Tensile strength prediction method through compressive concrete cube test

Автор: Hematibahar M., Kharun M., Vatin N.I.

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 2 (111), 2024 года.

Бесплатный доступ

The tensile strength of concrete is a crucial factor in civil engineering design of buildings and structures. Engineers are trying to find a new way to calculate tensile strength by using different characteristics in terms of the mechanical properties of concrete. This work aims to find the tensile strength through the apparent failure of cubic compression samples. In this way, the fracture angle, the diameter of the cubic sample, and the compressive strength were the factors most important in the tensile strength.

Tensile strength, compressive strength, concrete, high-performance concrete, basalt fiber, logistic algorithm

Короткий адрес: https://sciup.org/143182732

IDR: 143182732 | УДК: 69 | DOI: 10.4123/CUBS.111.2

Текст научной статьи Tensile strength prediction method through compressive concrete cube test

Tensile strength is an essential parameter in concrete building design. In addition, the tensile strength of concrete has the greatest effect on the performance and durability of the material. At the same time, the lack of a unique equation to find the tensile strength through the simple requirements of the mechanical properties of concrete and the fracture behavior of the concrete cube specimen.

Many studies have investigated methods to find the equation of tensile strength of concrete with respect to compressive strength. Still, this method was mostly related to finite elements and experimental studies. For example, Resan et al. [1] introduced a new approach to splitting tensile tests via a biaxial stress state element. Based on their method, a new biaxial stress state element configuration is constructed to identify the same internal forces related to compressive and tensile forces. Thus, sudden failure occurs, and the measured force is higher than that of the Brazilian split tensile test. Zhou et al. [2] presented a new mathematical model regarding the interface transfer zone (ITZ) and dynamic increasing factor of the concrete tensile strength (TDIF) through the study of the combination of 3D scanning technology and Clump-Cluster methods. In their method, the surface details of coarse aggregates are scanned through 3D scanning equipment. In the next step, according to the 3D scan model of the aggregates, mass models with specific shapes are produced. The lump forms are covered with cement and make spherical particles. Finally, all particles had a certain radius.

According to their research, the minimum partial radius for making mortar was 0.8 mm. However, Zhou et al. [2] used a new method to find the tensile strength, but their method was difficult and required many preliminary elements to find it. Bin Ahmed et al. [3] presented a new polynomial equation for predicting the 7- and 28-day tensile strength based on the experimental results of previous studies on the ratio of water to glue. The advantage of polynomial regression is the Continuity of the equation to reach the desired results. Bin Ahmed et al. [3] used polynomial regression and equations to reach true results according to their prediction. However, their model performed very well. The polynomial equation is a complex formula and requires programming.

Meanwhile, a simple formula with minimal elements is requested to find a unique tensile strength equation. Zhong et al. [4] defined a method based on Young's Modulus, the cross-section area, the elastic wave velocity of bars, the incident strain wave, and the reflected strain wave. The defined formula was based on the experimental results. However, the experimental results were accurate, and finding the tensile strength was difficult. Jin et al. [5] used a numerical method in the three-dimensional mesoscale with regard to split tensile strength with the effect of aggregate content and maximum aggregate size. They analyzed the numerical method in the meso-3D scale to find the tensile strength of the gap with the formula and equation. Indeed, they analyze the concrete with respect to the aggregates and the coating cement, which is converted into spherical cement masses. They analyzed the tensile strength of concrete samples based on the current mesoscale method. Zhaoa et al. [6] studied the effect of tensile strength and fracture toughness of concrete by Influencing the maximum aggregate weight ratio. They presented a new method to provide tensile strength equations. Zhaoa et al. [6] used the boundary effect model (BEM) for fracture analysis of specimens, and the most important factor in their studies was the weight and size of aggregates in the concrete. In their study, the toughness of the aggregate was an essential factor in finding tensile strength. Oyebisi et al. [7], using the concepts of reactivity index and mix design ratios, presented three equations to predict the tensile strength, but the results of their work were reliable. Previous studies have focused on experimental or complex methods to find the tensile strength of concrete. While there is a gap in a simple method to determine the tensile strength of concrete, this study intends to address this lack of research.

Moreover, other investigators are studying the relationship between compressive and tensile strengths by experimental methods. They used experimental methods to find an equation between tensile and compressive strength. In addition, other researchers investigate the relationship between compressive and tensile strength with experimental methods. They use experimental methods to find the equation between tensile and compressive strength. For example, Hematibahar et al. [8] studied the effect of adding gelatin powder, recycled aggregates, and almond shells to concrete for compressive and tensile strengths and chemical properties. According to their results, adding gelatin powder had the best result for increasing tensile strength. It was difficult to find the relationship between compressive and tensile strength for this type of concrete. Due to the lack of information about concrete properties and parameters, it was difficult to find the relationship between compressive strength and tensile strength using finite elements. Another example is Hematibahar et al. [9], who added 3D printing as reinforcement to concrete for compressive, tensile, and three-point bending tests. Their experimental results show that 3D-printed reinforced concrete can increase the strain of concrete samples. However, the relationship between compression cube specimens and tensile specimens was not clear. According to their results, compressive and tensile strength using the finite element method did not have a relationship with each other. It should be noted that compressive strength and tensile strength are related using the dimensions of the compression cube and the crack behavior of the compression cube specimen. [10]. In the same way, Kharun et al. [11] used chopped basalt fibers to enhance the mechanical properties of High-Performance Concrete (HPC). They could increase the compressive and flexural strength, but they did not use the tensile test, and they did not estimate the tensile strength of the concrete. Furthermore, they could not find a relationship between compressive and flexural strength. In general, the experimental results cannot provide an estimate of the tensile strength independently and without the finite element.

Other studies investigated mathematical equations to find the relationship between compressive and tensile strength. These studies are reviewed on mechanical properties to find equations. For example, many researchers have studied the variability of the mechanical properties of concrete through machine learning and other methods. In contrast, a new method for predicting the mechanical properties of concrete through the analysis of concrete failure when the specimen breaks is better and finds faster. For example, Liu [12] investigated the method of predicting high-performance concrete through machine Hematibahar, M.; Kharun, M.; Vatin, N.

Tensile strength prediction method through compressive concrete cube test;

learning. According to his analysis, the compressive strength of high-performance concrete was more than 120 MPa for 28-day curing periods. He predicted compressive strength based on 60 studies. However, the results of his study were variable; machine learning prediction problems cannot provide a unique equation to find concrete strength, and the prediction is related to past research.

Another example is that Zheng et al. [13] used artificial intelligence to find the mechanical properties of steel fiber-reinforced concrete. They used Gradient Boosting (GB), Random Forest (RF), and Extreme Gradient Boosting (XGB) according to machine learning techniques. They can predict the mechanical properties of steel fiber-reinforced concrete with high accuracy. The problem of machine learning and artificial intelligence is not being able to find a unique equation. Machine learning is used not only to predict the mechanical properties of concrete but also to predict other aspects of concrete structure elements. For example, Chen et al. [14] used machine learning and artificial intelligence algorithms to predict the mechanical behavior of fiber-reinforced polymer (FRP)-confined circular concrete columns. Similar to previous studies, Chen et al. [14] did not present any equations to predict the mechanical behavior of the concrete structure. In addition, Kodsy and Morcous [15] tried to predict the shear strength of beams by using machine learning methods. According to their results, they did not represent any prediction equation to find the shear strength of the concrete beam.

Another example is Neto and Haach's [16] study on the relationship between flexural and direct tensile strength. Their study was based on finding the unusual cross-section tensile strength for precast concrete elements. The theoretical analysis was established with more than thirty-two different types of cross-sections. The results show that the theoretical and experimental analysis outcomes were close together. Some studies used new approaches to find the tensile strength of concrete. For example, Liao et al. [17] investigated the Strut-and-Tie Methodology to find the tensile strength of concrete. The purpose of their study was to develop a new test method to find the tensile strength of concrete. According to the strut-and-tie concept and improving the experimental test of the ASTM C78, a new method of measuring tensile strength has been proposed. However, current studies are focused on finding the relationship between compressive and tensile strength. The requirements or limitations were the most important issues to achieve a unique concrete tensile strength equation.

The present study is focused on the relationship between compressive and tensile strength. Unlike other studies, the current research is focused on finding the tensile strength through the compressive strength, dimensions of the cube specimen, and the cracking behavior of the concrete cube specimen. This paper achieved a unique equation of tensile strength that is able to predict tensile strength. However, other studies show difficult equations, long processes, and many requirements or limitations to finding the tensile strength. The current study presents a simple method to find the tensile strength.

-

2 Materials and Methods

2.1 Methodology

The purpose of this archive research is to create a unique equation of tensile strength for which two types of concrete have been selected. High-performance concrete of crushed basalt fiber and mini bar is chosen to find the equation of tensile strength.

In this way, the pressure cube is first divided into elements due to the construction of new methods of elements. Then, the logistic algorithm was used to find the equation. In this equation, tensile and compressive stresses are considered to find the final equation.

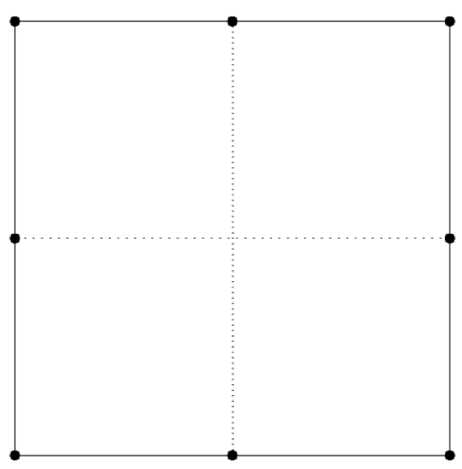

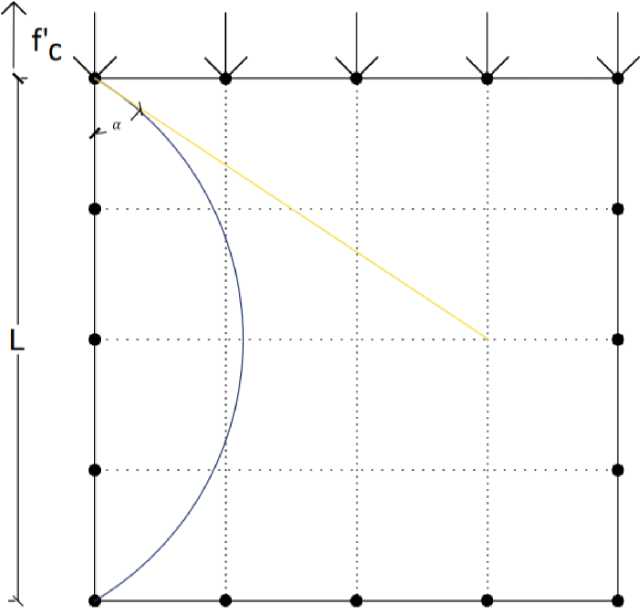

The compressive cube should be divided into elements with special properties (Fig. 1) to find the tensile strength. The elements have to follow these roles:

-

• The element can transfer force in two ways. The force can transfer in the x, y, and z directions.

-

• The element cannot fail separately. The connection between elements can be made to crack and fail.

The Fig. 1 b can be followed by (Equation (1), (2)) [18]:

V = A 9*10 - 6( f' c )2 (1)

f '

^ = (2)

m

Where is the logistic algorithm parameter ( ^ ) is the strain of concrete cube under compression test, and f'c is the compressive strength. The goal of the current study is to find the tensile strength through (the compressive stress of each element part).

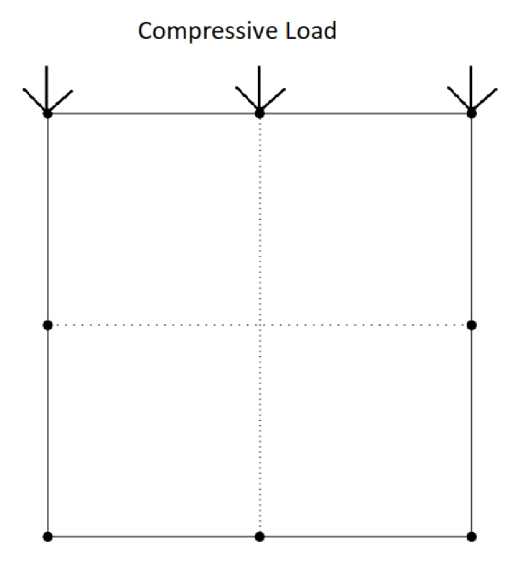

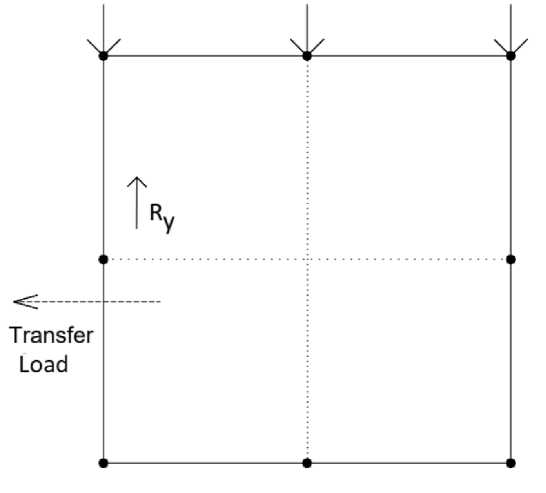

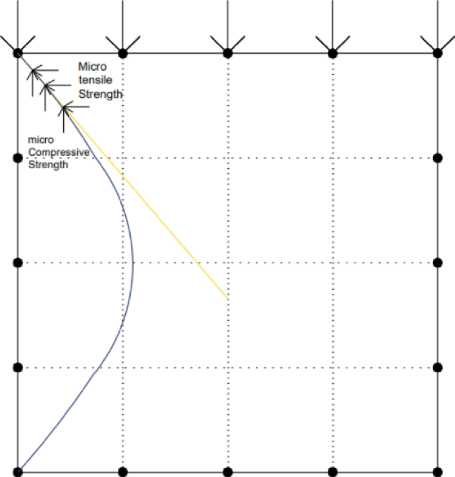

In the first step, the compressive load was applied to find the compressive strength (Fig. 2). The compressive load tends to transfer in the form of tensile load and tensile strength (Fig. 3). In this term, Ry is known as the first reaction compressive load. Meanwhile, in the compressive test, the micro tensile and compressive strengths have been formed in a curvature (Fig. 4). After the failure of the compressive cube specimen, the curvature (blue color) line (orange color) appeared as cracks and fractures (Fig. 5). The Equation (3) defines the tensile strength of cube:

ft = fcL ( cosa) (3)

Where ft is equal to tensile strength, f'c is compressive strength, L is the length, and is the degree of the curve (Fig. 5, equation (3)).

The current study calculated the tensile strength through equation (3) and found the accuracy of the calculation.

Fig. 1 - The cube sample Fig

Fig. 2 - The cube sample under compressive load

Compressive Load

Fig. 3 - The compressive strength tends to transfer tensile strength in the cube sample

Compressive Load

Fig. 4 - The micro compressive and tensile strengths under compressive load in cube sample

Compressive Load

Fig. 5 - Formation of curvature and other parameters in equation (3)

2.2 Experimental Study

The compressive strength of Basalt Fiber High-Performance Concrete (BFHPC) outcomes are derived from previous laboratory experiments [19]. The main purpose of the BFHPC study was to find the most stable and appropriate percentage of additional chopped and minibar basalt fiber percentages. However, the mechanical properties of High-Performance Concrete were significantly durable. Adding basalt fibers to this type of concrete improved the tensile, flexural strength, and durability of the current concrete type.

The compression test of a 100 mm3 cubic sample is applied in conjunction with GOST (Russian standard code design) and ASTM (American Society for Testing and Materials) standards. The compressive strength tests are performed for 7, 14, and 28 days with three different samples for each day [20–22].

According to the concrete mixture design method, the two types of aggregates are mixed by a 133-liter mixer for about 2 minutes, then water is added to the cement. Finally, the concrete is mixed for about 2 minutes after adding the chemical powders.

Concrete pan mixers with a constant speed of 48 rpm have been used to mix the material (Fig. 6 (a)). The concrete is installed for compression testing on 100 mm cubic concrete formworks (Fig. 6 (b)). The compression cubes are then molded underwater at 20 ° C for 48 hours. Next, the samples are stored on a wet cabinet at 15 ° C for 7-, 14- and 28-days during the curing period (Fig. 6 (c)). In the end, the cubes are cleaned before the compression test. Cleaning the cubes helped to achieve the best and most accurate compressive strength results (Fig. 6 (d)).

|

Specimens |

W/C |

C/Ag* |

Micro silica (Kg/m3) |

Quartz Flour (Kg/m3) |

Plasticizing (Kg/m3) |

Basalt fiber (Percentage) |

|

BFHPC |

0.375 |

0.315 |

125 |

100 |

12.5 |

- |

|

BFHPC-6 |

0.375 |

0.315 |

125 |

100 |

12.5 |

0.6 |

|

BFHPC-9 |

0.375 |

0.315 |

125 |

100 |

12.5 |

0.9 |

|

BFHPC-1.2 |

0.375 |

0.315 |

125 |

100 |

12.5 |

1.2 |

|

BFHPC-1.5 |

0.375 |

0.315 |

125 |

100 |

12.5 |

1.5 |

|

BFHPC-1.8 |

0.375 |

0.315 |

125 |

100 |

12.5 |

1.8 |

Table 1. The mixture design of Basalt Fiber High-Performance Concrete

* C/Ag: the cement per aggregates (sand + gravel) ratio.

(a)

(b)

(c) (d)

Fig. 6 - Mixing design devices: (a) Pan Mixer; (b) Concrete formwork; (c) Moist Cabinet; (d) cleaning method

The C0250 Matest Machine concrete compactor is used to deploy tests. Fig. 7 shows the Matest compression part machine. This machine could calculate the stress-strain curve and maximum compressive strength for materials.

The Portland cement (OPC), Micro Silica, Quartz flour, Superplasticizer, Quartz sand, Crushed Granite, tap water, and Basalt Fibers (chopped and minibars) were used to make BFHPC. Crushed granite is selected for the mixture design to improve the compressive strength of concrete. Furthermore, silica fume is added to the concrete to fill voids between the cementitious matrix and Basalt Fibers. The Basalt Fibers are mixed with High-Performance Concrete to enhance the flexural and tensile strength of High-Performance Concrete. Table 1 shows the Basalt Fiber High-Performance Concrete mixture material which was used in the current study.

However, basalt fiber reduces the compressive strength of high-performance concrete, so the flexural and tensile strengths are increased. The mechanical properties of Basalt Fiber High-Performance Concrete were more durable than those of other concrete mixtures by adding a 1.2% percentage of Basalt Fiber (BFHPC-12). Table 2 shows the mechanical properties of chopped and minibar Basalt Fiber High-Performance Concrete.

|

Concrete Types |

BFHPC (MPa) |

BFHPC-06 (MPa) |

BFHPC-09 (MPa) |

BFHPC-1.2 (MPa) |

BFHPC-1.5 (MPa) |

BFHPC-1.8 (MPa) |

|

Compressive Strength |

101.43 |

92.78 |

92.68 |

102.3 |

97.06 |

95.68 |

Table 3. The mechanical properties of Basalt Fiber High-Performance Concrete (chopped)

|

Concrete Types |

BFHPC (MPa) |

BFHPC-06 (MPa) |

BFHPC-09 (MPa) |

BFHPC-1.2 (MPa) |

BFHPC-1.5 (MPa) |

BFHPC-1.8 (MPa) |

|

Compressive Strength |

101.43 |

101.4 |

105 |

90.5 |

89.5 |

92.3 |

2.3 Validation

The current study applied four different validation types to find the best prediction methods. The Correlation Coefficient (R2), Mean Absolute Errors (MAE), and Root Mean Squared Errors (RMSE) Wilcoxon signed-rank test have been applied to find the most accurate method. Equation (4) illustrates the R2 formula:

Fig. 7 - The Matest compression test machine.

Table 2. The mechanical properties of Basalt Fiber High-Performance Concrete (chopped)

n A

R 2 = 1 -

Z ( y - y ) 2

n -

Z ( y - y ) 2

Where y, ˆy, and -y are the actual, predicted, and mean of the actual value, respectively.

The MAE method equation is equal to the sum of the numerical differences of the values of the community set divided by whole numbers (Equation (6)). The MAE equation is defined as (Equation (5)):

n

A

MAE = ∑ y - y n

RMSE calculates the average deviation of each actual data point and the predicted results. (Equation (6)):

RMSE =

1 П A 2 - Z( y - y )

-

3 Results and Discussion

3.1 Experimental Results

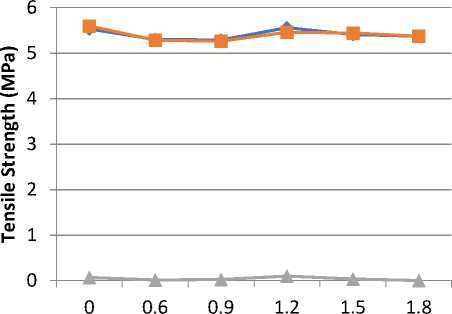

The tensile strength of chopped BFHPC results is shown in Table 4. The results showed the accuracy when the R2 was more than 0.93, MAE was more than 0.023, and RMSE was more than 0.00093. The errors are demonstrated in Fig. 8. According to the results, the experimental results and prediction results are close to each other. For example, BFHPC-1.8 experimental and prediction results

were 5.37 and 5.38, respectively. Table 4 and Fig. 8 illustrate that the experimental and prediction were close.

- ■ - Prediction

Basalt Fiber (%)

Experimental

Errors

Table 4. Tensile strength prediction for chopped basalt fiber

|

Basalt Fiber |

0 |

0.6 |

0.9 |

1.2 |

1.5 |

1.8 |

|

Compressive Strength (MPa) |

101.43 |

92.78 |

92.68 |

102.3 |

97.06 |

95.68 |

|

Experimental Tensile Strength (MPa) |

5.53 |

5.3 |

5.29 |

5.56 |

5.41 |

5.37 |

|

Prediction Tensile Strength (MPa) |

5.59 |

5.29 |

5.25 |

5.55 |

5.42 |

5.38 |

|

Length of Curve (m) |

0.138 |

0.146 |

0.1135 |

0.116 |

0.0815 |

0.117 |

|

Degree of Curve |

24 |

23 |

30 |

28 |

44 |

29 |

Fig. 8 - The errors, prediction, and experimental results of chopped basalt fiber HPC

The minibar BFHPC tensile strength results are shown in Table 5. The results showed the accuracy when the R2 was more than 0.99, MAE was more than 0.083, and RMSE was more than 0.00014. The errors are demonstrated in Fig. 9. Table 5 shows that the experimental and predicted results of BHPC and BHPC-0.6 were similar. Furthermore, Fig. 9 proved that there is no difference between the experimental and predicted strength.

|

Table 5. Tensile strength prediction for minibar fiber |

|||||||||

|

Basalt Fiber |

0 |

0.6 |

0.9 |

1.2 |

1.5 |

1.8 |

|||

|

Compressive Strength (MPa) |

101.4 |

101.4 |

105.4 |

90.5 |

89.5 |

92.3 |

|||

|

Experimental Tensile Strength (MPa) |

5.34 |

5.34 |

5.44 |

5.04 |

5.01 |

5.09 |

|||

|

Prediction Tensile Strength (MPa) |

5.34 |

5.34 |

5.46 |

5.06 |

5.01 |

5.08 |

|||

|

Length of Curve (m) |

0.1145 |

0.0924 |

0.108 |

0.14 |

0.1302 |

0.095 |

|||

|

Degree of Curve |

28 |

35 |

29 |

24 |

27 |

36 |

|||

|

6 ”ги 5 о. -С 4 ф 3 4-» СП ф 2 ’(Л С £ 1 0 |

Experimental ______________________________________ Peridection Errors —А— । — А । •А— । —А- । А । А—। 0 0.6 0.9 1.2 1.5 1.8 Basalt Fiber (%) |

||||||||

Fig. 9 - The errors, prediction, and experimental results of minibars basalt fiber HPC

-

4 Conclusions

Tensile strength is an important factor for building structures in civil engineering. Many engineers are trying to find new methods for finding tensile strength through compressive strength and concrete properties. This research examines the tensile strength of concrete and finds a new way through compressive strength and concrete cube failure tools. In this study, two concrete types have been investigated. According to the results, two types of concrete (high-performance concrete with crushed basalt fibers and mini bar) were analyzed to find the equation of tensile strength and the accuracy of the equations. This method was based on the logistic algorithm, and elements were made inside the cubic concrete to find the tensile strength. According to this method, tensile strength is related to the compressive strength of the cube compressive concrete. The tensile strength can be found through the failure angle, the diameter of the cube, and compressive strength. This method shows a formula that relates to the angle of refraction, the diameter of the cube sample, and the compressive strength. To find the reliability of R2, RSME and MAE are calculated.

Based on the results, the experimental results for R2 were 0.93, MAE was more than 0.023, and RMSE was more than 0.00093. In addition, R2 was more than 0.99, and MAE was more than 0.083. The RMSE was more than 0.00014 for the prediction results. General results can be concluded:

-

1. The fracture appearance of the concrete compressive cube sample and the compressive strength of the concrete can predict the tensile strength.

-

2. The experimental results and prediction distances were close to each other, and it seems that the formula was effective.

-

3. Not only is the logistic algorithm effective for finding the compressive stress-strain of concrete, but it also helps to find the tensile strength of concrete.

-

5 Conflict of Interests

The authors declare no conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

-

6 Fundings

Funding: The research is partially funded by the Ministry of Science and Higher Education of the Russian Federation as part of the World-class Research Center program: Advanced Digital Technologies (contract No. 075-15-2022-311 dated 20.04.2022)

Список литературы Tensile strength prediction method through compressive concrete cube test

- Resan, S.F., Chassib, S.M., Zemam, S.K. and Madhi, M.J. (2020) New Approach of Concrete Tensile Strength Test. Case Studies in Construction Materials, 12, e00347. https://doi.org/10.1016/j.cscm.2020.e00347.

- Zhou, X., Xie, Y., Long, G., Zeng, X., Li, J., Yao, L., Jiang, W. and Pan, Z. (2021) DEM Analysis of the Effect of Interface Transition Zone on Dynamic Splitting Tensile Behavior of High-Strength Concrete Based on Multi-Phase Model. 106577. https://doi.org/10.1016/j.cemconres.2021.106577.

- Bin Ahmed, F., Abid Ahsan, K., Shariff, T. and Rahman Meem, S. (2021) Formulation of Polynomial Equation Predicting the Splitting Tensile Strength of Concrete. Materials Today: Proceedings, 35, 3269–3278. https://doi.org/10.1016/j.matpr.2020.10.017.

- Zhong, W., Pan, J., Wang, J. and Zhang, C. (2021) Size Effect in Dynamic Splitting Tensile Strength of Concrete: Experimental Investigation. 270, 121449. https://doi.org/10.1016/j.conbuildmat.2020.121449.

- Jin, L., Yu, W., Du, X. and Yang, W. (2021) Meso-Scale Simulations of Size Effect on Concrete Dynamic Splitting Tensile Strength: Influence of Aggregate Content and Maximum Aggregate Size. 230, 106979. https://doi.org/10.1016/j.engfracmech.2020.106979.

- Zhao, Y., Xu, B. and Hou, J. (2020) Influence of Maximum Aggregate Weight Ratio on Tensile Strength and Fracture Toughness of Concrete. Mechanics of Materials, 148, 103406. https://doi.org/10.1016/j.mechmat.2020.103406.

- Oyebisi, S., Igba, T., Raheem, A. and Olutoge, F. (2020) Predicting the Splitting Tensile Strength of Concrete Incorporating Anacardium Occidentale Nut Shell Ash Using Reactivity Index Concepts and Mix Design Proportions. Case Studies in Construction Materials, 13, e00393. https://doi.org/10.1016/j.cscm.2020.e00393.

- Hematibahar, M., Esparham, A., Vatin, N.I., Kharun, M. and Gebre, T.H. (2023) Effect of Gelatin Powder, Almond Shell, and Recycled Aggregates on Chemical and Mechanical Properties of Conventional Concrete. STRUCTURAL MECHANICS OF ENGINEERING CONSTRUCTIONS AND BUILDINGS. https://doi.org/doi:http://dx.doi.org/10.22363/1815-5235-2023-19-2-233-250.

- Hematibahar, M., Hasanzadeh, A., Ivanovich Vatin, N., Kharun, M. and Shooshpasha, I. (2023) Influence of 3D-Printed Reinforcement on the Mechanical and Fracture Characteristics of Ultra High Performance Concrete. Results in Engineering, 101365. https://doi.org/doi:https://doi.org/10.1016/j.rineng.2023.101365.

- Hematibahar, M., Vatin, N.I., Hamid, T.J. and Gebre, T.H. (2023) Effect of Using 3D-Printed Shell Structure for Reinforcement of Ultra-High-Performance Concrete. 19, 534–547. http://dx.doi.org/10.22363/1815-5235-2023-19-5-534-547.

- Kharun, M., A. Alaraza, H., Hematibahar, M., Al Daini, R. and Manoshin, A. (2022) A. Experimental Study on the Effect of Chopped Basalt Fiber on the Mechanical Properties of High-Performance Concrete. AIP Conference Proceedings, 2559, 050017. https://doi.org/doi:http://dx.doi.org/10.1063/5.0099042.

- Liu, Y. (2022) High-Performance Concrete Strength Prediction Based on Machine Learning. Computational Intelligence and Neuroscience, 1–7. http://dx.doi.org/10.1155/2022/5802217.

- Zheng, D., Wu, R., Sufian, M., Ben Kahla, N., Atig, M., Farouk Deifalla, A., Accouche, O. and Azab, M. (2022) Flexural Strength Prediction of Steel Fiber-Reinforced Concrete Using Artificial Intelligence. Materials, 15, 5194. http://dx.doi.org/10.3390/ma15155194.

- Chen, P., Wang, H., Cao, S. and Lv, X. (2022) Prediction of Mechanical Behaviours of FRP-Confined Circular Concrete Columns Using Artificial Neural Network and Support Vector Regression: Modelling and Performance Evaluation. Materials, 15, 4971. http://dx.doi.org/10.3390/ma15144971.

- Kodsy, A. and Morcous, G. (2022) Shear Strength of Ultra-High-Performance Concrete (UHPC) Beams without Transverse Reinforcement: Prediction Models and Test Data. Materials, 15, 4794. http://dx.doi.org/10.3390/ma15144794.

- J.A.D, N. and V.G, H. (2023) Flexural and Direct Tensile Strength Ratio for Concrete Unusual Cross-Sections. Rev. IBRACON Estrut. Mater, 16104. https://doi.org/doi:https://doi.org/10.1590/S1983-41952023000100004.

- W-C, L., P-S, C., C-W, H. and S, W. (2022) An Innovative Test Method for Tensile Strength of Concrete by Applying the Strut-and-Tie Methodology. Materials. https://doi.org/doi:doi:10.3390/ma13122776.

- Hematibahar, M., Ivanovich Vatin, N., A. Alaraza, H., Khalilavi, H. and Kharun, M. (2022) The Prediction of Compressive Strength and Compressive Stress-Strain of Basalt Fiber Reinforced High-Performance Concrete Using Classical Programming and Logistic Map Algorithm. Materials, 6975. https://doi.org/doi:http://dx.doi.org/10.3390/ma15196975.

- Alaraza, H., Kharun, M. and Chiadighikaobi, P. (2022) The Effect of Minibars Basalt Fiber Fraction on Mechanical Properties of High-Performance Concrete. Cogent Engineering, 213660. https://doi.org/doi:https://www.tandfonline.com/action/showCitFormats?doi=10.1080/23311916.2022.2136603.

- (2013) GOST 10180. Concretes. Methods for strength determination using reference specimens https://docs.cntd.ru/document/1200100908

- (2016) ASTM C293 / C293M - 16 Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM International. https://www.astm.org/c0293_c0293m-16.html

- (2009) ASTM C1202-19 Standard Test Method for Electrical Indication of Concrete's Ability to Resist Chloride. ASTM International. https://www.astm.org/c1202-19.html