Study on heat transfer performance of non-integral capillary core sintered uniform plate

Автор: Jiang Weiyu, Sun Lili, Mao Jijin, Zhang Donghui, Levtsev Aleksei

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 5 т.7, 2021 года.

Бесплатный доступ

This paper mainly introduces the sintering process of the monolithic capillary wick and analyzes the influence of different copper powder particle size, filling rate, copper powder shape and heat source size on the heat transfer performance of the isothermal plate. The experimental results show that: (1) For the isothermal plate sintered with spherical copper powder, the capillary force of large particle size copper powder is small, but the flow resistance is also small, and the performance of the isothermal plate sintered with large particle size copper powder is better. (2) In the case of low filling rate, the isothermal plate is dried due to insufficient return fluid. In the case of high filling rate, on the one hand, the thickness of the liquid film at the evaporation end of the isothermal plate is large, resulting in additional thermal resistance. On the other hand, the thin film evaporation mode will be transformed into pool boiling mode, which will reduce the heat transfer performance. (3) Spherical copper powder sintered plate with regular shape has the best performance, while dendritic copper powder sintered plate has relatively high thermal resistance. (4) The heat source area has a great influence on the thermal resistance of the plate. Under the same heating power, the thermal resistance of the small area heat source is much higher than that of the large area heat source; The thermal resistance of sintered copper plate is lower than that of pure copper plate under two heat source areas.

Uniform plate, non-holonomic capillary core, copper powder sintering and heat transfer performance

Короткий адрес: https://sciup.org/14120544

IDR: 14120544 | УДК: 581.5, | DOI: 10.33619/2414-2948/66/28

Текст научной статьи Study on heat transfer performance of non-integral capillary core sintered uniform plate

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 581.5; 631.4

Since the 21st century, with the continuous development of modern electronic technology, electronic components show the trend of miniaturization and high performance. Because electronic components have the characteristics of high calorific value, it will increase the temperature and reduce its performance. Generally, the heat power of the chip in each area of the electronic equipment is different, so the thermal stress on the surface of the chip is different, which is easy to reduce or even damage the performance of the electronic equipment, and the local high temperature hot spots are easy to burn the electronic device. Compared with the traditional heat pipe, from the analysis of the heat transfer path, the heat transfer of the heat pipe is in the one-dimensional direction. The uniform temperature plate realizes the heat transfer in the two-dimensional plane, which can effectively solve the ‘hot spot’ problem of electronic devices.

Tang Yong et al. [1] prepared a new type of sintered copper mesh core by weaving, chemical deposition and sintering. Alkali-assisted surface oxidation process [2] was used to treat the wick structure. The experimental results show that the sintering process is conducive to enhancing the adhesion strength of the surface structure. The capillary force of the deposited capillary core structure is greater than that of the normal capillary core. Through the deposition time of about 15 min and the sintering temperature of about 500 °C, the deposited liquid wick can achieve the best heat transfer performance. Lewis et al. [3] used polyimide film as coating material and lithography technology to manufacture the wick structure. The thickness of the wick was only 0.3 mm, and TiO2 was deposited on the surface of the wick by ALD process, which played a hydrophilic role. Under the condition that 0.15 ml water was filled in the ultra-thin hot pipe, the heater area was 20 mm×10 mm, and the minimum thermal resistance measured in the experiment was 11.92 °C/W, and the effective thermal conductivity was as high as 541 W/(mK).

Li et al. [4–5] prepared a new type of wick structure, which is sintered from 50μm to 100μm mixed copper powder with thickness less than 1mm, and the total thickness of the copper-water flat heat pipe is 2mm. The effects of different heating power, inclination angle and cooling water temperature on the heat transfer performance of flat heat pipe were experimentally studied. The experimental results show that the maximum input power of the flat heat pipe in the horizontal direction is 120 W, and the minimum thermal resistance is only 0.196 ℃/W. Weibel et al. [6] made an ultra-thin nanostructured temperature plate. The liquid wick adopts a 200 μm thick copper powder sintering structure, and the carbon nanotubes (CNTs) shape is made into a mosaic array structure to enhance the ability of filling liquid in the cavity to infiltrate the liquid wick. The thickness of the isothermal plate is only lmm.

Test System for Heat Transfer Performance of Nonholonomic Capillary Core Isothermal Plate

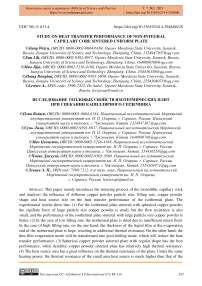

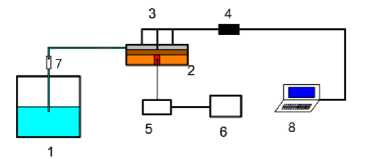

The heat transfer performance test system mainly includes four parts: heating system, water cooling system, temperature plate, data acquisition system. In the isothermal plate performance test device, the clamping device is composed of two aluminum plates with a thickness of 30 mm, and the corners are fixed and tightened by M16 bolts, so that the middle part can be closely contacted. Wood insulation materials are arranged at the bottom of the plate and the top of the cooling water jacket to reduce heat loss. The temperature is set in the low-temperature tank. After the water is cooled, the circulating pump is opened to produce the cooling water. The flow rate is determined by adjusting the rotor flowmeter, and then enters into the cooling water jacket cavity, and the heat on the surface of the homogenizer is taken away. The temperature measuring device adopts armored thermocouple, connected with intelligent temperature inspector, and finally reads data on the computer, so as to complete the whole temperature measurement process.

Figure 1. Experimental system schematic 1. Low temperature water tank 2. Experimental test section 3. Armored thermocouple 4. Temperature inspection instrument 5. Voltage regulator 6. Power supply 7. Rotor flowmeter 8. Computer

Figure 2. Vapor chamber testing system 1. Aluminum plate fixtures 2. Hard insulation materials 3. Cooling water jacket 4. Uniform plate 5. Heated copper block 6. Fastener bolts

Sintering process of non-integrated capillary core isothermal plate

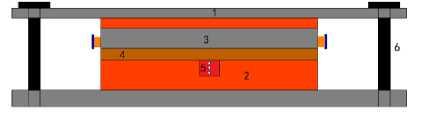

The main process of sintering process is as follows: the sintered copper powder liquid suction core is closely bonded to the off-duty, and the foamed copper is closely bonded to the upper plate. They are respectively tightened with fixtures and placed horizontally in the vacuum sintering furnace. Then the furnace door is closed for the next washing, and the vacuum is pumped to 0.05 Pa. After that, nitrogen is passed, vacuum is pumped again, and nitrogen is passed again, and hydrogen is passed. After setting the program, the switch is opened to start sintering. The sintering temperature is 950 °C, and the holding time is set to last for 3 hours. After sintering, the furnace door can be opened and the sample can be taken out under the condition of vacuum cooling in the sintering furnace, as shown in Figure 3.

The sintered wick was placed in the shell plate, and then the solder was placed between the upper and lower shell plates. The whole device was fixed with a fixture and placed horizontally in a vacuum sintering furnace. The sintering process was the same as before, but the maximum temperature set during sintering was 780 °C. When the temperature rose to 780 °C, it immediately entered the natural cooling stage.

( a ) Evaporation end

Figure 3. Capillary core combined with outer shell

( b ) condensation end

Taking the sintered copper powder structure as the lower wick and the foam copper structure as the upper wick, the influence of different wick structure and filling rate on the heat transfer performance of the isothermal plate was studied. The effects of different copper powder shapes on the heat transfer performance of the isothermal plate were studied. The heat transfer performance of the plate under different heating power was studied.

Experimental study on heat transfer performance of non-holonomic wicked plate

Experimental research content

The experimental research in this section is mainly divided into four parts:

Particle size parameter experiment of sintered copper powder

A total of 14 thermostats were prepared in this study. The particle sizes of spherical copper powder were 30 μm, 50 μm, 30 μm, 30 μm+90 μm, and the particle sizes of dendritic copper powder were 30 μm and 50 μm, respectively. The experimental data of the thermostats with the best performance were recorded after the test of each thermostat.

Filling rate parameter experiments

In this experiment, there are four isothermal plates sintered with spherical copper powder. The porosity of 30μm, 50μm, 90μm and 30μm + 90μm isothermal plates are 48.5%, 52.6%, 40.6% and 54.2%, respectively. The dendritic copper powder sintered temperature plate has two pieces, the porosity of 30μm and 50 μm is 74% and 71.1% respectively. The charging amount of uneven copper powder sintering temperature plate is shown in Table 1, and the charging amount of dendritic copper powder sintering temperature plate is shown in Table 2.

Table 1.

FILLING RATIO OF SPHERICAL COPPER POWDER SINTERED VAPOR CHAMBERS

|

70% 90% 120% |

|

|

30μm (g) |

2.91 3.75 5.00 |

|

50μm (g) |

2.92 3.76 5.00 |

|

90μm (g) |

2.47 3.18 4.24 |

|

30μm+90μm (g) |

3.25 4.18 5.58 |

Experiment of copper powder shape parameters

The research object of this experiment is the sintered copper powder type isothermal plate. In this experiment, four isothermal plates were produced. The shape of copper powder of the sintered isothermal plate was spherical and dendritic, and the particle sizes were 30 μm and 50 μm, respectively. The heat transfer performance of the four isothermal plates was compared and analyzed under the conditions of three filling rates of 70 %, 90 % and 120 %.

Table 2.

FILLING RATIO OF DENDRITIC COPPER POWDER SINTERED VAPOR CHAMBERS

|

70% |

90% |

120% |

|

|

30μm (g) |

3.17 |

4.07 |

5.43 |

|

50μm (g) |

2.71 |

3.48 |

4.64 |

Experiment of heat source size parameters

In this experiment, the copper plate sintered by spherical copper powder was selected, and the particle sizes were 30 μm and 50 μm, respectively. Two different sizes of heated copper blocks were designed: 15 mm×15 mm and 30 mm×30 mm, respectively. The heat transfer performance of the isothermal plate under different heat flux was compared and compared with the pure copper plate.

Experimental results and analysis

Effect of Sintered Copper Powder Particle Size on Experimental Performance of Uniform Temperature Plate

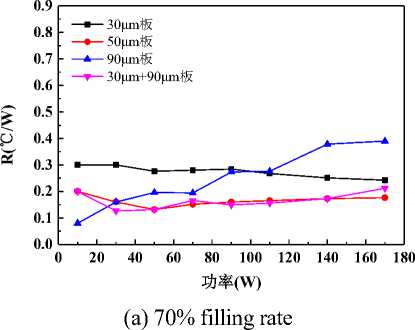

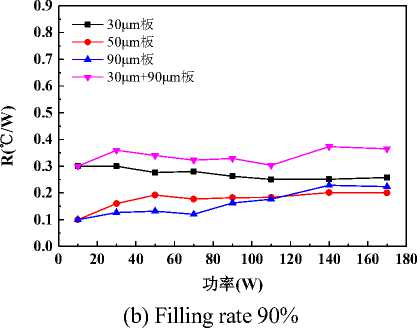

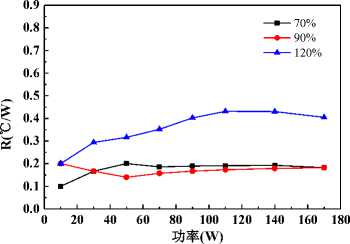

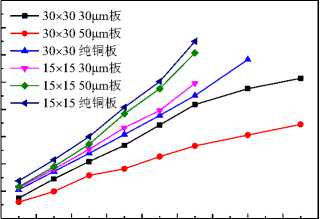

The thermal resistance of the plate made of four spherical copper powders varies with heating power as shown in Figure 4 (a–c). The heat source area is 30 mm×30 mm and the filling rates are 70%, 90% and 120%, respectively. The experimental results show that with the increase of heat flux, the thermal resistance values of the isothermal plates with different particle sizes under different filling rates change linearly. From the trend of curve, the performance of the larger particle size plate is relatively good. From the experimental results, it can be seen that the performance of the homogenized plate sintered with large particle size spherical copper powder is better, which indicates that the liquid return resistance has a greater influence on the thermal resistance performance of the homogenized plate made of spherical copper powder and plays a leading role.

(c) Filling rate : 120%

Figure 4. Thermal resistance of spherical copper powder sintered vapor chamber with heating power under different charging rates

Effect of filling rate on heat transfer performance of isothermal plate

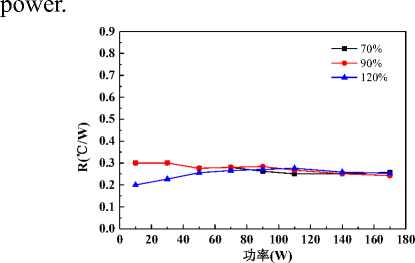

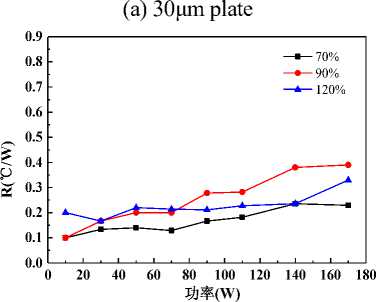

Sintered copper powder is spherical. Figure 5 shows the thermal resistance changes of 30pm, 50pm, 90pm and 30pm + 90pm isothermal plates, respectively. Three different filling rates are compared. It can be seen from the figure that with the increase of heat flux, the thermal resistance values of isothermal plates with different particle sizes change linearly under different filling rates.

For the 30 pm isothermal plate, the thermal resistance is slightly smaller when the filling rate is 120% and the heating power is low. With the increase of heating power, the thermal resistance almost remains unchanged, and the filling rate has little effect on the thermal resistance. For 50 pm and 90 pm isothermal plates, the thermal resistance value of the isothermal plate is relatively low under the condition of low filling rate. Because the particle size of copper powder increases, the capillary force decreases, the flow resistance is small, and the filling rate is too high. The liquid will be immersed in the suction core, and the liquid film will be thickened, which will bring additional thermal resistance. Moreover, the viscosity of the liquid is much higher than that of the gas, so the steam movement will be resisted, resulting in the phenomenon of carrying, and the reflux is blocked. The 30 pm+90 pm plate is made of mixed particle size, which can balance the capillary force and flow resistance. When the filling rate is 90%, the lowest thermal resistance of the plate is 0.13 °C/W.

It is found that when the heating power is 50W, the thermal resistance of 30 pm, 50 pm and90pm plates is relatively flat. It may be because only when the heating power reaches a certain condition, the working fluid inside the wick of the evaporation end will completely absorb heat and vaporize, and the thermal resistance is also slowly reduced in the process of normal heat transfer. However, when the heating power is about90 W, this phenomenon occurs in the 30 pm + 90 pm plate. Because the 30 pm+90 pm plate has a relatively large amount of filling under the condition of the same filling rate, it needs to improve the heating power to provide the heat needed for the normal operation of the plate, so it will appear gentle phenomenon under the condition of large

(c) 90μm plate (d) 30μm + 90μm plate

Figure 5. Thermal resistance of spherical copper powder sintered vapor chamber at different charging

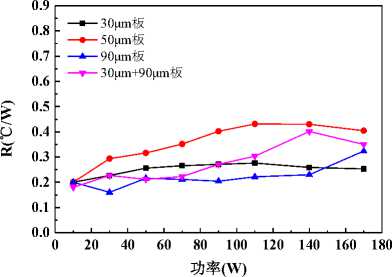

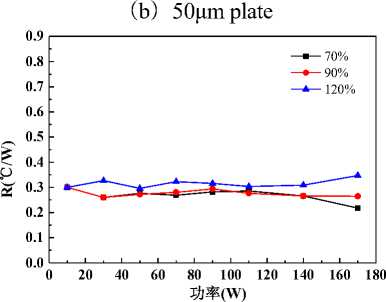

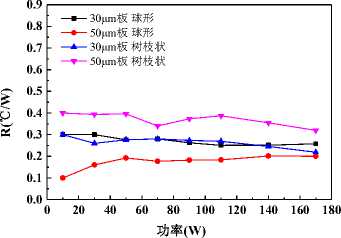

Effect of copper powder shape on heat transfer performance of isothermal plate

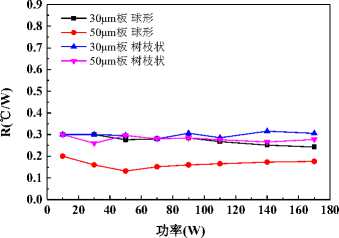

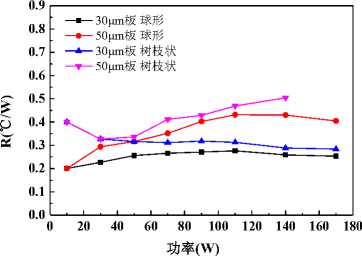

Figure 6 (a–c) shows the effect of copper powder shape on the performance of the isothermal plate under different filling rates. It can be seen from the figure (a) that the thermal resistance of the spherical 50 μm plate is smaller, the thermal resistance of the spherical and dendritic 30 μm plate is similar, and the thermal resistance of the dendritic 50 μm plate is poor. Figure (b) shows that the thermal resistance of the spherical 50 μm plate is the smallest, the performance of the dendritic 50 μm plate is the worst, and the others are similar. Figure (c) shows that the thermal resistance of spherical and dendritic 30 μm plate is relatively small. On the whole, the thermal resistance of the thermostat made of spherical copper powder is smaller than that of the thermostat made of dendritic copper powder at three filling rates, which may be due to the fact that the wick made of dendritic copper powder has more blind pores ( that is, the pores are not interconnected), thus the number of flow channels of the liquid working medium is reduced, the flow is blocked and the heat transfer performance of the thermostat is affected.

(a) Thermal resistance comparison of 70% plate

(b) Thermal resistance comparison of 90% isothermal plate

(c) Thermal resistance comparison of 120% isothermal plate

Figure 6. Comparison of the thermal resistance of vapor chamber under different charging rates

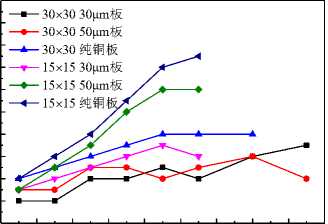

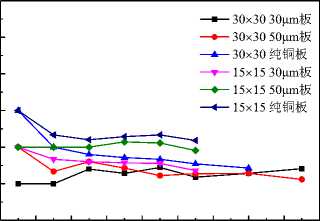

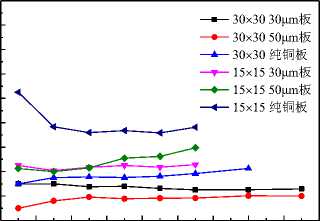

Effect of heat source size on heat transfer performance of isothermal plate

Figure 7 is the comparison of heat transfer performance between the uniform temperature plate and the pure copper plate made of copper powder with spherical shape, particle size of 30 pm and 50 pm under the conditions of two heat source sizes of 30x30 mm and 15 mm x 15 mm and filling rate of 70%.

It can be seen from the above figures that the failure power of the plate can reach 170 W under the condition of large heat source area, and the measured thermal resistance is smaller than that under the condition of small heat source area, because under the condition of the same heating power, the heat flux of the plate measured by large heat source area is relatively small, so the working fluid in the evaporation area is not easy to dry, and the liquid film is thin, so the thermal resistance value is low; The temperature uniformity of the plate is better than that of the pure copper plate, and the maximum temperature difference at the condensation end is small. The main reason is that the plate is sintered by copper powder, and the copper powder column (25 diameter is 3 mm) sintered by the wick at the evaporation end is connected with the rectangular convex ring of copper powder with a width of 2 mm around, so that there are more capillary channels and less reflux resistance, which greatly enhances the heat transfer ability, so the heat resistance value is small, which indicates that the process of the plate is effective.

-2

0 20 40 60 80 100 120 140 160 180

** (W)

(a) Maximum temperature difference comparison at condenser end

0.5

0.4

0.3

0 20 40 60 80 100 120 140 160 180

*^ (W)

(b) Comparison of isothermal thermal resistance at condensation end

0.0

-0.1

0 20 40 60 80 100 120 140 160 180

W(W)

(c) Comparison of surface temperature of heat source

g p

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 20 40 60 80 100 120 140 160 180

^^ (W)

(d) Comparison of thermal resistance of isothermal plate

Figure 7. Heat transfer performance of vapor chamber under different heat sources

Список литературы Study on heat transfer performance of non-integral capillary core sintered uniform plate

- Tang Y., Tang H., Li J., Zhang S., Zhuang B., Sun Y. Experimental investigation of capillary force in a novel sintered copper mesh wick for ultra-thin heat pipes // Applied Thermal Engineering. 2017. V. 115. P. 1020-1030. DOI: 10.1016/j.applthermaleng.2016.12.056

- Hu J., Yuan W., Yan Z., Zhou B., Tang Y., Li Z. Fabricating an enhanced stable superhydrophobic surface on copper plates by introducing a sintering process // Applied Surface Science. 2015. V. 355. P. 145-152. DOI: 10.1016/j.apsusc.2015.07.085

- Lewis R., Liew L. A., Xu S., Lee Y. C., Yang R. Microfabricated ultra-thin all-polymer thermal ground planes // Science Bulletin. 2015. V. 60. №7. P. 701-706. DOI: 10.1007/s11434-015-0760-9

- Li J., Lv L. Experimental studies on a novel thin flat heat pipe heat spreader // Applied Thermal Engineering. 2016. V. 93. P. 139-146. DOI: 10.1016/j.applthermaleng.2015.09.038

- Lv L., Li J. Effect of charging ratio on thermal performance of a miniaturized two-phase super-heat-spreader // International Journal of Heat and Mass Transfer. 2017. V. 104. P. 489-492. DOI: 10.1016/j.ijheatmasstransfer.2016.08.087

- Weibel J. A., Kousalya A. S., Fisher T. S., Garimella S. V. Characterization and nanostructured enhancement of boiling incipience in capillary-fed, ultra-thin sintered powder wicks // 13th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems. IEEE, 2012. P. 119-129. DOI: 10.1109/ITHERM.2012.6231422