Study of the influence of hybrid filler on the strain sensitivity of a nanocomposite material

Автор: Semenukha O.V., Voronina S.Yu., Fesik S.A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.25, 2024 года.

Бесплатный доступ

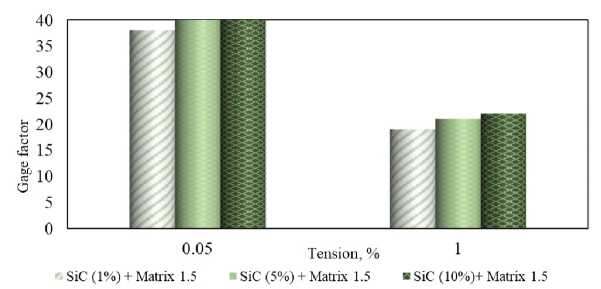

The reflector of spacecraft is in operation in the unfolded and folded position, thus an urgent task is to develop strain gauges that determine the position of the reflector. The paper presents a study of the influence of hybrid filler on the value of the strain resistance coefficient of a flexible strain-resistive element made of a nanocomposite material and describes the technological process of its manufacture using the vacuum infusion method. As hybrid filler, a composition containing an electrically conductive component (carbon nanotubes) and a solid component (silicon carbide), which promotes uniform distribution of the filler in the polymer matrix, were used. Using a rotational rheometer, the content of the carbon nanotubes (CNTs), at which the limiting level of viscosity for impregnation of glass fiber with a binder is achieved, was determined. The distribution features of the filler in the nanocomposite material were studied using a scanning electron microscope at the Krasnoyarsk Regional Centre for Collective Use of the Federal Research Centre KSC SB RAS. In the course of the work, the influence of the content of hybrid filler on the strain-resistive properties of the nanocomposite material was determined. The maximum values of the strain resistance coefficient were observed at the initial stage of the study (0.05 % tension): at 0.1 mm tension at a total length of 200 mm for the samples of a nanocomposite material with SiC hybrid filler of 1, 5 and 10 % and is 38, 40 and 40. The strain resistance coefficient of the nanocomposite material samples containing 1, 5 and 10 % SiC hybrid filler at maximum tensile (1 %) is approximately 19, 21 and 22 respectively.

Polymer composite material (PCM), strain-sensitive sensor, nanocomposite material, condition monitoring of transformable structures, carbon nanotubes, carbon fiber filler

Короткий адрес: https://sciup.org/148329739

IDR: 148329739 | УДК: 621.01 | DOI: 10.31772/2712-8970-2024-25-2-256-263

Текст научной статьи Study of the influence of hybrid filler on the strain sensitivity of a nanocomposite material

Modern trends in the development of space communication, navigation, radiolocation, and astronomy systems have led to the need for large-size space deployable antennas. In the course of the development of such designs there is an increasing interest in improving the fabrication and stacking of the radio reflective surface in the transport position of a transformable reflector with different apertures. When selecting a material for fabricating reflector segments having a flexible surface, composite materials based on the elastic binder polymethyldisiloxane draw attention. The most important requirements are stability of physical and mechanical properties of the material at a large temperature difference from -150 to +150 °C, optical transparency in any frequency band, and the possibility of elastic deformation of the material without destruction to ensure the deployment of space antennas.

The data on the condition and position of the reflector is collected by using the sensor systems mounted on the structural elements. Mechanical loads on the structural elements can be monitored by strain gauges. In order to measure strain, stress or force with a strain gauge sensor, the phenomenon of the effect of elastic deformation of a wire or semiconductor rod on the resistance of the sensor material is used [1]. Generally, conventional strain gauges made of metal foil and semiconductors can only detect low strains due to their limited tensile capability (approximately ~0.07 %) [2]. In order to increase sensitivity, strain gauges are made of composite materials where the polymer matrix is filled with carbon nanotube (CNT) particles, graphene or structural composites of ceramics and metals. This allows specialists to significantly increase the elasticity coefficient and increase the strain range that can be measured by the sensor [3].

The introduction of filler into a polymer matrix changes the structure and properties of the material. Mastering effective methods of CNT introduction into a polymer material and determining the level of their influence on the quantitative results of the final product, as well as technical charts at the current moment is a relevant and primary task in the field of modern product development. It is evident that this technology will find wide application in the production of structures from functional polymethyldisiloxane materials [4; 5].

It is known that carbon nanoparticles and nanofibres have a complex of unique physical and chemical properties and are considered to be an ideal reinforcing material for polymers. The multifunctional CNT filler improves the mechanical properties of the material (stiffness, compressive strength boundary), improves electrical conductivity, increases thermal conductivity, heat resistance and gives nanocomposite materials a new functional ability. Nevertheless, a serious problem in obtaining nanocom- posite material is the difficulty of homogeneous distribution of CNTs in the volume of a polymer matrix and providing a stable adhesive bond with it. This problem is caused by the strong van der Waals interaction of CNTs among themselves and their tendency to aggregation [6].

Currently, the ultrasonic method is mainly used to obtain a stable nanocomposite material with dispersed CNTs [7-9]. For effective distribution of particles in the volume of a polymer matrix, it is often combined with other dispersion methods:

-

– method including mechanical and ultrasonic dispersion;

-

– mechanical and ultrasonic dispersion with the addition of solid filler as a grinding agent within the polymer matrix volume;

-

– ultrasonic dispersion using a magnetic stirrer.

The sensitivity of nanocomposite materials is influenced by the method of dispersion of filler in the polymer matrix. This indicates that with the help of this factor it is possible to change physicalmechanical, thermophysical, optical, electromagnetic and other performance characteristics of a nanocomposite material. Previously, we treated SiC using the technique described in [10]. The treatment of SiC resulted in the increase of functional groups on the surface of the particles, which contributed to the enhancement of interfacial interaction between the filler particles and the polymer. A properly selected method of introduction contributes to the uniform distribution of nanotubes throughout the volume of the polymer matrix, improving their dampening and adhesion and, consequently, improving the characteristics of the nanocomposite material [11].

The aim of this study is to develop a technology for manufacturing a flexible strain-resistive element made of a hybrid composite material for monitoring the state of transformable structures with the level of the strain resistance coefficient not less than 10.

Over the course of developing the manufacturing technology of flexible strain-resistive element it is necessary to solve the following tasks:

-

– development of a technique for the introduction of filler for its uniform distribution in polymethyldisiloxane;

-

– development of nanocomposite material manufacturing technology;

-

– study of the influence of fillers on the strain resistance coefficient of a nanocomposite material under tension;

-

– fabrication of a flexible strain-resistive element based on a nanocomposite material.

The subject of the work is the manufacturing technology of a flexible strain-resistive element made of nanocomposite material.

Experiment

In this study, the samples of the nanocomposite material consisting of polymethyldisiloxane, T-53 glass fabric, silicon carbide (SiC) fraction F1200 (grain size: 2.5-3.5 μm) and Matrix 603 - CNT concentrate containing 10 % of CNTs from the total concentrate composition were used. The glass fabric was pre-treated with the APTES solution in chloroform to provide increased adhesion of polymethyldisiloxane to the fibre filler. Matrix filler was introduced into the matrix to give the material electrically conductive properties. SiC was introduced as a stirring agent (for additional grinding of CNTs throughout the volume of the binder and preventing their agglomeration). Thus, hybrid filler is a mixture of electrically conductive (CNTs) and grinding agent (SiC). Moreover, the addition of microfiller (SiC) reduces free space of the binder available to nanofiller (in our case CNTs) to form conductive networks. In a number of studies, the use of hybrid filler increases the electrical conductivity, as CNTs cannot diffuse into microfiller, which is a solid particle [12; 13].

In this paper, the technology of introducing fillers into the matrix, which we described earlier [14], was taken as a basis.

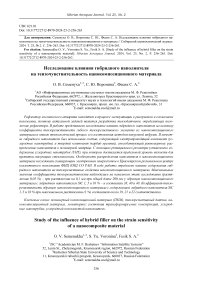

The nanocomposite samples were manufactured using a vacuum infusion method: glass fiber fabric was impregnated with a mixture consisting of polymethyldisiloxane and hybrid filler in a mould with subsequent curing in a desiccator at 120 ˚C for 30 min. Fig. 1 shows the technological scheme of manufacturing a flexible strain-resistive element made of a nanocomposite material.

Рис. 1. Технологическая схема изготовления гибкого тензорезистивного элемента из нанокомпозиционного материала

Fig. 1. Technological scheme of manufacturing a flexible strain-resistive element made of a nanocomposite material

The morphological features of the nanocomposite material were visualised at the Krasnoyarsk Regional Collective Use Centre of the Federal Research Centre KSC SB RAS using a high-resolution scanning electron microscope (SEM).

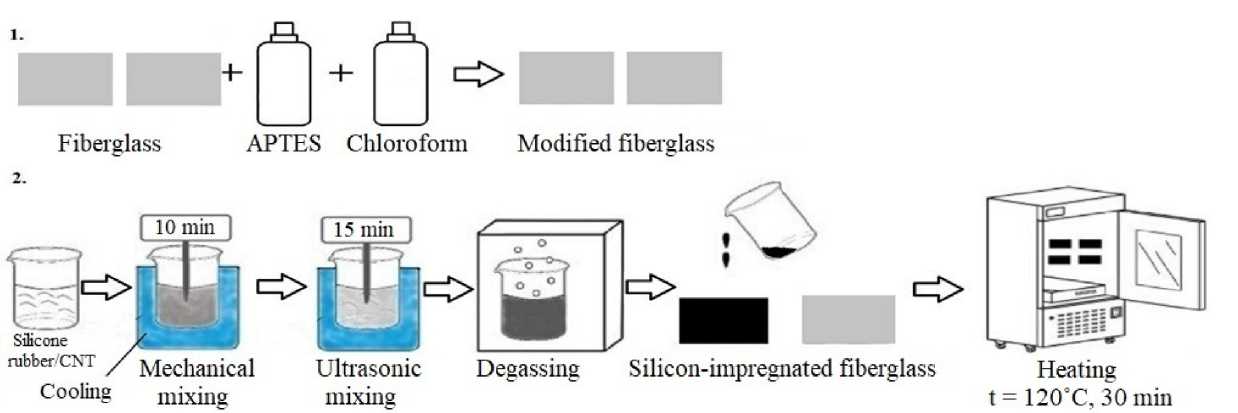

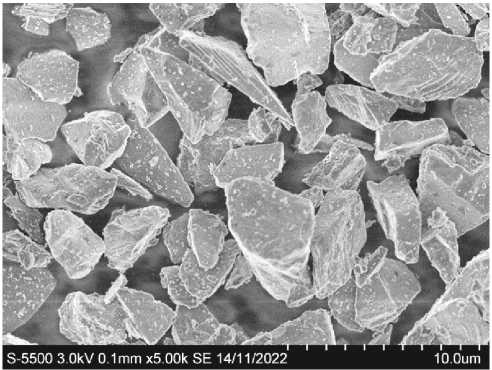

Fig. 2 shows a micrograph of the SiC filler, Fig. 3 depicts a sample of a nanocomposite material with hybrid filler.

Рис. 2. СЭМ микрофотография наполнителя SiC

Рис. 3. СЭМ микрофотография образца нанокомпози-ционного материала с гибридным наполнителем

Fig. 2. SEM micrograph of the SiC filler

Fig. 3. SEM micrograph of the sample of a nanocomposite material with hybrid filler

The technology and quality of reinforcing filler impregnation significantly depend on the viscosity of a polymer binder; therefore, in this work, the influence of the hybrid filler content on the viscosity of the uncured matrix for nanocomposite material fabrication technology was studied. It is known that the maximum binder viscosity allowing vacuum infusion is 300 mPa×s [15-17]. The results of determining the viscosity of the modified polymer matrix and initial polymethyldisiloxane were obtained. The determination of the dependence of viscosity on shear rate was carried out in the range of rotor frequency variation from 0.01 to 100 Hz. The samples were tested at a temperature of 25 °C using a rotary rheometer. It was revealed that at the content of 0.15 % CNTs the ultimate viscosity level (250 mPa×s) possible for binder impregnation of glass fibre by vacuum infusion was reached. Given this, the content of 0.15 % CNTs in the hybrid filler was used for further work, since the viscosity of the filled polymer system was 350 mPa×s at a content of 0.2 % CNTs. In the works by I. A. Timoshkin, the maximum viscosity of the binder, allowing vacuum infusion, which is 300 mPa×s, is given. The latter value significantly exceeds the maximum viscosity of the binder and does not allow obtaining a composite sample with qualitative impregnation [15-17]. The samples of a nanocomposite material with the following hybrid filler content were obtained:

– CNT 0.15 %, SiC 1 %;

– CNT 0.15 %, SiC 5 %;

– CNT 0.15 %, SiC 10 %.

The performance of a strain-resistive element is characterised by the strain resistance coefficient (K):

A R

R

K -Al ’

L where R and L are resistance and length of the strain-resistive element in the absence of tension respectively; ΔR and ΔL are the changes of resistance and length of the strain-resistive element under tension.

Fig. 4 shows the dependence of the strain resistance coefficient of the nanocomposite material samples on tension (up to 2 mm). The samples were composite plates with the size of 200×20 mm and the thickness 0.3 mm.

Рис. 4. Зависимость коэффициента тензорезистивности ( К ) образцов нанокомпозиционного материала с гибридным наполнителем SiC 1, 5 и 10 % от растяжения

Fig. 4. Dependence of the strain reseistance coefficient ( С ) of the samples of a nanocomposite material with SiC hybrid filler of 1, 5 and 10 % on tension

The maximum value of the strain resistance coefficient was observed at the initial stage of the study (0.05 % tension): at 0.1 mm tension at a total length of 200 mm in the samples of the nanocomposite material with hybrid filler SiC 1, 5 and 10 % and is 38, 40 and 40 respectively. The strain resistance coeffi- cient of the nanocomposite material samples with SiC hybrid filler content of 1, 5 and 10 % at maximum tension (1 %) is about 19, 21 and 22 respectively.

Fig. 5 shows the obtained flexible strain-resistive element based on a nanocomposite material with hybrid filler.

Conclusion

The technology of manufacturing a flexible strain-resistive element has been developed. The following tasks were solved to develop the technology:

Рис. 5. Гибкий тензорезистивный элемент из нанокомпозиционного материала

Fig. 5. Flexible strain-resistive element made of a nanocomposite material

– the method of filler introduction for its uniform distribution in polymethyldisiloxane was developed;

– the influence of hybrid filler on the strain resistance coefficient of nanocomposite materials was studied. The highest strain resistance coefficient was recorded for the samples containing 0.15 % CNT, 5 % SiC and 0.15 % CNT, 10 % SiC and it was 40 and 40 respectively at 0.1 mm tension (0.05 % of the total length of the 200 mm sample).

Работа выполнена в рамках государственного задания Минобрнауки России на выполнение коллективом научной лаборатории «Интеллектуальные материалы и структуры» проекта «Разработка многофункциональных интеллектуальных материалов и структур на основе модифицированных полимерных композиционных материалов, способных функционировать в экстремальных условиях» (Номер темы FEFE-2020-0015).

Acknowledgment

The work was carried out within the framework of the state assignment of the Ministry of Education and Science of Russia for the implementation of the project “Development of multifunctional intelligent materials and structures based on modified polymer composite materials capable of functioning in extreme conditions” by the team of the scientific laboratory “Intelligent Materials and Structures” (theme № FEFE-2020-0015).

Список литературы Study of the influence of hybrid filler on the strain sensitivity of a nanocomposite material

- Khanin M. V., Zaitsev G. P. Iznashivanie i razrushenie polimernyh kompozicionnyh materialov [Wear and destruction of polymer composite materials]. Moscow, Himiya Publ., 1990, 256 p.

- Khoshev A. V. [Strain-resistive films and their application in pressure sensors]. Sovremennaja tehnika i tehnologii. 2014. No. 10. P. 59–65 (In Russ.).

- Bazhenov S. L. Mehanika i tehnologija kompozicionnyh materialov [Mechanics and technology of composite materials]. Moscow, Intellekt Publ., 2014, 328 p.

- Bataev A. A., Bataev V. A. Kompozicionnye materialy [Composite materials]. Moscow, Universitetskaja kniga, Logos Publ., 2006, 400 p.

- Kraev I. D., Popkov O. V., Shuldeshov E. M., Sorokin A. E., Jurkov G. Ju. [Prospects for the use of organosilicon polymers in the creation of modern materials and coatings for various purposes]. Trudy VIAM. 2017, No. 12, P. 46–60 (In Russ.).

- Solomonov Yu. Metody rascheta cilindricheskih obolochek iz kompozicionnyh materialov [Methods for calculating cylindrical shells made of composite materials]. Moscow, Fizikomatematicheskaja literature Publ., 2009, 910 p.

- Tkachev A. G., Melezhik A. V., Dyachkova T. P. Sposob modificirovanija uglerodnyh nanomaterialov [Method for modifying carbon nanomaterials]. Patent RF, No. 2548083, 2013.

- Chervinskaya A. S. [The influence of ultrasonic treatment on the dielectric constant of composites based on water-dispersed paint and MWCNTs]. Trudy materialov Chetvertogo Rossiyskogo Belorusskogo seminara “Uglerodnye nanostruktury i ikh elektromagnitnye svoystva” [Proc. 4th Russian Belarusian Semin. “Carbon nanostructures and their electromagnetic properties”]. Tomsk, 2019, P. 29–32 (In Russ.).

- Mikitaev A. K., Kozlov G. V. [Effect of ultrasonic treatment on the structure of carbon nanotubes in polymer nanocomposites]. Fizika i khimiya obrabotki materialov. 2015, No. 2, P. 80–83 (In Russ.).

- Flerko M. Yu., Voronina S. Yu., Antishin D. V., Shalygina T. A., Semenukha O. V. A method for modifying the surface of silicon carbide with a controlled number of functional groups on surface. Journal of Advanced Materials and Technologies. 2022, Vol. 7, No. 4, P. 281–289.

- Sheryshev M. A., Tikhonov N. N. Organizaciya i proektirovanie predpriyatiy pererabotki plastmass [Organization and design of plastics processing enterprises]. St.Petersburg, Professiya Publ., 2018, 384 p.

- Bao H.-D., Guo Z.-X. Effect of electrically inert particulate filler on electrical resistivity of polymer/multi-walled carbon nanotube composites. Polymer (Guildf). 2008, Vol. 49, P. 3826–3831.

- Yang D., Tao J.-R., Yang Y., He Q.-M., Weng Y.-X., Fei B., Wang M. Effect interfacial size and multiple interface on electromagnetic shielding of silicon rubber/carbon nanotube composites with mixing segregated particles. Compos. Struct. 2022, Vol. 292, P. 115.

- Grebennikov E. V., Voronina S. Yu., Simunin M. M., Semenukha O. V. [The role of the method of introducing carbon nanotubes on the tensor resistivity coefficient]. Reshetnevskie chteniya : materialy XXVI Mezhdunar. nauch.-prakt. konf. [Reshetnev readings: materials of the XXVI Intern. scientific-practical. conf.]. Krasnoyarsk, 2022, No. 1, P. 648–650 (In Russ.).

- Timoshkin I. A., Aleshkevich, V. V., Afanas'eva E. S., Bulgakov B. A., Babkin A. V., Kepman A. V., Avdeev V. V. Heat-resistant carbon plastics with matrices based on a copolymer of bis-phthalonitriles and bis-benzonitrile]. Vysokomolekulyarnye soedineniya. 2020, Vol. 62, No. 2, P. 174–185 (In Russ.).

- Youns W. I. Poliuretanovye kompozity, poluchennye s pomoshh'ju vakuumnoj infuzii [Polyurethane composites obtained using vacuum infusion]. Patent RF, No. 2598608, 2012.

- Nelyub V. A., Buyanov I. A., Borodulin A. S., Chudnov I. V., Aleksandrov I. A., Muranov A. N., Kuznetsova M. N. Jepoksidnoe svjazujushhee dlja polimernyh kompozicionnyh materialov [Epoxy binder for polymer composite materials]. Patent RF, No. 2527086, 2014.