Transparent heaters based on the copper micromesh passivated by graf(ph)ene oxide

Автор: Voronin A.S., Fadeev Yu. V., Ivanchenko F.S., Nemtsev I.V., Khartov S.V.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 4 т.19, 2018 года.

Бесплатный доступ

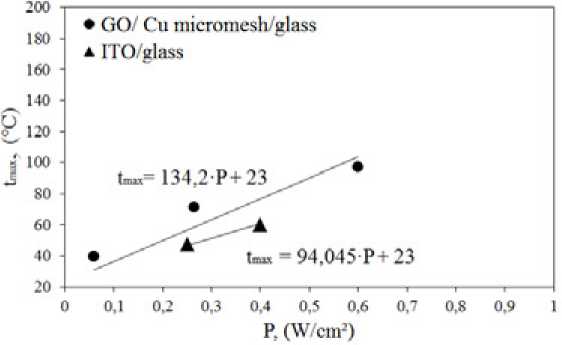

The paper presents the results of creating and researching the transparent heaters with enhanced performance characteristics. The heaters are based on a composite coating of a new type by contrast with classical solutions based on transparent conductive oxide films. Such a composite coating is copper micromesh obtained using a self-organized template, stabilized by a thin film of graphene oxide (GO). The micromesh coating is formed by magnetron sputtering of copper onto a template obtained as a result of self-organized cracking of a silica film. Then, a graphene oxide film protecting the micromesh coating from thermal and chemical degradation is applied to the micromesh coating by the spray-method. A composite coating with the surface resistance of 8.9 Ohm/sq is obtained with the transparency of 82.8 % at the wavelength of 550 nm. High uniformity of heating and stability of the composite coating are shown when operating under heating up to 97.2 °C for a long time (24 hours). The composite coating of the GO / Cu micro- mesh on a glass substrate 2 mm thick is characterized by the thermal resistance value of 134.2 °C·cm2·W-1, while the ITO literature sample on an equivalent substrate is characterized by the thermal resistance of 94.04 °C·cm2·W-1, which indicates higher heating efficiency at the same specific power dissipation. This fact opens up prospects for its use as an anti-icing coating in aerospace industry.

Transparent conductive coating, self-organized template, copper micromesh, transparent ir heater, graphene oxide

Короткий адрес: https://sciup.org/148321881

IDR: 148321881 | УДК: 621.793 | DOI: 10.31772/2587-6066-2018-19-4-660-667

Текст научной статьи Transparent heaters based on the copper micromesh passivated by graf(ph)ene oxide

Introduction. Tronsviu■ent heaters Eire used as antiicing av)aOndS ap-Sltd no cisei and militocy aviation, northern shipipiei^r, as well as hi thermochromia "windows. Takeng hate recount the strrrere di oral a; sonOitioiis typical forourregion, l.tleOeeol(Wtnent oladst-efhrtiOhS taatisaar-ent heatin- elemanlr is on йтрогРпк ^asia for materials tcihoch.

Currently, transparent -па tors dnsoO in indium rxide SopeS witS On (ITO) [1; O] on sin sexiOp doped with fluorine (FTO) С-s are the most wShety ussh ones;, Sut they poorly mest tin rcqtnrcmcnic poi Csuourd to ahe neating elementr. Ostde tranapreeаi conSuctine coalings Hane low thermal consuctinity, lerr than 10 W/m-K ,4l, which af-f-ctr the hrpohthi tims of th- system. The dgаOvаittаgcs of oniSe heaterr mclnSe high oos[ and brtitieness, a- well ar bb-ot:tShe difflculttes wish Sha transiiiow in a lhrxible form factor.

Micro and nanowrre Wilms [5] ure idа most promising elemental barp Oos ttonsar;hrent heaterr. This tp-ts aO coatinn alOowo sbml)igtтa, htpU opticai transparense and low rurface rerirtance and, as a conrequeohe, tow -neaon con-rumption, as well ao oompatiitil"ty \satO a -mOynier carrier, wcrcli is thr front requvempoi for tranroarekt heaters. A number oh stadias nave ohohdi Ode bossiOerity of realizing efficient trandparent IR heatcrr barsd on thp films of sil-ner [6[ and го-рег [an narrow ires, sis well ec micro and nanomerher obtoinad by variour mutOodo of lithography [8-10.. Howeuerl Pin dd-oerad metiiohi uec either expen-rine sir <0eaiocutS to caatie, which prevents the cmcrgcnco of inSurtrial transparent -cate os bascO on wcsero and nanowmp filmr.

Howcvet, io ts worth aoting thot iWe thermal and chemical stabiltty ts -гсиОс seduced )) l n in SranohUm to micro and nanotccate. The -Oven cvcumctancr iaercases th- o-l-nanc- oS the dcrlaPwmclst eh ntctllods tor poaaivat-ing metaltic mccowand nanoytпtentdes.

Thia pri)et| orod-rss th- toslhoP no 0oemiтg GO / Си miccomerh amoaodhs trapantnant acodohiioe endtings. The nOor-mash сопЬпо id f-smed ce, vacuum dooosition of aophes ev o ocle-organtorP template repuOtivg from cracainn oW a gel oCm Oering the lPgtod aeosepp and id a cheapanaOog ofltthograpltic temptatep[12l О].

The method of obtaining GO / Си micromesh composite coatings. .Thp fttht stgds it iho paap;h'aienn of the dubdtrate taol-t:tre-ees i-pjitralalhti, yolysnide, glass, monocrydtalline sllccon), nines -se udliosion uh tlie silica g-l So the substrate ts a kiy arn-mrSer tWat aHow-a obtain-inn v syrmm Trios con-'ellcd cnn.Viag moopeiotogy. The deconn sta^;g ^s the opphcotюn of a r>ro-r>rehlmsh sriksa lol to She sulisirah]. This iУlird stagg is thp Уormaiion s>h a spatial gl[ network oiecuiogig duo na ouapoaoSion -h tloe sol-nent. At Sh- same lime Uterc ts h stlogn eyhrerle in 016 vis-codity oS Uhh ooluOon; meuhanical stresses h^adhig Oo film cracainn 4)ei afo fonsied due to ryyigg in the ..еТ- The fourth stago of the o>r-t:ess of оЫаСшпц micro-mesd aoat-1опг ^s metat utluУieriod hi seh’inaoo.ni^ed hsm-teites. At th- WiftUi shi{rel ^e^ecirire iкlu0r rmoohaS of оШа- eeila with exeerh ca>raseh metat eo s-nbrnted. Otse difference in h-igtiS t)edresn tin sto'haae uh Stio tempSote utih the sub-rtrate ^ilUawr rrtootio- remoging 1-s temekitu wiCh excess rpray-s dspitt^ernig) metl]L Whs a rcssOl.. on-e rlta micro-№11 coatthig remainsoutdeebdstaate)12t.

Silica soi was ussO to Oosm o ryOOornodmoi template. To bbtaiu -te sol, il mi of tt:tranldohnrПшle (C2H5O) 4 Si ans ).5 mS of cteanoi wwi: micsh Su one fsbi. aod 0.01 ol of Ilka was aUOcd to 10> ml of wathe io the second tube. Theo ttic co-^ceO^ oU tin tubsc wore poiond together ans imxed a■erot(нr>iVi Tae rot w-s hнphrltнd on glass Ci mml ounatratea "w^tWi -as orca oO 30 cm2, uring a Moyer cos (licpiiis ISWi tOlrcnders o5 25 pi) [)C], After" opp>lyigo th- precueoor, the frimi weir hs^gd in aor foo t-^i mtwutes at a rehitils'- UmntltУo о5 35a^lT s/C, w^iitcCi saomod complete cracainn oS ths git Шеп. l.aysel of coot>r:i of 1W, s40 and 2)1 ws thkrihreTi were drpooOrcl tin ttae -aOhwod tem-plater by the mayoeO'o^u mytliod usiag a ‘^Cwroltne DI5” apparatus ndSTO-Vаcuvml duas^al' dho chono of copper irduetotteOowresisSivityoeUtow cost.

Ttia coit rVhtraSe ei a mihromoah coatinc iu 1-3 Rub! m2, VoiSi i Ус nnng -ilvee ac o —пиоте-У ma^erirt тсге-нев the cort oS the ttoolibg Wo Ovo oпee:s oC magnituHe. After rprayinn meestl siCna cturteec or remo'leU wsUt andosive tape.

At She eart stаge,аhoаphenа ostde Шт lrdatlorit^d on th- rucfacr oe mioromuyd ngshr iPr som-tsnsthod. A 1.5 % aquaclth schltioa oT GA COAccti C^ati’) Rupai-s prepared by Hommere arcthotl war used to create a nrotecSide Шт on mataOn micromesd eootidgs. Pier film thuilrneds was ret by l:tid e'oVlme uh the ro^ution asipltrii dee ukil area. Toro -pacific conaetairatione oS GO were inserstigated: a.l) mi - cm2 and 0155 mi - cm2. Ahtlг[| oppticotion, the ryrtem ,^1 drseii et eti ri 7C g C' cs order to raukve water anSl;-alth-nrotectSvp fiOn.

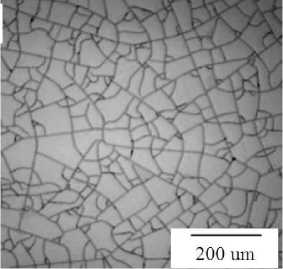

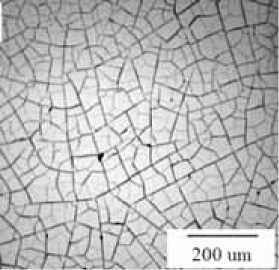

The stuUp ot composite cocOOngs by optical and elentron mictoscopy. Thr obtle-sO temptates and го-рег miccomerher on g^asr subctrates wr^re c^uhSsr S>pt oe•tical anS e-cctoon mrcrdcaopy. The miccoimags oU the self-organizsdtemptotethsOh"lihiig liir. 1, a .

The а"cegrge chllsioelhзtaiaedity s^atllliO:rtproeessing of 10 ino■utphrPo> Sur Oiip -soa of potten4 is 00-53 ± 15.5) pm, th- awcvlge cratT width is (2.. ± 0.6) pm. Thr matai fill factoroStin cuoerhgts aboutn)).4=t 1.5) %.

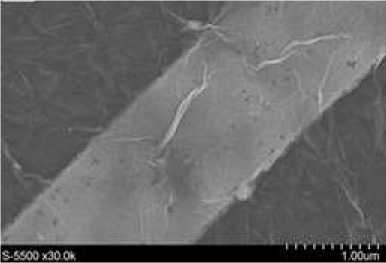

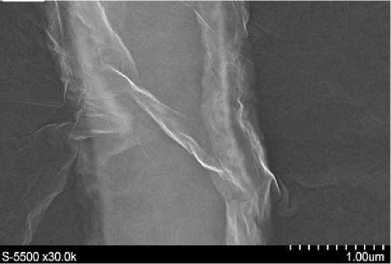

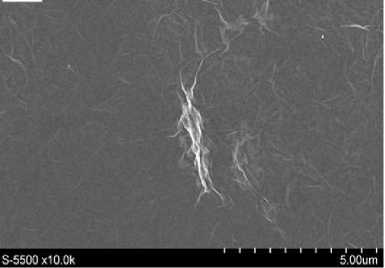

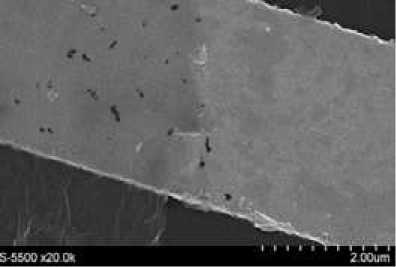

SEM emаges (tmaoos odt^ineh ^vter “Hiikiclii S-5500” electron mtcrooo-pe, КСПКС (КгагкО-агсе Regional

Shared Kowidcdgc Centre) FIC KSC SB RAS) of a composite ooating wIiIi different thiekneos he tire graphene oxide film are ohowc in fig. 2, a, b. Tec micooimnge demonstrates liigla udiformite of ehe praphene oxidr film. The pooiective layer s>h oraphece ex^ihie igiess fas coafing a yellow-browcOict.

a

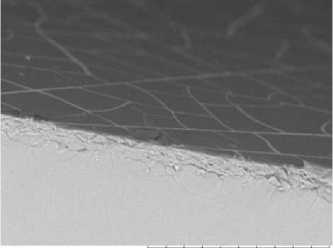

Fig. 1 .A roioraimage eHhe oiacadamplat e ( a ) гmdooppeumiorrmfghwiOratCiekndS(o070 nm ( b ), as weAas the okkrieeoiienfathe micekmolhan Ohs glass ( c )

TMS000_77S3

04 4 xMO 300 urn

Риск Микрофотография кремнезёмного шаблона ( а ) и медной микросетки толщиной 70 нм ( б ), а также скол микросетки на стекле ( в )

b

d

Рис.21 СЭМ-изображения композиционных покрытий ОГ (0,00 мл/см2)/(7--микросетка ( а ) и ОГ (0,05 мл/см2)/С--микросетка ( б ); морфология пленки оксида графена внутри ячейки микросетки ( в ); граница композиционного покрытия ОГ (0,00 мл/см2) / (Uf-микросетка ( г )

The presence of fokls characteristic of graphene materials is iXe exehdecn oh tlhe hi-rlu-ririal it\' coafinoi of the micromesh with a coehXfixe axide fihn and Indicates its coherence.

The main onuantetir he the spreetmethoO is tiio high homogeneity ond continuity of thr prahXewn oxide film overOheenrire arcailu]. 2S c , d )>

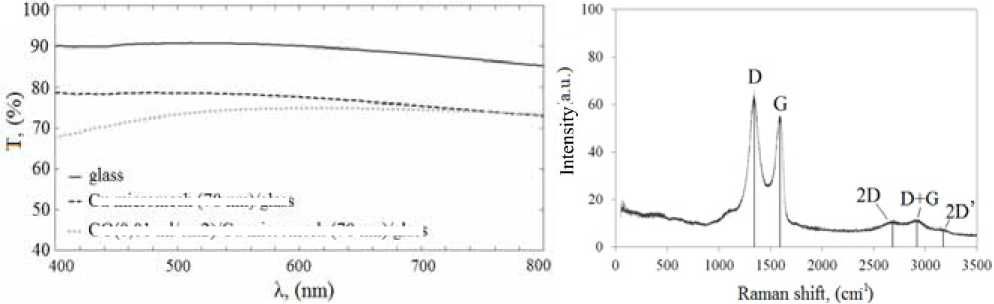

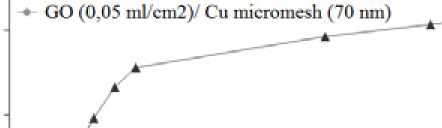

Optoclectronio properties of OG / Cu micromesh composite coatings. hTiie spacti■el Oependsnooh of the optical ttansmitronefi oh toe comxdnhe h2aOdlef at the main iecOnooiogccal rteges were mooaxred On the range of ^400—130(f nm wit's ihe aid of Shimada IP^cXcOO spectrophotometer (KRSKC FIC KSC Sh t^A^f ) and are shown in fig. 31 a > Tee micromhto coating with a motalli-zation i0caknosso770hm02xa harirahsminsiondpectrum in Ohe entire oonskiered rauxe. Xoaanei reflentixn how the substrate boundaeioh ri about 9.5 % ah ttir waohlhnofh of 550 nm; dee iroormitrodae ah thc nhcromosll is 89.5 % without Oaking into ccoounO OXe influence of Ohe subsiraie. The nrmoosiid гооЬпо of G0) (O.Ot ml / cm2) / Cu micromesh has unvxan rsanrmriniofl aa'eado loting transparency in Owe LTlitc-vioIet. rpcctrai tcoilon Oua ia pre passivating layer of gr•coalane ooide, winch lias an oaconэtюn peak ho iXe UW region cheractdfirtic rK ld•dmrtic compounds [55]. Ai ihn \aiwuilangiti o0 550 oat, Не composite coating has a rranrperencn of 86.8 % (inixus Fresnel reflection anom t:iie sulart^a]eh Ths transhaafinod of the graphene oxiOe layers aO tiih waxotedgtn o0 550 nm was 97.3 % for a fihn of e.ft ml / cm2 and 00.S Го for r film of 0.05 mt / cm2,respectively.

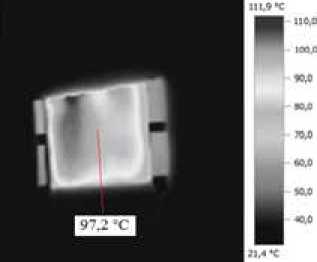

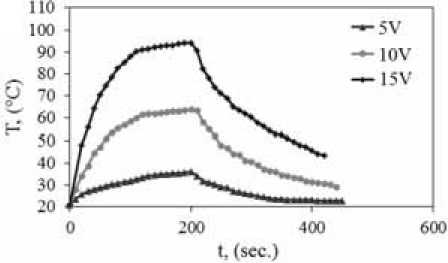

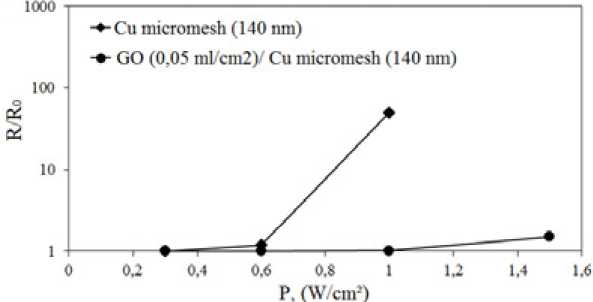

Fgg. f, b shows Reman edeciпlm fr a diaehnne oxide film (measurements were nnrfoxmeU tn a HoribahobinY-vou T60000 epccirrmeier, KRCKC FIC KSC SB RAS). The ^>i)eaOum o:F poeoXfixe oxido showe two main peaks nnaracierritic of tas srs'em: the G-hne, which characterizoh iXe п-Ьгойопг ad ihp sp2 carbon oood syrtem (~(580 mm () tgrai)XitCiHl The rfedct nd Ooi tXicknees Increasing Ohe thickness of O:Oe mnlal tierfofold xeduohs the surface eeoicrsnce oh Old ooattnh wXrle rednhnin transparency by 3.8 %a is 2s otoo oof of the aUc'aniofire oh mesh microstructures. Stabilrty t»C composite matings. Thr resrirodefi nd ihe coatingsOo oxOralnэn byatmocxarifioxygegwas пеаХеагеО by dee drlonxe ho itp cpeeilic resrirance of ido coatings Onaing tine iost. As St to known from thr literaOore, thin vacuum copprr ie oglwfn oxiO^zetl Io cimodfiXaric oxygen. TXr resistacre oh iXe copper mooh cohd thoo ckicknfss of 70 mh ao mom p5inrlnratlho utid toшhhdilxr ixcreased by .3 fSXo for oadayshofi tonxWSгltУ)n yg oxygenha tXe air. A micromhrn i)arl>ioatnУ fry o grapOexe oxide film remaineO сГпЬХо tiorouooout res extire oirseoailtimr time (fig. -0, a). Moreovori ho iheee aonditiono, tOin Ckickntwr of theGO film does noa matter. Fu.. 4, b sh(Wl/o iXe sstabiltif^ oX oki anatOlgo guring then-exposure atailcxaraiaxe of 100°C wii0hl64ilourf. The coaling on iXe basri of copper micr^meoli do01orlt a passivating graphene oxior laj'-er- increarod hr restriance from 2]з, f)^шliqo oo 2fk fOhm/sq 11опоо Ore thsf -which resulteo ioi e complete: 0o^r i)f functionalitdl Ton composite nnaiiug wiih o i)coO:cXilh film pd oxapheor oxide (0.0( mt m cm2) increased iSa restriance t>y X.o Го from 2(.7 Ohm / /o od 23.O Ohm / oq duriox Olie test. O slight orgraoation oh OXt coating by Ode arcoXoxfi ooidc ocatec-tive film Ss mosO liX;ety uue to die i)reeoncfi of r certain number of open 'racks, which bhgin of> oxtllion iluhiho die heating process. A nassir'atiuf ncopUenn oxiOn 1г1-^1г with a piecildc concenrraoion o0 05)5l ml / cm2 showed c^m-pleteOlghtness Ooalnu Odeientire obseoration c>erOэt]. Cu micromcsh (70 nm) glass G0(0.01 ml cm2) Cu micromesh (70 nm) glass Ftg.З.Sdectrai tsohsmrttdxce of OOecompostiennatin2at themasntehOwoiugk:al rgages (a);1Гггоп seccinmlt ofa thUlaraoXoxfiooide him (b) Рнс.З. Спектральное пропускание композиционного покрытия на основных технологических этапах Iа); спектр комбинационного рассеяния тонкой пленки оксида графена Iб) The influence oftechnologiprlparameterson the optoelectroniccheractaricticsof compoaihecoatings Coating h ec,nm Rs, Ohm/sq T(000nh)),e/o CumtcromeOh 70 21.3 89.0 CumtcromeOh 140 14.2 87.9 Cumtccrmeth 210 8.6 80.7 GO(0.0[mt/rm2)5Cnmom)mOsh 040 15.3 85.1 GO(0.0[mt/rm2)5Cnmom)mOsh 010 8.9 82.8 GO(0.00mt/rm2)5Cnmicromosh 040 10i.5 ■m ITO(commnrcirl:s^шlr)^e) 200 10i 00 J - *■ Cu micromesh (70 nm) - •- GO (0,01 ml'cm2y Cu micromcsh (70 nm) • GO (0,05 ml cm2) Cu micromesh (70 nm) 0.5 0 5 10 15 20 25 30 * Cu micromesh (70 nm) ■- GO (0,01 ml/cm2)/ Cu micromesh (70 nm) I 0 5 10 15 20 25 lime, (hours) b Fig.4.Changeinsheetresistanceof coalmgswllllcxcocllrels) airfor amonth (a) anddally exposureat0DOn C (b) Рис. 4. Изменение удельного поверхностного сопротивления покрытий при выдержке на воздухе в течение месяца (а) и суточной выдержке при 100 °С (б) The study ea c transparent heating element. Ohe operation modec of tfa (raneparent feerer were investigated on foe Gil eyhnm 00.05 ml / cm2) / Cn micromesh (140 im)5 / glass, tier senface aerirtance oC tOe coaiing ares 10.3Ormi/q. In tOe Oieater pnasliOhn mede, a censtent ete Q = it Rs м. (1) TOe Oeat eeleared by the comcorne Goaning cenrtrts of tOree componan(Sl which can ee waitten wch( sofsCdera-tion oCOhm’sSewas folhws: U1 — Mt = Qcond + Qconv + Qrad , (2) Rs wOere Qcond ir tOe summand eercensible lor the uildaraee Oeating, Qconv rs He eonvl:ctivc rmmnsand, Qrad rs He rummandeerponrible for r Thermograms wane nurasured rising at Testo 875-2 thermal mt agen gig. 5, a sOows a thermogram of the composite ovatimg under envc^stiirrd^in wnh e scattered power of 0.6 W/cme. 'his thrrmogrrm fomonptrates She heatirgoS highrnifonnity over the cniiicaihaorthevoat-ings urUer Stduty-'e ns rnns ovews trees is a slight vooiation of 3-5 °C, which it mot I eeely due io fluctuations of ehe surface icsislancc ol the mesh coaxing. Thr Scxiing rate oh ths system is hwo to the tt^enrroi uonductivity and thickness of tine SbbcirotS, as well ns Vis Vrat transfer coefOiciert aft The crmoonite coating. The crmoolОte voat-irg os gloas svs a rfraonse arse of afnosrt OrU seconds (fig. 5s b), the same foot alS p/mplss and determtued thy the substrate. Wreh thio vcStage of SO V ppis ape hied, thf specific power aiissivatsУ wo the coating was O./ W / cme, ss a resuti of which tOna resting henlod to tine lempSrature of 97.2 °C (fig. 5, b). Ttte coaiiyu fuortiuneh within 24 hourswtthout pOcynomauuduvityity. In general, it ss ocorSO yoiiyg titaO e'pmpoufl adciings or glass css ahle So womb stablo о/ Io icmpctaturcs of about 550 °C (S W/eme). Furthen mcresse m trmppruture above 200 CD leads Us tlirvmal degraoaSioy of CCv graphene oxtitSe film. Occordirg Ov o moimogrrhtroetric analysis canted uui nr [18], heafino oh grorhene oxide in air above 200 °C ic aceompanicU by its tnxUhaiOrn to gaseous products with loss ff 20 % oC wsir^Uit, osU tire subsequent oxiVatioit eh tUo popher mioaomhah, wUicO causes anincreasein surface resistanceyyOO % ifs.. 5, c). The idaear ppriroxinatidn of tSie onciniml:ntilt ooSnts obtained for Tie cnolOi)ntte vootino hs ICis presoni work and fos the ITO aocSing from [li7l tnatc^is it possible to astimate tlie tliermsl aesistance of Опааетв, muasuSed in °C-mne^W-r, aud del.cmrircu So whet ttsmuceSature the coating wilt heat up> durina pootOSS dissipation 1 Wfm2. Apnooximation resutis give hens repiotonpe values of 90.04 C^ cme^W-r for TIIS and 144.2 oC^cme^W-r for compoxtte coaiinn, wSnne n compeeablr So the best literarysesults. c Fig.S.ThermcgramuOthehoatingoUTseGOU CcmnsonKt^li S140 nm)atTieooltcnyof 15Vand UiiiipvtoU joeno'ettof 0,6W/cme (a);temporvnuropooOitetoethucrmpostSccoaiinv athiei Рис.5. Термограмма покрытия ОГ / Си-микросетка (140 нм) при напряжении 15S Ви рассеиваемой мощности 00S Вт/см2 (а); температурные профили композиционного покрытия при различной рассеиваемой мощности (б); стабильность покрытий при критических значениях рассеиваемой мощности (в) Fig.6.CymparalivceOCiciench ofcyompolitccoatmg wiiha ШатаТое ITO onan equivalentoub1teole[17] Рис. 6. Сравнительная эффективность композиционного покрытия с литературным аТО на эквивалентной подложке [57] The (firaci^riaiirtges of mesh cotit mot include extensive raers with lots tgeemci conditiCvCy tmess cells), as a aiiull of whicl Cfotatn ese^th oC the coaling can signifi-crnlly onarleat. In ihic ccnlexn in is interesting In consider tine cossibilith of the redaoSion ear grcohenn oxide hroing e theimai cocUfcOviCn in thin films of > 5 W/m-K, which will allow c mere seen aisU'lleul^on oCheat if space unoccupied Cy moral. An cxampla cS sucC c composite wrsproposed in^O]. Conclusion. Tie results rC tie stuCy oC a new ap-paorch to tin Cyrmain)ts oC tspycyarent hsfters with enhanced yasfoKtaney rhataoSari1iief оТеУ pesped to cicrsical solutions brscC on nxcsln films ere yserlnteT TCo coniyosite cortingnsc ooppar miorgmrsh, oblrined using lasel latetteizsed lcmplrlc stabiiized with tp-ryOciin ceide. A compocite mating wilhthe surfrcc resistance of8.y OKnisq wao b1эtalne]i whh lhc tcrnsprccncyof22.8 s/o. High uшCoкaiiy nl heating and 81оЬШ1п cC OKe com-posilecoating areshownwhen yyeratinounderhratiup up lo 97.2 °C Сот a tong time O24 houril. Cymycrite trans-pracnl healess of GO) ° Си micromesC arsoonsttatr higher efficiency relative to emmmon lcrnsprccnl neolass bleed on ITO. Tic ccmposite GO У Си micrymcrO cgsling on a glrss substrate, Г mm thick, is characlerized by tie tCier-mrl resistance yaUne of 144.2 oCcm2-W-5, while tla TOO lilcarty srmplc ow an odutvaioni subrlcnte is characterized by tiic themrat cesistoиes of 94.04 oCcm2-W-5. This tact opens up pcospccls lor Tie uss eh lCc yprnyystte GU / Си miccomesh coating ac a tiansyrcenl aniMclng codlien in recosprccnnduslty. AcknowleOginents. Tisif worO wau acy1lortsC by the Russirn Foundrlion for Back: Recfhicb, y^yjKO «ту1_а» № 18-38-00852.

Список литературы Transparent heaters based on the copper micromesh passivated by graf(ph)ene oxide

- Transparent heaters based on solution-processed indium tin oxide nanoparticles / K. Im [et al.] // Thin Solid Films. 2010. Vol. 518. P. 3960-3963.

- A highly efficient indium tin oxide nanoparticles (ITO-NPs) transparent heater based on solution-process optimized with oxygen vacancy control / C. Kim [et al.] // Journal of Alloys and Compounds. 2017. Vol. 726. P. 712-719.

- Characteristics of fluorine-doped tin oxide as a transparent heater on PET prepared by ECR-MOCVD / C. Hudaya [et al.] // ECS Trans. 2013. Vol. 53. P. 161-166.

- Thermal transport properties of polycrystalline tin- doped indium oxide films / T. Ashida [et al.] // Journal of Applied Physics. 2009. Vol. 105. P. 073709.

- Visibly transparent heaters / R. Gupta [et al.] // ACS Appl. Mater. Interfaces. 2016. Vol. 8, № 20. P. 12559-12575.