Влияние пентаэритритового эфира масляной кислоты на совместимость октилфеноксипропилфталата с поливинилхлоридом

Автор: Маскова А.Р., Аминова Г.К., Мазитов Р.М., Файзуллина Г.Ф., Мазитова А.К.

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Рубрика: Разработка новых полимерных материалов

Статья в выпуске: 5 т.10, 2018 года.

Бесплатный доступ

Для переработки поливинилхлорида (ПВХ) используют различные химикаты-добавки. Одним из способов улучшения физико-механических свойств ПВХ-материалов и упрощения процесса переработки полимера в соответствующие изделия является пластификация. В настоящее время возрастают требования к ПВХ-композициям по эко-логичности и технологичности. Поэтому возрастает необходимость разработки новых современных пластификаторов и повышение их ассортимента. В данной работе приведены результаты исследования совместимости нового пластификатора – октилфеноксипропилфталата с ПВХ с добавкой пентаэритритового эфира масляной кислоты и без него. Оценка совместимости пластификаторов с ПВХ производилась по критической температуре растворения ПВХ в пластификаторе и изменению твердости по Шору А в с сравнении с промышленным пластификатором диоктилфталатом. Также было изучено влияние пластификатора на температуру текучести и температуру стеклования. Было отмечено, что исследуемый нами в качестве пластификатора октилфеноксипропилфталат с добавлением пентаэритритового эфира масляной кислоты обладает достаточно высокой пластифицирующей способностью и хорошо совмещается с ПВХ.

Диоктилфталат, критическая температура растворения, октилфеноксипропилфталат, пластификатор поливинилхлорида, совместимость, твердость по Шору А, температура стеклования, температура текучести

Короткий адрес: https://sciup.org/142212250

IDR: 142212250 | УДК: 678 | DOI: 10.15828/2075-8545-2018-10-4-148-159

Текст научной статьи Влияние пентаэритритового эфира масляной кислоты на совместимость октилфеноксипропилфталата с поливинилхлоридом

Machine-readable information on CC-licenses (HTML-code) in metadata of the paper

-

Influence of the pentaerythritol ester of oil acid on compatability of octylphenoxypropyl phthalate with polyvinyl chloride. byDEVELOPMENT OF NEW POLYMER MATERIALS phenoxypropyl phthalate (OPOPP), proposed as a plasticizer of polyvinyl chloride.

The following substances were chosen for the experiments: C-70 PVC suspension; dioctyl phthalate (DOP) – industrial plasticizer; OPOPP and PEBA, which we synthesized for the first time.

The plasticizer compatibility with the polymer (PVC) parameter was used as the plasticizers effectiveness criterion. The current parameter is characterized, first, by the critical PVC dissolution temperature in the plasticizer, secondly by the Shore A hardness change [18, 19].

To determine the critical dissolving temperature (Tcd), 1g of PVC was mixed with 4g of plasticizer, the mixture was gradually heated at a rate of 2оC per minute and the tube contents appearance was visually determined. The critical dissolving temperature was assumed to be the temperature at which the polymer completely dissolved in the plasticizer and the solution became transparent. The research results in comparison with the industrial dioctyl phthalate analogue are given in the Table 1.

Plasticizers characteristics

Table 1

№

Sample

Tcd, оC

1

DOP

118

2

OPOPP*

119

3

OPOPP* + PEBA

118

* n = 1.0

The table data shows, OPOPP plasticizing effect is close to DOP in efficiency in accordance with Tcd indicator, and with the addition of PEBA, the efficiency is at the DOP level. Moreover, the amount of pentaerythritol ester of butyric acid should not exceed 5% of the mass of octylphenoxypropyl phthalate. Probably, the synergistic effect of the plasticizing action of the two types of plasticizers is affected here.

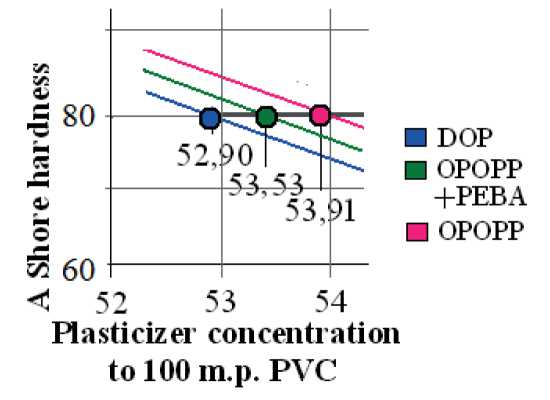

Shore A hardness change from the plasticizers concentration partially measured per 100 PVC parts has been studied at the next step (Fig. 1). This is a fairly reliable method and it is widely used in practice in order to evaluate the plasticizers effectiveness, expressed as a substitution factor. The

DEVELOPMENT OF NEW POLYMER MATERIALS

Fig. 1. A Shore hardness dependence on the Plasticizer concentration quantitative replacement factor indicates how much plasticizer should be added to the plastic compound in order to provide the same hardness value as achieved by DOP [18].

It is necessary to add OPOPP with the addition of PEBA only 1.2%, 2% more OPOPP to the PVC composition in order to achieve a Shore A hardness value of 80 provided by the DOP at a content of 52.9 parts, according to the given data.

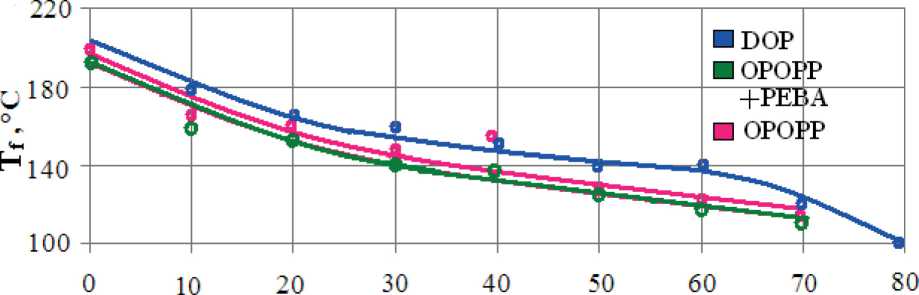

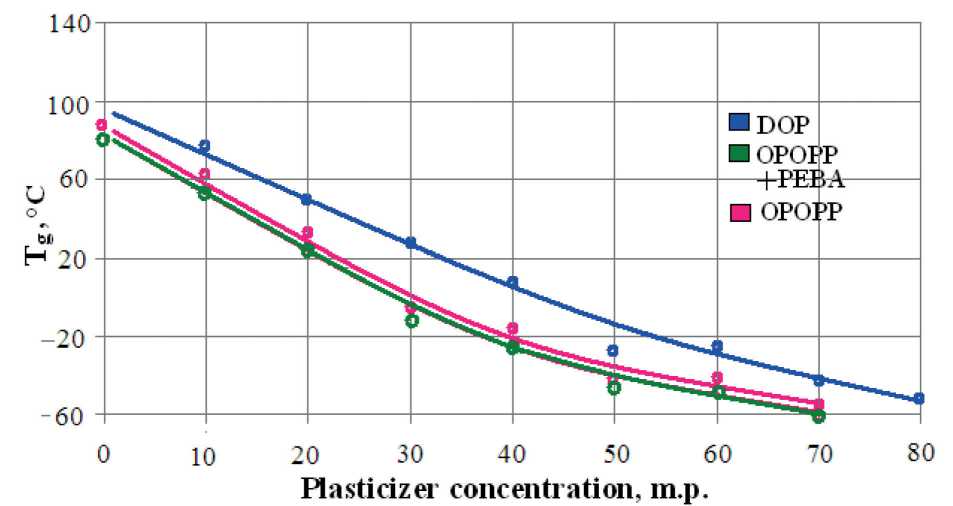

In order to determine the PVC composition temperature range, we studied the plasticizers effect on the flow temperature (Tf) and the glass transition temperature (Tg). As it is known these parameters largely determine plasticizing action effectiveness.

Preliminary thermomechanical curves were used in order to determine the glass transition temperature and the polymer composition fluidity. Thermomechanical analysis (TMA) is a fairly common method to study polymers. The task of the method is to observe the transitions from the vitreous state to the highly elastic and from the highly elastic to the viscous flow state (for some objects, directly from the vitreous to the viscous flow) with force and thermal action. The method makes it possible to evaluate the temperature ranges of polymer material operability as a plastic or elastomer, to reveal the transition opportunity into a fluid state and the yield temperature value which is necessary for its processing. Thus, TMA is as-

DEVELOPMENT OF NEW POLYMER MATERIALS sociated with the main operational and technological polymers and properties of compositions of them [19–23].

The research results (Fig. 2, 3) confirmed the OPOPP with the addition of PEBA is the best effective.

Plasticizer concentration, m.p.

Fig. 2. Flow temperature dependence on concentration plasticizer

Fig. 3. Glass transition temperature dependence on the plasticizer concentration

DEVELOPMENT OF NEW POLYMER MATERIALS

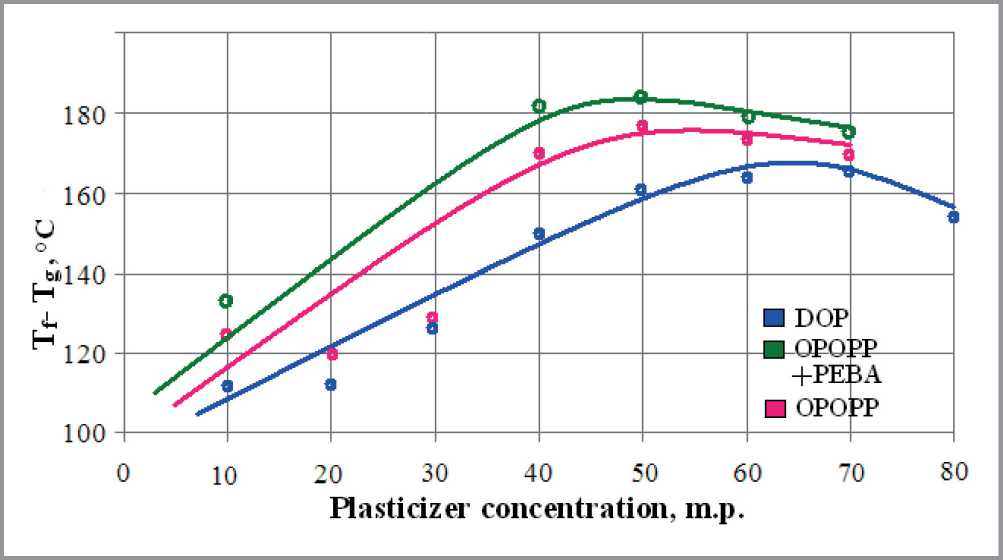

Thus, in case of OPOPP with the addition of PEBA, the high elasticity (Tm-Tc) interval (Fig. 4) reaches its maximum value at a content of 45 parts by weight; in the case of OPPOP, 50 parts by weight and in the case of DOP, 65 parts by weight. Moreover, most effectively OPOPP with the addition of PEBA reduces the plastic’s glass transition temperature.

Fig. 4. High elasticity interval dependence on the concentration

Thus, it was found that octylphenoxypropyl phthalate with the addition of pentaerythritol ester of butyric acid is better combined with PVC and has a high plasticizing ability. According to the considered parameters (the critical PVC dissolving temperature in the plasticizer, the Shore A hardness change, flow and vitrification temperature), it was determined that OPOPP with an additive PEBA predominates the industrial plasticizer DOP. It should be noted that with a minimum dosage, the pentaerythritol ester of butyric acid can be considered as a nanoadditive.

The performed research has been funded through the government grant «Synthesis and investigation of the modern polyvinyl chloride plasticizers» according to the Decree of the Government of the Republic of Bashkortostan of 07.02.2018 № 56 «On providing grants of the Republic of Bashkortostan to young scientists and groups of young researchers in 2018».

DEVELOPMENT OF NEW POLYMER MATERIALS