The investigation of thermal power characteristics of wood pulp

Автор: Yalechko Vladimir Ivanovich, Kochubey Viktoriya Vitalyevna, Gnatishin Yaroslav Mikhaylovich, Dzyadevich Boris Nikolaevich, Zaikov Gennadiy Efremovich

Журнал: НБИ технологии @nbi-technologies

Рубрика: Технико-технологические инновации

Статья в выпуске: 2 (11), 2014 года.

Бесплатный доступ

To study the heating value of wood we used integrated thermal analysis. We have studied the aspen wood aged 10 years. For sample 3 (bark), which is characterized by the largest coke residue, the heterogeneous oxidation process occurs most rapidly. The thermal analysis shows that the pattern of the cortex has the highest heating value.

Wood biomass, thermal analysis, mathematical modeling, heating value, utilization

Короткий адрес: https://sciup.org/14968319

IDR: 14968319 | УДК: 674.8 | DOI: 10.15688/jvolsu10.2014.2.6

Текст научной статьи The investigation of thermal power characteristics of wood pulp

The use of wood pulp as an energy feedstock is rather vital. Effective and ecologically combustion of biomass in fuel devices is determined by the characteristics of combustion mode.

The important role today is given to the issues of using wood biomass, including fast-growing types, as energy resources. In order to determine the combustion characteristics of wood biomass and setting the optimal parameters it is necessary to carry out the complex research.

The investigation methods of burning process are the physical modeling in the laboratory and semiindustrial plants, with further full-scale tests of the developed flowsheets and analytically through the mathematical models. Analytical research requires the information about the kinetic and thermal power characteristics of wood biomass.

It should be noted that the process can be followed by possible significant reduction of substantial funds and resources expended in obtaining the necessary information from the relevant experimental setups [2; 4; 9].

Research methodology

To study the calorific value of wood the authors used integrated thermal analysis, including thermogravimetry (TG), differential thermogravimetry (DTG) and differential thermal analysis (DTA). The objects of research were represented by samples: stem wood of aspen (sample 1), stem wood of aspen, mixed in equal proportions from the bark of aspen (sample 2), aspen bark (sample 3).

The age of aspen wood was 10 years.

Thermal analysis of samples of aspen wood was performed on derivator Q – 1 500 D system “F. Paulik – J. Paulik – L. Erdey” with the registration of the analytical signal of mass loss and thermal effects using a computer. Samples of wood were analyzed in dynamic mode with the heating rate of 10 °C/min in air. The mass of each sample was 100 mg. The reference substance was aluminum oxide [3; 6].

Results and discussion

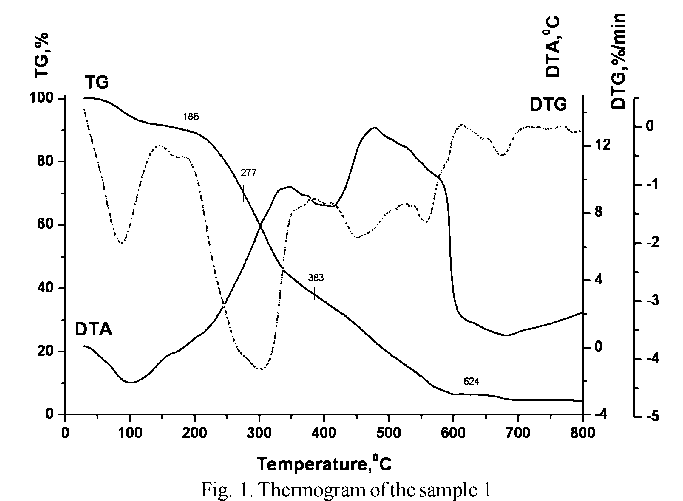

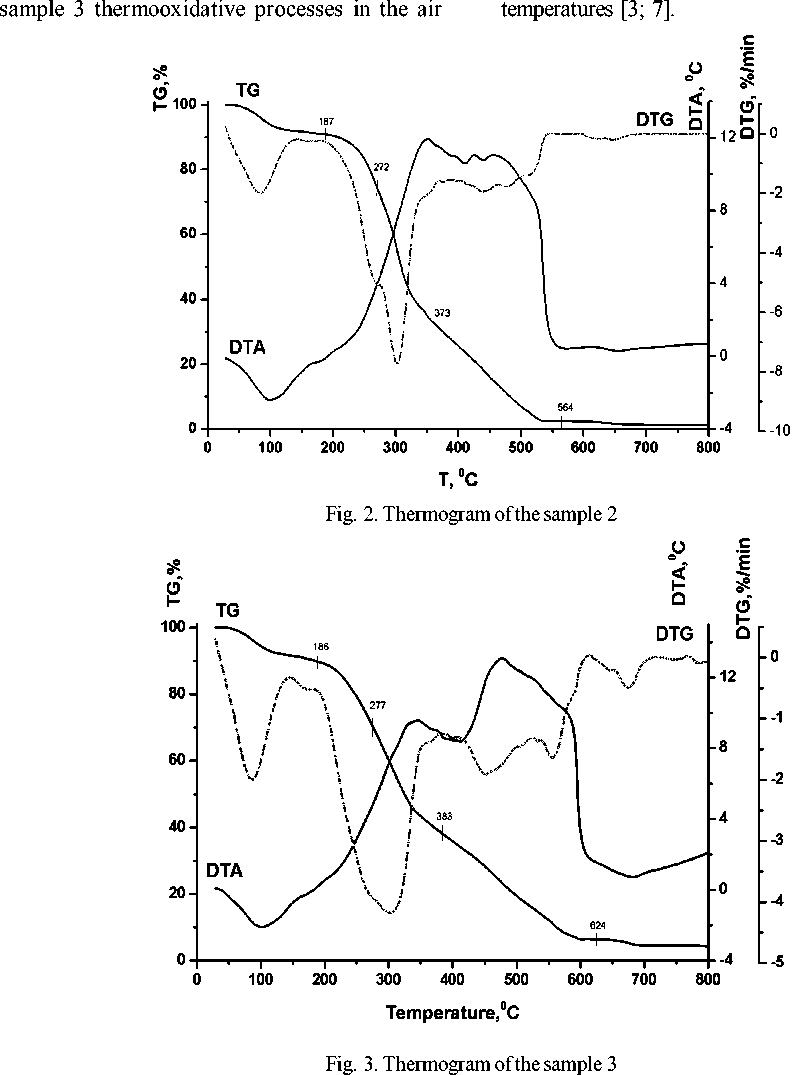

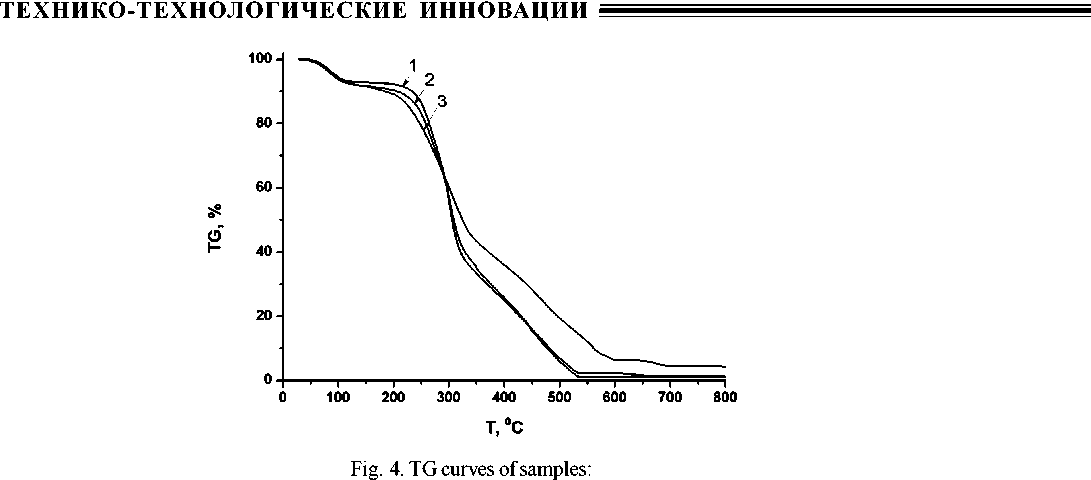

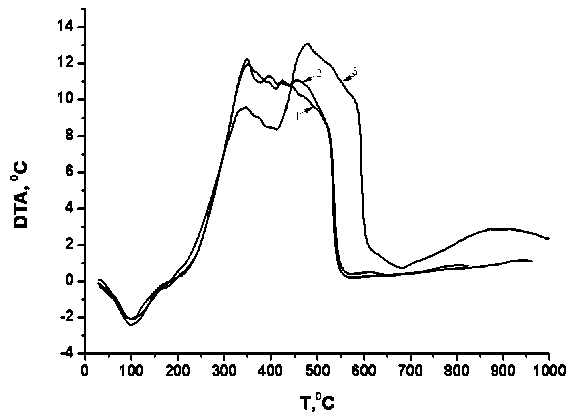

The thermograms of samples are presented in figures 1–3, and the results of their treatment – in table. Figures 4 and 5 show the comparison of TG and DTA curves of aspen wood samples.

At the first stage (20–187 °C) the endothermic processes take place due to evaporation of chemically bound water and constitutional water. Intensive mass loss is observed in samples of TG curves at temperatures higher than 200 °C.

At the second stage of thermolysis, which according to the differential thermogravimetric analysis takes place in the temperature range of 186–277 °C, along with the endothermic dehydration and pyrolysis processes (cleavage of volatile degradation products), which are accompanied by sharp decrease of the degree of cellulose polymerization, developing exothermic thermooxidative destructive processes, as DTA curve shows the course aspen samples (fig. 1–3).

Unlike other samples of aspen, the sample 3 in the second phase of thermolysis loses much mass (fig. 4). This indicates that the sample of bark undergoes the processes of cleavage of volatile decomposition products [3; 7; 8].

The third stage of thermolysis (277–383 °C) is accompanied by the largest mass loss of the aspen samples (see the table) and the appearance of bright exothermic effect on the curves DTA, there are active thermooxidative destructive phase flow are less intense. This shows a small weight loss of the sample and the appearance of the smallest compared with other samples, exothermic effect at the DTA curve.

At the fourth stage of thermolysis (372– 624 °C) burning of the carbonated residue of aspen samples occurs. For sample 3, which is characterized by the largest coke residue, heterogeneous oxidation process occurs most rapidly. This is evidenced by the appearance of the most striking in comparison with other samples exothermic effect on the DTA

processes, accompanied by flame combustion of volatile decomposition products (fig. 5). For curve, which is shifted into the region of higher

1 – sample 1; 2 – sample 2; 3 – sample 3

Fig. 5. DTA curves of samples:

1 – sample 1; 2 – sample 2; 3 – sample 3

Results of comprehensive thermogravimetric and differential thermogravimetric analysis of samples 1–3

|

Sample |

Stage |

Temperature range, 0С |

Loss of mass, % |

|

sample 1 |

1 |

20–187 |

7,6 |

|

2 |

187–277 |

19,5 |

|

|

3 |

277–372 |

43,3 |

|

|

4 |

372–569 |

28,5 |

|

|

sample 2 |

1 |

20–187 |

9,2 |

|

2 |

187–272 |

17,5 |

|

|

3 |

272–373 |

42,9 |

|

|

4 |

373–564 |

28,1 |

|

|

sample 3 |

1 |

20–186 |

10,0 |

|

2 |

186–277 |

20,4 |

|

|

3 |

277–383 |

31,2 |

|

|

4 |

383–624 |

32,0 |

Chemical analysis of elemental composition of dry weight mixture of aspen wood: carbon – 52.65 %, hydrogen – 4.38 %, oxygen – 37.4 %, nitrogen – 0.42 %, ash– 1.5 %, heating value is 18,4 MJ/kg.

Conclusions

As seen from conducted thermal analysis the sample of bark has the highest heating value. The processes of thermooxidative degradation and burnout of carbonated residue is accompanied by the largest exothermic effect.

The results of mathematical modeling make it possible to use them to develop effective constructions of appropriate fuel devices for efficient utilization of wood waste and wood biomass. During the combustion of biomass in power plants or boilers emitting only CO2 gas that will be absorbed by the plant during its growth.

Список литературы The investigation of thermal power characteristics of wood pulp

- Bakhracheva Yu.S. Fracture Toughness Prediction by Means of Indentation Test. International Journal for Computational Civil and Structural Engineering, 2013, Vol. 9, no. 3, pp. 21-24.

- Khzmalyan D.M. The Theory of Combustion Processes. Moscow, Energoatomizdat Publ., 1990. 221 р.

- Lipskis A.L., Kvikli A.V., Lipskene A.M., Maciulis A.N. The Calculation Kinetic Parameters of Thermal Degradation of Polymers. Macromolecular compounds, 1976, Vol. XVIII, рр. 426-431.

- Madoyan A.A. et al. More Efficiently Burn Low Grade Coal in Power Boilers. Moscow, Energoatomizdat Publ., 1991. 143 р.

- Semenova L.M., Bakhracheva Yu.S., Semenov S.V. Laws of Formation of Diffusion Layers and Solution of the Diffusion Problem in Temperature-Cycle Carbonitriding of Steel. Metal Science and Heat Treatment, 2013, Vol. 55, no. 1-2, pp. 34-37.

- Shestak Y. The Theory of Thermal Analysis. Moscow, Mir Publ., 1987. 326 р.

- Tsapko Y.V. The Study of Kinetic Parameters During Pyrolysis of Fire Protected Wood by Impregnating Agents. Fire safety, 2011, no. 19, pp. 163-169.

- Yegunov V.P. Introduction to Thermal Analysis. Samara, 1996. 154 р.

- Zeldovich Y.B., Bernblatt G.I., Librovich V.B., Makhviladze G.M. The Mathematical Theory of Combustion and Explosion. Moscow, Mir Publ., 1980. 122 р.