Using laser point scanning thermography for quality monitoring of products made of composite materials

Автор: Divin A.G., Karpov S.V., Zakharov Yu.A., Karpova N.A., Samodurov A.A., Golovin D.Yu., Tyurin A.I.

Журнал: Инженерные технологии и системы @vestnik-mrsu

Рубрика: Приборы и методы экспериментальной физики

Статья в выпуске: 1, 2024 года.

Бесплатный доступ

Introduction. Control of the presence of subsurface defects in products from composite materials is necessary for verification of products after release from production and in the process of operation. Aim of the Study. The purpose of the presented work is to estimate the parameters of subsurface defects using local laser thermography, suitable for quality control of both small objects and suspicious areas of large objects with curved surfaces.

Laser scanning thermography, non-destructive testing, composite materials, finite element analysis, mathematical modeling

Короткий адрес: https://sciup.org/147243165

IDR: 147243165 | УДК: 621.373.8:772.96 | DOI: 10.15507/2658-4123.034.202401.145-163

Текст научной статьи Using laser point scanning thermography for quality monitoring of products made of composite materials

Composite materials are suitable for manufacturing lightweight and durable products, so they can be used in aircraft and automotive industries, and for a renewable energy sector. At the same time, these materials are subject to increased reliability requirements, making the task of detecting internal defects at different stages of manufacturing and operation especially relevant [1]. The defects such as delamination and fiber damage in the material can lead to reduced mechanical properties including strength and stiffness, resulting in a potential risk of structural failure.

To detect internal defects, non-destructive testing (NDT) methods are usually used. In the case of composite materials, the scientific and technical literature provides information about a variety of NDT methods for assessing the quality of materials and detecting defects. Infrared thermography [2], ultrasonic [3] and thermoacoustic tests [4], X-ray inspection [5] are just some of the methods used to inspect products made from composite materials. Each of the above methods has its own advantages and disadvantages and associated areas of application. One of the most common methods is ultrasonic testing, which allows for accurate detection of internal defects, their position and size. The use of phased arrays and machine learning methods have significantly expanded the information content of the method and the accuracy of testing [6; 7]. However, this method has a drawback – there is a blind spot near the surface of the product. In addition, this method is demanding in terms of the quality of the test object surface and the presence of lubricant. Therefore, for such defects as delamination, lack of glue, and the defects located at a depth of 0 to 3 mm, it is advisable to use methods that are free of these disadvantages. Thermographic methods of active testing, which have recently Instruments and methods of experimental physics 147

^2^ ИНЖЕНЕРНЫЕ ТЕХНОЛОГИИ И СИСТЕМЫ Том 34, № 1. 2024 been developed significantly, can be used as such [8; 9]. These methods are based on a specially organized thermal effect on the product material and subsequent registration of the temperature field of its surface, the distortion of which indicates the presence of internal inhomogeneities in the material. These inhomogeneities can be caused by embedded elements, which are known in advance, and by defects that need to be detected. Halogen and xenon lamps, lasers, a flow of hot air or liquid, and thermoacoustic emission and dissipation of mechanical energy during friction or impact are used as a source of thermal influence [10‒12]. Additionally, there are known the methods involving the direct cooling of the tested product surface [13].

The use of incandescent lamps, in particular halogen lamps, which are most widely used in thermographic testing, makes it possible to heat quickly a large area of the test object and detect defects by the presence of anomalies in the non-stationary temperature field. However, in our opinion, the use of such lamps is not always advisable for several reasons. Firstly, the lamps do not provide uniform heating of the test object with a curved surface. Secondly, it is necessary to use various types of screens to protect against glares caused by the reflected infrared light of a hot lamp and its fittings from the surface of an object. In this regard, it makes sense to use local heating of the sample using a laser with the power necessary to achieve a given temperature contrast of the defective zone and a thermal imaging camera with a sensitivity threshold better than the temperature contrast of the defect in the thermal imaging image. The camera can be fixed relative to the test object, or move along with the source being at a certain distance from it [14; 15]. To increase efficiency of testing, you can use several laser radiation sources placed at a fixed distance from each other (from several mm to several cm), or a laser beam deployed in a line [16]. In addition, the use of a robotic manipulator as a tool for moving the laser makes it possible to maintain a given direction of the light flux relative to the normal to the surface and, thus, ensure uniform heating of the sample along the movement trajectory. If there are any structural inhomogeneities in the material, temperature anomalies zones occurring on its surface will be recorded using a thermal imaging camera. To detect the defects, researchers use technical vision systems based on machine learning technologies [17], and classical image processing tools [10].

Laser spot thermography has a higher sensitivity to surface and subsurface defects, but low productivity, so it is advisable to use it for additional inspection of product problem areas detected by other inspection methods, or for inspection of small-sized products. In the article by Rellinger T. and co-authors [18], it was shown that laser thermography in combination with other methods is a more reliable method than all currently known ones.

As the thermography analysis shows, the decisive effect on the effectiveness of testing is exerted by the choice of rational operating parameters when organizing the thermal effect on the test object, and the velocity of the thermal effect point on the surface of the sample. Thus, to measure these parameters, it is necessary to use numerical simulation of the temperature field on the sample surface that makes it possible to select acceptable testing parameters to ensure its effectiveness.

During a thermographic monitoring, it is important not only to find defects, but also to measure their boundaries and occurrence depth. Concerning long-pulse thermal effects

Vol. 34, no. 1. 2024 ENGINEERING TECHNOLOGIES AND SYSTEMS ^2^ caused by the energy of halogen lamps, there are many studies devoted to determining the monitoring effectiveness and the occurrence depth of defects [19‒21]; however, no similar studies has been found for the method of laser point thermography. To solve the problem of measuring defect parameters using the results of laser point thermography, it was necessary to do the following:

-

1) through using mathematical modeling, select rational modes of thermographic testing that ensure accurate detection of a “delamination” type defect in the subsurface layer of the composite material;

-

2) develop an installation and verify the monitoring method using a test sample;

-

3) develop a model to estimate the occurrence depth of defects, an algorithm for testing and data processing.

Literature Review

In the article by Jiao D. and co-authors [16] it is proposed to use a method of laser point thermography [18] for testing surface cracks with a small opening width, for which the linear laser scanning method produces blurred shapes and low temperature contrast. The proposed analytical models of the temperature field on the surface of the test sample show that the temperature gradient at the heating point is influenced by the distance from the crack to the heating point, and the ratio of the sample material thermal conductivity coefficients and the substance filling the crack. The low thermal conductivity of the crack material makes it difficult to transfer heat through it that when scanning with a point heat source, leads to a sharp change in the temperature gradient. Thus, in the temperature distribution along the sample scanning line, where the trajectory of the heating spot intersects the crack, higher temperature fluctuations will be observed. Jiao D. and co-authors in their article [16] propose to restore the shape and location of the entire surface crack in the product after repeated laser scanning of the sample surface in different directions. However, the author did not consider the possibility of using this method to detect subsurface defects.

In the article by Ibarra-Castanedo C. and co-authors [22], there was studied robotic line scan thermography (LST) for testing the aerospace industry products. The method involves line-by-line heating of a part with simultaneous obtaining of a series of thermograms using a thermal imager, which, together with a heating source, moves over a stationary sample. The robotic method enables to inspect large areas of objects under monitoring, following the “relief” of their surface with high accuracy and scanning velocity [14; 15]. The drawback of this method is inability to determine the occurrence depth of the defect, because the thermal imager moves with the heat source and records the areas temperature field concurrently after heating.

When using laser scanning thermography, an urgent task is to increase temperature contrasts. This is necessary to obtain information about the texture of the defect area, highlight the defect boundaries and increase the difference between the defect area and defect-free areas of the material. Contrast enhancement techniques typically involve converting sample surface temperature maps [23] or adjusting temperature distribution histograms [24]. However, when using these methods, noise in thermal images increases resulting in loss of defect information. That is why recently, special algorithms have been developed. For example, in the article by Li Y. and co-authors [25], a method for

ИНЖЕНЕРНЫЕ ТЕХНОЛОГИИ И СИСТЕМЫ Том 34, № 1. 2024 increasing the contrast of a thermal image with homomorphic technology was proposed. The essence of this technology is to perform a non-linear transformation of a thermal image with the result that the non-additive factors making up the image become additive to facilitate processing with increasing contrast in the frequency domain.

Some methods are based on preprocessing the data from defect-free areas in the infrared range [26]. The study results have shown that this method effectively reduces the effect of uneven laser energy distribution on the defect detection efficiency and improves the quality of information about internal defects. Moreover, the combination of the proposed preprocessing method with pulsed phase thermography and principal component analysis algorithms improves the ability of laser infrared thermography to detect defects inside aircraft carbon fiber reinforced plastics .

In this regard, we can conclude that in general, scanning thermography is extremely sensitive to the monitoring process parameters. Therefore, the study and justification of optimal modes of active thermal effect on the surface of samples through using numerical modeling for the correct and reliable operation of algorithms for post-processing temperature fields is an urgent task.

Materials and Methods

To select rational modes of the thermographic monitoring process, there were carried out numerical calculations of the temperature field of the virtual test sample surface. The equation of unsteady thermal conductivity (Fourier-Kirchhoff law) for a three-dimensional temperature field [27] was used to simulate the temperature field in the sample using the finite element method. The heat source was described in accordance with the equation1:

e • n\

- n • q = P • / ( О, e ) e , where P0 is rated laser power, W; f (O,e) is a function that considers the direction and degree of heat release irregularities in the laser beam-heated area; O = O(x, y, z, τ)are coordinates of central laser focusing point at the current time τ; e is vector quantity describing the radiation direction in relation to the body surface; n is the normal vector to the sample surface; q is the heat flow vector.

Inside the heating spot, heat release occurs according to the normal distribution law, which corresponds to the equation2:

. f ( O , e ) =

2 ло2

d^- ) 2o 2 J

d =

Ie'(x - O )||

e

where d is the set of points inside the laser beam at the current time; σ = 2.5 mm is the laser beam standard deviation with respect to the central laser focusing point coordinate.

External heat transfer is convective heat transfer on the side walls in accordance with the criterion equations of natural convection on horizontal and vertical walls3, and radiant heat transfer on the side walls of the plate in accordance with the Stefan-Boltzmann equation:

-n • q = eo (Tmb - T4), (4)

where T amb = 20 °C is the ambient temperature.

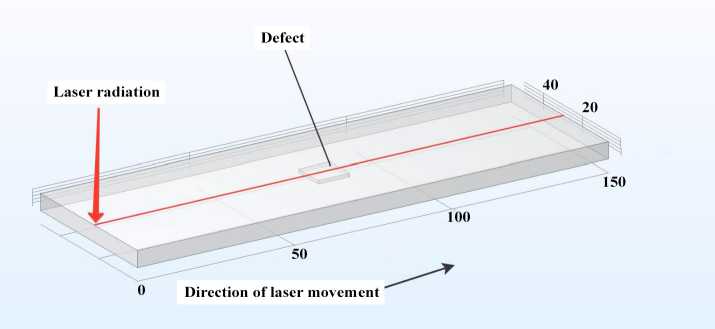

As a modeling object, we considered a plate made of fiberglass in the shape of a parallelepiped of size 150×40×10 mm. When modeling, the following material properties were: heat capacity с = 1 369 J/(kg ⋅ K), density ρ = 1 900 kg/m3, thermal conductivity 0,3 W/(m ⋅ K) . The internal cavity in the form of a parallelepiped of size 10×10×1 mm, located in the central part of the plate, was considered as a defect (Fig. 1).

F i g. 1. A model sample, mm

During the simulation, the heating spot moved along the middle line of the top face along the length of the sample long side. The following velocities for the laser beam moving were set: Vlaser = 5, 10 and 15 mm/s and the defect occurrence depth defdepth = 0.5; 1; 1.5; 2; 2.5 mm .

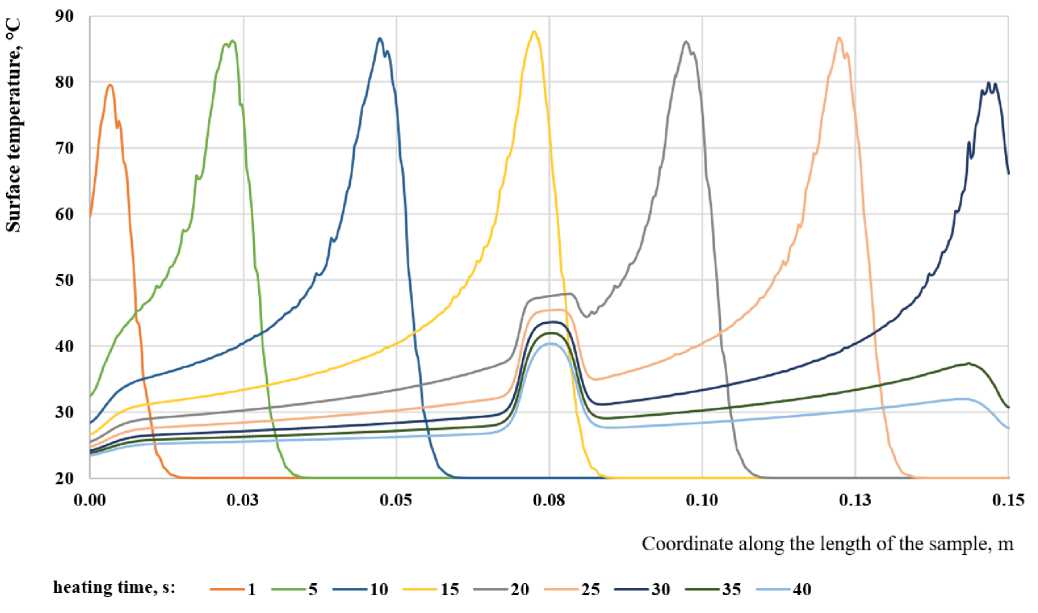

As a result of numerical modeling, there were found the data of temperature distributions on the surface of the sample along the laser scanning line. As an example there is given the temperature distribution (Fig. 2) across the red line (Fig.1) of a test sample containing a defect located at a depth of 1 mm. It can be seen that the presence of a defect significantly distorts the temperature field in the vicinity of the central point x = 75 mm. In this case, after the heating spot passes over the defect, the temperature difference (temperature contrast) between the defective and defect-free zones reaches its maximum.

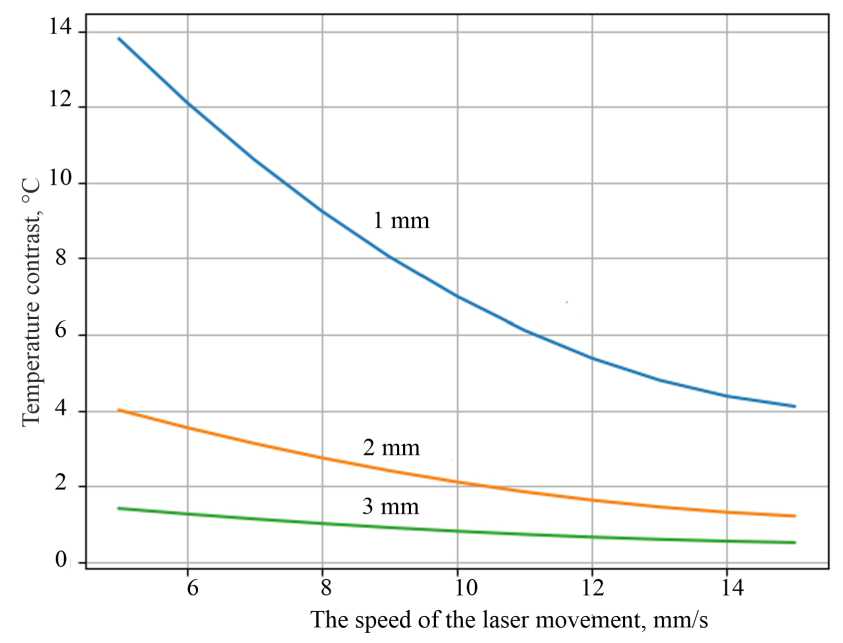

For the velocities of the heating spot movement along the surface of the sample in the range from 5 to 15 mm/s, the values of temperature contrasts were calculated; plotting the dependences shown in Figure 3 reveals that the most acceptable laser velocity can be dete rmined to be 5 mm/s for a laser power of 3 W and a defect depth of 1 mm.

F i g. 2 . Temperature of the sample surface along its length at different times (s), def depth = 1 mm, Vlaser = 5 mm/s

F i g. 3. Temperature contrasts on the defective sample surface at a depth of 1 mm, 2 mm and 3 mm, for different laser velocities

The criteria to select the operating parameters for monitoring are the temperature contrast of the surface above the defect (reliably detected by a thermal imager), and the temperature of the sample material, which should not exceed 100 °C.

Thus, the results of numerical modeling indicate the advisability of choosing a velocity of 5 mm/s, which provides a temperature contrast of at least 4 °C and heating the sample no more than 80 °C.

152 Приборы и методы экспериментальной физики

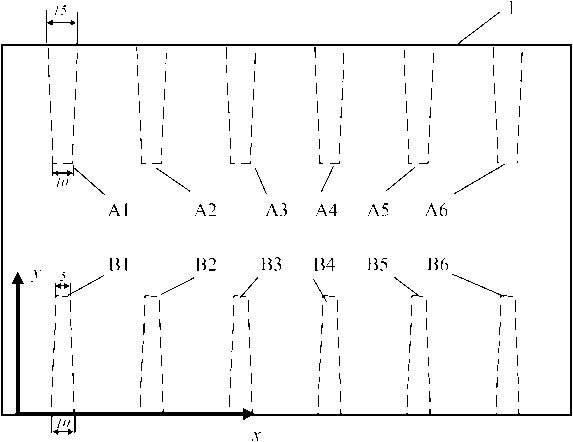

To check the adequacy of the numerical calculations, there were carried out experimental studies of a control sample made of fiberglass 1 (Fig. 4), which is a plate 200×350 mm and 5 mm thick. This sample had artificially created “delamination” type defects, because in it during the manufacturing process, there were placed titanium plates in a fluoroplastic shell at different depths (between 1 and 3 mm), which were later removed. Two groups A and B were formed, each containing six defects in the form of trapezoids, differing in size.

Group A defects with bases of 15 and 10 mm and a length of 50 mm had a depth of 1.2; 1.1; 2.3; 1.3; 1.0; 2.3 mm (according to Fig. 4 from left to right); and group B defects with bases of 5 and 10 mm and a length of 50 mm had a depth of 1.1; 3.1; 2.2; 1.2; 3.0; 2.1 mm respectively.

F i g. 4. Test sample sketch

The studies were carried out using a robotic complex consisting of a 5-axis robotic manipulator, the working part of which was a laser with adjustable power up to 3 W and a wavelength of 405 nm.

The basis of the robotic complex is a training and research manipulator with a spherical service area PASKAL DELTA 5Х-ARMDUINO (manufactured in Chelyabinsk (Russia). The Delta 5X robot (Fig. 5) belongs to the class of manipulators equipped with a direct computer testing system of the PCNC (Personal Computer Numerical Control) class. The robot control unit 3 receives data from the computer 5 , interprets it and controls the movement of the working body 2 (laser) of the manipulator 1 , energized by the power supply 8 . The thermal imaging camera 6 COX CG640 is used to obtain information about the temperature field of the control object 7 . It has uncooled long-wave bolometric detector with a resolution of 640x480 pixels, temperature sensitivity of no more than 30 mK, lens with a focal length of 20 mm and manual focusing.

The laser power is controlled by a Type 4 Arduino controller via its Pulse Width Modulation (PWM) output.

F i g. 5. Experimental setup

The thermal effect point moved from the laser along the sample surface at a given velocity by solving the inverse problem of kinematics and trajectory control.

During testing, the laser beam moved at a velocity of 5 mm/s along the surface of the control sample perpendicular to the long axes of the defective zones, thus scanning a set of defects with different depths. In addition, due to the trapezoidal shape of the defects at different laser passes, the trajectory of the heating point intersected the defects along segments of different lengths.

Based on thermal images recorded by a thermal imaging camera, thermograms were constructed using the developed software. To filter random noise, thermograms were smoothed using the convolve method from the NumPy library of the Python programming language.

Results

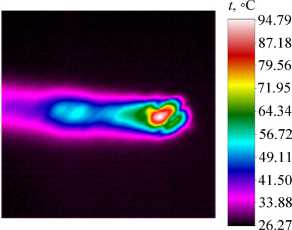

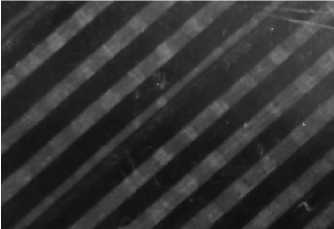

Figure 6a shows a typical thermal image frame when scanning the surface of a test object with a subsurface defect. In this case, the product surface (Fig. 6b) is inhomogeneous, which causes anisotropy of thermal properties.

а)

b)

F i g. 6. Temperature trace of a laser heating spot when passing through the product defect zone (a) and a photograph of the product material surface (b)

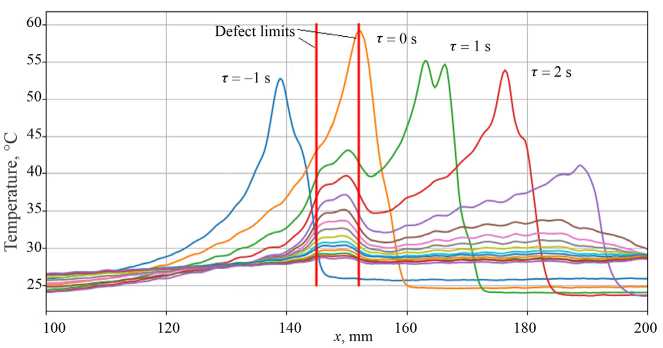

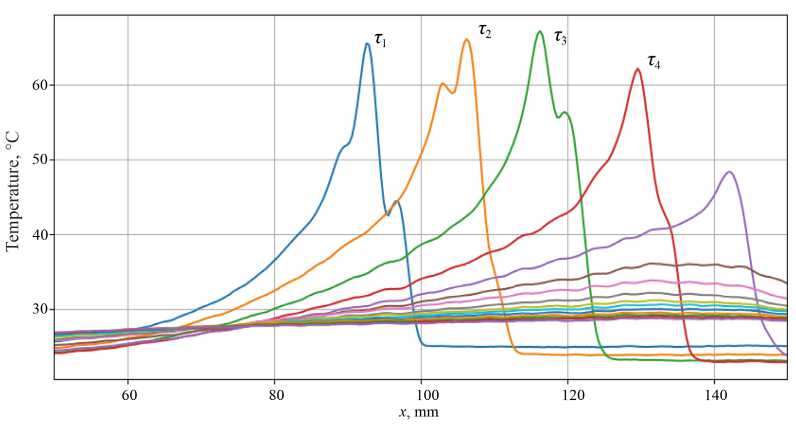

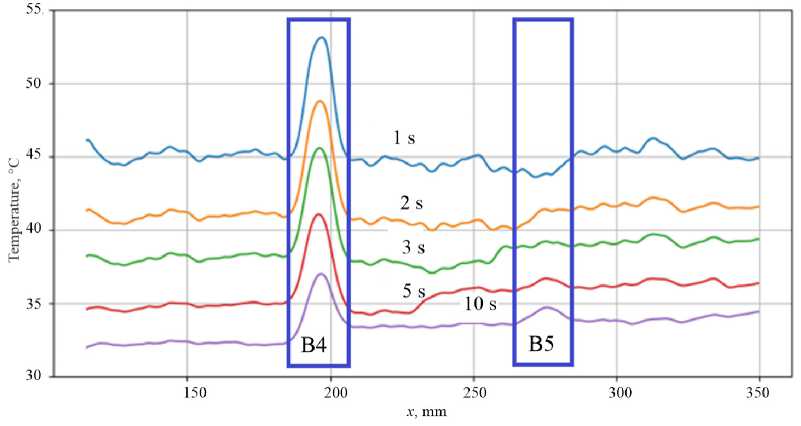

Based on the data obtained, the dependences of temperature on time and coordinate x in the defective (Fig. 7) and defect-free (Fig. 8) areas were revealed. The visible distortions of the temperature peaks at the moment of the heating spot passage of the sample area are explained by the inhomogeneity of the surface structure and thermal anisotropy of the material, which includes fibers with different emissivity degrees (Fig. 6b).

F i g. 7. Thermograms at various times in the vicinity of the defect B4 (Fig. 4)

F i g. 8. Thermograms at various points in time in the defect-free area

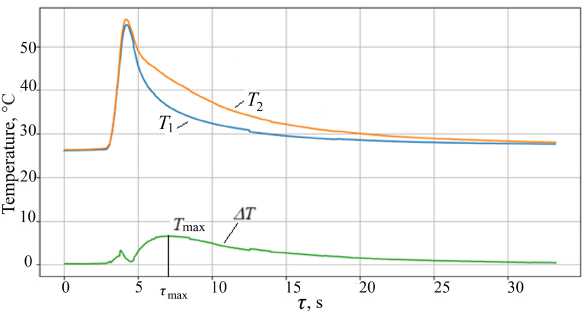

Of particular interest is the time dependence of the temperature difference in the defective and defect-free areas of the sample after passing through the laser heating spot, since the value of the maximum temperature and the time to reach this temperature are signs of the defect depth [28]. Fig. 9 shows the experimentally obtained dependences of temperature T 2 on time τ for the defective area B4 and temperature T 1 for the defect-free

^ ИНЖЕНЕРНЫЕ ТЕХНОЛОГИИ И СИСТЕМЫ Том 34, № 1. 2024 are. During and after heating, the temperature difference is determined by surface heterogeneity and is uninformative for the model of the dependence of the defect depth

∆T(τ) = T2(τ - ∆τ) - T1(τ), where ∆τ is an interval between the start of heating at the points at which temperatures T2 from T1 are measured. The cooling rate of the material depends on the presence of a defect. The smaller is the depth of the defect, the earlier and more significantly the rate of temperature change decreases, and the greater the temperature contrast (Fig. 9) between the defective and defect-free areas of the sample. To determine the defect depth from thermographic data, one can use analytical solutions obtained by solving a complex inverse problem of thermal conductivity or using the results of numerical calculations [13; 14]. The latter requires significant computing power and time. To estimate the defect occurrence depth, an estimation obtained using multivariate regression analysis is often sufficient. For a model that allows predicting the defect occurrence depth using the empirical data, we formed training samples consisting of the values of variables (predictors) and the values of the quantity being determined (in accordance with Table 1).

F i g. 9. Dependence of the temperature difference on time in the defective T 2 and defect-free T 1 areas of the sample after passing the laser heating spot of defect B4 (Fig. 4)

Temperature values T 2 and T 1 for constructing thermograms were taken as the average from an area of 20×20 pixels of the thermal image of the heating spot temperature trace (Fig. 6а).

T a b l e 1

Training sample structure

|

№ |

Maximum temperature Т max, °С |

Time to reach maximum temperature, τ max, s |

Depth of defect h , mm |

Defect width w , mm |

|

1 |

6.64 |

3.9 |

1.2 |

7.1 |

|

2 |

5.54 |

4.2 |

1.1 |

6.6 |

|

3 |

0.74 |

13.7 |

3.0 |

7.0 |

|

4 |

0.8 |

14.0 |

3.1 |

7.2 |

|

30 |

4.05 |

5.01 |

2.2 |

12.1 |

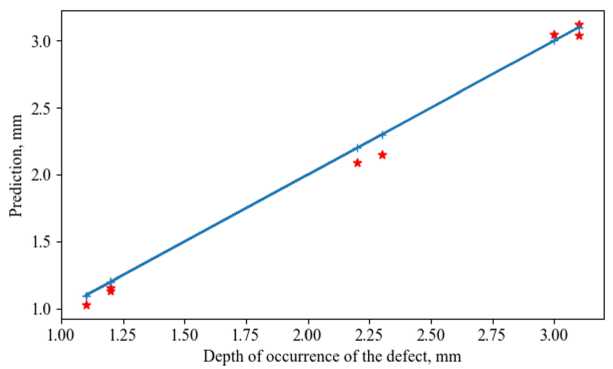

As a result of applying the nonlinear multivariate regression algorithm from the “Sklearn.linear_model” library of the Python programming language, a regression model was obtained that has the form:

h =- 0.24 T max + 0.04 t max + 0.045 - w + 2.31, (5)

where h is predicted value of the defect occurrence depth. At the same time, the quality metrics of the regression model were equal: coefficient of determination R2= 0.95, and the mean square error MSE = 0.016 mm2. Model verification on the test sample also showed satisfactory results (Fig. 10).

F i g. 10. Scatter diagram for the regression model for determining the defect depth of the (* means predicted values; + means a model)

The results obtained during experimental studies made it possible to propose and implement the following algorithm for detecting and determining the occurrence depth of defects.

-

1. Determining scan paths for a product made of composite materials to identify defects with different orientations;

-

2. Calculating control actions on the robot manipulator drives to implement the specified scan paths;

-

3. Scanning a product with a laser at a constant velocity along specified scan paths;

-

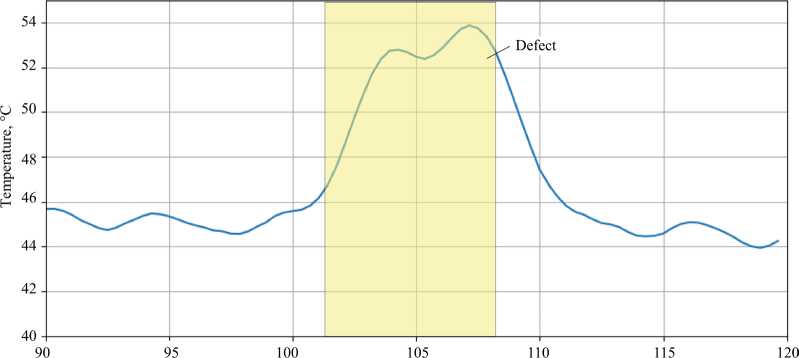

4. Constructing thermograms for scanning lines filtered from random noise using the “np.convolve” method based on temperatures obtained 10 s after passing the heating spot (Fig. 11). Thermograms for this time value will be informative for subsurface defects of the product located at depths of up to 3 mm.

-

5. Determining local amplitude values Ti ( i = 1, 2,…, n ) obtained thermograms and finding time values τi max after passing the heating spot, when these amplitudes become maximum and equal Ti max . By values τi max and Ti max the defect depths are found using the regression model (2).

-

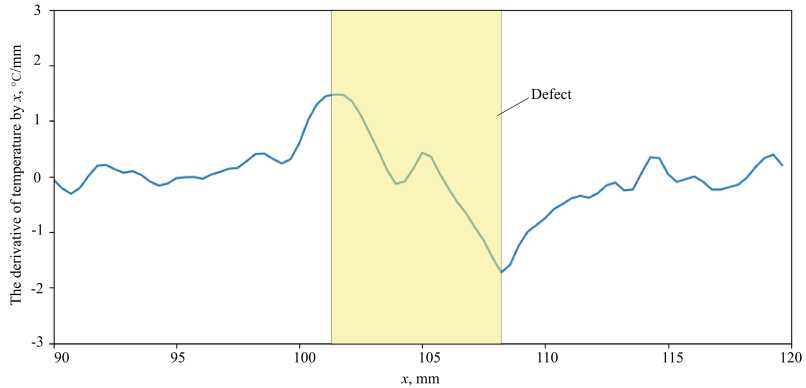

6. The boundaries of defects are determined by local maxima of the first derivative according to the x coordinate for the obtained thermogram (Fig. 12). As experiments have shown, the measuring error in the defect width based on the maximum and minimum of the first derivative does not exceed 5% if the occurrence depth is up to 1 mm, and 10% if the occurrence depth is from 1 to 3 mm.

F i g. 11. Thermograms obtained for different times after passing the heating spot

х, mm

F i g. 12. Thermogram for A4 defect ( y = 25 mm) after 4 s interval since heating beam passage

F i g. 13. The first derivative of the distribution T ( x ) according to the x coordinate to determine the defect boundaries

Discussion and Conclusion

The paper discussed a robotic complex, which implements the method of dynamic scanning thermography using the local thermal effect of a laser on the test object. The experimental studies carried out to identify subsurface defects of the “delamination” type have shown high sensitivity and the ability not only to determine the presence of a defect, but also to determine its boundaries and estimate its occurrence depth. The method is suitable for testing small-sized products, and for more careful monitoring of problem areas of large-sized objects made of composite materials [14]. The experiments have shown that at the initial stage of the thermal process, the surface structure of the product is of great importance that makes it possible to record surface defects, but at the same time, makes it difficult to detect subsurface defects. To detect such defects accurately, it is recommended to cover the surface of the test area with matte black paint.

Submitted 29.10.2023; revised 02.11.2023; accepted 17.11.2023

Список литературы Using laser point scanning thermography for quality monitoring of products made of composite materials

- He Y., Pan M., Chen D., Luo F. PEC Defect Automated Classification in Aircraft Multi-Ply Structures with Interlayer Gaps and Lift-Offs. NDT& EInternational. 2013;53:39-46. https://doi.org/10.1016/j. ndteint.2012.10.007

- Pawlak A.M., Gorny T., Dopierala L., Paczos P. The Use of CFRP for Structural Reinforcement -Literature Review. Metals. 2022;12(9):1470. https://doi.org/10.3390/met12091470

- Mathiassen K., Fjellin J.E., Glette K., Hol P.K., Elle O.J. An Ultrasound Robotic System Using the Commercial Robot UR5. Front. Robot. AI. 2016;3:1. https://doi.org/10.3389/frobt.2016.00001

- Frhaan W.K.M., Abu Bakar B.H., Hilal N., Al-Hadithi A.I. CFRP for Strengthening and Repairing Reinforced Concrete: A Review. Innovative Infrastructure Solutions. 2021;6:49. https://doi.org/10.1007/ s41062-020-00417-5

- Rajak D.K., Wagh P.H., Linul E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A review. Polymers. 2021;13(21):3721. https://doi.org/10.3390/ polym13213721

- Siljama O., Koskinen T., Jessen-Juhler O., Virkkunen I. Automated Flaw Detection in Multi-Channel Phased Array Ultrasonic Data Using Machine Learning. Journal of Nondestructive Evaluation. 2021;40:67. https://doi.org/10.1007/sl0921-021-00796-4

- Honarvar F., Varvani-Farahani A. A Review of Ultrasonic Testing Applications in Additive Manufacturing: Defect Evaluation, Material Characterization, and Process Control. Ultrasonics. 2020;108:106227. https://doi.org/10.1016/) .ultras.2020.106227

- Golovin D.Yu., Divin A.G., Samodurov A.A., Tyurin A.I., Golovin Yu.I. A New Rapid Method of Determining the Thermal Diffusivity of Materials and Finished Articles. Journal of Engineering Physics and Thermophysics. 2020;93:234-240. https://doi.org/10.1007/s10891-020-02113-8

- Golovin Yu.I., Samodurov A.A., Golovin D.Yu., Tyurin A.I., Divin A.G., Zakharov Yu.A. Measurement of the Thermal Diffusivity of Optical Materials and Products by a New Thermographic Express Method That Does Not Require Cutting Samples Out of the Bulk. Measurement Techniques. 2023;66:36-44. https://doi.org/10.1007/s11018-023-02187-9

- Li Y., Yang Z., Zhu J., Ming A., Zhang W., Zhang J. Investigation on the Damage Evolution in the Impacted Composite Material Based on Active Infrared Thermography. NDT & E International. 2016;83:114-122. https://doi.org/10.1016/j.ndteint.2016.06.008

- Golovin Yu.I., Golovin D.Yu., Tyurin A.I. Dynamic Thermography for Technical Diagnostics of Materials and Structures. Russian Metallurgy (Metally). 2021:2021:512-527. https://doi.org/10.1134/ S0036029521040091

- Berthe J., Chaibi S., Portemont G., Paulmier P., Laurin F., Bouvet C. High-Velocity Infrared Thermography for In-Situ Damage Monitoring During Impact Test. Composite Structures. 2023;314:116934. https://doi.org/10.1016/j.compstruct.2023.116934

- Doshvarpassand S., Wang X. Article an Automated Pipeline for Dynamic Detection of Sub-Surface Metal Loss Defects Across Cold Thermography Images. Sensors. 2021;21(14):4811. https://doi.org/10.3390/ s21144811

- Khodayar F., Lopez F., Ibarra-Castanedo C., Maldague X. Optimization of the Inspection of Large Composite Materials Using Robotized Line Scan Thermography. Journal of Nondestructive Evaluation. 2017;36:32. https://doi.org/10.1007/s10921-017-0412-x

- Khodayar F., Lopez F., Ibarra-Castanedo C., Maldague X. Parameter Optimization of Robotize Line Scan Thermography for CFRP Composite Inspection. Journal of Nondestructive Evaluation. 2018;37:5. https://doi.org/10.1007/s10921-017-0459-8

- Jiao D., Shi W., Liu Z., Xie H. Laser Multi-mode Scanning Thermography Method for Fast Inspection of Micro-cracks in TBCs Surface. Journal of Nondestructive Evaluation. 2018;37:30. https://doi. org/10.1007/s10921-018-0485-1

- Bang H.T., Park S., Jeon H. Defect Identification in Composite Materials Via Thermography and Deep Learning Techniques. Composite Structures. 2020;246:112405. https://doi.org/10.1016/jxomp-struct.2020.112405

- Rellinger T., Underhill P.R., Krause T.W., Wowk D. Combining Eddy Current, Thermography and Laser Scanning to Characterize Low-Velocity Impact Damage in Aerospace Composite Sandwich Panels. NDT & E International. 2021;120:102421. https://doi.org/10.1016/j.ndteint.2021.102421

- Marani R., Campos-Delgado D.U. Depth Classification of Defects in Composite Materials by Long-Pulsed Thermography and Blind Linear Unmixing. Composites Part B: Engineering. 2023;248:110359. https://doi.org/10.1016/j.compositesb.2022.110359

- Wei Y., Zhang S., Luo Y., Ding L., Zhang D. Accurate Depth Determination of Defects in Composite Materials Using Pulsed Thermography. Composite Structures. 2021;267:113846. https://doi.org/10.1016/j. compstruct.2021.113846

- Wang Z., Wan L., Zhu J., Ciampa F. Evaluation of Defect Depth in CFRP Composites by Long Pulse Thermography. NDT & E International. 2022;129:102658. https://doi.org/10.1016/j.ndteint.2022.102658

- Ibarra-Castanedo C., Servais P., Ziadi A., Klein M., Maldague X. RITA - Robotized Inspection by Thermography and Advanced Processing for the Inspection of Aeronautical Components. 2014. https:// doi.org/10.21611/qirt.2014.164

- Vandone A., Rizzo P., Vanali M. Image Processing for the Laser Spot Thermography of Composite Materials. In: Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security 2012. SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring. San Diego, 2012. Vol. 8347. https://doi.org/10.1117/12.914713

- Archer T., Beauchene P., Passilly B., Roche J.M. Use of Laser Spot Thermography for the Non-Destructive Imaging of Thermal Fatigue Microcracking of a Coated Ceramic Matrix Composite. Quantitative InfraRed Thermography Journal. 2021;18(3):141-158. https://doi.org/10.1080/17686733 .2019.1705732

- Li Y., Song Y.J., Yang Z.W., Xie X.Y. Use of Line Laser Scanning Thermography for the Defect Detection and Evaluation of Composite Material. Science and Engineering of Composite Materials. 2022;29(1). https://doi.org/10.1515/secm-2022-0007

- Wang Q., Hu Q., Qiu J., Pei C., Li X., Zhou H., et al. Image Enhancement Method for Laser Infrared Thermography Defect Detection in Aviation Composites. Optical Engineering. 2019;58(10):103104. https://doi.org/10.1117/Loe.58.10.103104

- Narasimhan T.N. Fourier's Heat Conduction Equation: History, Influence, and Connections. Reviews Geophysics. 1999;37(1):151-172. https://doi.org/10.1029/1998RG900006

- Chulkov A., Vavilov V., Nesteruk D., Burleigh D., Moskovchenko A. A Method and Apparatus for Characterizing Defects in Large Flat Composite Structures by Line Scan Thermography and Neural Network Techniques. Frattura ed Integrita Strutturale. 2023;17(63):110-121. https://doi.org/10.3221/ IGF-ESIS.63.11

- Hernandez-Valle S., Peters K. Numerical Simulation of Phase Images and Depth Reconstruction in Pulsed Phase Thermography. Measurement Science and Technology. 2015;26(11): 115602. https://doi. org/10.1088/0957-0233/26/11/115602

- Shen J., Zhang Y. [Calculation of Solid Cylinder Pore Defect Depth in Hot Shaft Forgings by Improved Fireworks Algorithm]. Zhongguo Jixie Gongcheng/China Mechanical Engineering. 2023;34(4). (In Chin.) https://doi.org/10.3969/jissn.1004-132X.2023.04.002