Testing of aluminum-silicon alloys mechanical properties on separately casted specimens

Автор: Krushenko G.G.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Авиационная и ракетно-космическая техника

Статья в выпуске: 3 (29), 2010 года.

Бесплатный доступ

The mechanical properties of aluminum alloys before casting into moulds were determined on separately casted control specimens casted in horizontal or vertical forms. A comparison of the mechanical properties (tensile strength t, elongation 8, hardness HB) of 12-mm-diameter individually casted of AK7ch alloy control specimens and its density in the solid state (p) showed that it is necessary to use specimens casted in a horizontal mold for evaluation of castings quality. It was estimated that position of separately casted test samples in the foundry metal form influences the indicators of mechanical properties of aluminium-silicon alloys.

Aluminum-silicon alloys, tested specimens, mechanical properties

Короткий адрес: https://sciup.org/148176224

IDR: 148176224 | УДК: 620.17

Текст обзорной статьи Testing of aluminum-silicon alloys mechanical properties on separately casted specimens

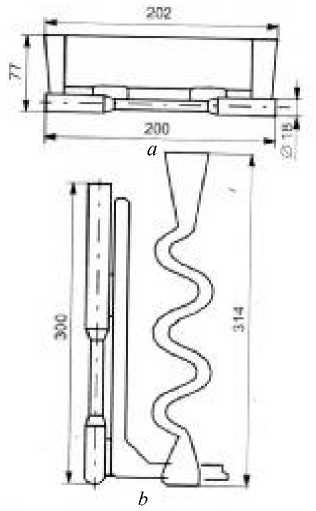

In chill mold casting of aluminum alloy parts individually cast test specimens with a diameter of 12 mm are poured in some plants in a horizontal chill mold and in others in a vertical one (see the figure).

In order to establish the influence of the position of test specimens in the chill mold on mechanical properties tests were made on one of the common aluminum casting alloys, AK7ch (RF Aluminium casting alloys GOST 1583–93: 6,0–8,0 % Si; 0,2–0,4 % Mg; Al – remainder), a typical representative of Al-Si system alloys. After tests of the 12-mm-diameter specimens cast in horizontal and vertical chill mold from their heads there were machined specimens with a gage length diameter of 6 mm, which were also tested to fracture. Before the test their density was found by the method of hydrostatic weighing [1].

According to the results obtained the tensile strength σ t of the separately cast vertical specimens is 238 MPa and of the horizontal 225 MPa while, on the other hand, the elongation δ is higher for the horizontal specimens, 6,19 % vs 3,3 %. Such differences in absolute values of the mechanical properties are related to the fact that the specimens were cast in different plants in which the alloys were produced from different charges and by different methods.

A study of the geometry of gating and feeding systems of both types of chill mold showed that they differ significantly. For example in the horizontal chill mold there was a single specimen with a weight of 0,125 kg. The specimen was poured and fed with a 0,675 kg tapered feeder head with delivery of metal to each 18-mm-diameter head by a vertical slitshaped feeder (the cross-sectional area of each of them was 7,57 ∙ 10–4 m2 and the total area 1,157 ∙ 10–3 m2) and to the 12-mm-diameter gage length by a feeder with a crosssectional area of 4 ∙ 10–4 m2. In the vertical permanent mold there were two specimens each weighing 0,165 kg. The metal was fed to it to the 18-mm-diameter heads by slit-shaped vertical feeders with a cross-sectional area of each of 2,52 ∙ 10–4 m2 (total area 5,04 ∙ 10–4 m2 from two slitshaped vertical metal lines). The weight of the gating and feeding system was 0,85 kg.

12-mm-diameter test specimens cast in permanent molds horizontally ( a ) and vertically ( b )

The length of the horizontal specimens was 200 mm, which corresponds to the required final size, while the length of the vertical ones was 300 mm, as a result of the longer length of the upper head which provided feeding of the solidifying specimen. Before testing the specimen was shortened to 200 mm. The mechanical properties were determined in the T5 heattreated condition and the hardness HB with parameters of 10/1000/30.

After tests of the 12-mm-diameter specimens cast in horizontal and vertical chill molds from their heads there were machined specimens ∅ 6 mm. An analysis of the results of tests its specimens showed that for horizontal specimens the mechanical properties differ less than for vertical. For example, the σ t of specimens from the heads of horizontal specimens differs by 1,7 % while for vertical by 2,7 % (1,58 times more) while for specimens from the lower heads more significantly with 6 by 0,4 and 10,0 % (by 25 times) and HB by 0,7 and 2,7 % (by 3,85 times).

For the vertical specimens all of the properties of the specimens ∅ 6 mm were higher from the lower heads. The density of the specimens of both heads of the horizontal specimens is the same while for the vertical specimens it is 0,31 % higher than the density of the specimens from the lower heads. It is known that the density of aluminum alloys of the system (Al-Si) to which АК7ch belongs reflects the presence in castings of discontinuities of gaseous and shrinkage origin on the macro- and microlevels and the amount of them correlates with the mechanical properties. At that it was established [2] a correlation between σt and ρ at the preparation of the alloy AK9ch (system Al-Si: 8,0–9,5 % Si; 0,17–0,30 % Mg; 0,2–0,5 % Mn; Al – remainder) by different technologies: σt was smaller than ρ approximately in 10 times (in limit of 9,90–10,40). So, if ρ is divided by 10 it can be σt without any testing alloy specimens on rupture.

A study of a longitudinal axial cross section of 12-mm-diameter tested specimens made it possible to reveal in the upper head of a vertically cast specimen a concentrated conical shrinkage cavity 10,5 mm deep, 7 mm below which is located a zone of scattered shrinkage porosity described by an ellipsoidal contour with a height of 12 mm and a width of 9 mm. In general the upper head has shrinkage defects to a depth of 30 mm, which is 21,4 % of the height of the head before machining. In the 12-mm-diameter gage length there are no shrinkage or other defects.

Measurement of the hardness HB (5/250/30) along the height of the vertical specimen showed that it remains constant (688 MPa) over the whole height and over the gage length all the way to a height of the specimen of 196 mm (68 mm below the ellipsoidal contour of the shrinkage porosity). Then the hardness drops continuously and reaches 595 MPa at a point 10 mm from the lower boundary of appearance of shrinkage porosity (the hardness was not determined in the zone of shrinkage defects). At the same time the hardness measured along the length of a specimen horizontally cast from the same metal (measurements made on the side surface) at 10 points was the same (724 MPa) and at one (on the head), judging from the somewhat smaller impression diameter (by about 0,2 mm), is somewhat higher.

A comparison of the results obtained indicates that horizontally cast specimens possess more stable properties over the whole length and this makes it possible to recommend them for mechanical property tests of aluminum casting alloys.

The obtained results were confirmed by cast the holder component made of AK7 Al-Si system (6,0–8,0 % Si; 0,2–0,5 % Mg; 0,2–0,6 % Mn) of aerospace engine into permanent mold at two different plants: σ t of specimens from that holder was 275 MPa and from holder it was 305 MPa (10,9 % more), accordingly, δ were 2,5 и 5,5 % (by 2,2 more).