The most effective crushing equipment and testing of recycled concrete aggregates

Автор: Lopatin Nikita Alekseevich, Motornaja Aleksandra Ilinichna, Neguliaeva Ekaterina Yurievna

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 10 (37), 2015 года.

Бесплатный доступ

The goal of this research is to study the international experience in managing the construction and demolition waste, to study the methods of testing recycled aggregates for concrete and reinforced concrete in comparison with the Russian practice, and to identify the most effective equipment for concrete waste recycling. Recycling of concrete waste could be the optimum solution for such problems as the lack of space for construction, the exhaustion of natural resources etc. The comparative analysis of the results of different researches showed, that up to 50% of recycled concrete aggregates of total amount of aggregate in concrete mixture has a little effect on the properties of concrete. The recycled aggregates are in demand, because they cost much lower than that the natural aggregates. The analysis of technical and economical qualities of different types of crushers showed, that swing-jaw crushers with their crossfunctionality and power are best for reutilization of concrete and reinforced concrete. Requirements for the type of the crusher depend on the utilization project of the particular building or construction, because each case is unique.

Recycling, construction and demolition waste, concrete blocks, crushers, waste management

Короткий адрес: https://sciup.org/14322183

IDR: 14322183

Текст обзорной статьи The most effective crushing equipment and testing of recycled concrete aggregates

Waste management and recycling of urban waste are important parts of the field of energy efficiency and environmental safety. Many results of researches in the field of construction energy efficiency and environmental safety demonstrate huge actuality of this area [1...7].

The main goal of this research is to study the international experience in managing the construction and demolition waste (the C&D waste) in comparison and to study the methods of testing recycled aggregates for concrete and reinforced concrete with the Russian practice, and to identify the most effective equipment for concrete waste recycling. To solve this problem by the method of theoretical analysis using technical and economic estimation, we have analyzed the entire process of producing recycled crushed aggregate and found out which crushers are the most suitable for recycling of concrete.

Recycling

In the XXI century there is a lack of natural recourses on our planet. There is even a concept of the "golden billion", according to which the needs of merely 1 billion people will be satisfied with the natural resources. It is possible that everything created by nature in 2 billion years, will be practically exhausted during the next 50 years if the use of natural resources remains at the current levels. [7]

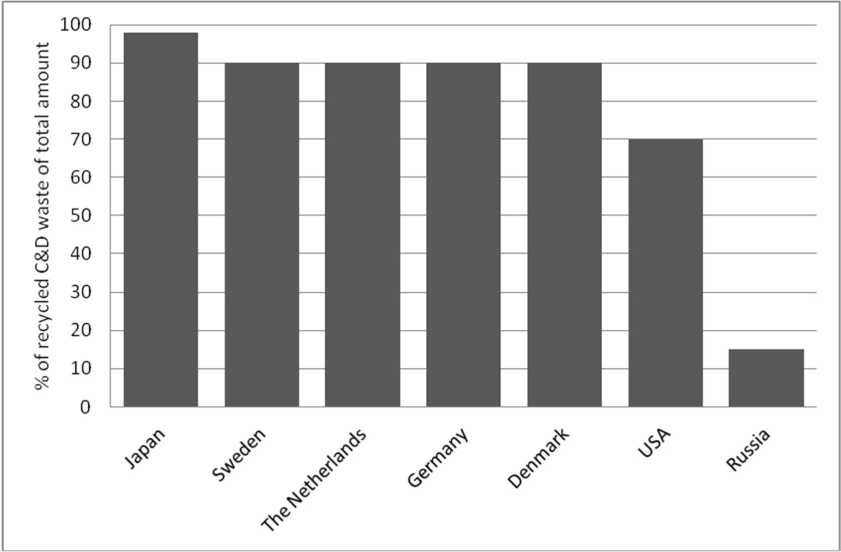

Such problem as generating large amounts of waste to be dealt with, exists in other countries too. For example, one-third of the construction waste generated in the city of Saint Paul, Brazil, is sent to waste deposits, and the rest is land filled. The United States recycles up to 70% of the waste at the time, while the Netherlands and Germany reuse up to 90% of the construction waste. In Taiwan, 30% of recycled construction waste is used for road and road base construction, and the rest is sent to landfills. In most developing countries, such as Tanzania, management of construction waste creates problems, because they are classified as solid waste and, instead of being reused, they are sent to landfills. Burying of the construction waste requires money spending on land acquisition and its maintenance in the future. In general, not only can recycling of construction waste using construction waste be a good solution for the problem of waste utilization, but also an alternative source of building materials [17].

Recycling of construction waste could help to:

-

• reduce the environment pollution [20];

-

• reduce the cost of the construction of new buildings by using recycled materials;

-

• reduce the amount of building waste in landfills;

-

• prevent the natural resources from exhaustion;

-

• save land areas for new building rather than deploying landfills;

There is such a term like as 'structure's service life', which means how long the structure can be usable. It can be different depending on a structure or a building. But we have marked three groups of buildings and structures, which are united by certain construction regulations (data is averaged):

-

• Stone buildings with reinforced concrete or steel frame and brick walls; the wall thickness is 2.5-3 bricks; the service life ~ 150 years.

-

• Stone buildings with a concrete frame and reinforced concrete or hardwood floors and walls; the wall thickness is 1.5-2 bricks; the service life ~ 125 years.

-

• The buildings of lightweight masonry with concrete or reinforced concrete floors; the service life ~ 100 years.

35 Лопатин Н.А., Моторная А.И., Негуляева Е.Ю. Наиболее эффективные дробильные установки и рециклинг вторичного бетонного щебня /

In modern cities construction waste is generated as a result of the:

-

• demolition of dilapidated accommodation, as well as demolition of buildings in the course of reconstruction of entire quarters;

-

• repair of roads;

-

• reconstruction of railway stations, platforms or tracks;

-

• production of new building materials, components and structures; reorganization of the industrial complexes;

-

• new construction;

-

• natural and man-made disasters. [10, 18, 30]

As is seen from the graph, our country lags behind a lot in this industry. This problem can be solved at any stage, but the solution requires great investments. Recycling of the construction waste is a potentially attractive market, because the supply and the demand for recycled concrete aggregates could be very high.

The specialists from different countries are already actively addressing the issue of recycling of the concrete waste. [21…24] For example, a group of scientists from the Institute of Technology, Eindhoven, The Netherlands, has conducted a study of the physical, chemical and mechanical characteristics of concrete blocks made with aggregate produced from recycled concrete waste. Eight samples of construction waste have been collected from various construction sites, brought to the recycling site, crushed and sieved to get the different fractions of the aggregate. Also, natural aggregates were used for the comparison. Tests on the recycled aggregates were conducted in the laboratory of the University of Dar-es-Salaam, Tanzania. The results showed, that the recycled aggregates were weaker, than natural aggregates by their physical and mechanical characteristics. But as long as 85% of the samples made with the recycled aggregate in the experiment reached a minimum required compressive strength and the chemical composition of the recycled materials was close to the natural ones, it was decided, that it's possible to use the recycled aggregates in the production of the new concrete blocks. In the production process, in each experiment, 100% of the recycled aggregate was used to replace both of coarse and fine fractions of natural aggregate. The results of the experiments showed that the blocks, in which the natural aggregate was entirely replaced with the recycled one were weaker than the natural aggregate blocks. Therefore, construction waste could be a potential source of raw material for the production of building materials.

The quantities of the local materials used for the production of building materials in countries such as Tanzania is 47%; the rest is imported. Almost worldwide the demand for the construction materials is growing constantly. Currently, the demand for aggregate in Tanzania is about 2 tons per capita per year, in New Zealand -

36 Лопатин Н.А., Моторная А.И., Негуляева Е.Ю. Наиболее эффективные дробильные установки и рециклинг вторичного бетонного щебня /

-

11 tones per capita per year; in EU - 1 ton per capita per year; in the UK - 5 tones per capita per year and 8 tones per capita a year in the United States. [12, 35] Average global aggregate demand is 3.8 tons of aggregate per capita per year. Relatively low demand for concrete aggregate, compared with other countries, in Tanzania is possibly due to the fact that more than 80% of the population lives in rural areas, taking into account the fact that studies show that the aggregate is consumed more in urban, than rural areas. [12]

Studies

A lot of studies have been conducted in order to understand how to use the recycled aggregate in the production of the building materials. [19, 29, 32, 33, 36, 37] Below is a table that shows the results of some experiments carried out by different experts.

Table 1. Comparative analysis of the results of different researches

|

Characteristic of the recycled aggregates, the test samples of concrete were produced with |

Natural concrete aggregates by recycled concrete aggregates replacement ratio in concrete mixture |

The size of gravel chippings |

Properties of aggregates, that were tested |

The results of the experiments |

|

8 samples of concrete with aggregates, produced of recycled concrete waste from different building sites |

60% of demolition waste aggregates, 20% of construction waste aggregates and 20% of natural aggregates |

fine aggregates: 5 mm and less; coarse aggregates: 5÷12 mm |

density; water absorption; compressive strength; chemical– mineralogical qualities |

The recycled aggregates were found to be weaker in terms of strength than those produced with natural ones. However, there is a possibility of recycling C&D waste, because 85% of tested block concrete specimens of recycled aggregates achieved the required properties |

|

Concrete samples, produced with concrete, ceramics and asphalt aggregates |

series of concretes containing 25% or 50% of the recycled aggregate, and the rest were the natural ones |

fine aggregates: 4 mm and less; coarse aggregates: up to 20 mm |

density; compressive strength; tensile strength; water absorption; sopritivity |

The use of 25% of mixed recycled aggregate in concretes has no effect on the sorptivity of the concrete. At replacement ratios of up to 50%, the recycled aggregate studied is apt for making concrete with sufficient strength at durability for housing construction |

|

4 samples of concrete, produced with 0%, 20%, 50% and |

20%, 50% and 100% of recycled coarse aggregates |

natural coarse aggregates: 4-22,4 mm; recycled coarse |

Anchorage strength of ribbed steel rebars to concrete |

Up to 50% of recycled concrete coarse aggregates doesn’t lead to |

Лопатин Н.А., Моторная А.И., Негуляева Е.Ю. Наиболее эффективные дробильные установки и рециклинг вторичного бетонного щебня /

|

100% natural concrete aggregates by recycled concrete aggregates replacement ratios |

aggregates: 4-22,4 mm; |

significant losses of anchorage force of steel rebars to concrete |

||

|

3 samples of concrete, produced with repeated recycled concrete aggregates of different generations (1st, 2nd and 3rd) |

100% of recycled coarse aggregate |

different |

compressive strength |

All samples achieved their target compressive strength. The compressive strengths of the 1st and the 2nd generation concrete samples were quite comparable to the control mix |

From all of this data we can conclude that the recycled concrete and reinforced concrete aggregates are usable and cost-effective. Up to 50% of recycled concrete aggregates of total amount of aggregate in concrete mixture has a little effect on the properties of concrete [2, 12, 28, 31, 34]. However, the question that has to be answered is how to bring into action the recycling of the concrete waste, and what equipment is the most effective for this purpose.

Crushing equipment

The analysis of the situation on the national and foreign markets for recycling has shown that there are many firms, both local and foreign, which are manufacturing equipment designed for recycling of concrete and reinforced concrete waste to obtain various fractions of gravel chippings, such as 10-20; 20-40; 40-80 with the same density as those, that the natural aggregates have (2-3 grams per cubic meter)[26].

After analyzing the specifications of this equipment, we could divide this equipment into 2 types:

-

1. mobile;

-

2. stationary

Today the mobile equipment is successfully replacing stationary crushing complexes. In relation to the production of gravel chippings it is mainly the case of producers with the capacity of 0.5 ... 0.8 million tons per year [15].

Analyzing mobile crushers, we found that their advantages and differences from the stationary ones are:

-

• сompact sizes (about m);

-

• In contrast to the stationary, which is necessary to be installed and set up every time all over again, mobile units can to be installed once and, in the future, they are transported from place to place assembled;

-

• A special foundation for them is not required;

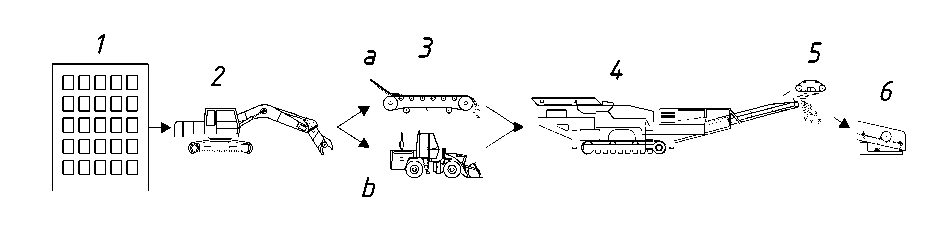

All these qualities minimize the time of the transportation. We made a sheme illustrating the whole complex for primary processing of concrete and reinforced concrete (Fig. 2):

-

1. Destruction of concrete and reinforced concrete buildings, whose service life has expired. There are two ways of destruction:

-

1. Traditional - Demolition of buildings (5-6 floors) with a powerful road-building machinery;

-

2. Subversive demolition of high-rise skyscrapers by directional blasting;

-

2. Cutting of large concrete and concrete debris with hydraulic shears (a) or diamond cutters (b);

-

3. Transporting debris to a feeder, with the help of a belt conveyor (a) or truck (b);

-

4. Feeding of the debris into the crusher and crushing the debris;

-

5. Extraction of metal parts with magnetic separator;

-

6. Separation of different rubble fractions certain fraction by mechanical screening;

Лопатин Н.А., Моторная А.И., Негуляева Е.Ю. Наиболее эффективные дробильные установки и рециклинг вторичного бетонного щебня /

Figure 2: The whole complex for primary processing of concrete and reinforced concrete

This order of actions allows us to get the aggregate of various fractions.

Our evaluation of economic characteristics showed that the most expensive and energy-consuming equipment are crushers. Below we present a classification of the different crushers and describe their operation principles:

-

• Rotary crusher: crushing is carried out by rotor beaters rigidly fixed to the rotating around a horizontal pivot rotor;

-

• Jaw crusher: crushing is carried out by compression of the material between the jaws; there are also swing-jaw crushers, which differ from the jaw crushers in that they have two cinematically independent crushing jaws with their individual rebalance transmissions;

-

• Cone crusher: crushing is carried out by the compression of the material between the cones located one inside the other;

-

• Roll crushers - crushing is carried out by the compression of the material between the roller and the fixed plate [14, 25];

Each type of crusher is designed for a specific type of the construction waste. For example, using roller crusher for the recycling of the concrete is unacceptable, because the rolls are not able to crush the elements of the reinforcement. Another important factor is a principal possibility of making a crusher mobile. For example, cone crushers, may be only stationary because of their height.

Rotary crushers are rather unreliable and have a low reduction range (5-6) and low flakiness index. Also, they are not easy in use. [11]

Jaw crusher is suitable for reutilization of the concrete, whose mark not higher than B20. However, the swing-jaw crusher is much more cross-functional (Fig. 3), because it can crush the concrete harder, than B40 and the elements of the reinforcement with a diameter of up to 16 mm. The swing-jaw crusher is the most suitable for crushing of the concrete and the reinforced concrete.

We have analyzed technical and economical qualities of crushers, produced by different manufacturers. In the issue we decided to compare the main technical qualities of the jaw crusher and the rotary one. The results of our analysis are shown in the table 2.

Table 2. Analysis of technical and economical qualities of different types of crushers

|

Technical Specification |

Type of crusher |

||

|

Jaw |

Rotary |

||

|

1 |

The average cost of the crusher (millions of rubles) |

15..20 |

20…25 |

|

2 |

The maximum capacity of the crusher (Tonnes per hour) |

300 |

400 |

|

3 |

Specific energy consumption |

Low |

High |

|

4 |

The maximum engine (kw) |

370 |

340 |

|

5 |

The maximum feed opening(mm) |

1300×1100 |

1600×1400 |

|

6 |

The maximum weight (Tonnes) |

70 |

68 |

|

7 |

Flakiness |

High |

Low |

|

8 |

Reduction range |

10…20 |

5…6 |

Лопатин Н.А., Моторная А.И., Негуляева Е.Ю. Наиболее эффективные дробильные установки и рециклинг вторичного бетонного щебня /

The most wearing part Toggle

Saw of crusher

We have analyzed several factors influencing the cost of mobile crushers. In the table we showed the range of prices by the years 2014-2015. From this table it is clear, that rotary crushers have higher price and unit costs, than jaw ones. However, they are also more productive. Performance of the crusher depends on such factors as size and strength of the concrete debris and the lifetime of the equipment. As can be seen from the table rotary crusher requires a lot of energy, but it also produces a high flakiness rubble. This means that in this rubble contains no more than 10% of plate-like and needle-shaped particles.

The analysis of the foreign market showed, that the equipment, produced by the "Caterpillar" corporation is the most popular among

The swing-jaw crushers, produced within our country by the company "Mekhanobr" are also in great demand. This type of equipment is also used for the demolition of buildings with the degree of responsibility II or less. Below there is the list of the main advantages of the swing-jaw crusher over the jaw crusher:

-

• The productivity of the swing-jaw crusher is 1.5-2 times higher than the productivity of the jaw crusher; however, the varies inversely to the service life;

-

• High flakiness index: crushed stone, produced by the swing-jaw crusher, has a cubic shape, which reduces the number of pinhole between the particles; jaw crusher produces particles of an acicular shape;

-

• Low energy consumption;

-

• The increased reduction range, compared to the other types of crushers.

Requirements for the type of the crusher depend on the utilization project of the particular building or construction, because each case is unique.

Conclusion

Thus, nowadays different concrete and reinforced concrete buildings are demolished, reconstructed and built constantly. In the course of this there is produced about 16 million tons of the construction and demolition waste in St. Petersburg annually. 60% of this amount is concrete and reinforced concrete waste, which make recycling a very promising industry. The recycled aggregates are in demand, because their cost much lower than that the natural aggregates. Swing-jaw crushers with their cross-functionality and power are best for reutilization of concrete and reinforced concrete.

Лопатин Н.А., Моторная А.И., Негуляева Е.Ю. Наиболее эффективные дробильные установки и рециклинг вторичного бетонного щебня /

Список литературы The most effective crushing equipment and testing of recycled concrete aggregates

- Vatin N.I., Gorshkov A.S., Rymkevitch P.P., State program's realization of residential and public buildings energy efficiency improvement (2014) Construction materials, the equipment, technologies of XXI century, 1(180), pp. 39-46.

- Vaysberg L.A., Kameneva E.E., Study of Composition and Physical-Mechanical Properties of Secondary Crushed Stone from Crushed Concrete (2014), 6, pp. 41-45.

- Dmitrieva M.V., Kamenik L.L., Osnovnye napravlenija razvitija sistemy pererabotkoj stroitel'nyh othodov (2011), 132, pp. 111-115.

- Vatin N.I., Nemova D.V., Gorshkov A.S., The energy saving formula (2013) Construction of Unique Buildings and Structures, pp. 49-63

- Denafas G., Ruzgas T., Martuzeviˇcius D., Shmarin S., Hoffmann M., Mykhaylenko V., Ogorodnik S., Romanov M., Neguliaeva E., Chusov A., Turkadze Ts., Bochoidze I., Ludwig Ch., Seasonal variation of municipal solid waste generation and composition in four east european cities (2014) Resources, Conservation and Recycling, T. 89, pp. 22-30.

- Cheremisin A.V., Negulyaeva E.Yu., Molodtsov D.V., Fedorov M.P., Korablev V.V., Maslikov V.I., Chusov A.N., Allaberdiyev G., Allaberdiyeva E., Kurbanmuradov O., Ritzkowski M., Laboratory investigation of biodegradation processes of municipal solid waste (MSW) model samples of ashgabat city (2008) V sbornike: ECOBALTICA' 2008, pp. 128-131.

- Kamenik L.L., Doktrina resursoobespecheniya Rossii v usloviyakh mirovogo krizisa (2013) Retsikling otkhodov, 2 (44), rr. 3-4.

- Oleinick S.P., Solomin I.A., Kharitonov S.E., The processing of building wastes to get crushed stone and sand blends (2007) Industrial and Civil Engineering, 7, pp. 58-59.

- Luneva G., Stroitelnym otkhodam -vtoruyu zhizn, biznesu -pribyl, obshchestvu -uluchsheniye ekologii (2006) Retsikling otkhodov, 2 (2), pp. 2-4.

- Solomin I. A., Oleinick S. P., Kharitonov S. E., The analysis of the composition and the amount of building wastes formed during demolition of decrepit dwellings in Moscow (2007) Industrial and Civil Engineering, 12, pp. 55-56.

- Oleinik S. P., Basic technological equipment of crush-and-sorting complexes (2005) Industrial and Civil Engineering, 4, pp. 40-41.

- Sabai M.M., Cox M.G.D.M., Mato R.R., Egmond E.L.C., Lichtenberg J.J.N., Concrete block production from construction and demolition waste in Tanzania (2013) Resources, Conservation and Recycling, 72, pp. 9-19.

- Oleinik S. P., Design figures when predicting the formation of secondary resources (2006) Industrial and Civil Engineering, 6, pp. 57-58.

- GOST 14916-82 Crushers. Terms and definitions

- Perelygin V., Mobilnost kak preimushchestvo (mobilnyye ustanovki drobleniya i grokhocheniya) (2008) Osnovnyye sredstva, 11.

- Oleinik S. P., A centralized system for building waste monitoring (2006) Industrial and Civil Engineering, 3, pp. 43-44.

- Suresh Kumar Lachimpadi, Joy Jacqueline Pererira, Mohd Raihan Taha, Mazlin Mokhtar, Construction waste minimization and precast construction (Mixed System and IBS) methods im high-rise buildings -A Malasia case study (Resourses, Conservation and Recycling) (2012) Resources, Conservation and Recycling, 68, 96-103.

- Jianzhuang Xiao, He Xie, Chuanzeng Zhang, Investigation on building waste and reclaim in Wenchuan earthquake disaster area (2012) Resources, Conservation and Recycling, 61, pp. 109-117.

- Lopez-Gayarre F., Serna P., Domingo-Cabo A., Serrano-Lopez M.A., Lopez-Colina C., Influence of recycled aggregate quality and proportioning criteria on recycled concrete properties (2009), Waste Management, № 12, pp. 2022-3028

- Noguchi T., Kitagaki R., Tsujino M., Minimizing environmental impact and maximizing performance in concrete recycling (2011), Structural Concrete, № 12 ???

- Mariano L.S., Da Costa M.D.R.D.M.M., Braga M.C.B., A feasibility study of recycling of construction and demolition waste for structural purposes (2013), Journal of Solid Waste Technology and management, № 39(3), pp. 204-213

- Silva R. V., de Brito J., Dhir R. K., Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production (2014), Construction and Building Materials, № 65, pp. 201-217

- Behera M., Bhattacharyya S. K., Minocha A. K., Deoliya R., Maiti S., Recycled aggregate from C&D waste & its use in concrete -A breakthrough towards sustainability in construction sector: A review (2014), Construction and Building Materials, № 68, pp. 501-516

- Md. Safiuddin, Ubagaram Johnson Alengaram, Md. Moshiur Rahman, Md. Abdus Salam, Mohd. Zamin Jumaat, Use of recycled concrete aggregates in concrete: a review (2013), Journal of Civil Engineering and Management, № 19:6, pp 796-810

- GOST 14916-82 Crushers. Terms and definitions.

- GOST 25137-82* Rock products used in construction, solid broken stone and sand made from industrial wastes and porous aggregates for concrete. Classification.

- Bravo M., de Brito J., Pontes J., Evangelista L., Durability performance of concrete with recycled aggregates from construction and demolition waste plants (2015), Construction and Building Materials, 7, pp. 357-369.

- Medina C., Zhu W., Howind T., de Rojas M. I. S., Frias M., Influence of mixed recycled aggregate on the physical mechanical properties of recycled concrete (2014), Journal of Cleaner Production, 68, pp. 216-225.

- Kanellopoulos A., Nicoladies D., Petrou M. E., Mechanical and durability properties of concretes containing recycled lime powder and recycled aggregates (2014), Construction and Building Materials, 53, pp. 253-259.

- Xiao J., Ding T., Research on recycled concrete and its utilization in building structures in China (2013), Frontiers of Structural and Civil Engineering, 7(3), pp. 215-226.

- Guerra M., Ceia F., de Brito J., Julio E., Anchorage of steel rebars to recycled aggregates concrete (2014), Construction and Building Materials, 72, pp. 113-123.

- Beltran M. G., Barbudo A., Agrela F., Galvin A. P., Limenez J. R., Effect of cement addition on the properties of recycled concretes to reach control concretes strengths (2014), Journal of Cleaner Production, 79, pp. 124-133.

- Koshiro Y., Ichise K., Application of entire concrete waste reuse model to produce recycled aggregate class H (2014), 67, pp. 308-314.

- Huda S.B., Alam S.M., Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete (2014), 65, pp. 574-582.

- Matias D., de Brito J., Rosa A., Pedro D., Mechanical properties of concrete produced with recycled coarse aggregate -Influence of the use of superplasticizers (2013), 44, pp. 101-109.

- Lotfi S., Deja J., Rem P., Mroz R., van Roekel E., van der Stelt H., Mechanical recycling of EOL concrete into high grade aggregates (2014), 87, pp. 117-125.

- Younis Kh. H., Pilakoutas K., Strengh prediction model and methods for improving recycled aggregate concrete (2013), 49, pp. 688-701.