The research of dependence between the input parameters of plasma spraying and microstructure of the obtained coatings

Автор: Yu. Yu. Balashov, M. S. Rudenko, M. N. Volochaev, A. V. Girn

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.20, 2019 года.

Бесплатный доступ

Today, protective coatings are applied to almost all parts and components of engineering products in order to ensure high performance properties of machines, with the lowest economic cost. The method of plasma spraying allows to apply heat-resistant coatings on a different kind of basis, in addition to a wide variety of materials. Therefore, rocket and space engineering is primarily interested in the method. In modern conditions of high rate of mechanical engineering development engineers must develop and put into operation products within the shortest possible period of time. As a rule, engineers select the modes of plasma spraying using the method of selecting the empirical relationship between the properties of the coatings and the values of the specified parameters of plasma spraying, which suggests conducting a huge number of experiments. That is why we see the need to find new methods for selecting the plasma spraying parameters, which are based on mathematical and analytical apparatus. We set the task to study and show the applicability and prospects of the proposed method. In the work we carried out the operations of spraying nichrome coating, at different values of the arc current. We studied the adhesive strength of the coatings obtained and their microstructure. We showed the relationship between the arc current and the adhesion of the coatings using their microstructure. These studies have made it possible to exclude a large number of experiments, which usually establish an empirical relationship between the values of the input parameters of the deposition process and the values of the characteristics of the coatings obtained. In the future, we assume that the database of such relationships will make it possible to fully use this method in engineering industries.

Plasma spraying, protective coatings, microstructural analysis, metallographic studies

Короткий адрес: https://sciup.org/148321698

IDR: 148321698 | УДК: 621.793.74 | DOI: 10.31772/2587-6066-2019-20-3-384-389

Текст научной статьи The research of dependence between the input parameters of plasma spraying and microstructure of the obtained coatings

Introduction. The production of modern technology is not possible without the use of a wide range of coating methods, which make it possible to give the best performance to parts and components of products at the lowest economic cost. One of the most effective methods for applying coatings to parts of products operating under extreme conditions (aggressive environments, high temperatures, extreme loads, vibrations, etc.) is gas-thermal, in particular, the plasma method.

The scope of the materials range that can be applied by gas-thermal methods is very extensive. The increased interest in the plasma coating method is due not only to the available list of materials that can be taken for spraying, but also to the possibility of applying refractory materials (for example, oxides, borides, carbides) on a completely different kind of substrate (both metals and plastic, glass, ceramics, etc.), at high quality indicators achievement (high values of adhesion, cohesion, low porosity, etc.) of the resulting coatings [1–5]. As a result, the most high-tech industries, such as rocket and space technology and aircraft engineering show increased interest in progress in this direction.

Today, the methods for selecting coating conditions are based on deriving an empirical dependence of the resulting coatings properties (such as adhesion and cohesion values, residual stress level) on the input parameters of spraying modes (the arc current value, the plasma torch speed, the distance from the plasma torch nozzle to the substrate etc.) [4–10]. This approach requires the accumulation of a large amount of statistical data by conducting a huge number of experiments (~ 1000) for each material with a certain ratio of components.

This method works well in mass production, but in rocket and space technology, where each product is unique, this leads to irrational consumption of materials and equipment wear, as well as to large time consuming, which makes it necessary to find a new approach to the selection of mode parameters of plasma spraying.

To introduce the necessary operational properties of the obtained coatings at the design stage, it is necessary to have accurate knowledge about the effect of each of the main parameters of the spraying mode on the microstructure of this type of coating. In this regard, the task was set to identify the influence of the plasma spraying process parameters on the microstructure of one of the typical (similar to the most commonly used) coatings. The aim of this work was to establish an unambiguous relationship between the value of one of the parameters (the arc current value) and the resulting microstructure of this coating.

Spraying and adhesive strength. The nature of the interaction and the completeness of the physicochemical reaction between the grains depends on the fused particles energy at the moment of collision with the substrate, which is made up of their temperature and speed. The whole variety of influences, which we call the spraying mode parameters, ultimately affects the speed of the particles and their temperature.

To conduct the experiments, the steel 45 was chosen as the base material, since this material is often used due to its cheapness and sufficient strength characteristics. Nichrome coating (NiCr) is often sprayed onto the steel as a buffer layer between the steel and the main heatresistant coating to equalize their linear coefficient of thermal expansion values. The adhesion between the base and the layer sprayed on it determines the adhesion of the entire coating. Adhesion is one of the main indicators characterizing the coating quality [2; 5–14].

The spraying was carried out on 50 × 20 mm size plates, necessary for studying the coatings morphology, and “heads”, in order to establish the adhesive strength of the coatings obtained. The parameters of the plasma spraying process were selected based on works [1–11; 15], and taking into account the experience of laboratory engineers. The spraying process parameters are given in tab. 1.

Table 1

Parameters of spraying modes

|

Sample № |

I , A |

U , B |

G пг, l/min |

G пор , kg/Mmin |

L , mm |

v , m/s |

5, mm |

n |

|

|

Ar |

H 2 |

||||||||

|

1-14.03.19 |

250 |

97 |

50 |

5 |

0,032 |

90 |

0,3 |

6 |

2 |

|

2-14.03.19 |

300 |

88 |

|||||||

|

3-14.03.19 |

350 |

83 |

|||||||

Note. I is the current strength (A); U is the voltage (V); G пг - consumption of plasma-forming gas components (Ar - argon, H 2 -hydrogen); G пор - powder consumption (kg / min.); L is the distance from the nozzle exit to the spraying surface; v is the plasma torch speed; 5 is the distance between adjacent spray paths; n is the number of spray layers.

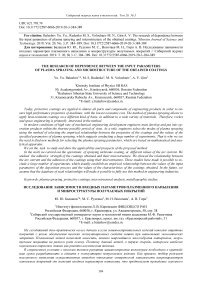

a b c

Fig. 1. The boundary between the grains of the coating:

a – when the arc current is equal to 250 A; b, с – when the arc current is equal to 350 A

Рис. 1. Граница между зернами покрытия:

а – при значении тока дуги равном 250 А; б, в – при значении тока дуги, равном 350 А

All operations for the preparation and conducting of plasma spraying, as well as experiments to establish the adhesive strength of the obtained coatings, were carried out in the “Plazhim” laboratory of Reshetnev Siberian State University of Science and Technology.

The coatings adhesive strength was studied using “Eu-rotest-T50” tensile testing machine. The obtained values of the coatings adhesive strength are presented in tab. 2.

Table 2

Adhesive strength of coatings

|

Sample № |

I , A |

P , kN |

σ, MPa |

|

4-14.03.19 |

250 |

6,315 |

12,862 |

|

5-14.03.19 |

300 |

6,609 |

13,463 |

|

6-14.03.19 |

350 |

6,895 |

14,045 |

Note. I is the value of the arc current; P is the force at which the coating separated from the sample; σ is the adhesive strength of the coating.

Microstructural studies. All studies related to the clarification of the obtained microstructure of the coatings were performed on the equipment of the center for collective use of the FRC KSC SB RAS. To begin with, it was necessary to find out the shape and nature of the particles forming the coating location relative to each other, including the surface area along which both the particles are in contact with each other and the particles with the base surface. To do this, a FB-2100 scanning ion microscope was used (with a focusable ion beam setup, which makes it possible to cut samples with ~ 100 nm thickness), with the help of which it was possible to establish that, for this material, an increase in the arc current leads to an increase in the area of adhesion hotbeds and , further, to merge them together. Also, a decrease in the distance between grains with an increase in the arc current can be noticed, which is shown in fig. 1. All this affects the increase in the coating mechanical characteristics.

According to the data obtained, it can be seen that a further increase in the arc current, a decrease in the diameter of the sprayed particles, and an increase in the speed of the sprayed particles will not have a strong effect on adhesion and cohesion, since the grains have almost the maximum contact surface area between them.

The interaction of particles between each other and with the substrate. The limiting value of the coating adhesion value, in theory, is the smallest value of the ultimate strength between the base and coating materials. This is based on the following considerations: after molten particles get on the base material and deform, during crystallization, a chemical compound of the base material and the coating is formed in the places of adhesions, which is stronger than the two pure materials. When the coating is separated of the base, the destruction occurs not at the coating – base interface, but with one of the materials (substrate, or coating) tearing out [8–13].

In practice, it is not possible to achieve such adhesion values for gas-thermal coatings, since the adhesion between the materials does not occur over the entire grain area, but only partially; as well as for reasons of rapid metal oxidation at elevated temperature, gas adsorption during spraying in the atmosphere, etc. As a result, the adhesion values are lower than the strength values of the base and coating materials.

Therefore, in order to clarify the nature of two materials interaction, we cut samples of 5 × 3 × 0.1 μm at the base – coating boundary and studied using the Hitachi HT7700 transmission electron microscope.

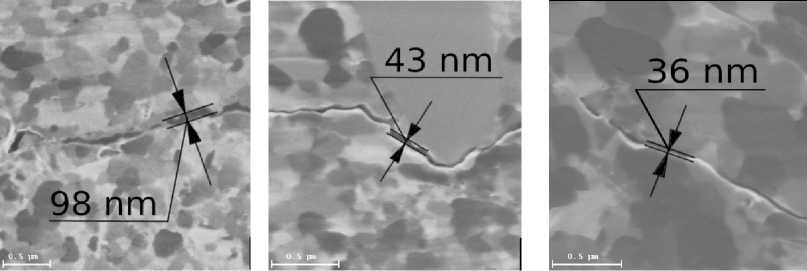

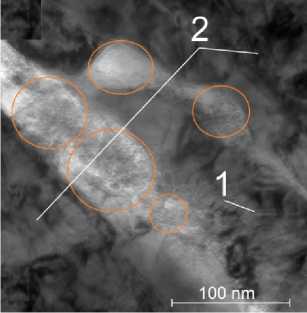

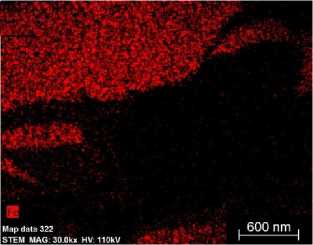

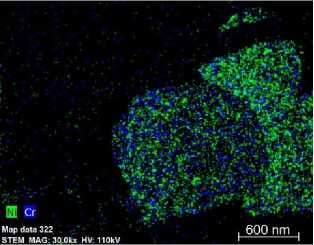

As a result of the study, we found that possible chemical compounds between steel and nichrome are practically absent. Instead, an amorphous phase appeared at the boundaries between the grains of steel and nichrome, including equal amounts of Ni, Cr, Fe atoms, which was shown by element analysis (in fig. 2 the areas with an amorphous structure are marked by ovals; in fig. 3 the result of the element sample analysis is given).

It is known that at high cooling rates (comparable in order with values of 107 – 109 K / s) from a melt of substances having a crystalline structure at room temperature in a thermodynamically equilibrium state, they acquire an amorphous structure. Particles melted on the surface carry an enormous amount of energy, sufficient to melt the sur- face steel layer in fractions of a second when they hit the substrate. The molten NiCr mixes with the molten layer of steel and, due to the strong heat removing to the substrate (steel), the mixed melt does not have time to form a crystalline structure [8–14]. Obviously, to reduce the cooling rate of the molten layer, it is necessary to spray onto an artificially heated substrate.

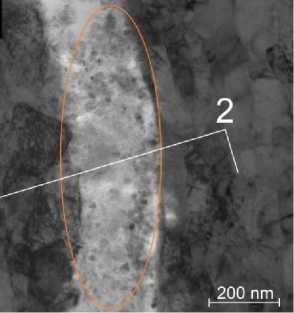

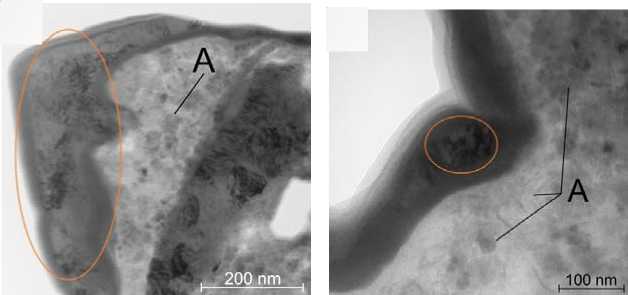

It is worth noting that a chemical compound has nevertheless partially formed, which is recorded in the obtained microstructure images (in fig. 4, the areas with the chemical compound are indicated by circles). This suggests that the substrate temperature, which is equal to room temperature, is close to that necessary for the chemical reaction between Cr, Ni, and Fe elements. In the future, the studies on the formation of the NiCr coatings microstructure depending on the temperature of the artificially heated substrate during the plasma spraying process should be carried out.

Conclusion. Based on the results of the work done, we can see the effectiveness of the parameters selection of the plasma spraying mode by the method which includes the study of the resulting coatings microstructure. Thus, the coatings morphology study made it possible to draw conclusions about the effect of the arc current on the adhesion of the obtained coatings without carrying out a large number of experiments.

In the future, the accumulated knowledge regarding the effects of each spraying mode parameters on different properties of the coatings will allow to minimize the number of necessary experiments, as well as to develop mathematical and analytical methods for selecting spraying modes for new materials.

In the future, it is necessary identify groups of materials which differ in the nature of the influence of spraying mode parameters on the formation of the microstructure.

a

b

Fig. 2. The areas with amorphous phase (marked by ovals): 1 – NiCr; 2 – Steel; а – General view of the sample; b – some enlarged areas

c

Рис. 2. Области с аморфной фазой (выделены овалами): 1 – NiCr; 2 – сталь; а – общий вид образца; б – некоторые увеличенные области

a

b

Fig. 3. Topographic map of elements obtained by element analysis: а – the dedicated area for analysis; b – the map Fe; с – the map Ni and Cr

c

Рис. 3. Топографическая карта элементов, полученная в результате поэлементного анализа: а – выделенная зона для анализа; б – карта Fe; в – карта Ni и Cr

b

Fig. 4. The areas with formed the chemical compound (marked by ovals); A – amorphous phase: a – General view of the sample; b , c – some enlarged area

Рис. 4. Области со сформировавшимся химическим соединением (выделены овалами); А – аморфная фаза: а – общий вид образца; б , в – некоторые увеличенные области

For example, in some literary sources, such as [2], it is stated that an increase in the value of the arc current unambiguously leads to an increase in the number of adhesion hotbeds between grains. In our case, when NiCr interacted with the steel, an increase in the arc current led to an increase in the cross-sectional area of the adhesion hotbeds. Such a discrepancy in the results directly indicates that for various materials a change in the spraying parameters values can have a different effect on the microstructure of the coatings, and therefore on their properties. All this determines the vector of further work in this direction.

Список литературы The research of dependence between the input parameters of plasma spraying and microstructure of the obtained coatings

- Mikheev A. E., Kolmikov V. A. Povishenie ekspluatatsionnih harakteristik poverhnostey konstruktsiy letatelnih apparatov. Avtomatizatsiya protsesov obrabotki [Improving the performance of the surfaces of aircraft structures. Automation of processing]. Moscow, MAKS Publ., 2002, 224 p.

- Puzriyakov A. F. Teoreticheskie osnovi tekhnologii plazmennogo napileniya [Theoretical foundations of plasma spraying technology]. Moscow, Bauman’s MSTU Publ., 2008, 360 p.

- Heimann R. B. Plasma Spray Coating. 2nd edition. VCH Verlagsgesellschaft mbH, Weinheim, VCH Publishers, Inc., New York, 1996, 339 p.

- Ananthapadmanabhan P. V., Thiyagarajan T. K., Sreekumar K. P., Satpute R. U., Venkatramani N., Ramachandran K. Co-spraying of Alumina-Titania: Correlation of Coating Composition and Properties with Particle Behaviour. Plasma Jet, Surfaces & Coatings Technology. 2003, No. 168, P. 231–240.

- Lashenko G. I. Plasmennoye uprochnenie i napilenie [Plasma hardening and spraying]. Kansk, Ecotekhnologiya Publ., 2003, 64 p.

- Abramyan I. A., Andronov A. V., Titov A. I. Fizicheskie osnovy elektronnoy i ionnoy tekhnologii [Physical bases of electron and ion technology]. Moscow, Vysshaya shkola Publ., 1984, 265 p.

- Barvinok V. A. Upravlenie napryazhennym sostoyaniem i svoystvo plazmennykh pokrytiy [Voltage control state and properties of plasma coatings]. Moscow, Mashinostroenie Publ., 1990, 246 p.

- Kudinov V. V. Plasmennye pokrytya [Plasma coatings]. Moscow, Nauka Publ., 1977, 270 p.

- Poliyak M. S. Tekhologiya uprochneniya. Tekhol. metodi uprochneniya [The technology of hardening. Technological methods of hardening]. Vol. 1. Moscow, L.V.M. – SCRIPT, Mashinostroenie Publ., 1995, 832 p.

- Kudinov V. V., Bobrov G. V. Nanesenie pokrytiy napyleniem. Teoriya, tekhnologiya i oborudovanie [Spray coating. The theory, technology and equipment]. Moscow, Metallurgiya Publ., 1992, 432 p.

- Bartuli C., Smith R. W. Comparison between Ni-Cr-40 vol% TiC Wear-Resistant Plasma Sprayed Coatings Produced from Self-Propagating High-Temperature Synthesis and Plasma Densified Powders. Journal of Thermal Spray Technology. 1996, Vol. 5, No. 3, P. 335–342.

- Krasnov A. N., Sharivker S. Yu., Zilberber V. G. Nizkotemperaturnaiya plasma v metallurgii [Lowtemperature plasma in metallurgy]. Moscow, Metallurgiya Publ., 1970, 216 p.

- Rozenfeld I. L. Korroziya i zashita metallov [Сorrosion and protection of metals]. Moscow, Metallurgiya Publ., 1970, 448 p.

- Artsimovich L. A., Sagdeev R. Z. Fizika plazmy dlya fizikov [Plasma Physics for Physicists]. Moscow, Atomizdat Publ., 1979, 320 p.

- Devkin M. M., Sevastiyanov N. D. Ochistka poverhnostey detaley metallicheskim pescom [Surface cleaning of parts to metal sand]. Ed. by L. F. Liokumovich. Moscow, Mashinostroeniye Publ., 1968, 65 p.