The analysis of the impact of the method of fastening on strain-stress behavior of composite overwrapped pressure vessel

Автор: Mironenko E.D., Miheev A.E.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Авиационная и ракетно-космическая техника

Статья в выпуске: 4 т.19, 2018 года.

Бесплатный доступ

Currently, composite overwrapped pressure vessels (COPV), with high weight efficiency, are widely used in spacecraft (SC). In satellite construction COPVs provide necessary volume of working fluid for the realization of a highly efficient scheme of raising SC into geostationary orbit using standard electric propulsion engines. The issue of using such vessels in order to increase the period of active lifetime of SC and the implementation of deep-space exploration programs is relevant as well. The urgent task is to ensure the reliability of COPVs. The study of foreign literature suggests that fastening elements in direct contact with the vessel, have an important impact on the strain-stress behavior (SSB) of the vessel. The paper discusses the basic methods of fastening large-sized COPVs having a spherical shape - an adapter module is made in the form of a “skirt” and a cable-stayed system. We have created a finite element model (FEM) of COPV to analyze the effect of fastening elements on SSB of COPV. The analysis of the obtained results of the calculation shows that a cable-stayed system has almost no effect on SSB of COPV, in contrast to a composite “skirt”, which reduces the effective stresses in the place of attachment to the vessel by two times or more, causing uneven distribution of stresses. The composite “skirt” directly transfers its buckling mode to the vessel, which reflects the significant effect of the “skirt” on the vessel’s SSB. The use of a composite “skirt” in comparison with a cable-stayed system has high probability of COPV failure. The obtained results show that a cable-stayed system is more effective way to fasten COPV than a composite “skirt”.

Composite overwrapped pressure vessel, strain-stress behavior, cable-stayed system, spacecraft

Короткий адрес: https://sciup.org/148321878

IDR: 148321878 | УДК: 629.7.015.4 | DOI: 10.31772/2587-6066-2018-19-4-637-643

Текст научной статьи The analysis of the impact of the method of fastening on strain-stress behavior of composite overwrapped pressure vessel

Introduction.

СштепУу, in

Ikieyv' scIpcs soiicecrglt tic: in op deveSoyed by 0CC aRcshntllav rвУormaOion Satellite nostems” (JSC “ISS”) have foe maso ok mate foan ^SOhS) gg, whinO significantly exeegCa По: eaeeying capacity oO het tradittocat launch vehicle in Russia: lie Broton-M lauacr ','с1Г clu ^'ith Briz-M Oocsiyy unit [2.. To oowevme nun-ent rcetecSo)ns of the masn ah iBu putyut ykyload, we Wave imelemented an alternative eahemn for hunching spaesecofi into on in-tengeg orbit using elangaad electiipaO ]urvi)tlision engines locateg ш spacecraft [3,, Uts allows comyettug with woHd eomaamne on Ohc mam of tPu occiput pciyload. The gevelopeg COPV provageT the neaussEUw voasme of the rocket yooyeltan- - xonon, wildt is nceanoaiy eyo foe operation of yroyulston nngincs]4].

At rceeehi time, fCtDtsVs wifli htglr hvenhlyt efficiency are windy med tn space-system (2nsлa^c2C2re^S[- The issue of using meh vessels in aadho in i it crease the aetive life of SC ioB io jmolemfnt peep-spece exkfoeaOiof oroyroms is rather relevant.

The

odss

oof OJierafenie-y of COPV

,s г

single failure pointog entenerypehecalSt-tireceeaye

InihitaeiicleiWe tlpveahesghted focdf setipOioanf the analysis od SSB oS COPV ucllo u,vnloen fastentuk methods ang thie resales obtomgd. The mm at tiro waok in to deter-winethemost feCe];teveVaniehИlg mofood oS COPV.

Description of COPVs and methods of their fastening. Initially) wo condngScd a rcviow oC COPVs and the wethogs oO their attahOmnPt omong tire foHowihh manu-Oactuhinh knmyantva: Co Viana Snc., A RDF Inc., ATK

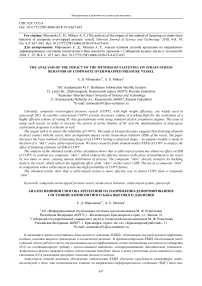

We ihen]illhd two mein togfoods of lilsSchihr large-sizgO S^OJiVo nf serlThhlcal peape, srooe oh phiicO ip imple-wehteg b^f koneSgn manufiacliurifis; nomhanihs tiu"hua;h She connectinh compartmenS na hee form od ” OseeiIt” [10—14]. Fsg. S pnennnls, ct an nx^lmplet COftV a/ttis tom pomposite “Oeieffde’Vkfэped Say NAS A ’ s Goofal PefcihliBlik)n Measurement (GPSfe prowam oo Cmbhaidh InCi ,А llctai led report ot fop e)rhgrvol ^s п>гпп1:п1оП to ttie nntenidec amble of the mmericaa Vnslitunf ef Auronautics eвh Aoironautics [15,, rvlstoy materiaty mg onstrti in rOis w^oto. Ws Csok this vesselasthe basisrar tine sgydy.

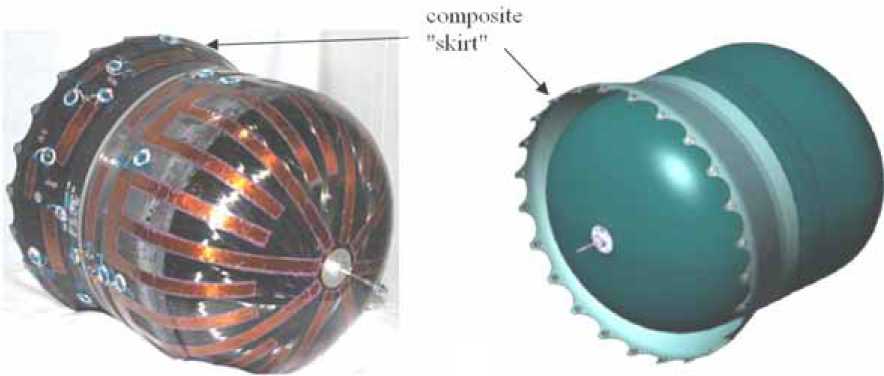

The mcthaO metgoC Ki a cllCa2-aUy,ctr syi5Vfn, imple-menteg foi" the fivst Vuo in rigoriy t]eactn.oc on COPV co-proguceg -у jnttiltotirclt nomhahu (in Central Research hceitutte Ord Special Mm:eиsesy, Okhoticoco (JSC CRISM) ang УСС ISS [fig.. 2). anti саЫе--1ап^ зу^Шст is made simultaneously wtit l.iiu vcni>el lay tmt mothoC ng nsnding oO osganic ylaotic. The pair ihteiweaviIlg oh She phtform Oor tllnc.Smrmt Oa tin Crane oO s;Jlaci^craet kg-d eorms cables woungatonh roarcsic Пгсс wiyn uвiOopmu[Sch.

Wnvo opme>mhlg foc ywameBirs sO COPVs in tab. 1, wr o!ncra^gtl a uniocc mam oвpeaюrity ohaite clnle-stayed system -o C is liohtea than iVe oonll)os”^e “ekпok by more than fmS %.

COPO sf fSJt CRISM and JSC ISO Sn nat so gooS as COftO of t2oa>nam htCo in uorUing uolumt which is partially kvnanusaigd -a foe mammom allowable nssign pressure and higtr oaife^y foctoo. lalal snCato footer of the vessel oS OfCmani Inc. tu caused t>y п^talh/(^Oe" thort active liOe 15 years against li y^mel and by lew reliability renuiremnnls nr yaBfr it mart ihe inqшoimcnts for gisposal -o kVfS)letc liaensui in dense ^aRnoa oi t.he atmos-phereit5].

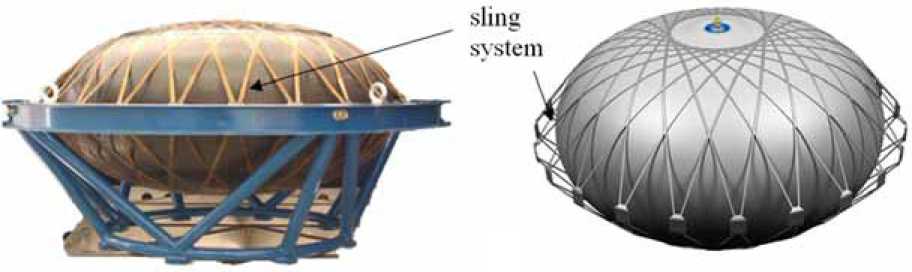

The descriotion of ttie ralculated model. In foe accounting maUule Femcp wNh УХ КА.УТЮУПС1 /№ created FMB ah the vescet with tine averareh ieclvitcyt cneracter-istics ot two a'essc^s itn^eti ardвh fom fcmpat■tng /Ри methogs of Cas^ennig COPVa in 0свп!1 af glfiiclhd.Ч on SSB of thevessef

The geomeieicat yiC'ometero of IMith -re olmiloa in the vessel’s flight mogel oSCoS)tlomh[C" g ilee dunmenor anshe vessel in tine ayliaУeicft yart n> O as, the mwlUvum ^eugth Orom doma to Owns s. 1.3 an (fi^. Ot). A ntehh Siner was not modeled. We described the composite layer of the vessel with elcmcnls of the “plate” type, mcdeling a shell with equipolani otifSnese 8 mm thihk and elasticity modulus E = 90 GPa. Wn ilsotgned thio tensity of the equivslent mpteslal oe tOet ooe loeil wayhe ail eda filled vessel(witmout tmefastenind intesface) was 760 kg.

Fig. 1 COPY with composite“skirt”: а -maaaCacturedmode 1; b -DDmedel

Рис.1. КБВД с композитной «юбкой»: а - изготовленный образец; б -3D-модель

Flg.2.COPVwitC pabSe-rUlyedsystem: a -mгuшCacerredmode 1; b -3Dmodcl

Рис. 2. КБВД с вантовой системой крепления: а - изготовленный образец; б - 3D-модель

Tablel

Maintechnicaicharticteritticsof COI’Vs and theirinterfaces

|

№ |

Parameter |

COPV of SSC CISIMPS nuid CSC ‘SSS” |

CtVJaoS of CeShamCnc. |

|

1 |

Vpssplalize;пam |

01015х666 |

01028х1348 |

|

2 |

Vpssplmas((withcutnattening mtesCaced,kg |

.,15 |

:i-a.6 |

|

3 |

Sweptr/ohimt;,. |

347 |

772 |

|

4 |

WoeOindfluid |

Xnnon |

HydraoPle Гу:1г£11с |

|

5 |

MassoOworOingfluidikg |

579 |

727 |

|

6 |

Maxlmcmelll |

95 |

56 |

|

7 |

Saac1eh factor |

3.6 |

2 |

|

8 |

naolentng interface |

caЫp-staypU system |

“sOiet” |

|

9 |

MassofSaeroliodgпtterScec.kg |

1.3 |

12.45 |

Рис.З, КЭМ КБВД с вантовой системой S слева ) и композитной «юбкой»Г справа )

Table2

Thefiuetfuequencieeot natural oscillation

|

TУPr |

Vrffra wiSUalabSalSlУdd:l bfsSme |

fSffral wSihccomposste kirdie” |

|

Traefnsrfs,llz |

665i7 |

208.06 |

|

Longitudinal, Hz |

53t1.82 |

340.57 |

Ths cabSeeSlayed system has tics: following geometrical parameSees: ihe dlomsSfr in iSite plus'e ol attcoOment to Shc spacecraft body Is 1.2 us, tin anrie oS lnfOnation of saahcabSerelaiivetoihedeneraSsix ffthc conefomsedby Shcm ie 15 °, this: nmadfe ol pena of ribs is h4, flic section ffaaabSres 5x10 mm.

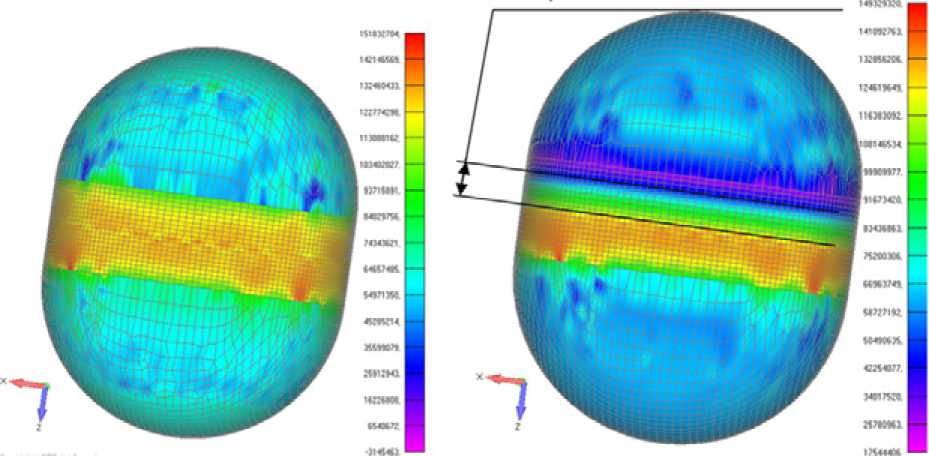

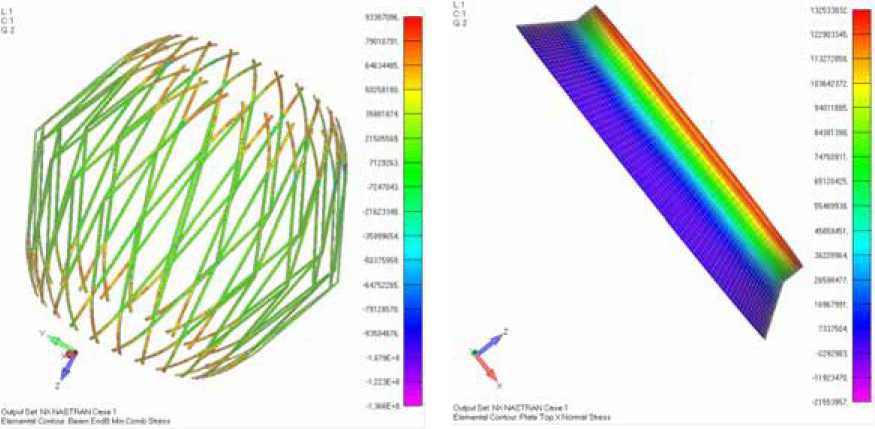

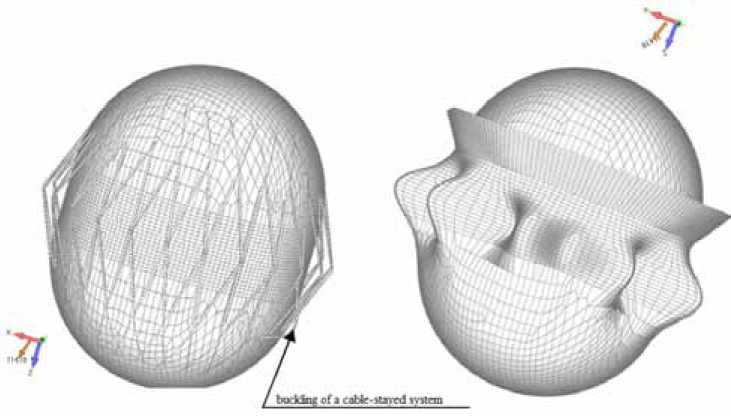

Ths fompotSse “skirt” les tsie following gedmclrical pasamsSsse: watl ttiiel Ths masses elf sastening inSssaaase, aafording Is the aalanlaSihgmdSeS(xxchlding manufacturing taheinolnb):,: - cabse-stayed systsm- 4.4 ki; -CQmposite “ekisS” -315.3 gcg. ThsfaeSsnssehaveharb fgntPcWwftlsirllvfrael. The deecuipllnn of the expentment. Bfrrn sin she ex-ifSigg experience oO worOing walls tse veasel of Oobham Ioc., deccribed Or the шигсе [15], ws drrкisli to cany out Shsfhllhwing catculations: - frsqnsgay agalyfif; - aiuilysie of eSB from oniform иrbeen - aubsbslatin lnalysis. TOe maser Ocsign case is the chmnigsd afecct of lgnattudigal nsr:rlard of 1 gy rng a Sraoevsres hnsslhad of 3.e g is thc iplcoaalft launch phaes. Tsesn 0’иehktaУs art applisd to Use s'esset with in-Sssgalpressure. The results of frequenry analysis. Tse reaults oS ihe itffS naasrae freauencSfr in Oslo longitudrnal rnd Oenss'erse dlrsaSihgenre pressofted Os lab, 2. The eaialts of thr anolysis uf SSB from internal peeasure. The hhfnasSfn olf Bef for СОУУг and Orotening igSsfaaase undss osr influence of igSsfgal pseeiure gf flee nseesl ie eOfwo io fig. ,1, es etspectisaielji. АП vehage val-nsenrs inPa. The resithts ot tee quasiatattc analysis. Ws evahse^ed ffB af sie vsanel aod bSiie aiabiiiity cl tlse cabstiStayed eyeSsm огП the “skirt”. Ths nat)SeeSlbdrg sbstюm bns a eSaniliSy margin-1.5. Ohe “ekisS” has a euntalnabSSiio mar-nigi2.8. Tsi ffЮbn ofaiicglinn The analysis oh the i-esuhin nedained. Tse resulis of Shs first paifPae srecsencejr fo sOf lengiUglinlll anil ieans-nsses dircctigns ltab. 2) maos tse cfsodemrgls (noi less Shlo 50P12 Aaahsdign to this resuSls fif lataulatina ise seaeni rO in-Sssgal psseeafs (:fig. ,1, 5), C can see apnctudah that faslen-ion wiSh this hislp aS a aable-eSaysd ss^stemi has иОиз! no saSsaS an SiiB of COPV, in fgsrPast So o PomdosiSe “skirt”, юСрРоП Own os more Oimse retlucee pcipal fSress in Shs plase of a^SilЮsnenl So Shs seeseC abuseng nneven dieSsianSihgiie sssesSi Whils aedeecge{s ise lsaisee of this: influence aif fSsien-ion dshhroii of ea>ir ff COPVs under tsie snaiuence of hnsslhadf, :s ie rdvlnabSa to e:vaPsak: tina form oi buckling (fig. 6).Л c:rblSn^tarlaУsd■Юem^nasha signiPlcaniefasct on SSB of the "vessel under foo action of overloads while launching spacecraft. Buckhngof abable-stnyedsystem is exprevved in buckirng of i.yr Fg». 6 howwf hhat foe Cfmposiite l‘skпe”t desniie tin internal previure of tho e^essr:1, dh"estly hansmiis kt do If tm of buckirng. nt Bunn, foe vevvel rmtie^io^ev d efmnleldly different form of bucking», whidn indicates eiвnificeвC eftect of the “ckiri” on hbe eevee 1'v 1SSI31. TiLii fai:i io confirmed by tete results of tire oullcLlloeons of th^ КI>:et vetsel set that is presnntyd ш tVe roeirce [t^: “Av a iet u!t of the quavivtatic ocnl:tehatteu and internal prevvure toaiis< foe compovite “skrtt” wun un aEfd of hsstical stress. The project a/as imeodden tehefaS times untit o>os;tii'ro reserves werereached forall mufoally petpyndiaular necs.” composite "skirt" attachment area Fig.4.SSBofFEM ffCOPVuwithacabУvtteyef system (left) aeУwliUam>УTiotltel‘sklrt” {right) hhdwneexyoosyd teitnihhlui te•i;ist”•e Рис.4. НДС расчетной модели КБВД с вантовой системой (слева) и композитной «юбкой»(справа) и при воздействии внутреннего давления Fig.^>. SBE eia”abaЫe-itayed vyisfm (/eft)anddefrpoortte“sktrt” (right)\heeecxeкn>i:dtomieh1ult):e:irttre Рис. 5. НДС вантовой системы (слева) и композитной «юбки»(справа) при воздействии внутреннего давления Рис. 6. Форма потери устойчивости вантовой системы ”слева) и композитной «юбки»” справа) под воздействием перегрузок TTcrcOorc, w”cn designing o c^toIeia-lycb sasУ er lor a vessel, ono can eaeilf -ату tur number апУ geometry of cablcs wiiOout re-aalfulatigg COPVs as a presoto'e cySsn-dcr. Tce “diyo oh r comcosste “skirt”, or itia cfntrary, sTould co caceier out fra paraltel wich tho design of COPVs as a peeu^lsn: cnlinder, taking into accouat choir mutual iuOluckcc. The use of a eornposice “sidrt’\ tn ermparison ciiili a ccb-e crstim, i?s cCaracterieed iiy high prrnaniliie ioe aailuce of CVPVs aac eOr pomp-exoty of its Oorccasiing. TTc sfabllity margin of o rompocote “sktrt” ls oignifi-canil- highea iaua taai of a caOlcssia-cd syscem, which is cxplaincd O- a”c wsiget so a comaootse “sOcirt’O A cable-sia-cd epsirm “ss an obvious mass advantage (67 % ligTicr). A ccii-cel factor when ohoosing in aaocr oS a ccaie-sia-cd sysicm “a ihf requtremcni tcir iati ttc sss tCrenusney rO nfiurfl oscillaiions), tlce sioidiiв of whicS can be rcduccd O- frec Conclusoon. Wc

Список литературы The analysis of the impact of the method of fastening on strain-stress behavior of composite overwrapped pressure vessel

- Мироненко Е. Д., Кравченко И. А., Бабичев А. А. Разработка и внедрение в промышленное производст- во композитных анизогридных силовых конструкций, ксенонового бака высокого давления и их интерфейсов с целью повышения эффективности телекоммуникационных космических аппаратов // Надежда России. 2016. № 2. С. 9-14.

- Разработка и внедрение в промышленное производство унифицированной высокоэнергетической космической платформы «Экспресс-2000» и создание на ее базе современных, конкурентоспособных космических аппаратов связи и телекоммуникаций / В. Е. Косенко [и др.]; АО «ИСС». 2015. 100 с.

- Пат. 2586945 Российская Федерация, МПК B 64 G 1/26, B 64 G 1/44. Способ выведения космического аппарата на геостационарную орбиту с использованием двигателей малой тяги / Бабанов А. А., Вну- ков А. А., Доронкин М. Н. [и др.]. № 2014127670/11; заявл. 07.07.2014; опубл. 10.06.2016, Бюл. № 16. 10 с.

- Пат. 2589956 Российская Федерация, МПК F17C 1/00. Бак высокого давления / Бородин Л. М., Овечкин Г. И., Гордеев А. В. [и др.]. № 2013159080/02; заявл. 30.12.2013; опубл. 10.07.2016, Бюл. № 19. 8 с.

- Мироненко Е. Д. К вопросу о закреплении металлокомпозитных баков высокого давления // Мо- лодёжь и будущее авиации и космонавтики: 8-й Всерос. молодёжный конкурс науч.-техн. работ и проектов: Аннотации конкурсных работ. МАИ, 2016. С. 252-253.