The method of the automation of the plasmotron movement by six-axis robotic manipulator

Автор: Kalashnikov A.S., Rudenko M.S., Kucherenko A.D., Girn A.V., Mikheev A.E.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 4 vol.22, 2021 года.

Бесплатный доступ

The article presents a method for automating the creation of trajectories of the plasmotron movement by a six-axis robotic manipulator. The automation system was created on the basis of an industrial robot from KUKA. The automation of the creation of trajectories of the plasmatron over the surface of the part is implemented as follows: the trajectory of the plasmatron is created in a graphic editor in the .dwg format. The created file is loaded into the CAM program for CNC machines. A CAM program converts a vector or an area specified by vectors into a control command in g-code format, which is then converted to KRL by a program written in the Python programming language. The development of the program consisted of two stages: the creation of rectilinear movements and the creation of curvilinear movements. The result of the method is presented.

Plasma spraying, industrial robot, Python, automation

Короткий адрес: https://sciup.org/148329600

IDR: 148329600 | УДК: 621.785.53 | DOI: 10.31772/2712-8970-2021-22-4-700-707

Текст научной статьи The method of the automation of the plasmotron movement by six-axis robotic manipulator

In the aerospace, metallurgical, and oil-producing industries, the requirements for safety, reliability, and durability of products during operation under extreme conditions (high temperatures, dynamic loads, corrosive environments, etc.) are increasing every year. To meet these requirements, it becomes necessary to apply protective coatings to products. One of the methods for applying protective coatings is plasma spraying, which is widely used in aerospace engineering [1–4].

Every year the number of products used in rocket and space technology is growing, their shape and size are becoming more complicated [5–8]. In this regard, the methods of applying plasma coatings become practically impossible. The working body for coating is a plasmotron [9–10]. A jet of low-temperature plasma is created in the plasmotron, into which the powder of the coating material is fed, the powder melts under the influence of the plasma temperature and is applied to the substrateproduct. However, in order to obtain a coating, the plasmotron must be moved over the surface of the substrate along a certain trajectory and at a certain speed. To do this, the plasmotron is placed on a robot manipulator, which ensures its movement.

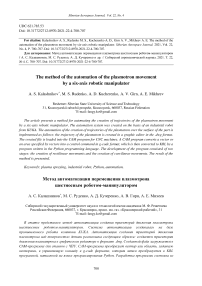

There are a large number of industrial robot manipulators on the market that can move the plasmo-tron during the spraying process, for example, robots from KUKA, Doosan ROBOTICS, ABB, etc. [11–13]. The robot manipulator is a six-axis industrial mechanism with drives and gearboxes. A plas-motron is installed on the mounting flange of the A6 axis (fig. 1).

Fig. 1. The axes of a six-axis industrial robotic arm and the possibility of their movement

Рис. 1. Оси шестиосного промышленного six-axis industrial robotic arm робота-манипулятора и возможность их передвижения

There are plasmotrons that are capable of coating hard-to-reach places [14], but without a program for automating the movement of the plasmotron, their efficiency drops. Manufacturers of industrial robots provide paid software for creating control programs, the functionality of which is excessive for the movement of the plasmotron during coating. The acquisition of such software is not advisable, however, manual programming of trajectories is labour-intensive. Therefore, the task of developing a method for automatically controlling the movement of a plasmotron by an industrial robot is of current interest.

The system of the automation of the movement control process was developed for the industrial robot of the KUKA KR16-2 series, it is worth noting that the method can also work with other versions of industrial robots. If the plasmotron is moved by a 6-axis KUKA robot, it is controlled from a portable programming device – the KUKA smartPAD control panel. KUKA robotic arms are programmed in KRL. Plasmotron movement trajectories can be specified by the following types of commands:

– Point-to-Point (PTP) movement – movement occurs along the fastest trajectory, which, as a rule, is not a straight line. Due to the fact that the axes of the robot perform rotational motion, non-linear trajectories are executed faster than linear ones;

-

– linear movement (LIN) – movement is performed in a straight line;

-

– circular movement (CIRC) – movement along a circular path. Auxiliary (lying on the trajectory) and target points are set;

-

– SPLINE movements – for complex curved trajectories [11].

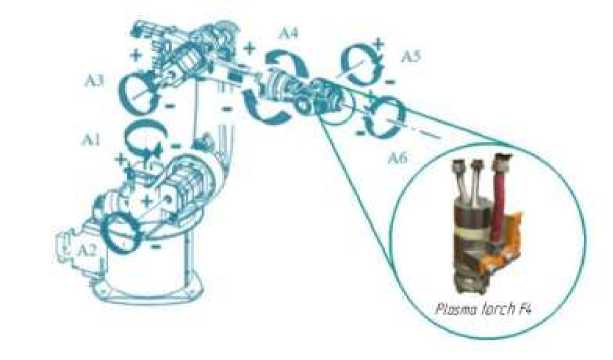

Automation of creating trajectories for processing a flat surface is implemented as follows: the trajectory of the plasmotron movement is created in a graphical editor in .dwg format. The created file is loaded into the CAM program for CNC machines. A CAM program converts a vector or a region defined by vectors into a control command in g-code format, which is then converted to KRL by a program written in the Python programming language.

| Python program

Setting me pan and setting the starting poert

Create Wes on smartPAD and save them tor future worts

Analysis ct me saved tiles and'me control program (g-code) and trie formation of the control program 'Ue in the required term

Uploading a new NC program tile to KUKA

Operator actions

Creation of a control program tor a part in a cam program ig-cooei

Fig. 2. The flowgraph of an automated algorithm for creating a control program

.src format stores the program code, and the second file of the format .dat stores the coordinates of the points, the shaft rotation angles and other necessary parameters.

The Python program developed by us parses files from the KUKA smartPAD control panel and the trajectory file in g-code format from the CAM program using regular expressions using the re module [15]. Then the program generates a file with a control trajectory, supplementing the program code in the file with .src format. This file is loaded on the KUKA smartPAD.

The algorithm of actions for creating a control program is shown in the flowchart in fig. 2.

The created program converts the g-code format in KRL into LIN movement, which was implemented at the first stage of the method development. Further, the distance between the points of the trajectory is analyzed and determined whether they lie on a straight or curved section, which was implemented at the second stage of development.

Рис. 2. Блок-схема автоматизированного алгоритма создания управляющей программы

First stage

At the first stage, the creation of linear trajectories (LIN movement) is implemented, which is necessary and sufficient for coating rectangular areas of the part surface.

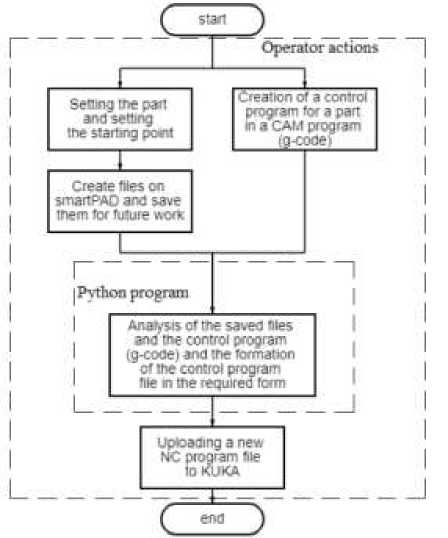

In the created motion trajectory by the CAM program, the starting point is set by zero coordinates, for this, as indicated in the flowchart, it is required to set the starting point, according to which all points of the trajectory will be recalculated. The trajectory in g-code format is shown in fig. 3. These data are converted to KRL format. The possibility of having a change in coordinates along one axis is taken into account. Extra data for us, such as spindle speed and others are ignored.

Xl.177Y-32.378 X1.6O1V-32.322 X1.458Y 32.232 XI. 342V 32.116 X1.2S2V31.973 XI.196V 31.812 XI.177V 31.642

|

LIN |

{x |

1.177, |

V -32.378} |

|

LIN |

{X |

1.601, |

Y -32.322} |

|

LIN |

(X |

1.458, |

V -32.232} |

|

LIN |

(X |

1.342, |

V -32.116} |

|

LIN |

(X |

1.252, |

Y -31.973} |

|

LIN |

{X |

1.196, |

Y -31.812} |

|

LIN |

(X |

1.177, |

V -31.647} |

Fig. 3. Specifying a linear motion in the control program in g-code format and in KRL

Рис. 3. Задание прямолинейного движения в управляющей программе в g-code формате и в KRL

Second stage

At the second stage, the motion commands CIRC and SPLINE for curved sections of the trajectories were evaluated, since the use of LIN for these purposes leads to a long “hanging” of the plasmo-tron over one area, which violates the calculated spraying mode. The results of the evaluation showed that for the given task it is more advantageous to use the SPLINE movement, since it provides smooth movement at a given speed without “hang-ups”, in contrast to CIRC.

The implementation algorithm with SPLINE movement is based on the program of the first stage with further analysis of the trajectory points. The CAM program divides a curved line into a set of points, respectively, by estimating the distance between two adjacent points using the formula rn = J(xn+j - xn )2 + (yn+j - yn )2, one can determine whether they lie on a straight or curved line and, accordingly, change the linear motion command to SPLINE.

UN (X 975.198, V 247.396) SPUME

SPl (X 975.145, V 247.579}

SP1 (X 975.119, V 247.772)

SPl (X 975.122, V 247.967) SPl (X 975.154, V 248.159) SPL (X 975.214, V 248.341} SUN (X 976.080, V 256.159) EHDSPlINE

UN (2 280.108)

UN (X 974.604, V 257.487}

Fig. 4. Defining a curvilinear movement in the control program (KRL)

Рис. 4. Задание криволинейного движения в управляющей программе (KRL)

To achieve this, it is necessary to eliminate the absence of one of the coordinates of the point when it is repeated (when moving parallel to the X or Y axes). The beginning of the movement SPLINE is set by the SPLINE command and ends with the ENDSPLINE command, the movement within this block is formed by the SPL command for a curved line and the SLIN command for a straight line. Movement along the Z axis is formed by changing only this coordinate, carried out by the movement of LIN. The commands in the control program have the form shown above in Fig. 4.

Conclusion

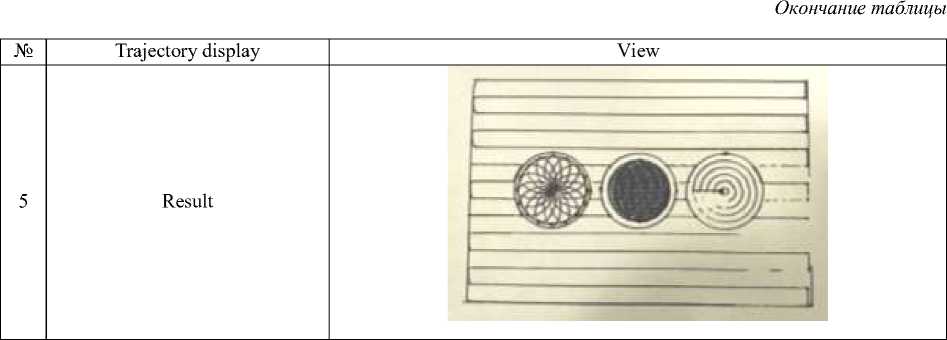

The created program in the Python language allows one to program the movement of the plasmo-tron on a 6-axis KUKA KR16-2 robotic arm using a CAM program for CNC machines. This simplifies the creation of trajectories of the plasmotron on the surface of the parts. The table shows the stages of automating the creation of trajectories of the plasmotron. To visualize the result of the program, a marker was installed on the mounting flange of the robot manipulator, which displayed the specified trajectory.

Stages of automating the creation of trajectories

|

№ |

Trajectory display |

View |

|

1 |

In the graphic editor |

® о |

|

2 |

In the CAM program for CNC machines |

^йО*- .Г— |

|

3 |

In g-code format |

Х73.500Y-41.038 X-73.500Y-41.038 X-73.500Y-33.577 X73.500Y-33.577 X73.500Y-26.115 Х-73.500 X-73.500Y-18.654 Х73.500Y-18.654 |

|

4 |

In KRL |

LIN {X 907.113, Y 209.41} LIN {X 907.113, Y 216.871} LIN {X 1054.113, Y 216.871} LIN {X 1054.113, Y 224.333} LIN {X 1030.237, Y 224.333} SPLINE SPL {X 1030.745, Y 224.91} SPL {X 1031.229, Y 225.514} SPL {X 1031.685, Y 226.142} SPL {X 1032.113, Y 226.793} |

In the future, it is planned to improve the program for three-dimensional trajectories, for example, using the finishing processing of the relief of a three-dimensional part in the CAM program, it is possible to spray a coating with a plasmotron on three-dimensional parts of simple shapes, such as a reflector. It is also planned to reduce the number of steps of the automation algorithm by introducing a Python program into the CAM program with a macro and consider other automation options.

Список литературы The method of the automation of the plasmotron movement by six-axis robotic manipulator

- Khasuy A. Tekhnika napyleniya [Spraying technique]. Moscow, Mashinostroenie Publ., 1975, 288 p.

- Kudinov V. V. Plazmennye pokrytiya [Plasma coatings]. Moscow, Nauka Publ., 1977, 270 p.

- Mikheev A. E., Kolmykov V. A. [Improving the performance characteristics of the surfaces of structural elements of aircraft]. Avtomatizatsiya protsessov obrabotki. Moscow, MAKS Press Publ., 2002, 224 p.

- Zuev D. M., Shakhmatov A. V., Khanov V. Kh. [The concept of reconfigurable space lab on the example of the spacecraft ReshUCube]. Kosmicheskie sistemy. Moscow, Pero Publ., 2021, P. 17–18.

- Aysha S. Hameed, Bindu G. R-Single segment approach and landing guidance and control for an unpowered reusable launch vehicle. Aerospace Science and Technology. 2021, No. 115, P. 106777. Doi: https://doi.org/10.1016/j.ast.2021.106777.

- Anan’ev A. I., Borshchev Yu. P., Kvardakov M. Yu. et al. [The formation of geometricallycomplex parts of space vehicles by means of selective laser melting]. Vestnik NPO im. S.A. Lavochkina. 2017, No. 1(35), P. 87–92 (In Russ.).

- Ethan P. Hopping, Wensheng Huang, Kunning G. Xu. Small Hall Effect Thruster with 3D Printed Discharge Channel: Design and Thrust Measurements. Aerospace. 2021, Vol. 8, P. 227. Doi: https://doi.org/10.3390/aerospace8080227.

- Lawand Lydia, Massimo Panarotto, Petter Andersson, Ola Isaksson, Michael Kokkolaras. Dynamic Lifecycle Cost Modeling for Adaptable Design Optimization of Additively Remanufactured Aeroengine Components. Aerospace. 2020, No. 8, P. 110. Doi: https://doi.org/10.3390/aerospace7080110.

- Mikheev A. E., Girn A. V., Ravodina D. V., Yakubovich I. O. [Plasmatron for coating of refractory dispersed materials]. Siberian Journal of Science and Technology. 2018, Vol. 19, No. 2, P. 365–372 (In Russ.). Doi: 10.31772/2587-6066-2018-19-2-365-372.

- Mikheev A. E., Girn A. V., Yakubovich I. O., Rudenko M. S. [Spraying of coatings with a plasma torch with powder feeding in a satellite plasma]. Siberian Aerospace Journal. 2021, Vol. 22, No. 1, P. 194–200 (In Russ.). Doi: 10.31772/2712-8970-2021-22-1-194-200.

- Kompaniya KUKA Roboter [KUKA Roboter Company]. Available at: https://www.kuka.com (accessed 28.11.2021).

- Proizvoditel’ promyshlennykh robotov Doosan Robots [Manufacturer of industrial robots Doosan Robots]. Available at: https://doosanrobots.ru (accessed: 28.11.2021).

- Promyshlennye roboty ABB [BB Industrial robots]. Available at: https://new.abb.com/products/robotics/ru/ (accessed: 28.11.2021).

- Mikheev A. E., Girn A. V., Yakubovich I. O., Rudenko M. S. [Plasmatron for coating the inner surfaces of products]. Siberian Journal of Science and Technology. 2020, Vol. 21, No. 2, P. 274–278 (In Russ.). Doi: 10.31772/2587-6066-2020-21-2-274-278.

- re – Regular expression operations. Available at: https://docs.python.org/3/library/re.html (accessed: 28.11.2021).