The influence of the method of fuel supply into the combustion chamber on the quality of mixing and on the carbon oxide formation

Автор: A. V. Baklanov

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 3 vol.21, 2020 года.

Бесплатный доступ

The burning of fuel in the combustion chamber of a gas turbine engine (GTE) is accompanied by formation of toxic substances. The most dangerous among them are carbon oxides that have a detrimental effect on humans and environment. In this regard the article is solving the urgent problem of determining the optimal method of gaseous fuel supplying in GTE combustion chamber to ensure low carbon-oxide emissions. The paper presents the design features of injectors that work with a separate supply of air and fuel. Natural gas is used as fuel. One of the considered injectors provides jet fuel supply by means of a perforated spray, and another one provides twisted fuel supply by means of a swirler built into the fuel channel. The main geometric parameters of the injectors are given as well, such as the size of the swirler, the number of blades, and the diameter of the output nozzle. In this regard the quality of air-fuel mixture preparation in a swirl jet in the outlet of the burner with two types of injector is defined. It is found that the best quality of mixing is ensured by the injector with jet spray. The design of a heat pipe simulator, in which the tested nozzle is placed, is considered. The design of a stand installation designed for testing injectors in a heat pipe simulator, as well as the modes under which these tests were carried out, are presented. The results were obtained in a heat pipe simulator with installed jet injectors and injectors with a swirling fuel jet. An analysis was conducted, which resulted in conclusions about the effectiveness of using jet injectors. According to the conducted research, the parameters of the injector with a swirling fuel jet are characterized by the presence of high values of CO levels in the combustion products, which is explained by the extremely low quality of mixing fuel with air and, consequently, low efficiency of fuel combustion. Jet fuel injection has low CO values, which indicates good quality of mixing fuel with air and high efficiency of a combustion process. As a result, we have received recommendations on setting the selected type of injectors in a full-size combustion chamber.

Combustion chamber of gas-turbine engine, emission reduction, diffusion combustion, injector, burner, mixing.

Короткий адрес: https://sciup.org/148321757

IDR: 148321757 | УДК: 621.43.056 | DOI: 10.31772/2587-6066-2020-21-3-356-363

Текст научной статьи The influence of the method of fuel supply into the combustion chamber on the quality of mixing and on the carbon oxide formation

Introduction. The quality of the preparation of airfuel mixture in the combustion chambers of gas turbine engines largely determines the level of emissions of toxic substances, herewith the quality of mixing is ensured by the way fuel is fed into the combustion chamber [1]. For this reason, the issue of the reasonable choice of a fuel supply method and determination of its influence on the formation of toxic substances in the combustion products of gas turbine engines is relevant. The main toxic substances in the combustion of hydrocarbon fuels are nitrogen oxides and carbon monoxide [2], therefore, reducing the level of their concentration is one of the most important tasks of engine manufacturers.

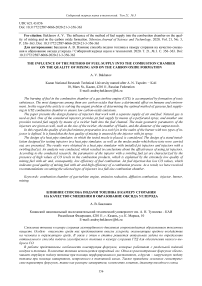

The burner unit of the annular combustion chamber includes an annular plate in which swirling gas burners are installed regularly around the circumference, between the inner and outer shells of the flame tube (fig. 1). In the center of these burners there are injectors that provide fuel supply [3].

Fig. 1. Burner device of a serial combustion chamber: 1 – injector; 2 – swirler; 3 – mixing chamber;

4 – jet nozzle in the primary zone of the chamber behind the nozzle heads 4 of each of the swirling burners, flows of the fuelair mixture are formed, these flows have paraxial circulation areas. The presence of such areas ensures the circulation of hot combustion products and active centers from the combustion zone to the base of the fresh mixture torch, which creates conditions for stable ignition and flame stabilization.

The fuel supply method can be jet in the form of fuel jets and in the form of a swirling fuel jet. This paper considers two injectors operating on gaseous fuel, which differ in the way of fuel supply [4].

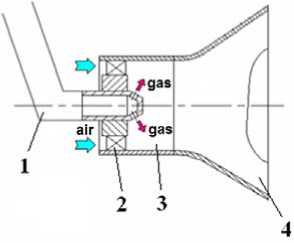

The principle of operation of the first one is to supply a swirling gas stream from the center of the burner. The injector (fig. 2) includes: body 2 , screw 1 with a nut (plug) 3 and a throttling washer 4 .

Fig. 2. Centrifugal gas injector: 1 – screw; 2 – injector body; 3 – nut (plug);

4 – throttling washer

Рис. 1. Схема горелочного устройства серийной КС: 1 – форсунка; 2 – завихритель; 3 – камера смешения;

4 – сопловой насадок

Рис. 2. Центробежная газовая форсунка:

-

1 – шнек; 2 – корпус форсунки; 3 – гайка (заглушка);

4 – дросселирующая шайба

The fuel supplied by the gas injectors 1 along the axis of each of the burners is mixed in the mixing chamber 3 with the air flow swirling in the swirler 2 . As a result,

The body of the injector 2 is made with an internal passage for supplying gas and with the metering holes A for gas outlet. The body has a flange with holes for attach- ing the injector to the combustion chamber body and a threaded channel for installing the screw 1. The throttling orifice 4 is installed to provide the required gas flow through the injector.

The injector operates in the following way: gas flows from the gas collecting main through pipelines to the injectors, passes through the fuel passage in the injector body. Getting on the blades of the screw 1 , it twists and leaves the metering holes A. Mixing with the air that goes out of the burner swirler, the gas enters the combustion chamber [4]. Such an injector can be classified as a centrifugal gas injector.

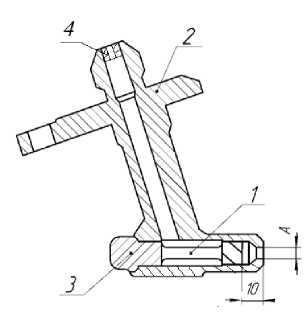

The screw installed inside the injector body (fig. 3) is a swirler with four blades twisted along a helical curve of right-hand thread, stroke – 32 mm, blade thickness – 1 mm.

Fig. 3. Injector screw (swirler):

D

10.5 mm; D inner screw = 5 mm;

outer screw

α o = 45o; а o = 4 mm; S 1 = 5 mm

Рис. 3. Шнек (завихритель) форсунки: Д нар.шн. = 10,5 мм; Д внутр.шн. = 5 мм; α o = 45 ; а o = 4 мм; S 1 = 5 мм

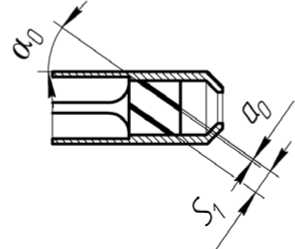

The second injector (fig. 4) differs from the first one in that the screw is excluded from the design, and at the tip of the injector there are four equally spaced holes (instead of one hole) for gas outlet [5].

To check the quality of fuel-air mixing behind the burner with a jet gas injector in comparison with a centrifugal gas injector, additional studies were carried out to determine the quality of the preparation of the fuel-air mixture at the outlet from the burners with these injectors.

Fig. 4. Jet gas injector. Four holes with the diameter d = 2.9 mm

Рис. 4. Струйная газовая форсунка. Четыре отверстия диаметром d = 2,9 мм

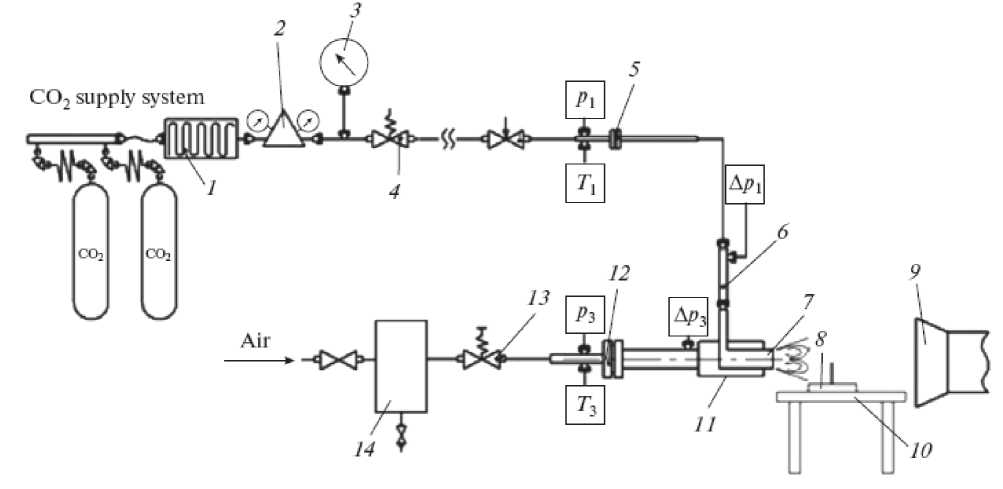

The studies were carried out on a testing stand (fig. 5), which includes three systems: air supply, gas supply and measurement system.

The burner is placed on the test-bench equipment as follows: the injector is installed in the receiver body, to the connecting branch of which fuel is supplied. The burner is placed with the sleeve part in the orifice of the receiver cover. The fuel from the jet injectors is fed into the inner cavity of the jet nozzle, as a result, fuel-air mixture is formed at the outlet of the burner. The fuel is supplied to the propellant feed system from the cylinder manifold. Carbon dioxide (CO 2 ) is used as a gas to replace methane. To measure the concentration fields at the outlet of the burner, a coordinate device with a receiver of the gas analyzer called PKU-4-MK-S is installed. This device allows us to move the detector receiver axially and radially. Concentration measurements are made from the center of the burner, for which the nozzle axis “0” is taken, with further movement of the sampling instrument in both directions along the burner nozzle, across the jet every 4 mm. According to this principle, measurements are performed repetitively in seven sections: at the nozzle exit section and every 50 mm up to the distance of 300 mm [6].

The measurements of CO2 concentrations in the burner jets were also aimed at determining the distance at which the concentration pattern is equalized, as well as at fixing the rate of concentration change along the jet axis [7; 8].

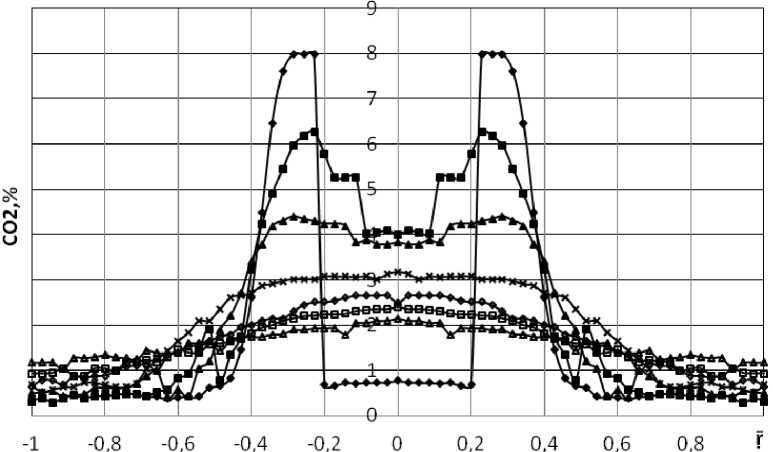

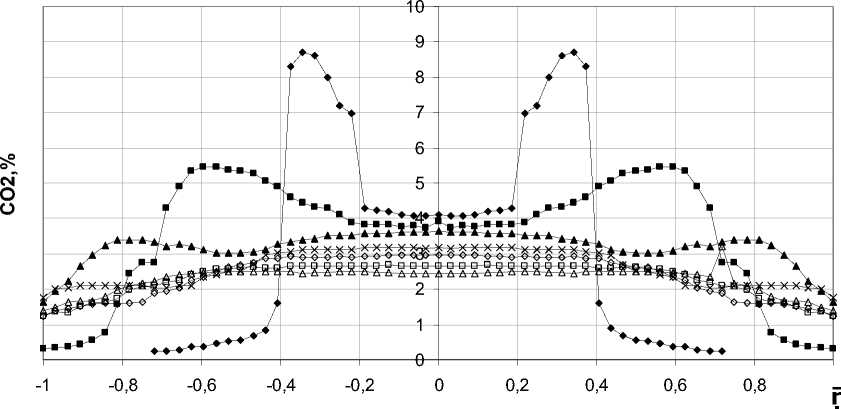

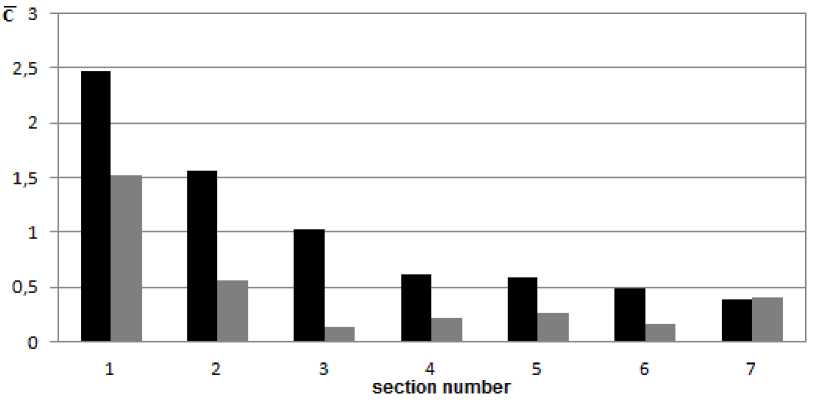

To visualize the intensity of the mixing process, fig. 6 shows the characteristics of СО2 = f (r), showing in detail the change in the concentration over the cross section of the swirling jet.

According to the data in fig. 6, it can be seen that behind the burner with a centrifugal gas injector, there is no significant expansion of the mixing area, which is associated with the formation of the high flow rate of fuel gas, which leads to the high ejection ability of the jet forming a narrow flow core, in which intensive mixing of fuel with air occurs. Beyond the relative coordinate r = -ri- rmax corresponding to the value of 0.5, mixing does not occur, since this area contains practically no fuel.

The burner with a jet gas injector has a wide concentration field and its low level, which is explained by the volumetric recirculation zone provided by the presence of jet fuel supply, which makes it possible to mix fuel with air throughout the entire volume of the swirling jet formed behind the jet nozzle.

The quality of preparation was assessed analyzing the dependence characterizing the maximum relative deviation of concentration from the mean integral value of the concentration field [9]:

C =

C -C max mi

С mi

where C – maximum value in the measured concen-max tration field; Сmi – mean integral value of concentration.

In accordance with this dependence, the indicator of the ideally regular distribution of the concentration of the air-fuel mixture in the section is the value C = 0.

Fig. 7 shows that the best mixing quality in all seven sections is observed for the burner with a jet gas injector. That proves the quality of the mixture preparation.

The measurements of the concentration fields behind the swirl burners confirm that the mixing process is achieved in the burner with a jet gas injector due to the jet fuel supply to the recirculation zone, and in the burner with a centrifugal gas injector due to the high ejection ability of the swirling fuel jet inside the air stream swirled in the opposite direction [10].

Further studies comprised placing the injectors into the combustion chamber in order to determine the emissions of nitrogen oxides and carbon monoxide. The compartment is 1/8 part of a full-size combustion chamber, consisting of an outer and inner shell, a flame tube with a burner unit, in which four burners with injectors are installed. The combustion can is bounded by cooling sidewalls on both sides [11].

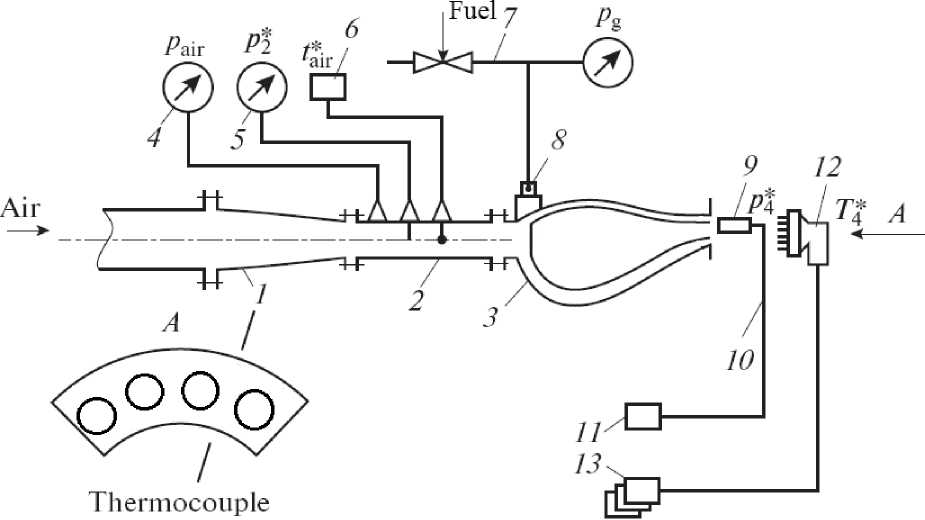

The combustion chamber compartment is studied on a testing stand, the diagram of which is shown in fig. 8. The stand is equipped with the necessary systems for measuring and registering parameters. The stand includes a gas turbine engine (blowing engine), which is used to supply compressed air to the tested compartment of the combustion chamber 3 . Air is taken from the high-pressure compressor, then it enters through the pipeline into the central line 1 . Air consumption is measured by a flow meter.

The stand is equipped with a measuring section 2 with recording the readings of a pressure sensor 4 , 5 ; the air temperature is controlled by a chromel-alumel thermocouple 6 . The fuel (natural gas) is supplied through the fuel system 7 to the fuel manifold 8 of the combustion chamber compartment, and then it enters the front-line device and injectors. To measure the temperature in the outlet of the compartment, a survey rake 12 is installed at the outlet of it, the data from which is transmitted to the recording equipment 13 . To determine the composition of combustion products, a gas sampling probe 9 and a line for transporting combustion products 10 to the gas analyzing equipment 11 are located at the outlet of the compartment.

The gas analyzer testo350 [12] is used to determine the CO content in combustion products.

The compartments were tested under the following conditions: Air pressure Pa = 1.37 kPa, Air flow Ga = 1.72 kg / s, Air temperature Ta = 488 K, superficial velocity speed λ = 0.28. The change in the excess air ratio was carried out by reducing the fuel consumption.

After determining the component composition of combustion products for carbon monoxide, the emission index EIi is calculated, according to the equation [13]:

EI i = µ i (1 -α i ⋅ L 0 ) ⋅χ i ⋅ 10 - 3. (2) µ в

Fig. 5. Structure of test stand:

1 – Heater; 2 – outlet reducer; 3 – pressure gauge; 4 – cutoff valve; 5 – flow meter; 6 – tee joint; 7 – burner; 8 – gas analyzer; 9 – ventilation device for removing carbon dioxide from the working room; 10 – coordinate table; 11 – receiver; 12 – flow meter;

13 – electromagnetic valve; 14 – moisture separator; absolute pressure and СО 2 temperature sensors installed upstream of the flow meter (throat); sensor for measuring pressure difference across the СО 2 path; absolute pressure and air temperature sensors installed upstream of the flow meter; and sensor for measuring air pressure difference installed upstream of the receiver

Рис. 5. Принципиальная схема стенда:

1 – нагреватель; 2 – выходной редуктор; 3 – манометр; 4 – отсечной клапан; 5 – расходомер; 6 – тройник;

-

7 – горелка; 8 – газоанализатор; 9 – вентиляционное устройство для отвода углекислого газа из рабочего помещения; 10 – координатный стол; 11 – ресивер; 12 – расходомер 13 – электромагнитный клапан; 14 – влагоотделитель

a

b

Fig. 6. Field of CO 2 concentrations in various sections of a swirling jet: а – centrifugal gas injector (CGI); b – with jet injector (JI)

♦ - nozzle cut; ■ - 50 mm; ▲ - 100 mm; x — 150 mm; ◊ — 200 mm; □ — 250 mm; A - 300 mm

Рис. 6. Поле концентраций СО2 в различных сечениях закрученной струи: а - ЦБГФ; b - СГФ

-

♦ - срез сопла; ■ - 50 мм; ▲ - 100 мм; x - 150 мм; ◊ - 200 мм; □ - 250 мм; A - 300 мм

Where L 0 = 16.7 – stoichiometric coefficient of methane combustion (kg of air / kg of fuel); α i – total or local air-to-fuel ratio; µ i – molar mass of the determined toxic substance; µ в – molar air mass; χ i – volume fraction of a toxic substance (ppm). When calculating EIi we have taken the following values of molar masses:

цсо = 28.010 kg / kmol and ц в = 28.964 kg / kmol [14; 15].

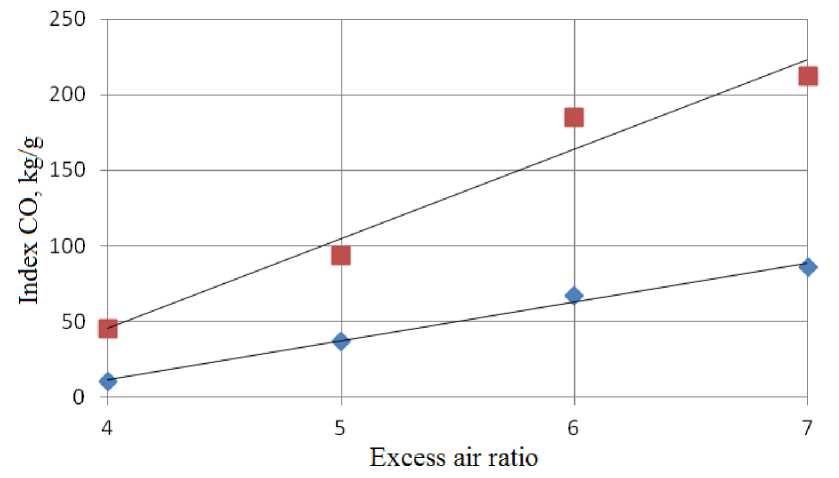

According to the results of the measurements (fig. 9), it can be seen that the value of the carbon monoxide emission index in the compartment with a jet gas injector has decreased by half compared to the compartment with a centrifugal gas injector.

The results showed that it is preferable to use gas distribution with the help of jet feed, which, in contrast to the supply of swirling fuel jets, not only increases the interface of the mixed media, but it also allows us

(by appropriate orientation and range of the jets) to distribute fuel over the air flow section with the required concentration profile in the flame tube in a simple and reliable way.

Fig. 7. The quality of the preparation of the air-fuel mixture in a swirling stream: ■ – the burner with centrifugal gas injector (CGI); – the burner with jet injector (JI)

Рис. 7. Качество подготовки топливовоздушной смеси в закрученной струе: ■ – горелка с ЦБГФ; – горелка с СГФ

seating plate

Fig. 8. Stand for testing the sections of a combustion chamber

Рис. 8. Стенд для исследования отсеков камеры сгорания

Fig. 9. CO index at the outlet of the compartment: ♦ - JI; ■ - CGI

Рис. 9. Индекс СО на выходе из отсека: ♦ - СГФ; ■ - ЦБГФ

Conclusion.

-

1. The organization of jet fuel supply will allow us to perform the most efficient combustion of gaseous fuel in comparison with the fuel supply with a swirling jet, which makes it possible to halve the index of carbon monoxide in the combustion products of the combustion chamber compartment.

-

2. Jet fuel supply provides better preparation of a fuelair mixture.

-

3. It is recommended to install a jet gas injector as a measure to reduce carbon monoxide in combustion products of a gas turbine engine.

Список литературы The influence of the method of fuel supply into the combustion chamber on the quality of mixing and on the carbon oxide formation

- Matveev S. S., Zubrilin I. A., Orlov M. Yu., Matveev S. G., Chechet I. V. Investigation of fuel distribution in partially premixed swirled burner with pilot flame. Proceedings of the ASME Turbo Expo Turbomachinery Technical Conference and Exposition. Сер. “ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, GT 2016” 2016.

- Baklanov A. V., Neumoin S. P. [A technique of gaseous fuel and air mixture quality identification behind the swirl burner of gas turbine engine combustion chamber]. Russian Aeronautics. 2017, Vol. 60, P. 90–96 (In Russ.).

- Gritsenko E. A., Danilchenko V. P., Lukachev S. V. Konvertirovanie aviatsionnykh GTD v gazoturbinnye ustanovki nazemnogo primeneniya [Conversion of aviation gas turbine engines to land-based gas turbines]. Samara, SNTs RAN Publ., 2004, 266 p.

- Mingazov B. G. Kamery sgoraniya gazoturbinnykh dvigateley [The combustion chamber of gas turbine engines]. Kazan, Izd-vo Kazan. gos. tekhn. un-ta Publ., 2004, 220 p. (In Russ.).

- Baklanov A. V. [Controlling fuel combustion process by burner design change in gas turbine engine combustion chamber]. Vestnik Moskovskogo aviatsionnogo instituta. 2018, Vol. 25, No. 2, P. 73–85 (In Russ.).

- Markushin A. N., Baklanov A. V. [Testing stands for researching the processes and maturation of low emission combusters]. Vestnik of the Samara State Aerospace University. 2013, No. 3(41), P. 131–138 (In Russ.).

- Lefebvre A. H., Ballal D. R. Gas Turbine Combustion: Alternative Fuels and Emissions. Third Edition. CRC Press, 2010, 560 p.

- Lefebvre A. H. Fuel effects on gas turbine combustion-ignition, stability, and combustion efficiency. Am. Soc. Mech. Eng. (Pap.); (United States). 1984, Vol. 84, No. CONF-840611.

- Gritsenko E. A., Danilchenko V. P., Lukachev S. V. et al. Nekotorye voprosy proektirovaniya aviatsionnykh gazoturbinnykh dvigateley [Some issues of designing aircraft gas turbine engines]. Samara, SNTs RAN Publ., 2002, 527 p.

- Gokulakrishnan P., Fuller C. C., Klassen M. S., Joklik R. G., Kochar Y. N., Vaden S. N., Seitzman J. M. Experiments and modeling of propane combustion with vitiation. Combustion and Flame. 2014, Vol. 161, No. 8, P. 2038–2053.

- Yi T., Gutmark E. J. Real-time prediction of incipient lean blowout in gas turbine combustors. AIAA journal. 2007, Vol. 45, No. 7, P. 1734–1739.

- Moses C., Roets P. Properties, Characteristics and Combustion Performance of Sasol Fully Synthetic Jet Fuel. ASME Journal of Engineering for Gas Turbines and Power. 2009, Vol. 131, No. 4, P. 041502-041502-17.

- Canilo P. M., Podgornyy A. N., Khristich V. A. Energeticheskie i ekologicheskie kharakteristiki GTD pri ispol'zovanii uglevodorodnykh topliv i vodoroda [Energy and environmental characteristics of gas turbine engines when using hydrocarbon fuels and hydrogen]. Kiev, Nauk. Dumka Publ., 1987, P. 224.

- Dubovkin N. F. Spravochnik po teplofizicheskim svoystvam uglevodorodnykh topliv i ikh produktam sgoraniya [Handbook of the thermophysical properties of hydrocarbon fuels and their combustion products]. Moscow – Leningrad, Gosenergoizdat Publ., 1962, 288 p.

- Isserlin A. S. Osnovy szhiganiya gazovogo topliva [Basics of burning gas fuel]. Leningrad, Nedra Publ., 1987, 336 p.