The use of ultrasonic methods for viscosity control of solutions in the pectin production

Автор: Mishchenko E.V., Mishchenko V.J.

Журнал: Вестник аграрной науки @vestnikogau

Статья в выпуске: 3 (42), 2013 года.

Бесплатный доступ

The construction of the ultrasonic viscometer for the viscosity continuous control of a liquid in a stream is developed. Perspective of the application of ul'traacoustics methods of control of the viscosity in the production of pectin substances from plant raw materials is showed.

Viscosity, ultrasonic vibrations, pectin, vegetal raw materials, rheology

Короткий адрес: https://sciup.org/147124086

IDR: 147124086 | УДК: 534.8

Текст научной статьи The use of ultrasonic methods for viscosity control of solutions in the pectin production

It is necessary to create new equipment and new technologies to solve the tasks of food and processing industry for the coming years. Development of rational structures and choice of optimum modes of processing of food materials may be provided only on the basis of careful study of production processes, with the view of physical-mechanical properties of the processed mass.

Processing of various food materials is accompanied by complex physical-chemical, biological and mechanical processes, the study of which allows you to organize effective and objective control of the quality and management of the technological production cycle. Most of the processes in the food industry is related to the processing of disperse systems, suspensions and colloidal solutions, various elastic-viscous materials. Rheological studies help to understand better the physics of the phenomena occurring in the processing of food materials.

Knowledge of the physical and mechanical properties is used in the calculation of processes that must be carried out to create new machine design and alterations to existing machines, as well as to select the optimum operation of the equipment and the optimum technological scheme of production. Rheological properties of materials can be used as control parameters for creating automated machine control systems, aggregates, industrial sites, for automated control of product quality. Rheology can control the structure and quality of products by making additions, changes in modes and methods of mechanical and technological processing.

Ultrasonics is one the promising lines in control of different rheological parameters [1,2,3]. This is due to its capabilities, the birth of advanced electronics, innovations in touch technology, the availability of computer equipment, techniques of signal and image processing. In addition, ultrasonic methods are methods of nondestructive monitoring, and if a significant number of processes are continuous, it is essential to create full-time devices that determine the viscosity of the material in the flow.

At present in the sphere of ultrasonics they use modern automated computer methods based on the traditional methods of measurement. However, the creation of automated systems, embedded directly in the production chain, can significantly increase the speed and accuracy. Also on the basis of these systems, you can create computer systems to collect and display information that is especially important in studying rheological properties of different materials.

MATERIALS AND RESEARCH METHODS

During the process of extraction of pectin substances from plant raw materials the viscosity is one of the most important factors influencing the content of extractive agent in the solution. You can evaluate amount of the extractive agent by its magnitude that transferred to a solution, that is, monitor continuously the technological process of extraction itself.

An ultrasonic fluidity meter was developed to control the viscosity of the solution containing pectin. Its operating principle is to measure the changes of sound wave amplitude when it passes through the medium.

-

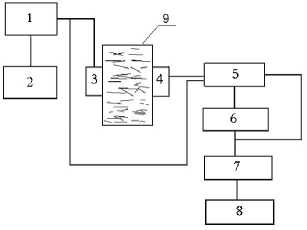

Figure 1 shows a structure flowchart of the installation.

Figure 1 – a structure flowchart of the experimental assembly: 1 - oscillation generator; 2 - control device; 3- ultrasonic acoustic transmitter; 4 – radiation receiver; 5 – preamplifier;

6 – detector; 7 – L-CARD; 8 – a computer; 9 - a vessel with the liquid.

The device consists of a power unit, an oscillation generator, radiator ultrasonic vibrations, an ultrasonic acoustic transmitter, a radiation receiver, a preamplifier, a detector and a system of information processing. The ultrasonic acoustic transmitter and the radiation receiver are installed on the vessel, containing the investigated liquid.

The device operates in the following way. The power supply unit generates continuously an electrical current to the oscillations generator, which generates high-frequency electrical signal and sends it to the radiation source, converting the electrical signal to ultrasonic vibrations. When passing through the investigated medium fluctuations are picked up by the radiation receiver and are converted into an electrical signal. The signal is amplified by the preamplifier, converted by the detector and processed by the system of information processing. Simultaneously, the impulse is delivered to ultrasonic radiator and current fed into the preamplifier increases and falls in the data processing unit. The received signals are processed by the information processing system, the amplitude of input and output signals are determined, and they determine the viscosity of the investigated liquid judging by the difference of the amplitudes. The function of the detector is to convert alternating current into direct current that allows you to monitor continuously the viscosity of the fluid through any time intervals.

RESULTS AND DISCUSSION

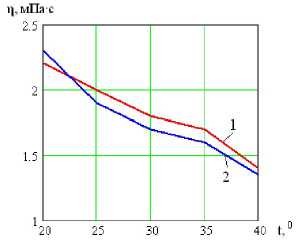

Comparative tests of a standard viscometer were conducted. We used a viscometer with a sliding ball. Figure 2 shows a dependency diagram of the dynamic viscosity η of pectin solution and temperature.

Figure 2 - Dynamic viscosity-temperature relationship: 1 - a standard viscometer; 2 – engineering sample

As it is seen in Figure 2, the conducted experimental studies have shown quite good convergence compared to traditional methods for measurement of viscosity, and let greatly increase the speed of the device, as the method applies to non-destructive testing.

CONCLUSION

We can make a conclusion about the prospects of the use of methods of ultrasonic diagnostics in the production of pectin substances. On the basis of conducted researches a pilot model of ultrasonic viscometer was developed [4] which will be used in developing an automated complex for obtaining pectin substances from beet press by the method of vibration extraction.

Список литературы The use of ultrasonic methods for viscosity control of solutions in the pectin production

- The foundations of physics and ultrasound technology. Study guide for higher schools/B.A.Agranat, M.N.Dubrovin, N.N.Havsky. etc. -Moscow: Vysshaya. wk., 1987. -352 p

- Petrov, K. Process measurement and instrumentation in food industry. -2nd ed., Rev. and add. -Moscow: Agropromizdat, 1985. -344 p

- Shutilov V.A. Fundamentals of Ultrasound Physics: study guide. -Leningrad: Publishing House of Leningrad University Press, 1980. -280 p

- Utility patent number 52,483, the Russian Federation. MPK7 G 01 N 11/00. A device for the continuous measurement of the fluid viscosity in the flow [Text]/Yatsun S.F., Mishchenko V.J., Bezmen P.A., Mishchenko V.V.; An applicant and patentee Kursk State Technical University. -№ 2005130664/22, Appl. 03.10.2005, Publ. 27.03.2006, Bull. Number 9