The heat transfer characteristics in the furnace for one-stage oxygen fuel-fired autogenous smelting of copper sulphide concentrates

Автор: Skuratov Alexander P., Pareckiy Valery М., Skuratova Svetlana D.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 4 т.5, 2012 года.

Бесплатный доступ

The theoretical basics of copper-bearing sulphide concentrate one-stage recycling technology in oxygen fuel-fired furnaces for blister copper (white matte) melting are stated. The pre-design furnace heat transfer characteristics investigation based on polyzonal mathematical model has been led. It has been found that the designed scheme of the unit with vertical charge-oxygen fires provides adequate durability and efficiency.

Oxygen fuel-fired autogenous smelting, kfp furnace, vertical fire, one-stage process, blister copper, heat transfer mathematical model

Короткий адрес: https://sciup.org/146114665

IDR: 146114665 | УДК: 536.

Текст научной статьи The heat transfer characteristics in the furnace for one-stage oxygen fuel-fired autogenous smelting of copper sulphide concentrates

The comparative advantage analysis of different variants of copper-bearing sulphide raw material has shown that the most environmental safety effect and energy saving when one-stage autogenous smelting of blister copper or matte, containing no less than 75…79 % of copper (white matte) [1]. In this case, when smelting the maximum quantity of charge heat energy and the biggest part or the whole sulpher convert into high-concentrated gases. Whereby the convertation becomes the one-stage less energy-consuming process of copper melting almost without slag formation and with minimum volume of concentrated sulphide gases or removed at all.

Experimental

The thermodynamic analysis of the regular sulphide raw material smelting process shows that when blister copper smelting (white matte) in system Cu-Fe-S-O-SiO2 the sulfur partial pressure decreases and the oxygen partial pressure increases [2, 3].

Consequently, the concentration of ferric iron in melted slag increases until the oxide phase becomes inhomogeneous along with raising of equilibrium copper content. As a result, when stage of

white matte or blister copper production the slag forms with loadstone content till 35 % and copper till 8…15 %.

The most promising method for one-stage production of white matte is the melting with formation of high-basic slag, particularly CaO-FeO-Fe 2 O 3 -SiO 2 oxide melt system. The advantage of this system is its homogeneity at 1200.. .1400 ° C when certain proportion of calcium and ferrum and high partial oxygen pressure typical for high-grade matte and blister copper melting. In addition, slag becomes more prepared for non-ferrous depletion till dump and can be used in ferrous metallurgy as a material for cement production. Tests have shown that these slags under certain proportion of СаО and SiO 2 selfgrind into the powder. The decomposition is a result of belit polymorphic transformation accompanied with slag volume increase on 10…12 %.

The melting technology had been successfully worked out by State Research Center of Russia FSUE «Institute «Gintsvetmet» and «Institute of Metallurgy» of the Ural Branch of the Russian Academy of Sciences using oxygen fuel-fired smelting (KFP) [4]. The technology choice proved by following factors:

-

- KFP process has least power consumption for 1 copper ton;

-

- KFP furnace is the simplest in constructional way and durable autonomous melting unit combining functions of charge melting, slag and matte separation, matte accumulation in quantity needed for its further processing;

-

- KFP process is a white matte and high-basic self-grinding slags with further decoppering are the most progressive technology in world practice of sulphide raw material autogenous smelting.

The disadvantages of the process should include the need for a workshop to finalize the slag processing (copper containment up to 3 %), slag chemical reactivity towards furnace lining, increased oxygen consumption in comparison with process one, limitation in quartz flux processing that is important for foundry running indexes when high concentration of noble metals in quartz flux [3, 4].

The concentrate processing technology scheme sets up one-stage melting of white matte or blister copper to receive high-basic combined silica-calcium slags or ferric-calcium ones. In this case, the concentration of unlinked loadstone and copper in the slag decreases considerably (till 7…8 % and 2 % correspondingly), the slag becomes fluid under the 1250…1350 °С and its phase composition is better prepared for decoppering till dump condition on the preparation plant. As a result, the copper extraction increases up to 98…99 %, SO 2 concentration in melting gases reaches 40…60 % with recovery in them up to 80 % sulfur, significantly improves the process of conversion is increased by several times the performance of specific units.

The correct choice of melting equipment, efficient construction development and optimization of furnace heating parameters providing high techno-economic indexes and durability of KFP system in whole play the important role for successful industrial implementation of new one-stage technology. In this case, the experience in specific nature of one-stage smelting thermo-physical processes allows us to choose furnace work area correctly, appoint the flame orientation in reaction zone, determine the scheme and modes of lining cooling, set up the required temperature level in technological zones and it’s control when current input parameters changed as well. Previous research and further semiindustrial experiments have shown that furnace arch placement of charge-oxygen torches provides – 434 – better lining work conditions in comparison with front one [5]. That, in turn, makes possible to rise thermal stress of reaction volume and gives the opportunity to increase the unit specific productivity or copper concentration in matte.

To solve the question about industrial furnace unit construction the estimation from the thermo-technological point of view about reaction shaft installation purposefulness in the time of unit capacity increase (thermal load) is needed. For this purpose the competitive calculation-theoretical analysis of three modifications KFP furnace thermal performance has been made: with arch and front placement of charge-oxygen torches and reaction shaft-tower as well. The calculation with help of zonal model [5-9] has made it possible to determine thermo-physical operation characteristics of three KFP construction modifications, shown their working efficiency and set the most thermo-stressed parts of lining for intensive cooling. At that, the obtained results and additional science-economical researches [4] carried out in Gintsvetmet institute have shown the rationality of KFP method in vertical flame with arch torches without additional furnace height due to special chamber or reaction tower installation. The furnace unit construction simplification allows it’s usage for new technological processes of copper production (one-stage oxygen fuel-fired and fired-barbotage smelting), the furnace fabrication and maintenance costs decrease, the adaptation of used furnaces (particularly the reverberatory smelting) with it’s transformation into KFP.

As a result of semi-industrial experiments conducted together with Gintsvetmet institute, material and heart balance calculations, numeric experiments on mathematical models the furnace KFP-20 has been offered. The furnace square from top with cross-suspended type arch has follow inside dimentions: length, width and height are 8.3, 3.0 and 5.0 m consequently; the depth of bath is 1.1 m; the height of gas space is 3.9 m; the floor area 25 m2. Two charge-oxygen torches are placed on the longitudinal axis of the arch with distance between their axis 1.0 m and between front wall – 1.5 m. Gases come out from rear of the furnace through uptake with width 3.0 m. Lining evaporation cooling is realized by copper squared caissons with cross-section 0,065 x 0,065 m. The number of caissons in slag band and gas space are 25 and 16 consequently.

Technological data and parameters of the furnace are: dry charge productivity 4.639 kg/s (16.03 t/h); specific dry charge productivity 16.0 t/(m2∙24 hours); total technological oxygen consumption (90 vol. % О2) for smelting 0.789 nm3/s (2822 nm3/h); output of white matte and slag 75.6 and 2.1 % consequently; flow rate of exhaust gases 0.934 nm3/s (3363.4 nm3/h) following content (vol. %): SO 2 – 52.95, CO 2 – 17.07, N2 – 25.45, O2 – 4.53; the temperatures of smelting products: matte, slag and exhaust gases consequently 1210, 1250 и 1265 ° С; sulfate dust content 0.593 kg/nm3.

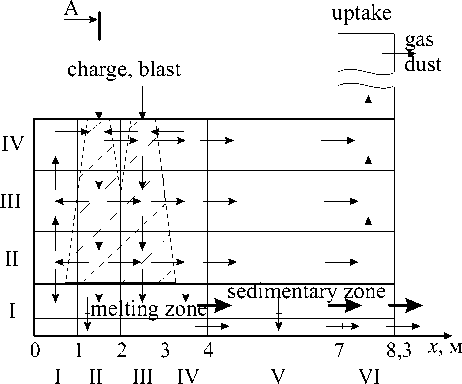

Heat exchange mathematical model of offered furnace construction binds together previously approved schemes of KFP zonal calculations [5-7]. The geometry of three-dimension polyzonal model and the scheme of smelting products movements in the KFP-20 furnace work area shown in Fig. 1. To make mathematical model closer to the real technological processes, taking place in the unit, the under layer space had been divided though width and length on three and six calculation levels correspondingly. The division helps to find the flame zones where basic physic-chemical smelting processes take place and near-wall areas of gas phases where more precise estimation of lining condition is required (temperature and thickness of skull) in dependence on aerodynamic and heat modes of furnace operation. Thus, within the frame of I-IV areas along the length the smelting zone is placed, within V-VI – sedimentary zone (zone of separation of melt on slag and matte).

The uptake is placed in VI area, what was additionally made along the height as a fourth layer. Each area from first five ones along the length consisted of four volume zones of smelting products (gases, dust and alloy) and four surface zones of walls and arch. In the end of sedimentary zone (VI area) each layer has one volume zone only. The uptake consists of one volume and four surface zones. The slag surface is presented by three surface zones – first in the smelting zone, others in the sedimentary one. Total number of under layer space calculation zones where smelting energetic parameters (temperatures and thermal flows) were estimated is 73, including 34 gas phase volume zones and 39 surface zones of lining and slag, counting front and rear walls.

The two arch torches with charge productivity 2.3193 kg/s each are placed along longitudinal axis of the model in II and III areas, correspondingly in the distance 1.5 and 2.5 m from front wall. It is accepted that within the frame of I-IV areas 97 % of condensate phase are separated on bath surface. Another 3 % are equally distributed through the furnace work volume, partially separated on bounding surfaces and bath in sedimentary zone and taken away through uptake as a dust.

The copper square cross-sectioned caissons are placed in front and side walls of the first and second layers of smelting zone (I-IV areas). Thus, the lining is caissoned through the four meters of the furnace on the height 2.6 m from bath surface.

In the developed model the smelting bath had three parts lengthwise, each one consisted of upper slag zone and bottom matte zone. The first part correspond to smelting zone (first four meters of the model), the second located from forth to seventh meter, the third is under the uptake. Thus, the second and the third parts are sedimentary zone. Other geometrical parameters as well as mass-exchange scheme are shown in Fig. 1. As you see from the figure, the bath model consists of six calculation volume zones: three zones of slag and three zones of matte. The melting bath depth is 1.1 m. Bath was caissoned along the whole slag belt with width 0.8 m.

À I

--► - gas, melt, dust; - slug; - matte;Roman numerals - calculated numbers of sites and tiers

Fig. 1. The zonal model scheme of heat exchange in KFP-20 furnace

The mathematical model allows to calculate average zone temperatures in melting bath. For this purpose, the bath is represented as a set of non-transparent for radiation zones. The quantity, configuration and size of zones are chosen from unit construction and characteristics of physicchemical reaction in single parts of the bath. For each zone the algebraic equation of heat exchange and thermal balance is written as follows:

Е с , - Т , ) + Q r, + Q о, + q = 0 , (1)

i where ci – specific heat capacity of smelting products (slag and matte), J/(kg∙К); Gij – the slag and matte mass transfer from I to j zones and come out from j zone, kg/s; Ti, Tj – zone temperatures, average to mass. K; Qrj – resulting thermal flow through batch surface, W; Qoj – heat sink through the bounding, W; Qj – unbound variable, containing internal heating effects of chemical reaction in j zone and known values of smelting compounds physical heat coming in j zone, W.

The value Q rj includes resulting radiational and convectional thermal flows from volume zones, bounding with furnace under layer space. This value is determined from preliminary calculation of under layer space with follow equation:

Q j - j a f r +^ (1 - тМ . (2)

where Af and Af - selective coefficients of radiation heat exchange between zones of under layer i space i and melting bath under layer space j, W/K4; Ti и Tj – zones temperatures of under layer space i and bath surface j, K; αj – coefficient of heat loss by convention between volume zone of under layer space i, joining to bath surface zone j, W/(m2∙K); Fj – j zone square, m2.

The value of heat sink to the environment Q oj is determined by following equation:

Q o -a h ( T - t J f, (3)

where a h - coefficient of heat loss from melting to the skull surface in j, W/(m2K T j and T msj -average to mass temperature of melting in the j zone and skull smalting temperature in the zone, K; F j – area square in the j zone covered with skull, m2.

The a h value obtained with help of criteria correspondence [10] is determined by equations:

-

a) for a smelting zone

-

a h = 3 ' 96 ' 10 24 T j ( T j - T msj ) ; (4)

-

b) for a sedimentary zone

a h - 2 . 9940 - 55 I *8^2 ( T j - Т ич ) - - . (5)

Note, that charge heat radiation depends on it’s composition and extent of sulfide oxidation. It is easily determined by heat of sulfide oxidation reaction and slag formation taking into account heat losses for thermal dissociation of higher sulfides and carbonates. The generalization of theoretical data and KFP furnace operation experiments has afforded to suggest following laws for calculation of chemical reaction resulting heat effects in flame Q hf and in bath Q hb (кJ):

Qhf = 4.187mc(16170Sc - 4074.87Cu + 10896.93Fec + 8334.36Zn + hf c c c c c

+ 2377.67Pb c + 10841.53Asc) + mfc(15085Sfc - 3801.43CUfc +

+ 11510Fefc - 40285O2fc + 9910Znfc) - 20130mmtFemt -

- 7650mfsCaOfs + 95690msl - 36378m d ;

Qhb = 4.187msl ( 1750Fesl - 38000 ). (7)

Here m – mass of a component, kg; indexes: c – consentrate, fc – flotation concentrate, fs– fluxing stone, d – dust, mt – matte, sl – slag. The content of melting compounds given in mass. %.

The calculation of heat exchange in the furnace is led in two steps. First, the heat exchange in under layer space is calculated. Basing on this calculations the value of Q rj and melting compounds physical heat are determined. The melting compounds are master data on the second step – the heat exchange calculation in the melting bath. Next the additional calculations of heat exchange in the gas phase and melting bath could be made until required precision. In the result of solution of heat exchange and thermal balance zonal equations system [5, 6] the temperatures of smelting products in gas phase volume and melting bath, surfaces of lining and slag and different average zone local energetic parameters are determined.

Results and discussion

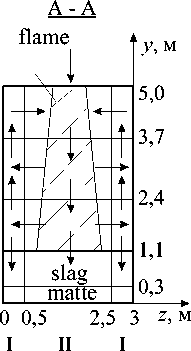

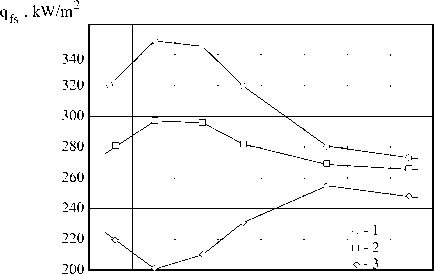

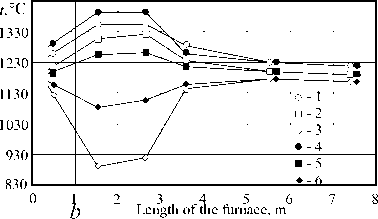

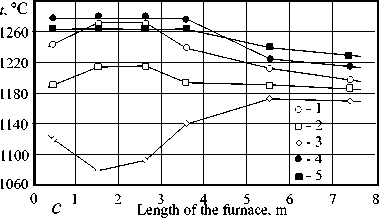

The Fig. 2 shows calculated furnace heat condition for designed (nominal) technological mode of charge smelting with following content, %: Cu – 18.41; Fe – 22.88; S – 21.25; SiO 2 – 4.16; CaO – 12.00; Sb – 0.52; Zn – 0.86; Pb – 0.37; As – 0.49; O2 – 8.76; C – 1.84; others – 8.46. Designed charge capacity of the unit 4.639 kg/s. Melting in flame on matte with 76 % copper content ([Cu] mt ) when specific technological oxygen consumption (90 vol. % О2) 0.17 nm3/kg of the charge. The heat output in the flame is 1827, in the bath – 68 kJ/kg of the charge. The designed torch construction has 20° flame expansion angle, energetic length – 4 m, aerodynamic length – from collar to melting surface. Output of exhaust dust is 18 % of smelted concentrate mass. The temperatures of charge and oxygen coming in the unit are 50 and 15 °С correspondingly. To obtain more precise results all calculations have been made taking into account the selectiveness and particle radiation in furnace volume [8].

As it shown, the furnace heat condition is notable for essential unevenness of temperature and heat flows distribution in smelting zone. The temperature maximums take place in flame area near the bath surface. Moving toward the uptake, the temperature of gas-dust flow decreases. The same lengthwise distribution have wall temperatures and temperatures of falling radiation flows. The analysis shows that designed (project) scheme of caissoned furnace provides effective lining cooling and medium level of temperatures and heat flows. Overall, the following integral calculation heat exchange indexes for designed (project) furnace technological mode have been obtained: the maximum density of falling radiational flows 348 kW/m2, temperature maximums of flame and liquid skull film on the walls correspondingly 1361 and 1282 ° C, exhaust gases temperature 1182, slag temperarture - 1241 ° C. The smallest thickness of skull in the most thermo-stressed areas is appear to be no less than 0.03 m, that provides durable work of the lining [9]. The smelting thermal balance calculation shows sufficient – 438 –

Table. KFP-20 furnace heat balance when copper content in matte ([Cu] mt = 75.6 %)

|

Heat input |

Heat output |

||||

|

Input components |

kW |

% |

Output components |

kW |

% |

|

1. Flame heat radiation |

8477.3 |

94.2 |

1. With slag |

3436.8 |

38.2 |

|

2. Heat radiation in the bath |

315.5 |

3.5 |

2. With matte |

1325.5 |

14.7 |

|

3. Physical heat of charge and blast |

208.8 |

2.3 |

|

1941.8 772.2 371.8 1153.5 |

21.6 8.6 4.1 12.8 |

|

Total: |

9001.6 |

100 |

Total: |

9001.6 |

100 |

à

Fig. 2. Heat flows and temperatures distribution in KFP-20 furnace: a – the density of falling radiation flows on the surface of the wall q fs : 1, 2 and 3 – in the bottom, middle and top areas; б – temperatures of gas-dust environment: 1, 2, and 3 – central layers in bottom, middle and top layers; 4, 5 and 6 – near-wall layers in bottom, middle and top areas; в – temperatures: 1, 2 and 3 – lining surfaces in bottom, middle and top areas; 4 and 5 – surface and the average weight of the slag

efficiency of designed unit as well. Thus, the total heat sink through the lining and with cooling agent is 16.9 % (table).

Conclusions

-

1. New technological scheme theoretical basics for one-stage KFP smelting of copper containing sulfide concentrate to blister copper (white matte) and high-basic self-braking slag are stated.

-

2. The KFP-20 furnace design is offered, the effective scheme and modes of lining cooling are set, the limits of technological and mode parameters alteration are estimated.

-

3. The zonal mathematical model have been developed and KFP-20 furnace heat exchange process features have been researched.

-

4. The possibility of one-stage KFP method is proved in vertical flame with a help of arch torches without additional furnace height increase at the expense of precombustion chamber installation, that allows to decrease furnace production and maintenance costs.

-

5. It is shown, that hard skull layer with thickness in the frame of 0.03…0.05 m decreases lining wear and under high temperature level of the process prevents emergences connecting with lining and vaporizing cooling elements burnout near charge torch area.

Изложены теоретические основы технологии одностадийной переработки медьсодержащего сульфидного концентрата в печах автогенной кислородно-факельной плавки на черновую медь (белый матт). На основе многозональной математической модели проведены предпроектные исследования особенностей теплообмена в печи. Установлено, что конструкция разработанного печного агрегата с вертикальным расположением шихтово-кислородных факелов обеспечивает достаточную надежность и экономичность его работы.