Thermal performance and water erosion resistance of sheep wool-reinforced compressed stabilized earth bricks

Автор: Nasrat Nasratullah Abdul, Ghafoor Abu-Mahadi Mohammed, Ibrahim Hashemi Mohammad, Nasim Obeid Mahmoud Abdelsalam Aref

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 4 (118), 2025 года.

Бесплатный доступ

The thermal performance property of a building envelope is straightly based on the character of the materials used in the construction. The materials used must be resistant to mechanical stresses and the effects of water on the walls to confirm the safety of the residents but ought also to have assured insulating effects to provide for the thermal performance of the building envelope. The object of research is the thermal performance and water erosion resistance of compressed stabilized earth bricks (CSEBs) using sheep wool as a fiber (SWF) and cement as a stabilizer agent. The study was conducted on bricks produced using local raw materials in Kabul, Afghanistan. Method. In this study, 0%, 0.05%, 0.1%, 0.2%, 0.3%, and 0.4% SWF and 0%, 5%, and 10% ordinary Portland cement were used. ISOMET 2104 instrument was used for the study of thermal performance. The effect of different amounts of SWF in the bricks, different amounts of cement, and the bulk density of the bricks on thermal conductivity, volumetric heat capacity, and thermal diffusivity was investigated. To determine the resistance of compressed stabilized earth bricks (CSEBs) to surface-contact water pressure, a study was conducted on bricks containing a low amount of cement (5%), both with and without 0.1% SWF, in accordance with the NZS 4298 (1998) standard. Result. The study found that the thermal conductivity is affected first by bulk density, then by cement, which causes a decrease in voids in the bricks, and then by an SWF. The volumetric heat capacity is affected first by SWF, then by bulk density, and then by cement. The thermal diffusivity is affected first by bulk density, then by SWF. As a result of a one-hour continuous test on the bricks using the water spray method with a water pressure of 50 kPa in the pipe according to the standard, no erosion occurred in either type of bricks. Overall, the findings demonstrate that the CSEBs exhibit adequate thermal and water erosion resistance properties, making them suitable for use in construction as a sustainable construction building material, particularly in regions with moderate climates and where resistance to water erosion is required.

CSEBs, Thermal performance, Water erosion, Cement effect, Bulk density effect, Sheep wool

Короткий адрес: https://sciup.org/143185049

IDR: 143185049 | DOI: 10.4123/CUBS.118.2

Текст научной статьи Thermal performance and water erosion resistance of sheep wool-reinforced compressed stabilized earth bricks

Earth construction, which is cool in summer and warm in winter, is one of the ancient and nearly all common buildings in human history. It can lessen environmental issues and increase living comfort. Compressed stabilized earth bricks (CSEB) produced from various local soil types will have distinct thermal and physical characteristics [1], [2], it offers a sustainable alternative to burnt clay bricks/cement concrete blocks. These bricks are compressed manually or motorized and cured for 28 days to get the desired compressive strength. Because a small amount of stabilizer is required, the energy usage for one m³ of CSEB is about four times less than one m³ of burnt bricks and about two times less than the average brick-making sector. Upon application, the blocks can be solid, hollow, round, or customized and can be used for columns, floors, and roof construction, as a load-bearing structure can withstand up to 4 floors without concrete columns [3]. CSEB material may lower indoor air temperature by 25-27°C and also reduce relative humidity to 60-80% overall [4]. The procedure of heating buildings during the cold season produces a suitable effect. In this regard, lowering energy use during the production of construction materials or during the heating process at home became one of the century's biggest challenges [5]. Building sustainability and energy efficiency are contemporary concerns, primarily because this industry accounts for 40% of energy use and CO2 emissions [6]. As a result, more environmentally friendly buildings that meet comfort standards, consider lowering gas emissions, and use locally produced, ecologically friendly materials are currently needed [7]–[9]. According to estimates, 40% of people on the planet reside in earth-based buildings. Nonetheless, this percentage is greater about 50% in developing nations, where at least 30% of people reside in rural areas and the remaining portion in urban or suburban areas [10].

Afghanistan is a mountainous country with hot summers and dry and generally cold winters with heavy snow. The average temperature ranges from -10°C to 34°C [11]; in the winter, at the higher mountain regions, with extremes as low as -45°C, and in the summer, as high as 50°C in the desert regions [12]. Soil is the primary construction material in Afghanistan, where 95% of buildings are constructed using soil. The main types of soil-based house construction include sun-dried bricks (adobe walls) and cob walls. The soil in most regions of Afghanistan has a clayey nature, and the easy availability of sand makes it suitable for producing stabilized compressed earth bricks. While stabilized compressed earth bricks may be somewhat more expensive due to the composition of the soil and the cost of cement, they are still more cost-effective than fired bricks or cement concrete blocks which are used predominantly in urban areas. Additionally, they are environmentally sustainable and human-friendly, making them a worthwhile option to consider [13]. The soil used for the produce of compressed stabilized earth bricks shall be of a suitable quality, free of deleterious and organic materials graded in accordance with ISO 14688-1 [14]. It is advised to utilize coarse sand for the production since the blocks will be stronger and have a higher density [15]. Soil composition and moisture content of soil can influence the strength of CSEB. To produce high strength CSEB, the soil's composition can be changed until the particle size distribution falls within the optimum curve limit. The compressive strength and rate of water absorption of CSEBs are significantly impacted by the compaction pressures used during production [16]. Additionally, the inclusion of granules or fibers, along with the compaction process, can influence the mechanical and thermal performance due to their physico-mechanical interactions within the soil matrix [17]. Natural soils tend to absorb more water, exhibit low tensile strength, and are susceptible to scraping and erosion [18]. The addition of appropriate stabilizers can significantly enhance the soil's strength, stability, permeability, and durability by promoting effective compression during molding and good curing [19], [20]. For soils with a plasticity index of 15% or lower, cement is typically used as the stabilizing agent. In contrast, for soils with a plasticity index of 15% or higher, lime is recommended either alone or in combination with cement [21], [22]. By the variations in local soil properties, CSEBs produced from different sources will exhibit differing mechanical characteristics [1], [2].

Despite their potential, there has been no prior research conducted in Afghanistan on the use of sheep wool as a natural additive in CSEBs to enhance their performance. Sheep wool, being locally available due to widespread livestock farming, possesses excellent insulating properties and can potentially improve flexural tensile strength in earthen composites. However, its influence on water erosion and thermal performance needs to be thoroughly investigated before it can be recommended for widespread use.

This study aims to investigate the effects of varying percentages of sheep wool as a fiber and cement as a stabilizing agent on thermal performance (thermal conductivity, heat capacity, thermal diffusivity), and water erosion resistance in compressed stabilized earth bricks to be satisfied their longevity. The findings are intended to support the development of locally sourced, climate-responsive building materials suitable for low-cost housing in both urban and rural areas of Afghanistan.

-

2 Materials and Methods

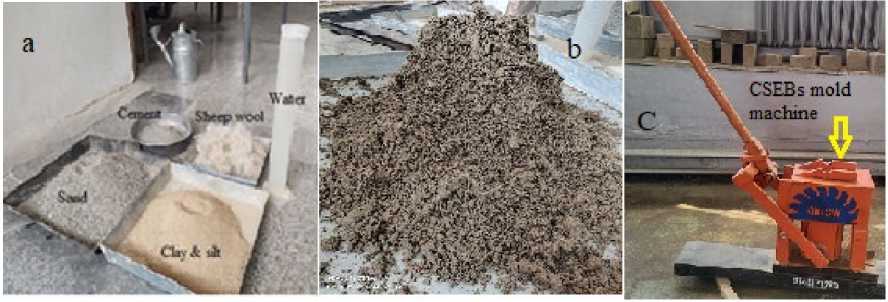

Carefully choosing the proper soil, sand, stabilizing agents, and water is essential for producing high-quality earth bricks, while in (Figure 1), the raw materials for CSEBs production are shown for this Nasrat, N.A.G.; Abu-Mahadi, M.I.; Hashemi M.N.; Obeid, M.A.A.

Thermal performance and water erosion resistance of sheep wool-reinforced compressed stabilized earth bricks;

study. Furthermore, since these elements have a high impact on the bricks' quality and longevity, it is also crucial to make sure the bricks in the mold are properly compacted and that there is enough curing time.

Soil: For this study, the soil was sourced from the Deh-Sabz district in Kabul province, Afghanistan. It is commonly used in its natural form to produce sun-dried bricks, fired bricks, and other construction activities throughout in area. Prior to use, the clay soil's properties, such as plastic limit, liquid limit, plasticity index, particle composition, and pH, were determined (Table 1). Moreover, the soil intended for the brick mixture was sieved through about a 2.5 mm mesh to remove nodules and other impurities. Based on recommendations from [23], the mixture composition for the study consisted of 28% clay and silt, and 72% sand. These proportions were determined by evaluating the observed shrinkage cracks and the composition of the clay and sand used for CSEB production (Fig. 1a, Table 1). To determine the suitability of a given soil for use in CSEBs, certain preliminary tests—such as smell test, soil composition analysis, and consistency tests—are necessary [24].

Fig. 1 - Show: a) CSEB raw materials, b) mixture for CSEBs, and c) CSEBs production molding machine

Table 1. Clay soil properties

|

Properties |

Values |

|

Natural moisture |

7.5 % |

|

Specific gravity |

3.33 |

|

pH |

9.5 |

|

Composition |

|

|

Clay and silt |

90 % |

|

Sand |

10 % |

|

Atterberg limits |

|

|

Plastic limit (PL) |

19 % |

|

Liquid limit (LL) |

27.45% |

|

Plasticity Index (PI) |

8.45 % |

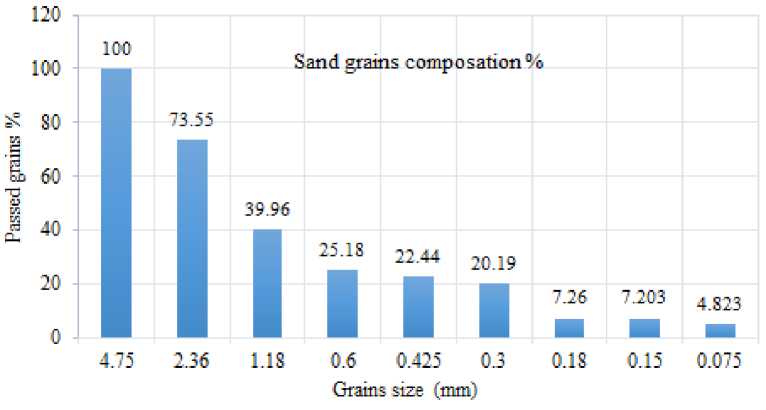

Sand : In this study machine-crushed sand sourced from a local crushed plant was used. The sand was sieved through a 4.75 mm sieve before use. Its properties, determined in accordance with AASHTO T-84 and ASTM C-128 standards, included a specific gravity of 2.9, a bulk specific gravity (SSD) of 2.69, and a water absorption rate of 0.6%. These characteristics indicate low porosity and high suitability for construction applications. The sand was free of organic matter and impurities, and exhibited an appropriate grain size distribution, as shown in (Figure 2). Therefore, for this study, machine-crushed sand was selected as the preferred option.

Fig. 2- Show sand grains size composition in %

Stabilizer: Soil stabilization techniques are primarily categorized into chemical, mechanical, and physical methods. Mechanical stabilization involves the compaction of materials to alter their density, compressibility, permeability, porosity, and overall strength. Physical stabilization refers to the careful blending of different grain fractions or natural soils, as well as the addition of fibers to modify the material's texture and improve its engineering properties [25]. Chemical stabilization involves incorporating cementitious materials such as cement, lime, fly ash, bitumen, or combinations thereof into the soil to chemically react with its components and improve its structural performance [26, 27]; whichever, for compressed stabilized earth block production, the most widely utilized stabilizers are cement and lime [28].

In this study, ordinary Portland cement (Grade 53) in amounts of (0%, 5% and 10%) relative to the dry soil weight was used as a stabilizer agent. Bricks with less than 5% cement are often too friable to handle [29]. However, [24] recommended 5% to 10% of cement as a stabilizer agent. While [30] suggests that for CSEB production, more than 10% cement content becomes uneconomical.

Sheep wool fiber (SWF) : Sheep wool is a natural material fiber that has a mixed composition of soft, intermediate, and coarse hair, and due to its physicochemical properties, it can be used as a component of composites. Wool fibers are a multicellular material composed of the epidermis, cortex, and medulla [31]. Fiber-reinforced CSEBs typically exhibit greater tensile strength, improved crack and crack propagation resistance, and higher compressive strength, depending on the kind of fiber and soil [32]. Sheep wool can be used into composite materials due to its distinct physicochemical characteristics, which aligns with sustainable development and bio-economy strategies [33]. Aymerich et al. [34] studied the flexural strength of the earthen specimens by using (2, 3) % and (2, 3) cm lengths of sheep wool fibers and reported that sheep wool fibers increased the residual strength, the ductility, and the energy absorption of the material after the first cracking.

In this study, sheep wool was incorporated into the soil mixture at contents of 0%, 0.05%, 0.1%, 0.2%, 0.3% and 0.4%, relative to the dry weight of the soil (Fig. 1a). The wool fibers, measuring approximately 2 to 10 cm in length, were obtained from local market sources.

Water: Groundwater was used for preparing the brick mixture. The materials were mixed by hand and molded using a CINVA-Ram machine, a manually operated press commonly used for brick production (Fig. 1c). According to NZS 4298 (1998) [35] the optimum moisture content (OMC) of the mix was determined using the drop test method. The dimensions of the produced bricks were 302 × 152 × 102 mm. After molding, the bricks were kept under moist conditions for 7 days, with water sprayed three times daily. The experiments on bricks were conducted after 28 days of curing.

2.1 Methodology for Thermal Performance

The thermal performance was evaluated using an ISOMET 2104 (Applied Precision/Cytiva Ltd., Technicka 5, 821 04 Bratislava, Slovakia), instrument for prepared specimens (Table 2). This device is equipped with two types of probes: a needle-shaped probe designed for soft samples, and a circular flatsurface probe intended for hard and planar specimens (Fig.3). The instrument automatically measures thermal conductivity (λ), volumetric heat capacity (Cp), and thermal diffusivity (α) using the Transient

Plane Source (TPS) method. The measurements were conducted within an operational temperature range of 15°C to 50°C, with an accuracy of ±5.

Fig. 3- Show ISOMET 2104, instrument for thermal performance measurement of CSEBs

Table 2. Bricks specimens, raw material contents and their density

|

Specimens |

SWF % |

Cement content % |

Dry soil content amount, % |

Bulk density kg/m3 |

|

Bk1 |

- |

- |

Sand 72%, Clay & silt 28%, |

2167.8 |

|

Bk2 |

0.1 |

- |

Sand 72%, Clay & silt 28%, |

2349.3 |

|

Bk3 |

- |

5 |

Sand 72%, Clay & silt 28%, |

2082.3 |

|

Bk4 |

- |

10 |

Sand 72%, Clay & silt 28%, |

2306.6 |

|

Bk5 |

- |

10 |

15% gravel, 50% sand, and 35% clay & silt |

2167.8 |

|

Bk6 |

0.05, |

10 |

Sand 72%, Clay & silt 28%, |

2157.1 |

|

Bk7 |

0.1 |

10 |

Sand 72%, Clay & silt 28%, |

2178.5 |

|

Bk8 |

0.2 |

10 |

Sand 72%, Clay & silt 28%, |

2157.1 |

|

Bk9 |

0.3 |

10 |

Sand 72%, Clay & silt 28%, |

2157.1 |

2.2 Method for Water Erosion Experiments (Pressure Spray Method)

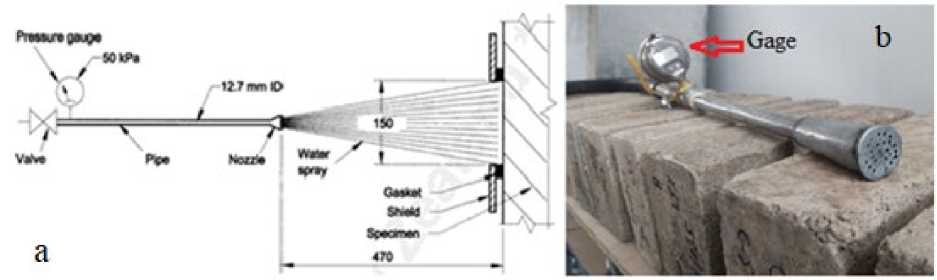

This test analyzes the degradation process of a specimen caused by water falling on it and verifies the surface resistance to erosion, thus evaluating the durability of the analyzed blocks. The test involves spraying water by a pressure of 50 kPa at 47.5cm distance onto the full width and 15 cm long face of the soil bricks for one-hour duration or until the specimen is completely eroded through (Fig. 4). Considering the standard, the water spry was stopped after every 15 minutes to measure and record the depth of erosion. The erosion is measured in millimeters using a flat-ended rod with a diameter of 10 mm. The erodibility index is then determined by mentioning Table (3) below, NZS 4298 (1998) [35]. in this study we examined the minimum (5%) cement stabilized bricks with (0% and 0.1%) SWF reinforced of bricks.

Table 3. Erodibility indices from pressure water spray erosion test, NZS 4298 (1998) [35]

|

Property |

Criteria |

Erodibility index |

|

Depth of erosion D (mm/hr.) |

0 ≤ D < 20 20 ≤ D < 50 50 ≤ D < 90 90 ≤ D < 120 D ≤ 120 |

1 2 3 4 5 (fall) |

Fig. 4- Show, a) Water pressure spray test method arrangement [35] , and b) water spry used instrument

-

3 Results and Discussion

-

3.1 Thermal Conductivity

Thermal conductivity (λ) measures how well a material conducts heat, that expressed in W/m·K. It indicates the amount of heat that passes through one square meter of material, one-meter-thick, when there is a temperature difference of 1°C (or 1 K) across its surfaces. Lower λ values mean better insulation. Materials with λ < 0.065 W/m·K are generally classified as insulating materials [36]. Pape M.T. et al. [37] absorbed thermal conductivity values of 0.7–0.8 W/m.K for CSEBs using 6–10% cement, whatever their density was (1757–1950 kg/m³). According to [14] standard, the thermal conductivity values for CSEBs A, B, and C classes, are 0.23 - 0.46, 0.46 – 0.81, and 0.81 – 0.93W/m.K, respectively.

In the Materials and Methods section, it was stated that SWF was used at contents of 0%, 0.05%, 0.1%, 0.2%, 0.3%, and 0.4% in the CSEBs. When using 0.4% wool, horizontal cracks began to appear in the bricks a few hours after molding. This was attributed to the separation of soil particles within the bricks, likely caused by the clumping or agglomeration of the SWF.

Therefore, it can be concluded that the addition of more than 0.3% SWF leads to cracking and compromises the physical integrity of the bricks. As a result, the 0.4% SWF mix was excluded from further experimental testing.

As mentioned earlier, this study investigated the thermal conductivity, thermal diffusivity, volumetric heat capacity, and water erosion resistance of the prepared bricks (Table 2). The results and detailed discussion of these experiments are presented below.

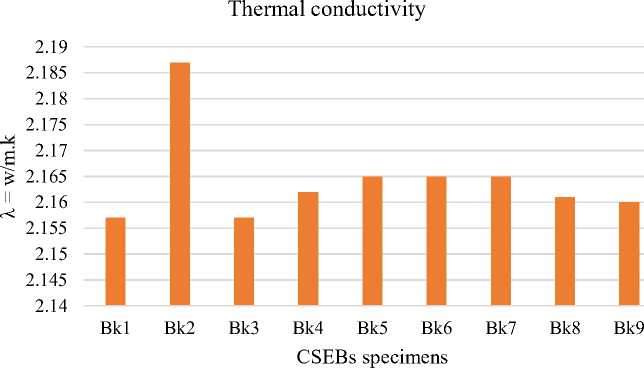

In this study, as summarized in Table 4, nine (9) of compressed stabilized earth bricks (CSEBs) were assayed, considering cement, sheep wool fiber (SWF) of various content, and bulk density to assess their influence on the thermal conductivity property of the bricks.

Table 4. Thermal conductivity values of CSEBs with their additives and bulk density

|

Specimens |

SWF, % |

Cement content, % |

Thermal conductivity λ = W/m.k |

Bulk density, kg/m3 |

|

Bk1 |

- |

- |

2.157 |

2167.8 |

|

Bk2 |

0.1 |

- |

2.187 |

2349.3 |

|

Bk3 |

- |

5 |

2.157 |

2082.3 |

|

Bk4 |

- |

10 |

2.162 |

2306.6 |

|

Bk5 |

- |

10 |

2.165 |

2167.8 |

|

Bk6 |

0.05 |

10 |

2.165 |

2157.1 |

|

Bk7 |

0.1 |

10 |

2.165 |

2178.5 |

|

Bk8 |

0.2 |

10 |

2.161 |

2157.1 |

|

Bk9 |

0.3 |

10 |

2.160 |

2157.1 |

Fig. 5- Show thermal conductivity values of CSEBs

Thermal conductivity was evaluated with results presented alongside SWF, cement content and bulk density values as shown in (Table 4). The findings indicate that both cement content and sheep wool fiber inclusion and density influence the thermal conductivity and other physical properties of the bricks. Specimens Bk1- Bk5 were prepared with cement contents (0%, 5%, and 10%) and without SWF. It was observed that increasing the cement content from 0% to 10% resulted in only minor variations in thermal conductivity, ranging from 2.157 W/m·K to 2.165 W/m·K. The average thermal conductivity across these specimens was 2.160 W/m.k, with a standard deviation (SD) of 0.004 W/m.k which falls within the low variability range, and their average density was 2181.125 kg/m³, SD 92.85 kg/m³, which also falls in the low variability range. However, an increase in density was more pronounced, rising from 2082.3 kg/m³ (Bk3) to 2306.6 kg/m³ (Bk4). Although cement helps with mechanical strength and densification, its effect on thermal insulation properties is minimal in CSEBs within the tested range.

The inclusion of SWF at varying percentages (0.05% to 0.3%) in (Bk6–Bk9) with a 10% cement combination did not yield significant changes in thermal conductivity, which remained relatively continual between 2.160 W/m·K and 2.165 W/m·K. However, a little reduction in density was observed with increasing fiber content, dropping from 2157.1 kg/m³ (Bk6) to 2178.5 kg/m³ (Bk7). The average thermal conductivity across these specimens was 2.163 W/m.k, with a standard deviation (SD) of 0.0027 W/m.k, which falls within the low variability range and their average density was 2162.45 kg/m³, SD 10.7 kg/m³, which also falls in the low variability range. Notably, specimen Bk2, which contained 0% cement and 0.1% SWF, had a density 2349.3 kg/m3 and higher thermal conductivity 2.187W/m.K compared to the other specimens. This indicates that the density has a remarkable role in the thermal conductivity, likely affected by applying higher compaction pressure during molding conditions, which reduces porosity and enhances particle-to-particle contact, thereby improving heat transfer. Warore A. et al. [38] also found that thermal conductivity increases with material density. All specimen’s thermal conductivity results are shown in Figure (5).

-

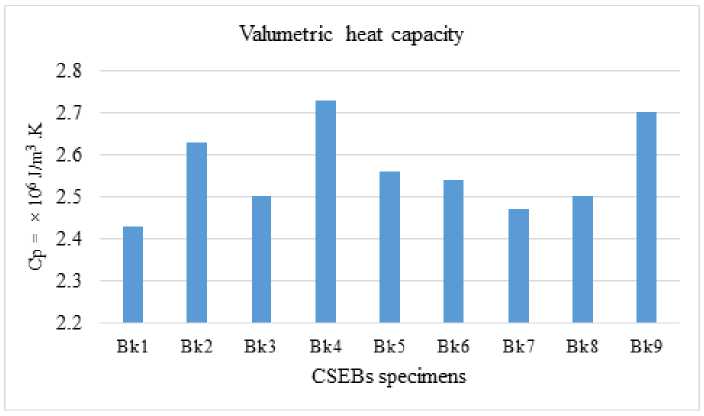

3.2 Volumetric Heat Capacity (Cp)

The volumetric heat capacity (C ₚ ), specified as the amount of heat essential to raise the temperature of a unit volume of material by one-degree Kelvin, have a significant role in specifying the thermal mass and energy efficiency of building materials. It is typically indicated in J/m³·K or similar units. This property is serious for understanding a CSEB's thermal performance in buildings, as it determines how much heat the blocks can store and release, affecting temperature regulation within a building. Volumetric heat capacity was evaluated with results presented alongside SWF, cement content and bulk density values as shown in (Table 5, Fig. 6). The findings indicate that SWF inclusion, cement content and bulk density influence the volumetric heat capacity properties of the bricks.

Influence of cement content on C ₚ : Specimens Bk1–Bk5 were analyzed to assess the effect of cement content (0%, 5%, and 10%) without fiber reinforcement. Increasing cement content from 0% to 10% resulted in a notable increase in volumetric heat capacity, from 2.43 × 10⁶ J/m³·K (Bk1) to 2.73 × 10⁶ J/m³·K (Bk4). In comparison specimens BK1 (0% cement and 2.43 × 10⁶ J/m³·K) and BK5 (10% cement content and 2.56 ×106 J/m³·K) their bulk density is the same but they differ in Cp. The increase Nasrat, N.A.G.; Abu-Mahadi, M.I.; Hashemi M.N.; Obeid, M.A.A.

Thermal performance and water erosion resistance of sheep wool-reinforced compressed stabilized earth bricks;

of cement corresponds straight with the increase in bulk density, as cement increases compaction and reduces porosity, thereby enhancing the material’s ability to store heat.

Effect of SWF addition : The inclusion of SWF at varying percentages (0.05% to 0.3%) in combination with 10% cement (Bk6–Bk9) did not yield significant variation in C ₚ , which remained relatively stable between 2.47 × 10⁶ J/m³·K and 2.70 × 10⁶ J/m³·K. The impact of SWF on C ₚ is nonlinear; at low SWF (e.g., 0.1%), C ₚ decreases (BK7: 2.47 × 10⁶ J/m³·K) but at higher SWF (e.g., 0.3%), C ₚ increases significantly (BK9: 2.70 × 10⁶ J/m³·K). At low (≤ 0.1%), SWF may not disperse evenly, causing micro-porosity and disrupting matrix continuity then C ₚ lower. At higher (≥ 0.2%), SWF are my evenly distributed, possibly improving interfacial bonding and reducing defects then consequently then C ₚ higher. It should be mentioned that during mixing of the mixture considering SWF values increasing, the SWF disruptions were very difficult and were less workable. The low variability metrics coefficient of variation (COV = 4.02%), standard deviation (SD = 0.103), suggest that the addition of SWF does not terms the thermal storage capacity of the bricks.

Effect of bulk density : Generally, C ₚ increases with bulk density. The higher value of C ₚ (2.73 × 10⁶ J/m³·K) was recorded in Bk4, which had the second-highest bulk density (2306.6 kg/m³) with 10% cement. Similarly, Bk2, with the highest bulk density (2349.3 kg/m³) without cement content, also showed elevated C ₚ (2.63 × 10⁶ J/m³·K). we can say that bulk density is a significant predictor of C ₚ , which denser materials tend to store more heat per unit volume.

In general, the dataset indicates low to moderate variability and good consistency in volumetric heat capacity, as presented by the COV of ~ 4.04% and a relatively small SD = 0.104×106 J/m3. K. This suggests that the material formulation and production process yielded fairly uniform thermal performance across specimens.

Table 5. Show the CSEBs volumetric heat capacity (Cp), considering SWF, cement content and bulk density

|

Specimens |

SWF, % |

Cement content, % |

Volume heat capacity, Cp = J/m3. K |

Bulk density, kg/m3 |

|

Bk1 |

- |

- |

2.43 ×106 |

2167.8 |

|

Bk2 |

0.1 |

- |

2.63 ×106 |

2349.3 |

|

Bk3 |

- |

5 |

2.50 ×106 |

2082.3 |

|

Bk4 |

- |

10 |

2.73 ×106 |

2306.6 |

|

Bk5 |

- |

10 |

2.56 ×106 |

2167.8 |

|

Bk6 |

0.05, |

10 |

2.54 ×106 |

2157.1 |

|

Bk7 |

0.1 |

10 |

2.47 ×106 |

2178.5 |

|

Bk8 |

0.2 |

10 |

2.50 ×106 |

2157.1 |

|

Bk9 |

0.3 |

10 |

2.70 ×106 |

2157.1 |

Fig. 6- Show volumetric heat capacity values of CSEBs

Overall, the volumetric heat capacity (Cp) of the samples is firstly impressed by cement content and bulk density, with lower effects from SWF additives depending on the values. While lower to high Nasrat, N.A.G.; Abu-Mahadi, M.I.; Hashemi M.N.; Obeid, M.A.A.

Thermal performance and water erosion resistance of sheep wool-reinforced compressed stabilized earth bricks;

cement content increases thermal energy storage per unit volume, the inclusion of SWF should be carefully to prevent disrupting the matrix and decreasing thermal performance. These findings exhibit the significance of optimizing both SWF inclusion amounts and mixing techniques to attain the maximum thermal performance in compressed stabilized earth bricks.

-

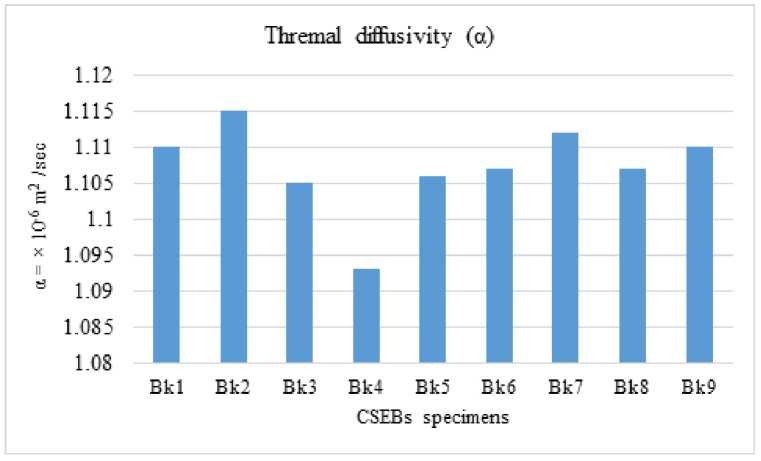

3.3 Thermal Diffusivity (α)

Thermal diffusivity (α) is a measure of how quickly heat propagates through a material, it reflects the material’s ability to respond to transient temperature changes. Volumetric heat capacity was evaluated with results presented alongside SWF, cement content and bulk density values as shown in (Table 6, Figure. 7). The findings indicate that SWF inclusion, cement content and bulk density influence the volumetric heat capacity properties of the bricks.

Influence of cement content: The effect of cement content (0%, 5%, and 10%) without SWF in specimens Bk1– Bk5 slightly decrease in thermal diffusivity. The values reduce from 1.110 × 10 ⁻ ⁶ m²/s (Bk1) to 1.093 × 10 ⁻ ⁶ m²/s (Bk4), with low SD = 0.0074 and COV = 0.71%. This indicates a minor reduction in the value at which heat is conducted through the material. This trend aligns with the observed increase in bulk density and volumetric heat capacity, as higher density typically increases thermal inertia, slowing down the heat transfer process.

Influence of bulk density: The bulk density of the compressed stabilized earth bricks (CSEBs) does not appear to have a significant influence on thermal diffusivity. For instance, BK4 (2306.6 kg/m³) and BK5 (2167.8 kg/m³) exhibit different bulk densities but share the same cement content (10%), and yet their thermal diffusivities differ only slightly. Similarly, BK1 (2167.8 kg/m³) and BK2 (2349.3 kg/m³) show varying bulk densities, and both have 0% cement content—except for BK2, which contains 0.1% sheep wool fiber (SWF). Despite these differences in density and fiber content, the variation in their thermal diffusivity remains minimal. These observations suggest that bulk density does not play a dominant role in determining the thermal diffusivity of the tested CSEBs.

Effect of SWF: A slight increase in thermal diffusivity is observed with the addition of SWF, as seen when comparing Bk2 (with 0.1% SWF) to Bk1 (without SWF). However, in the case of specimens Bk6 to Bk9, which contain SWF in the range of 0.05% to 0.3% and have the same cement content also nearly equal bulk density, there is no significant influence on thermal diffusivity. This is further supported by the very low standard deviation (SD = 0.0025) and coefficient of variation (COV = 0.22%), indicating minimal variability in thermal diffusivity across these samples. The values remained relatively constant between 1.107 × 10 ⁻ ⁶ m²/s and 1.112 × 10 ⁻ ⁶ m²/s. These extremely low variability metrics confirm that the presence of SWF does not reasonably affect the rate of heat propagation through the bricks.

Table 6. Show the CSEBs thermal diffusivity (α), considering SWF, cement content and bulk density

|

Specimen |

SWF, % |

Cement content, % |

Thermal diffusivity α = m2/sec |

Bulk density, kg/m3 |

|

Bk1 |

- |

- |

1.110 ×10 -6 |

2167.8 |

|

Bk2 |

0.1 |

- |

1.115 ×10 -6 |

2349.3 |

|

Bk3 |

- |

5 |

1.105 ×10 -6 |

2082.3 |

|

Bk4 |

- |

10 |

1.093 ×10 -6 |

2306.6 |

|

Bk5 |

- |

10 |

1.106 ×10 -6 |

2167.8 |

|

Bk6 |

0.05, |

10 |

1.107 ×10 -6 |

2157.1 |

|

Bk7 |

0.1 |

10 |

1.112 ×10 -6 |

2178.5 |

|

Bk8 |

0.2 |

10 |

1.107 ×10 -6 |

2157.1 |

|

Bk9 |

0.3 |

10 |

1.110 ×10 -6 |

2157.1 |

Fig. 7- Show thermal diffusivity values of CSEBs

-

3 . 4 Water Erosion

A water erosion test was conducted on CSEBs with a low cement content of 5% to evaluate their surface resistance under short-term water exposure. The experiment was performed in accordance with the NZS 4298:1998 [35] standard, with each sample subjected to a continuous water pressure of 50 KPa for one hour. Two types of bricks were evaluated: one without the addition of SWF and another incorporating 0.1% SWF.

Visual and physical inspections after the test revealed (Fig. 8), very small holes are visible on the surface of the bricks. These holes are approximately 2 mm in width and 1–1.5 mm in depth in both types of CSEBs. However, when evaluated against the relevant standard (0 ≤ D < 20, Table 3), which assesses surface defects based on the use of a 10 mm diameter flat-ended rod, these holes are considered insignificant. So can say that no erosion or surface degradation occurred in either type of brick. Both the 5% cement bricks with and without 0.1% wool maintained their structural integrity and surface cohesion throughout the duration of the test.

The absence of erosion in both types of bricks indicates that even a low cement content of 5% is sufficient to provide adequate surface stability under short-term water pressure shooting. This suggests good bonding between the soil particles and cement, which enhances the mechanical strength and resistance to disintegration.

The addition of 0.1% sheep wool fiber did not result in any observable difference in erosion resistance during this test. This may be due to the relatively short duration of the test, which might not have been sufficient to reveal potential long-term benefits of fiber inclusion, such as improved crack resistance or enhanced durability under cyclic wetting and drying conditions.

-

4 Conclusions

The main objectives of this work were to study the influence of thermal performance and water erosion resistance of compressed stabilized earth bricks (CSEBs) by using different amounts of cement content and sheep wool fiber. For thermal performance results, ISOMET 2104, instrument was used, an instrument that gives results for thermal conductivity, volumetric heat capacity, and thermal diffusivity.

-

1) Thermal conductivity: The findings indicate that both cement content and sheep wool fiber inclusion and density influence the thermal conductivity of the bricks. Specimens Bk1-Bk5 were prepared with 0%, 5%, and 10% cement contents and without fiber. It was observed that increasing the cement content only minor variations in thermal conductivity, ranging from 2.157 W/m·K to 2.165 W/m·K. However, an increase in density was more pronounced, rising from 2082.3 kg/m³ (Bk3) to 2306.6 kg/m³ (Bk4). The inclusion of SWF (0.05 to 0.3%) in Bk6–Bk9 with 10% content did not significantly vary the thermal conductivity rate.

-

2) Volumetric heat capacity: Results indicated that cement content, considering their increasing ratio, influences the volumetric heat capacity of CSEBs. Specimens (BK1-BK5) with 0%, 5%, and 10% cement contents have volumetric heat capacities that vary from 2.43 × 10⁶ J/m³·K (BK1) to 2.73 × 10⁶ J/m³·K (BK4). Volumetric heat capacity (C ₚ ) also increased with increasing bulk density. The higher value of C ₚ (2.73 × 10⁶ J/m³·K) was recorded in Bk4.

-

3) Thermal diffusivity: The effect of cement content is not significant; the thermal diffusivity in Bk1–Bk5 specimens slightly decreases, from 1.110 × 10 ⁻ ⁶ m²/s (Bk1) to 1.093 × 10 ⁻ ⁶ m²/s (Bk4). The bulk density of CSEBs also does not appear to have a significant influence on thermal diffusivity. For instance, BK4 (2306.6 kg/m³) and BK5 (2167.8 kg/m³) exhibit different bulk densities and have the same cement content (10%), and yet their thermal diffusivities differ only slightly. The presence of SWF does not reasonably affect the rate of heat propagation through the bricks. As seen comparing Bk1 (without SWF) to Bk2 (with 0.1% SWF).

-

4) Water erosion: The erosion test that was conducted considering the NZS 4298:1998 [35] standard demonstrated that even with a low cement content of 5%, the bricks exhibited no surface erosion after one hour of a continuous 50 kPa water pressure spray experiment. The addition of 0.1% SWF did not significantly alter the erosion resistance under these short-term conditions, though it may offer benefits under prolonged or cyclic wetting scenarios. From this, it can be concluded that there is a good bond between the brick particles, indicating that the bricks are well compacted and do not contain significant voids that could expose them to the risk of water erosion.

Overall, the findings demonstrate that the CSEBs exhibit adequate thermal and durability properties, making them suitable for use in construction as sustainable construction building material, particularly in regions with moderate climates and where resistance to water erosion is required. For future research work, it will be appropriate to focus on long-term durability testing, including repeated wet-dry cycles and freeze-thaw resistance. as well as searching to increase thermal insulation performance. It is worth noting that during the mixing process, increasing the SWF inclusion led to significant challenges in achieving uniform dispersion. This resulted in clumping or agglomeration of the SWF, as shown in Figure 1b, which in turn reduced the workability of the mixture.

It is mentionable that scanning electron microscopy (SEM) would be valuable for analyzing the internal structure of the bricks and clarifying the bonding mechanism of SWF with the surrounding matrix. However, due to the lack of access to such instrumentation in Afghanistan, the microstructural analysis of SWF integration remains a limitation of the present study.

-

5 Acknowledgements

The authors would like to express their sincere appreciation to the Faculty of Engineering, Department of Civil Engineering, Kabul Polytechnic University, and Herat University, Afghanistan, for providing the laboratory facilities essential to produce specimens and conducting the thermal performance experiments.

-

6 Fundings

The author(s) received no financial support for the research, authorship, and publication of this article.

-

7 Conflict of Interests

The author(s) declared no potential conflicts of interest concerning the research, authorship, and publication of this article.