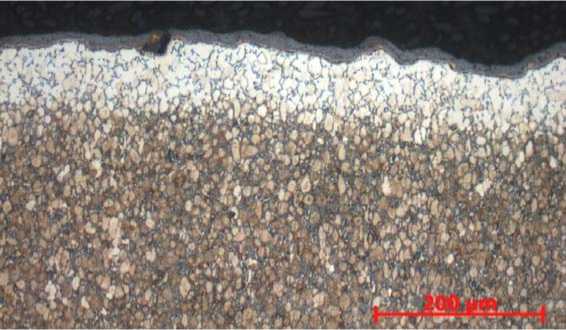

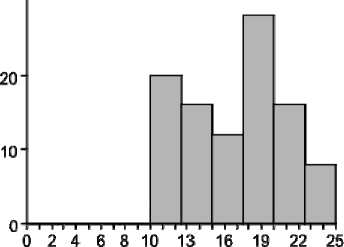

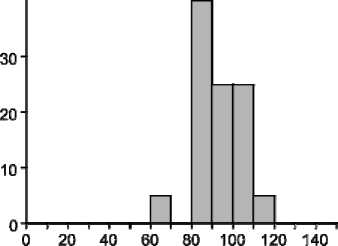

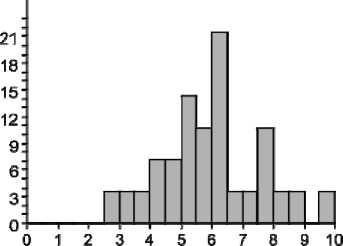

Statistical processing of microstructures was carried out after alphanizing in graphite (Fig. 4, 7), as well as after alphanizing in vacuum (Fig. 10) in the SIAMS 700 program. The results are presented in histograms (Fig. 5, 6, 8, 9, 11, 12).

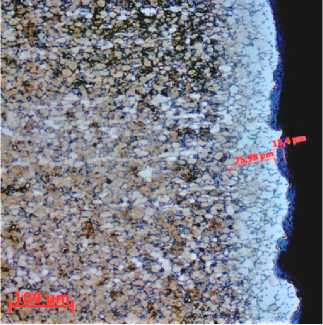

Fig.. 4. Microstructure of the BT6 alloy after alphanizing in graphite. ×200

Рис. 4. Микроструктура сплава ВТ6 после альфирования в графите. ×200

%

мкм

|

Number of measurements |

25 |

|

Minimum length, µm |

10.5 |

|

Maximum length, µm |

23.0 |

|

Average length, µm |

17.0 |

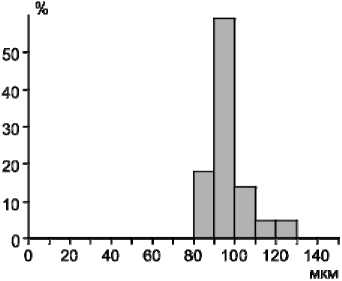

Fig. 5. Thickness of the dark coating layer after alphanizing in graphite

Рис. 5. Толщина тёмного слоя покрытия после альфирования в графите

%

|

Number of measurements |

20 |

|

Minimum length, µm |

62.2 |

|

Maximum length, µm |

118.0 |

|

Average length, µm |

93.6 |

мкм

Fig. 6. Thickness of the light layer after alphanizing in graphite

Рис. 6. Толщина светлого слоя после альфирования в графите

After alphanizing, several diffusion layers were revealed in graphite (Fig. 4), which differ in color. A thin dark layer (oxide film) with a thickness of 17.0 μm (average) is observed on the surface of the sample. Then a light alpha layer with a thickness of 93.6 μm (average value) is visible. The total thickness of the coating, calculated by adding the average thicknesses of the dark and light layers, is 110.6 µm (Fig. 5, 6).

We also measured the thickness of the layer in the sample after alphanizing in graphite using the microstructure shown in Fig. 7.

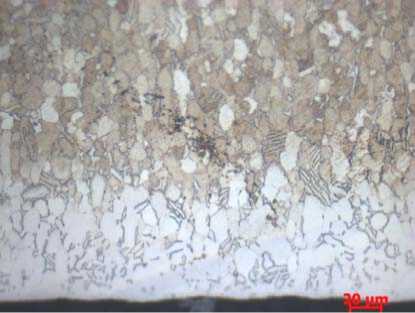

Fig. 7. Microstructure of the BT6 alloy after alphanizing in graphite. ×200

Рис. 7. Микроструктура сплава ВТ6 после альфирования в графите. ×200

Fig. 8. Thickness of the coating after alphanizing in graphite (dark and light layers)

|

Number of measurements |

22 |

|

Minimum length, µm |

80.3 |

|

Maximum length, µm |

122.7 |

|

Average length, µm |

96.5 |

Рис. 8. Толщина покрытия после альфирования в графите (тёмный и светлый слои)

The average thickness of the coating (dark and light layers together) in Fig. 7 is 96.5 µm (Fig. 8).

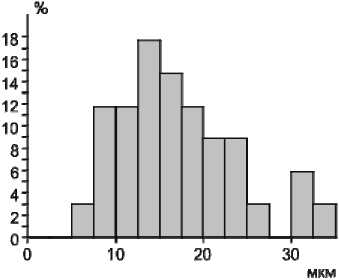

The grain size in the diffusion layer obtained after alphanizing in graphite was determined (Fig. 9).

The average grain size is 17.2 µm.

Number of measurements34

Minimum length, µm7.4

Maximum length, µm34.5

Average length, µm17.2

Fig. 9. Grain size in the diffusion layer (alphanizing in graphite)

Рис. 9. Размер зерна в диффузионном слое (альфирование в графите)

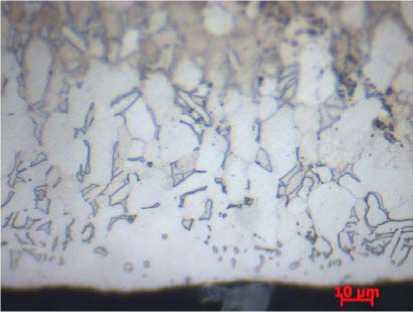

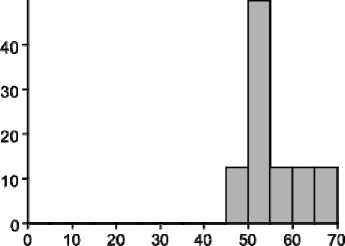

Alphanizing in a vacuum (Fig. 10) contributed to the formation of a light alphanized layer with a thickness of 56.2 μm (Fig. 11). No oxide layer was detected on the surface.

The average grain size in the diffusion zone according to Fig. 12 was 6 microns (vacuum).

Fig. 10. Microstructure of the BT6 alloy after alphanizing in vacuum. ×500

Рис. 10. Микроструктура сплава ВТ6 после альфирования в вакууме. ×500

Number of measurements8

Minimum length, µm49.3

Maximum length, µm66.8

Average length, µm56.2

Fig. 11. Thickness of the coating layer obtained after alphanizing in vacuum

Рис. 11. Толщина слоя покрытия, полученного после альфирования в вакууме

%

мкм

Fig. 12. Grain size in the coating obtained after alphanizing in vacuum

|

Number of measurements |

28 |

|

Minimum length, µm |

2.9 |

|

Maximum length, µm |

9.6 |

|

Average length, µm |

6.0 |

Рис. 12. Размер зерна в покрытии, полученном после альфирования в вакууме

According to literature data [12], the coating thickness of the product should be ≥ 40 µm. The proposed technologies made it possible to obtain a layer (minimum values) ≥ 72 μm (graphite) and ≥ 49 μm (vacuum), which ensures that the requirements for the part are met.

The structure of deformed titanium alloys is largely determined by the temperature and rate conditions of deformation [5].

The structure may contain twins. Phase α has a GP crystal lattice. In titanium with a GP lattice, the direction of twinning is <1011>. Twinning plane {1012} [1; 2].

In the alphanizied layer (α-phase, HP lattice), parallel lines (plates) are observed in individual light grains. This may be due to the polymorphic transformation of titanium upon heating: β (BCC) → α (GP). According to the principle of structural and dimensional correspondence to P.D. Dankov and S.T. Konobeevsky, the shape and orientation of the nuclei of a new phase during crystallization in an anisotropic medium should contribute to a minimum surface energy, and the minimum is obtained with the greatest similarity in the arrangement of atoms on the touching faces of the old and new phases. In titanium, during the polymorphic transformation β (BCC) → α (GP), mutually parallel planes: {001} β is parallel to {110} α . Mutually parallel directions: <110> β parallel to <111> α . B.G. Livshits in [21] explains that in metals “almost always, when a new phase α is formed inside the old phase β , a greater or lesser structural correspondence is observed between the phases, that is, there are planes and directions that are similar in the arrangement of atoms. In the case of sufficient correspondence, the crystal shape of the resulting phase depends on the anisotropy of the elastic properties of both phases. If the elastic moduli of the α phase for all directions are less than the elastic moduli of the β phase, then the α phase will precipitate in the form of plates upon cooling.” This lamellar shape of the α phase can be observed in Fig. 10.

Electron microscopic examination. The images obtained during the SEM study are presented in Fig. 13–19. Below each image is data on the chemical composition of the selected areas (spectra).

electronic image

40 pm

Fig. 13. Microstructure and chemical composition in spectra (at. %) of the BT6 alloy (graphite, sample center)

|

Spectrum |

Al |

Ti |

V |

|

1 |

88.69 |

11.31 |

|

|

2 |

12.07 |

87.93 |

|

|

3 |

13.63 |

86.37 |

|

|

4 |

14.33 |

85.67 |

|

|

5 |

8.69 |

80.76 |

10.55 |

|

6 |

15.18 |

84.82 |

|

|

7 |

86.19 |

13.81 |

Рис. 13. Микроструктура и химический состав в спектрах (ат. %) сплава ВТ6 (графит, центр образца)

Solid solution grains were detected (spectrum 2, Fig. 13): 12.07% aluminum; 87.93% titanium. Intermetallic compounds are visible: 88.69% titanium; 11.31% vanadium (spectrum 1); 8.69% aluminum; 80.76% titanium; 10.55% vanadium (spectrum 5); 86.19% titanium; 13.81% (at.) vanadium (spectrum 7).

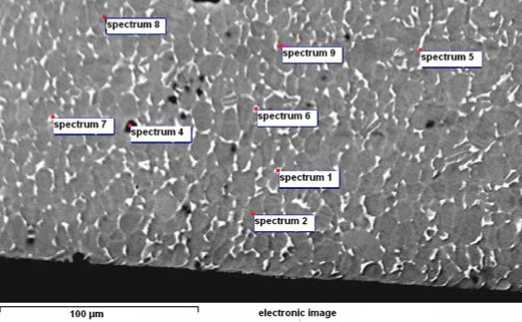

In the structure in Fig. 14 α-phase grains are seen (spectrum 2: 78.68% titanium; 14.60% aluminum). Precipitates along grain boundaries (spectrum 1) – phase containing 12.32% aluminum; 71.03% titanium; 10.58% vanadium. There is a phase with oxygen (spectrum 4): 77.26% oxygen; 3.95% aluminum; 12.64% titanium. Spectra 5, 6, 7 – phases along the grain boundaries of the α – solid solution. They contain 11.02–12.17% aluminum; 68.73–70, 66% titanium; 9.82–12.06% vanadium. Spectrum

8-phase containing 15.50% aluminum and 78.80% titanium. Spectrum 9 – titanium-based solid solution (90.23% titanium).

Fig. 14. Microstructure and chemical composition in the spectra (at. %) of the alphanized layer of the alloy BT6 (graphite)

|

Spectrum |

O |

Al |

Ti |

V |

|

1 |

12.32 |

71.03 |

10.58 |

|

|

2 |

14.60 |

78.68 |

||

|

4 |

77.26 |

3.95 |

12.64 |

|

|

5 |

11.90 |

68.73 |

10.13 |

|

|

6 |

12.17 |

70.66 |

9.82 |

|

|

7 |

11.02 |

70.51 |

12.06 |

|

|

8 |

15.50 |

78.80 |

||

|

9 |

90.23 |

Рис. 14. Микроструктура и химический состав в спектрах (ат. %) альфированного слоя сплава ВТ6 (графит)

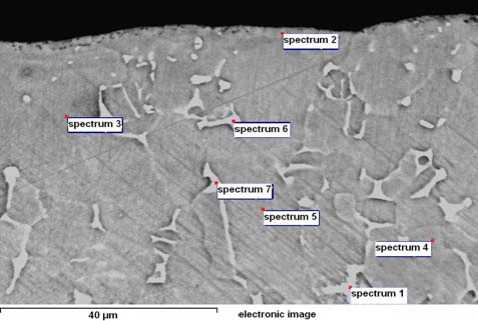

Fig. 15. Microstructure and chemical composition in the spectra (at. %) of the alphanized layer of the BT6 alloy (vacuum)

|

Spectrum |

Al |

Ti |

V |

|

1 |

4.51 |

84.25 |

11.24 |

|

2 |

6.49 |

89.95 |

3.55 |

|

3 |

7.70 |

90.26 |

2.04 |

|

4 |

7.29 |

89.71 |

3.01 |

|

5 |

7.17 |

91.11 |

1.73 |

|

6 |

4.81 |

82.18 |

13.02 |

|

7 |

5.39 |

81.64 |

12.98 |

Рис. 15. Микроструктура и химический состав в спектрах (ат. %) альфированного слоя сплава ВТ6 (вакуум)

No oxygen was detected in the layer (Fig. 15). A region of solid solution was identified: 7.17% aluminum; 91.11% titanium; 1.73% vanadium (spectrum 5). Intermetallic compounds are visible along the boundaries: 4.51% aluminum; 84.25% titanium; 11.24% vanadium (spectrum 1); 4.81% aluminum; 82.18% titanium; 13.02% vanadium (spectrum 6); 5.39% aluminum; 81.64% titanium; 12.98% (at.) vanadium (spectrum 7).

Scientists from many countries have shown interest in studying the ternary diagram of titanium – aluminum – vanadium, since the alloys of this system are important for use in various fields of modern industry. Thus, in 2014, a work by Chinese scientists was published [21], in which the Al–Ti–V ternary system was studied. An analysis of 42 literary sources was carried out. Information about binary systems Al–Ti, Ti–V, Al–V is provided. Thermodynamic modeling was performed. Isothermal sections were constructed at 800, 900, 1000, 1100, 1200 °C. A good agreement was obtained between the experimental and calculated data. The phases of the ternary system have been clarified. The authors believe [21] that the work will make it possible to develop new alloys based on the Al-Ti-V system.

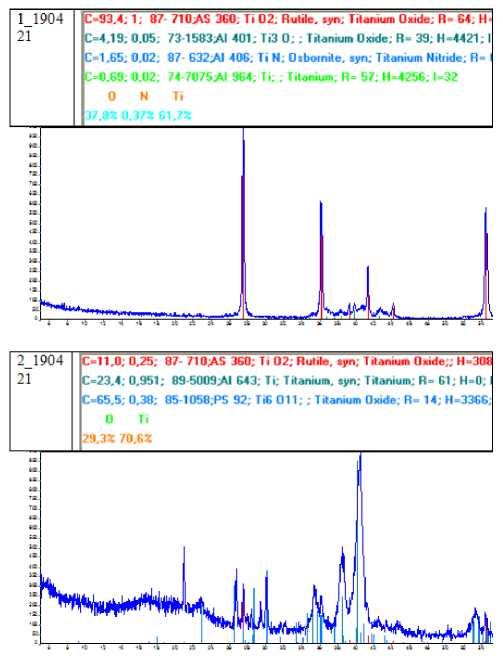

X-ray phase analysis. Powders of two samples were studied after oxidation using two technologies. Oxides TiO 2 , Ti 3 O, Ti 6 O 11 and titanium nitride TiN were discovered (Fig. 16). In the sample alpha-nized in graphite, TiO 2 , Ti 3 O, and TiN phases were detected in the surface layer. In the sample alpha-nized in vacuum – TiO 2 and Ti 6 O 11 .

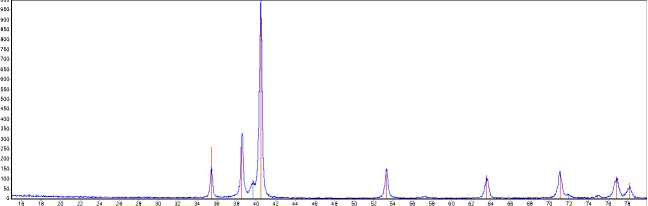

X-ray phase analysis was also performed at the center of the sample. The phases identified were Al 3 Ti 17 ((Al,V) 3 Ti 17 ) – 94.8%; Ti 0.7 V 0.3 – 5.2% (Fig. 17).

Fig. 16. X-ray phase analysis of the BT6 alloy after alphanizing in graphite medium (1) and in vacuum (2)

Рис. 16. Рентгенофазовый анализ сплава ВТ6 после альфирования в среде графита (1) и вакууме (2)

Al

8,57% 1,62% 89,7%

......

C=94,8; 1; 77-6855;PB 681; ( AI3 TH 7 J8.1; ; Aluminum Titanium; R = 83; H=4«1; 1=341 Э

C=5,19; 8,888; 81-8817;PI 966; Ti8.7 VB.3; ; Titanium Vanadium; R= 86; H=8; 1=3486254

Fig. 17. X-ray phase analysis of the BT6 alloy (center)

Рис. 17. Рентгенофазовый анализ сплава ВТ6 (центр)

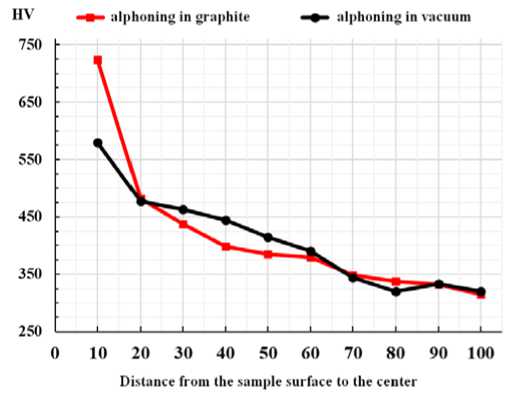

Microhardness study. It has been established that chemical-thermal treatment contributes to a significant increase in microhardness in the diffusion layer (Fig. 18).

Alphanizing in graphite made it possible to obtain microhardness HV724 at a distance of 10 μm from the surface. Then the microhardness values decrease and at a distance of 100 µm the microhardness is HV315.

Alphanizing in vacuum made it possible to obtain microhardness HV580 at a distance of 10 μm from the surface. Then the microhardness values decrease and at a distance of 100 µm the microhardness is HV320.

Fig. 18. Microhardness of the BT6 alphanized alloy

Рис. 18. Микротвердость альфированного сплава ВТ6

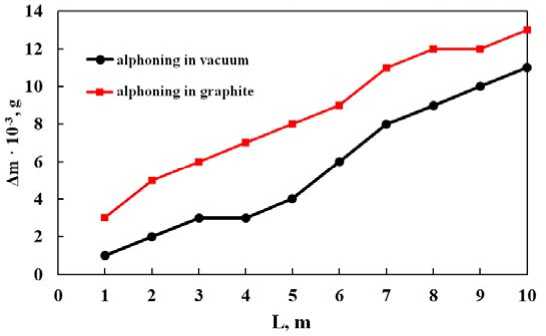

Wear resistance research. The test results are presented in Fig. 19.

Research has revealed that alphanizing using two technologies ensures the wear resistance of the product, but the best result is obtained after alphanizing in a vacuum.

Fig. 19. Loss of sample mass (Δm) of the BT6 alloy at abrasive wear path length (L) of 1–10 m after alfanizing in graphite and in vacuum

Рис. 19. Потеря массы образца (Δm) сплава ВТ6 при длине пути абразивного износа (L) 1–10 м после альфирования в графите и вакууме

Conclusion

-

1. The phase composition and structure of the BT6 alloy after alphanizing have been determined:

– TiO 2 phases were found in the diffusion layer after alphanizing in graphite; Ti 3 O; TiN, after al-phanizing in vacuum – TiO 2 ; Ti 6 O 11 ;

– in the alphanized layer after processing in graphite, grains of α – solid solution, Ti-Al-V, Ti-V and Ti-Al intermetallic compounds were identified; after treatment in vacuum, more titanium is contained, areas with 100 at.% titanium are also identified, a solid solution region (α) and Ti-Al-V, Ti-V and Ti-Al intermetallic compounds are visible.

-

2. It has been established that chemical-thermal treatment (alphanizing) contributes to a significant increase in microhardness in the diffusion layer.

-

3. Research has revealed that alphanizing in graphite and vacuum ensures wear resistance of the product, but the best result is obtained after alphanizing in a vacuum.

-

4. Alphanizing using two technologies helps to obtain diffusion layers with a thickness of more than 40 microns (as required by design documentation), leads to an increase in microhardness and wear resistance. However, it can be recommended that the alphanizing of the BT6 alloy be carried out in a vacuum, since this technology is carried out for 2 hours instead of 8 hours (in graphite).

The thickness of the oxidized layer is on average 103.6 microns (graphite), and in a vacuum – 66.8 microns. The average grain size in the layer is 17.2 microns (graphite); 6.0 µm (vacuum).

Alphanizing in graphite made it possible to obtain HV724 (10 µm) on the surface. Then the microhardness values decrease and at a distance of 100 µm the microhardness is HV315.

Alphanizing in a vacuum made it possible to obtain HV580 (10 µm) on the surface. Then the microhardness values decrease and at a distance of 100 µm the microhardness is HV320.

Список литературы Study of the influence of alphanizing on the structure and properties of the alloy BT6

- Belov S. P., Brun M. Ya., Glazunov S. G. et al. Metallovedenie titana i ego splavov [Metallurgy of titanium and its alloys]. Moscow, Metallurgiya Publ., 1992, 352 p.

- Il`in A. A., Kolachev B. A., Pol`kin I. S. Titanovy`e splavy`. Sostav, struktura, svojstva. Spravochnik [Titanium alloys. Composition, structure, properties. Handbook]. Moscow, VILS-MATI Publ., 2009, 520 p.

- Vul`f B. K. Termicheskaya obrabotka titanovy`kh splavov [Heat treatment of titanium alloys]. Moscow, Metallurgiya Publ., 1969, 376 p.

- Borisova E.A., Bochvar G.A., Brun M. Ya. et al. Titanovy`e splavy`. Metallografiya titanovy`kh splavov: monografiya [Titanium alloys. Metallography of titanium alloys: monograph]. Moscow, Metallurgiya Publ., 1980, 464 p.

- Aleksandrov V. K., Anoshkin N. F., Bochvar G. A. et al. Titanovy`e splavy`. Polufabrikaty` iz titanovy`kh splavov: monografiya [Titanium alloys. Semi-finished products from titanium alloys: monograph]. Moscow, Metallurgiya Publ., 1979, 512 p.

- Vozdvizhenskij V. M., Zhukov A. A., Postnova A. D., Vozdvizhenskaya M. V. Pod obshh. red. V. M. Vozdvizhenskogo. Splavy` czvetny`kh metallov dlya aviaczionnoj tekhniki [Non-ferrous metal alloys for aviation technology]. Ry`binsk: RGATA Publ., 2002, 219 p.

- Titan i ego splavy [Titanium and its alloys]. Moscow, Izdatel`stvo AN SSSR Publ., No. 1, 1958, 209 p.

- Chechulin B. B., Ushkov S. S., Razuvaeva I. N., Gol`dfajn V. N. Titanovy`e splavy` v mashinostroenii [Titanium alloys in mechanical engineering]. Moscow, Mashinostroenie Publ., 1977, 248 p.

- Petzow Ed. G., Effenberg G. Troyney splavy [Ternary Alloys]. Weinheim, VCH, 1990, Vol. 3, 646 p.

- Matchin I. E. [Alfalfing of titanium alloys in vacuum]. Мaterialy XXIII Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials XXIII Intern. Scientific. Conf “Reshetnev reading”]. Krasnoyarsk, 2019, Ch. 1. P. 262–263. (In Russ.)

- Che`n Zhuj [Influence of alphanizing and nitriding of BT6 alloy on the structure, coating thickness and hardness of the processing zone]. Мaterialy Vserossiyskaya nauchno-tekhnicheskaya konferencziya studentov. Studencheskaya nauchnaya vesna 2017: Moskovskiy gosudarstvenny`y tekhnicheskiy universitet im. N. E`. Baumana. Moscow, 2017, P. 1–2. (In Russ.)

- Prokop`ev I. V., Zhukovskij V. B. [Creation of wear-resistant coating of titanium alloy parts by surface alphoning] Мaterialy XVII Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials XVII Intern. Scientific. Conf “Reshetnev reading”]. Krasnoyarsk, 2013, Ch. 2. P. 435. (In Russ.)

- Andreeva N. A., Dneprovskaya T.I., Trusevich S.N. Sposob polucheniya iznosostojkikh pokry` tiy na poverkhnosti izdeliy iz titana i ego splavov [Method of obtaining wear-resistant coatings on the surface of products made of titanium and its alloys]. Patent RF, No. 2550674, 2015.

- Ry`zhenkov I. N., Kolachev B. A., Danilov Yu. P., Kiseleva A. B. Sposob oksidirovaniya titanovy` kh splavov [Method of oxidation of titanium alloys]. A.s. SSSR, No. 816195, 1979 (2006).

- Siva Rama Krishna D., Brama Y. L., Sun Y. [Thick rutile layer on titanium for tribological applications]. Tribology International. 2007, Vol. 40, P. 329–334.

- Yang H., Qian Z., Zhou X. Ju, Don H. [Effect of surface treatment by ceramic conversion on the fretting behavior of NiTi shape memory alloy]. Tribology Letters. 2007, Vol. 25, No. 3, P. 215–224.

- GOST 19807–91. Titan i splavy` titanovy`e deformiruemy`e. Marki [Titanium and titanium alloys are deformable. Brand]. Moscow, Standartinform Publ., 1992. 6 p.

- GOST 9450–76. Izmerenie mikrotverdosti vdavlivaniem almazny`kh nakonechnikov (s Izmeneniyami N 1, 2) [Measurement of microhardness by indentation of diamond tips (with Changes N 1, 2)]. Moscow, Standartinform Publ., 1993. 31 p.

- Diagrammy` sostoyaniya dvojny`kh metallicheskikh sistem: spravochnik: V 3t.: T.3. Kn.1 / pod obshh. red. N. P. Lyakisheva. [Diagrams of the state of double metal systems: handbook: B 3t.: T.3. Kn.1 / pod obshch. red. N. P. Lyakisheva]. Moscow, Mashinostroenie Publ., 2001, 872 p.

- Murray J. L., Wriedt H. A. Bull. Alloy Phase Diagrams. 1987, Vol. 8, No. 2, P. 148–165.

- Livshits, B. G. Metallography. Moscow, Metallurgy Publ., 1990, 336 p.

- Lu X., Gui Na, Qiu A., Wu G., Li C. [Thermodynamic Modeling of the Al-Ti-V Ternary System]. Metallurgical and Materials Transactions A. 2014, August, 10 P. DOI: 10.1007 / s11661-014-2317-y.