Водоотводные мостовые лотки из полимера, армированного стекловолокном: физические, механические и эксплуатационные свойства

Автор: Кавказский В.Н., Кирсанова Т.А., Усанова К.Ю., Вафаева Х.М., Васюткин Е.С.

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 4 (109), 2023 года.

Бесплатный доступ

Объектом исследования является лоток мостовой водоотводной из стеклопластика. Целью данной работы является исследование физико-механических характеристик стеклопластика, используемого для изготовления лотков мостовых водоотводных, и определение эксплуатационных характеристик типового подвесного лотка водоотводной.

Композит из стекловолокна, полимер, армированный стекловолокном, система дренажа мостов, прочность, модуль упругости, водопоглощение, плотность, твердость по Барколу

Короткий адрес: https://sciup.org/143182712

IDR: 143182712 | УДК: 69 | DOI: 10.4123/CUBS.109.19

Текст научной статьи Водоотводные мостовые лотки из полимера, армированного стекловолокном: физические, механические и эксплуатационные свойства

-

1 Введение / Introduction

Нарушение организации поверхностного водоотвода с проезжей части мостовых сооружений приводит к снижению прочности дорожной одежды [1], [2] сокращению межремонтных сроков, снижению уровня безопасности и удобства движения транспортных средств [3], а также к загрязнению окружающей среды [4], [5].

Одним из элементов организации водоотвода с поверхности мостов являются водоотводные лотки [6], которые могут устанавливаться под пролетными строениями (подвесные лотки), в уровне проезжей части или на подмостовых конусах. Водоотводные лотки выполняют из металла, железобетона или полимерных композиционных материалов, а именно стеклопластика.

Исследования по оценке систем водоотведения из железобетона показывают, что воздействие химически агрессивных стоков приводит к быстрому износу системы и уменьшению ее срока службы меньше расчетного [7]. Железобетонные системы водоотведения подвергаются эрозионному износу, вызванному потоком сточных вод, а также склонны к усадке и набуханию, вызванными циклами смачивания и высыхания. При длительном контакте железобетонных лотков с сульфатами, которые могут содержаться в воде, происходит сульфатная коррозия бетона, которая приводит к растрескиванию и разрыхлению микроструктуры и снижению прочности и жесткости изделия [8]. Другой распространенной причиной разрушения железобетонных изделий является коррозия арматуры, вызванная попаданием ионов-хлора в тело изделия [9], [10]. Срок службы железобетонных лотков в большинстве случаев не превышает 5-8 лет, после чего требуется их ремонт или замена.

Системы водоотведения из металла также подвергаются коррозии [11], [12], [13] и, сложны в обслуживании при замусоривании и замерзании. При использовании водоотводных лотков из нержавеющей стали повышается коррозионная стойкость [14], но также и увеличивается стоимость системы [15].

Исследования композиционного материала стеклопластика демонстрируют ряд преимуществ перед описанными выше аналогами, а именно высокая прочность на продольный разрыв [16], [17], [18] высокая жесткость [16], [17], [18] вандалоустойчивость, малый вес, высокая коррозионная стойкость [19], [18] в том числе к нефтепродуктам [20], стойкость к ультрафиолету, насекомым и грибкам [19], [18], а также высокая морозостойкость.

Основные области применения стеклопластика в строительстве — это арматура [21], [22], [23], [24], трубы [25], [26], фасадные панели [27], [28], композитные профили [29], футеровочные полимерные листы [30] и армирование ледовых массивов [31]. Применение на мостовых сооружениях подвесных водоотводных стеклопластиковых лотков (рисунок 1) распространено менее широко, чем указанные выше изделия.

Рис. 1 - Подвесной водоотводный лоток в конструкции моста Fig. 1 - Fiberglass Bridge Drain Systems

Несмотря на широкое применение стеклопластиковых изделий в строительной индустрии, отсутствуют подробные исследования стеклопластиковых водоотводных мостовых лотков, что ограничивает их применение. Таким образом, целью работы является исследование физикомеханических характеристик стеклопластика, применяемого для производства водоотводных мостовых лотков, а также определение эксплуатационных характеристик типового подвесного водоотводного лотка.

-

2 Материалы и методы / Materials and Methods

-

2.1 Объект исследования

водоотводный лоток U-и его геометрические

(б)

-

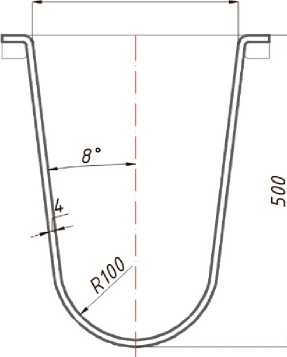

Объектом исследования является стеклопластиковый подвесной образного сечения, типоразмером 300х500. Общий вид лотка характеристики представлены на рисунках 2а, 2б.

(a)

Рис. 2 - Общий вид (а) и геометрические характеристики лотка (б)

Fig. 2 - General view (a) and geometric characteristics of the лотка (b)

Опытная партия лотков изготовлена методами ручного контактного формования и напыления, при котором различные виды стекловолокна пропитываются огнестойкой полиэфирной изофталевой смолой с последующим отверждением. Опытный образец лотка представлен на рисунке 3.

Рис. 3 - Экспериментальный образец

Fig. 3 - Experimental specimen

Стекловолокно для производства изделия выполняет армирующую функцию и представляет собой чередование слоёв эмульсионного стекломата плотностью 300 г/м2 и стеклоткани плотностью 560 г/м2. Изделие имеет гелькоутое декоративно-защитное покрытие серого цвета (RAL7040) на изофталевой неопентилгликолевой основе, стойкое к УФ-излучению, солям и химическим реагентам.

2.2 Определение физико-механических показателей материала стенки

Экспериментальные исследования образца проводились через 168 ч после его изготовления при температуре (22.5±1) °С и относительной влажности воздуха (52±2) %. Перед проведением всех испытаний (кроме испытания на водопоглощение) образцы были кондиционированы по ГОСТ 12423 (ISO 291:2008) “Пластмассы. Условия кондиционирования и испытания образцов (проб)” при температуре (23±0.5) °С и относительной влажности окружающей среды (50±3) %. Время кондиционирования составляло 48 часов для испытания на характеристику твердости по Барколу и 24 часа для остальных испытаний.

Средняя плотность стеклопластика получена отношением массы образца к его объему, определяемыми непосредственно взвешиванием и обмером. Испытывалось 5 образцов прямоугольной формы с размерами 15 х 10 мм, вырезанных из стенки лотка (рисунок 3).

Водопоглощение стеклопластика определялось на пяти образцах в виде плитки квадратной формы размером 50х50 мм, вырезанных из стенки лотка (рисунок 3). Торцы и кромки образцов зачищались наждачной шкуркой и ламинировались полиэфирной смолой. Перед испытанием образцы сушились при температуре (50 ± 2) °С до постоянной массы. Во время испытания образцы погружали в дистиллированную воду при температуре (23±1)°С в течение 24 ч. После испытания образцы извлекались из воды и взвешивались. Масса воды, поглощенная каждым образцом, определялась по разности между массой образца до и после испытания и выражалась в процентах по отношению к начальной массе.

Характеристика твердости по Барколу определялась на 7 образцах прямоугольной формы размерами 50 х 50 мм, вырезанных из стенки образца (рисунок 3). Твердость поверхности материала определяли с помощью твердомера Баркола с индентором из закаленной легированной стали в виде конуса усеченного (угол наклона 26 градусов), диаметр плоской вершины индентора 0.157мм. Для каждого образца выполняли не менее 10 измерений твердости в разных его точках.

Предел прочности при сжатии определялся на образцах, вырезанных из стенки лотка (рисунок 3) в двух направления: параллельном (в направлении 0°) и перпендикулярном (в направлении 90°). Для испытания в каждом направлении использовали 7 образцов со средней длиной грани 10.1 мм, шириной 10.0 мм, толщиной 4.0 мм.

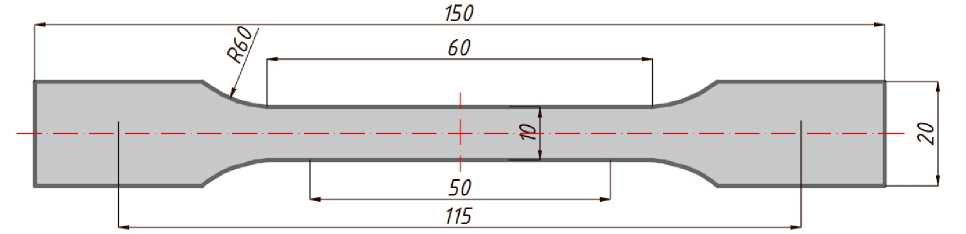

Предел прочности при растяжении определялся в двух направлениях, аналогично испытанию на определение предела прочности при сжатии. Образцы вырезались из стенки лотка (рисунок 3) в том же количестве, что для испытания на предел прочности при сжатии, форма образцов представлена на рисунке 4.

Рис. 4 - Форма образца для испытания на растяжение

Fig. 4 - Tensile Strength Test Specimen Shape

Предел прочности при сжатии/растяжении определялся как отношение максимальной нагрузки, предшествующей разрушению образца к площади его поперечного сечения.

Модуль упругости при сжатии определялся на 10 образцах прямоугольной формы размерами 40 х 20 мм, вырезанных из стенки лотка (рисунок 3) в двух направления: параллельном (в направлении 0°) и перпендикулярном (в направлении 90°). Для испытания в каждом направлении использовали по 5 образцов. Модуль упругости при растяжении определялся на 14 образцах (рисунок 4), вырезанных из стенки лотка (рисунок 3) в двух направления: параллельном (в направлении 0°) и перпендикулярном (в направлении 90°). Для испытания в каждом направлении использовали по 7 образцов. Использовалась автоматическая система записи, которая предоставила полную кривую «напряжение/относительная деформация». Определялись значения напряжения при сжатии, измеренное при значении относительной деформации £ 2 = 0.0025 и £ 1 = 0.0005. Модуль упругости при сжатии/растяжении определялся по формуле (1):

^ 2 -^ 1

£ 2 - £ 1

где: о2 это напряжение, измеренное при значении £2; О1 это напряжение, измеренное при значении £1 .

Для испытания на предел прочности при сжатии предел прочности при растяжении, модуль упругости при сжатии и модуль упругости при растяжении использовалась машина испытательная универсальная Tinius Olsen H10 KT ("Tinius Olsen Testing Machine Co., Inc.", Филадельфия, США).

2.3 Гидравлический расчет лотка

Целью гидравлического расчета является проверка пропускной способности типового подвесного водоотводного лотка из стеклопластика.

В качестве района проектирования выбран город Кемерово (Западная Сибирь, Россия). Гидравлический расчет соответствует [32], [33]. Водосбор осуществляется с площади асфальтобетонных покрытий, составляющей 1.193 га. Протяженность линии водоотводящих лотков составляет 873 м, уклон линии лотков составляет 0.0140.

Расчетный расход дождевого стока в линии лотков определяется в соответствии с формулой (2):

) _ Z mid • л1 ' 2 •F г = f.1.2-n-0.1 • Kt '

где: Qr это расчетный расход дождевого стока в линии лотков; Zmid это средний коэффициент покрова; А это параметр, характеризующий расчетный дождь; п это показатель степени, определенный для Западной Сибири согласно [32] и равный 0.72; F это общая площадь водосбора равная 1.193 га; tr это расчетная продолжительность дождя; Kt это коэффициент, учитывающий снижение расчетного расхода при расчетной продолжительности дождя менее 10 минут, определенный в соответствии с [33] (п.6.2.8) и равный 0.99.

Средний коэффициент покрова, Zmid , определяется как средневзвешенная величина в зависимости от значений коэффициента покрова для разного вида поверхностей по формуле (3):

Z^ mid f ’

где: Zi это коэффициент покрова по видам материала покрытий, принимаемый в соответствии с [32] (таблицы 13, 14) и равный 0.292 в нашем случае (асфальтобетонные покрытия); Fi это площадь соответствующего вида покрытия.

Параметр, характеризующий расчетный дождь, А , определяется в соответствии с формулой (4):

А = q20^ 20 "7 1 + ^У " , \ 1дтг/

где: q20 это интенсивность дождя продолжительностью 20 мин при P=1, принимаемая согласно [32] (рисунок А.1) и равная 67 л/(с^га); Р это период однократного превышения расчетной интенсивности дождя, принимаемый согласно [32] (п. 7.4.3) и равный 1; тг и у это среднее количество дождей за год и показатель степени, определенные для Западной Сибири согласно [32] (таблица 8) и равные 80 и 1.54, соответственно.

Расчетная продолжительность дождя, tr , определяется по формуле (5):

^ r = ^ соп + ^ сап ,

где: гсоп это время поверхностной концентрации дождевого стока, принимаемое согласно [32] (п. 7.4.6) и равное 3 мин; tcan это продолжительность протекания дождевых вод по лоткам, определяемое по формуле (6):

t ern = 0.021 ^, (6)

^соп где: 1сап это длина линии лотков; vcan это скорость течения воды в лотках, определяемая по формуле (7):

^сап C^Rl, где: С это коэффициент Шези; R это гидравлический радиус потока в лотке; i это уклон линии лотков.

Коэффициент Шези, С , определяется по формуле (8): 1

С=пш^

где: п ш это коэффициент шероховатости, характеризующий материал лотка и принятый равным 0.009; y это показатель степени при гидравлическом радиусе.

Показатель степени при гидравлическом радиусе, у , определяется по формуле (9):

у = 2.5 -^ИШ- 0.75 -JR-ОпШ- 0.1)- 0.13,

Гидравлический радиус потока в лотке, R , определяется по формуле (10):

R = р

Л где: р это площадь живого сечения потока в лотке, определяется геометрическими размерами сечения лотка и расчетной степенью наполнения и составляет 0.0454 м2 при расчетной степени наполнения 0.52; л это смоченный периметр потока в лотке, определяется геометрическими размерами сечения лотка и расчетной степенью наполнения и составляет 0.587 м.

-

3 Результаты и обсуждения / Results and Discussion

3.1 Результаты экспериментальных исследований стеклопластика

Результаты испытаний на определение средней плотности стеклопластика представлены в таблице 1.

Таблица 1. Средняя плотность стеклопластика

Table 1. Density of fiberglass composite

|

№ образца |

Средняя плотность, кг/м3 |

№ образца |

Средняя плотность, кг/м3 |

|

1 |

1760 |

4 |

1790 |

|

2 |

1755 |

5 |

1765 |

|

3 |

1780 |

- |

- |

|

Среднее |

1770 |

||

По результатам испытаний значение средней плотности стеклопластика составило 1770 кг/м3. Полученное значение сопоставимо с результатами других исследователей: 1500 - 2100 кг/м3 в [34], 1630 кг/м3 в [35], 1480 - 1780 кг/м3 в [36] и 1400 - 1750 кг/м3 в [37].

Результаты испытаний на определение водопоглощения стеклопластика представлены в таблице 2.

Таблица 2. Водопоглощение стеклопластика

Table 2. Water absorption of fiberglass composite

|

№ образца |

Масса до выдержки в воде, г |

Масса после выдержки в воде, г |

Водопоглощение, % |

|

1 |

13.49 |

13.552 |

0.46 |

|

2 |

13.462 |

13.501 |

0.29 |

|

3 |

13.563 |

13.612 |

0.36 |

|

4 |

13.425 |

13.492 |

0.50 |

|

5 |

13.598 |

13.662 |

0.47 |

|

Среднее |

0.42 |

||

По результатам испытаний значение водопоглощения стеклопластика составило 0.42 %. Полученное значение сопоставимо с результатами других исследователей: 0.7-4.0 % в [37], 1 % в [38] и [39].

Результаты испытаний на определение характеристики твердости по Барколу стеклопластика представлены в таблице 3.

Таблица 3. Твердость по Барколу стеклопластика

Table 3. Barcol's hardness of fiberglass composite

|

№ образца |

Характеристика твердости по Барколу, ед. |

№ образца |

Характеристика твердости по Барколу, ед. |

|

1 |

42 |

5 |

40 |

|

2 |

40 |

6 |

41 |

|

3 |

41 |

7 |

42 |

|

4 |

41 |

- |

- |

|

Среднее |

41 |

||

По результатам испытаний среднее значение твердости по Барколу стеклопластика составило 41 ед. Полученное значение сопоставимо с результатами других исследователей: 39.6 ед. - 42.8 ед. в [40], 32 ед. - 40 ед. в [41] и 43 ед. в [42].

Результаты испытаний на определение предела прочности при сжатии образцов из стеклопластика представлены в таблице 4.

Таблица 4. Предел прочности при сжатии образцов из стеклопластика Table 4. Compressive strength of fiberglass composite specimens

|

№ образца |

Предел прочности при сжатии в направлении 0°, МПа |

№ образца |

Предел прочности при сжатии в направлении 90°, МПа |

|

1 |

111.2 |

8 |

98.1 |

|

2 |

107.5 |

9 |

101.3 |

|

3 |

108.6 |

10 |

102.5 |

|

4 |

114.5 |

11 |

100.4 |

|

5 |

103.1 |

12 |

97.6 |

|

6 |

110.7 |

13 |

104.5 |

|

7 |

102.6 |

14 |

98.9 |

|

Среднее |

108.3 |

Среднее |

100.4 |

По результатам испытаний значение предела прочности при сжатии в направлении 0° образцов из стеклопластика составило 108.3 МПа, предел прочности при сжатии в направлении 90° образцов из стеклопластика составило 100.4 МПа. Полученные значения сопоставимы с результатами других исследователей: 114 МПа в [43] и 104.22 МПа в [44].

Результаты испытаний на определение предела прочности при растяжении образцов из стекопластика представлены в таблице 5.

Таблица 5. Предел прочности при растяжении образцов из стеклопластика Table 5. Tensile strength of fiberglass composite specimens

|

№ образца |

Предел прочности при растяжении в направлении 0°, МПа |

№ образца |

Предел прочности при растяжении в направлении 90°, МПа |

|

1 |

178.2 |

8 |

146.3 |

|

2 |

166.4 |

9 |

152.4 |

|

3 |

168.6 |

10 |

157.7 |

|

4 |

173.3 |

11 |

150.1 |

|

5 |

103.1 |

12 |

143.5 |

|

6 |

151.6 |

13 |

148.6 |

|

7 |

158.8 |

14 |

152.7 |

|

Среднее |

165.8 |

Среднее |

150.1 |

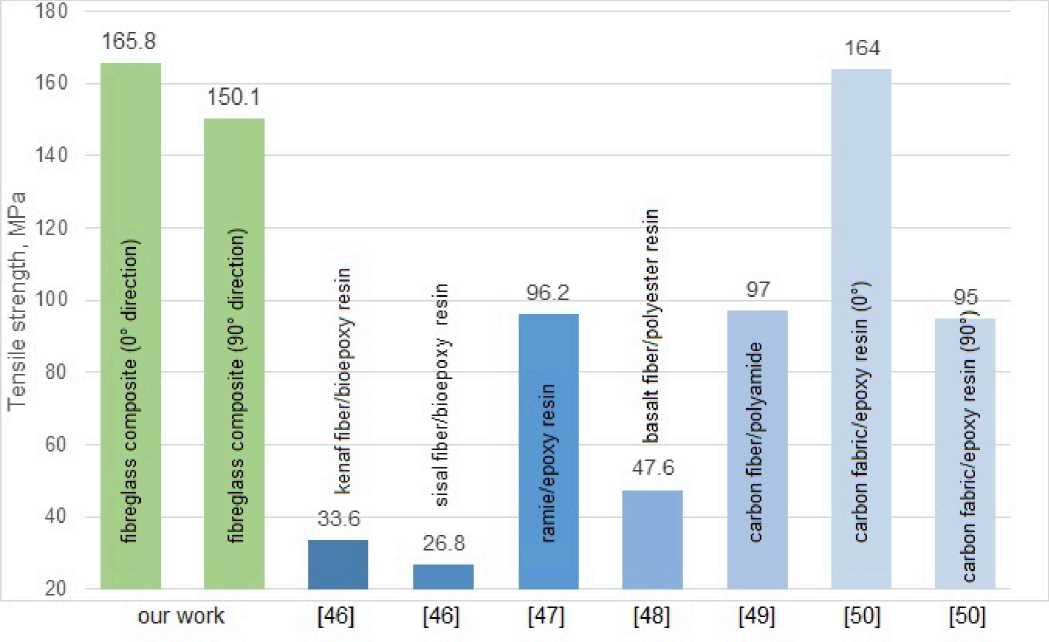

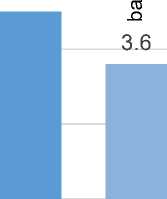

По результатам испытаний значение предела прочности при растяжении в направлении 0° образцов из стеклопластика составило 165.8 МПа, предел прочности при сжатии в направлении 90° образцов из стеклопластика составило 150.1 МПа. Полученные значения сопоставимы с результатами исследований стеклопластика других авторов: 118 - 146 МПа в [42] и 170 МПа в [45]. На рисунке 5 представлено сравнение предела прочности при растяжении исследуемого стеклопластика в сравнении с другими типами армированных пластиков: натуральное кенафовое волокно/биоэпоксидная смола [46], натуральное сизалевое волокно/биоэпоксидная смола [46], ткань рами/эпоксидная смола + кремниевый полимер [47], базальтовое волокно/полимер на основе полиэфира [48], углеродная фибра длиной 25 мм + полиэфирная ткань/расплавляемый порошок полиамида 12 [49], нетканое углеродное полотно/эпоксидная смола (параллельно направлению волокон (0°) и перпендикулярно направлению волокон (90°)) [50].

Рис. 5 - Сравнение предела прочности при растяжении различных видов армированных пластиков

Fig. 5 - Comparison of tensile strength of different types of fiber reinforced polymer

Из рисунка 5 видно, что предел прочности при растяжении стеклопластика превышает предел прочности при растяжении всех видов пластмасс, армированных натуральными волокнами, и сопоставим только с армированным пластиком с наполнителем из углеродного волокна.

Результаты испытаний на определение модуля упругости при сжатии образцов из стеклопластика представлены в таблице 6.

Таблица 6. Модуль упругости при сжатии образцов из стеклопластика Table 6. Compressive elastic modulus of fiberglass composite specimens

|

№ образца |

Модуль упругости при сжатии в направлении 0°, ГПа |

№ образца |

Модуль упругости при сжатии в направлении 90°, ГПа |

|

1 |

11.9 |

6 |

9.2 |

|

2 |

11.7 |

7 |

10.3 |

|

3 |

12.1 |

8 |

9.5 |

|

4 |

10.9 |

9 |

9.8 |

|

5 |

11.9 |

10 |

10.1 |

|

Среднее |

11.7 |

Среднее |

9.7 |

По результатам испытаний значение модуля упругости при сжатии в направлении 0° образцов из стеклопластика составило 11.7 ГПа, значение модуля упругости при сжатии в направлении 90° составило 9.7 ГПа. В исследовании [51] были обнаружены похожие результаты, а именно 12.1 ГПа.

Результаты испытаний на определение модуля упругости при растяжении образцов из стеклопластика представлены в таблице 7.

Таблица 7. Модуль упругости при растяжении образцов из стеклопластика

Table 7. Tensile elastic modulus of fiberglass composite specimens

|

№ образца |

Модуль упругости при растяжении в направлении 0°, ГПа |

№ образца |

Модуль упругости при растяжении в направлении 90°, ГПа |

|

1 |

14.1 |

8 |

10.7 |

|

2 |

13.7 |

9 |

10.2 |

|

3 |

14.2 |

10 |

9.6 |

|

4 |

14.0 |

11 |

10.3 |

|

5 |

13.6 |

12 |

10.2 |

|

6 |

13.9 |

13 |

9.6 |

|

7 |

13.7 |

14 |

9.5 |

|

Среднее |

13.9 |

Среднее |

10.0 |

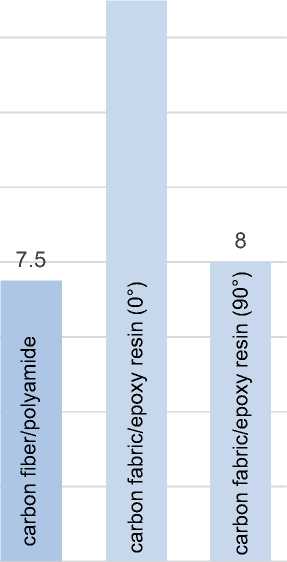

По результатам испытаний значение модуля упругости при растяжении в направлении 0° образцов из стеклопластика составило 13.9 ГПа, значение модуля упругости при растяжении в направлении 90° - 10.0 ГПа. Полученные значения сопоставимы с результатами исследований стеклопластика других авторов: 10.68 ГПа в [52] и 18 ГПа в [53]. На рисунке 6 представлено сравнение предела прочности при растяжении исследуемого стеклопластика в сравнении с другими типами армированных пластиков: натуральное кенафовое волокно/биоэпоксидная смола [46], натуральное сизалевое волокно/биоэпоксидная смола [46], ткань рами/эпоксидная смола +

кремниевый полимер [47], базальтовое волокно/полимер на основе полиэфира [48], углеродная фибра длиной 25 мм + полиэфирная ткань/расплавляемый порошок полиамида 12 [49], нетканое

углеродное полотно/эпоксидная смола (параллельно направлению перпендикулярно направлению волокон (90°)) [50].

волокон

(0°) и

го

1 12

О

о и го ф ч—

О и го го тз о Е ф

W с ф

13.9

our work

о ъ о -Q ч— "го

(Л (Л

1.05

[47] [48]

[49] [50] [50]

[46] [46]

Рис. 6 - Сравнение предела прочности при растяжении различных видов армированных пластиков

Fig. 6 - Comparison of tensile modulus of different types of fiber reinforced polymer

Из рисунка 6 видно, что модуль упругости при растяжении стеклопластика превышает модуль упругости при растяжении всех видов пластмасс, армированных натуральными волокнами, и сопоставим только с армированным пластиком с наполнителем из углеродного волокна.

Экспериментально показано, что физико-механические характеристики стеклопластика подходят для эксплуатации при воздействии агрессивной среды в сложных климатических условиях, в том числе в качестве использования для производства водоотводных сооружений дорожного полотна мостов.

3.2 Результаты гидравлического расчета стеклопластикового лотка

Расчет выполнен для водоотводного подвесного лотка, представленного на рисунке 2б. Исходя их геометрических размеров сечения лотка площадь живого сечения потока (с о ) при расчетной степени наполнения 0.52 составит 0.0454 м2, смоченный периметр потока ( / ) составит 0.587 м.

Для определения гидравлического радиуса потока в лотке воспользуемся формулой (10):

0.0454

= 0.077 м.

R =---- 0.587

Показатель степени при гидравлическом радиусе согласно формуле (9):

у = 2.5 • 70009 - 0.75 • 70077 • (70009 - 0.1) - 0.13 = 0.1082 .

Коэффициент Шези, по формуле (8):

С = — • 0.077 0.1 082 = 84.22 .

0.009

Скорость течения воды в лотках, по формуле (7):

V can = 84.22 • 70.077 • 0.009 = 2.771 м.

Продолжительность протекания дождевых вод по лоткам, по формуле (6): tca п = 0.021 • 873- = 6.62 мин .

2.771

Расчетная продолжительность дождя, по формуле (5):

t r = 3.00 + 6.62 = 9.62 мин .

Параметр, характеризующий расчетный дождь, по формуле (4):

Л = 67 • 20 0.72 • (1 +

1д1 1д80

■) = 579.184.

Средний коэффициент покрова, по формуле (3):

_ 0.292^1.193

-

Zmid = 1^193 = 0.29 2 .

9 62

1.2^0.72-0.1

Расчетный расход дождевого стока, по формуле (2): 0.292 • 579.184 1.2 • 1.193 л

Q r =----- п ^ 1.2.0.72-0.1 -- 0.99 = *25.71-.

Таким образом, исследуемый лоток обеспечивает пропуск расчетного расхода дождевого стока 125.71 л/с при наполнении, не превышающем максимально допустимое.

4 Выводы / Conclusions

Проведены экспериментальные исследования физико-механических характеристик стеклопластика, применяемого для производства водоотводных мостовых лотков и определены эксплуатационные характеристики типового подвесного водоотводного лотка. По результатам исследования можно сделать следующие выводы:

-

1. Экспериментально показано, что физико-механические характеристики стеклопластика подходят для эксплуатации при воздействии агрессивной среды в сложных климатических условиях, в том числе в качестве использования для производства водоотводных сооружений дорожного полотна мостов. Средняя плотность стеклопластика составила 1770 кг/м3, водопоглощение составило 0.42 %, твердость по Барколу составила 41 ед., предел прочности при сжатии в направлении 0°/90° составил 108.3 МПа/100.4 МПа, предел прочности при растяжении в Kavkazskiy, V.; Kirsanova, T.; Usanova, K.; Vafaeva, K.; Vasyutkin, E.

-

2. Предложено конструктивное решение водоотводного мостового лотка из стеклопластика, обеспечивающее пропуск расчетного расхода дождевого стока 125.71 л/с при наполнении, не превышающем максимально допустимое.

Drainage bridge trays made of glass fiber reinforced polymer: physical, mechanical and operational properties;

направлении 0°/90° составил 165.8 МПа/150.1 МПа, модуль упругости при сжатии в направлении 0°/90° составил 11.7 ГПа/ 9.7 ГПа, модуль упругости при растяжении в направлении 0°/90° составил 13.9 ГПа/10.0 ГПа.

Дальнейшими исследованиями по этой теме могут стать экспериментальные исследования характеристик пожаробезопасности композиционного материала стеклопластика для производства водоотводных подвесных лотков [54], [55], [56].

5 Fundings

This research was supported by a grant from the Russian Science Foundation No. 21-1900324,

Список литературы Водоотводные мостовые лотки из полимера, армированного стекловолокном: физические, механические и эксплуатационные свойства

- Ren, D., Shang, J., Xu, J., Huang, M., Chen, X., Cao, C. and Ai, C. (2023) Detection and Quantitative Evaluation of Pumping Distress on Bridge Deck Pavement through Field and Laboratory Experiments. Construction and Building Materials, Elsevier, 378, 131208. https://doi.org/10.1016/J.CONBUILDMAT.2023.131208.

- Aksyonkin, V.I., Zolotarev, M.L. and Krasnov, V.S. (2017) Development of Principles For Ensuring Transport Security of The Russian Federation In The Arctic [Razvitie Principov Obespecheniya Transportnoj Bezopasnosti Rossijskoj Federacii v Arktike]. Scientific problems of logistics and logistics of the RF Armed Forces [Nauchnye problemy MTO VS RF], 231–239. https://www.elibrary.ru/item.asp?id=30043370.

- Bakr, A.R., Fu, G.Y. and Hedeen, D. (2020) Water Quality Impacts of Bridge Stormwater Runoff from Scupper Drains on Receiving Waters: A Review. Science of The Total Environment, Elsevier, 726, 138068. https://doi.org/10.1016/J.SCITOTENV.2020.138068.

- Aksyonkin, V.I., Zolotarev, M.L. and Myshin, A.V. (2018) Technical Standards Documents of Common Technical Requirements to Road Technical Means. Scientific problems of logistics and logistics of the RF Armed Forces [Nauchnye problemy MTO VS RF], 3(9), 132–142. https://www.elibrary.ru/item.asp?id=36499321.

- Frolov, A.N. (2020) Special Features of Calculating Rain and Snowmelt Runoff from Ash Dumps. Proceeding of the VNIIG, Vol. 297., 36–47. https://www.elibrary.ru/item.asp?id=44351723.

- Vasyutkin E.S, Galushko, M.M., Lazarev, Yu.G., Dzhalalov, A.I. and Burin, D.L. (2022) Strength Calculation of a Suspended Bridge Tray from Polymer Composite Materials [Prochnostnoj Raschyot Podvesnogo Mostovogo Lotka Iz Polimernyh Kompozicionnyh Materialov]. Route navigator [Putevoj navigator], 51, 50–53. https://www.elibrary.ru/item.asp?id=48698591.

- Tang, Y., Bao, Y., Zheng, Z., Zhang, J. and Cai, Y. (2022) Performance Assessment of Deteriorating Reinforced Concrete Drainage Culverts: A Case Study. Engineering Failure Analysis, Pergamon, 131, 105845. https://doi.org/10.1016/J.ENGFAILANAL.2021.105845.

- Liu, D., Wang, C., Gonzalez-Libreros, J., Guo, T., Cao, J., Tu, Y., Elfgren, L. and Sas, G. (2023) A Review of Concrete Properties under the Combined Effect of Fatigue and Corrosion from a Material Perspective. Construction and Building Materials, Elsevier, 369, 130489. https://doi.org/10.1016/J.CONBUILDMAT.2023.130489.

- Firouzi, A., Abdolhosseini, M. and Ayazian, R. (2020) Service Life Prediction of Corrosion-Affected Reinforced Concrete Columns Based on Time-Dependent Reliability Analysis. Engineering Failure Analysis, Pergamon, 117, 104944. https://doi.org/10.1016/J.ENGFAILANAL.2020.104944.

- Sun, B., Xiao, R., Guo, J. and Zhao, Q. (2019) Probabilistic Chloride Penetration Models and Corrosion Initiation Probability of RC Bridge Based on Long-Term Test Data. Journal of Bridge Engineering, American Society of Civil Engineers, 24, 04019012. https://doi.org/10.1061/(ASCE)BE.1943-5592.0001370.

- Zunita, M. and Kevin, Y.J. (2022) Ionic Liquids as Corrosion Inhibitor: From Research and Development to Commercialization. Results in Engineering, Elsevier, 15, 100562. https://doi.org/10.1016/J.RINENG.2022.100562.

- Soufeiani, L., Foliente, G., Nguyen, K.T.Q. and San Nicolas, R. (2020) Corrosion Protection of Steel Elements in Façade Systems – A Review. Journal of Building Engineering, Elsevier, 32, 101759. https://doi.org/10.1016/J.JOBE.2020.101759.

- Li, L., Mahmoodian, M., Li, C.Q. and Robert, D. (2018) Effect of Corrosion and Hydrogen Embrittlement on Microstructure and Mechanical Properties of Mild Steel. Construction and Building Materials, Elsevier, 170, 78–90. https://doi.org/10.1016/J.CONBUILDMAT.2018.03.023.

- Hemmasian Ettefagh, A., Guo, S. and Raush, J. (2021) Corrosion Performance of Additively Manufactured Stainless Steel Parts: A Review. Additive Manufacturing, Elsevier, 37, 101689. https://doi.org/10.1016/J.ADDMA.2020.101689.

- Chuaiphan, W. and Srijaroenpramong, L. (2020) Evaluation of Microstructure, Mechanical Properties and Pitting Corrosion in Dissimilar of Alternative Low Cost Stainless Steel Grade 204Cu and 304 by GTA Welding Joint. Journal of Materials Research and Technology, Elsevier, 9, 5174–5183. https://doi.org/10.1016/J.JMRT.2020.03.034.

- Sharma, H., Kumar, A., Rana, S., Sahoo, N.G., Jamil, M., Kumar, R., Sharma, S., Li, C., Kumar, A., Eldin, S.M. and Abbas, M. (2023) Critical Review on Advancements on the Fiber-Reinforced Composites: Role of Fiber/Matrix Modification on the Performance of the Fibrous Composites. Journal of Materials Research and Technology, Elsevier, 26, 2975–3002. https://doi.org/10.1016/J.JMRT.2023.08.036.

- Wu, G., Ren, Y., Du, J., Wang, H. and Zhang, X. (2023) Mechanical Properties and Failure Mechanism Analysis of Basalt-Glass Fibers Hybrid FRP Composite Bars. Case Studies in Construction Materials, Elsevier, 19, e02391. https://doi.org/10.1016/J.CSCM.2023.E02391.

- Ding, S., Zou, B., Zhuang, Y., Wang, X., Feng, Z. and Liu, Q. (2023) Effect of Printing Design and Forming Thermal Environment on Pseudo-Ductile Behavior of Continuous Carbon/Glass Fibers Reinforced Nylon Composites. Composite Structures, Elsevier, 322, 117362. https://doi.org/10.1016/J.COMPSTRUCT.2023.117362.

- Navaratnam, S., Selvaranjan, K., Jayasooriya, D., Rajeev, P. and Sanjayan, J. (2023) Applications of Natural and Synthetic Fiber Reinforced Polymer in Infrastructure: A Suitability Assessment. Journal of Building Engineering, Elsevier, 66, 105835. https://doi.org/10.1016/J.JOBE.2023.105835.

- Karim, M.A., Abdullah, M.Z., Deifalla, A.F., Azab, M. and Waqar, A. (2023) An Assessment of the Processing Parameters and Application of Fibre-Reinforced Polymers (FRPs) in the Petroleum and Natural Gas Industries: A Review. Results in Engineering, Elsevier, 18, 101091. https://doi.org/10.1016/J.RINENG.2023.101091.

- Bekker, А.Т. and Umansky, А.М. (2016) Application of Basalt-Plastic Reinforcement in the Structures of Offshore Hydroengineering Constructions. Izvestiya B.E. Vedeneev VNIIG, 282, 61–75. https://www.elibrary.ru/item.asp?id=27638901.

- Biryukov, A.N., Dudurich, B.B., Kazakov, Yu.N. and Tokarev, N.V. (2017) Application of Composite Materials in the Construction, Renovation and Reconstruction of Objects Transport Infrastructure. Construction and road building machinery, 10, 46–52. https://www.elibrary.ru/item.asp?id=32398998.

- Biryukov, A.N., Biryukov, D.V., Vasyutkin, E.S. and Belyi, A.A. (2019) Application of Composite Reinforcement for Concrete Structures [Primenenie Kompozitnoj Armatury Dlya Betonnyh Konstrukcij]. Composite systems for underground and civil construction sites [Kompozitnye sistemy na ob"ektah podzemnogo i grazhdanskogo stroitel'stva], 61–66. https://elibrary.ru/item.asp?id=41612966.

- Galushko, M.M., Ledyaev, A.P., Korolenok, L.M. and Kuleshov, D.E. (2019) Earthquake-Resistant Structures of Linings of Underground Structures with Composite Reinforcement [Sejsmostojkie Konstrukcii Obdelok Podzemnyh Sooruzhenij s Kompozitnym Armirovaniem]. Composite systems for underground and civil construction sites [Kompozitnye sistemy na ob"ektah podzemnogo i grazhdanskogo stroitel'stva], 94–101. https://www.elibrary.ru/item.asp?id=41558854.

- Nurmukhametov, R.R., Vatin, N.I., Mirsayapov, I.T., Vasyutkin, E.S., Burin, D.L. and Vasyutkin, S.F. (2020) FRP Helical Micro Screw Pile with Cast Iron Pile Cap: Review. Construction of Unique Buildings and Structures, 90, 8903–8903. https://doi.org/10.18720/CUBS.89.3.

- Vatin, N., Ilizar, M. and Nurmukhametov, R. (2020) Composite Helical Micro Pile's Bearing Capacity. IOP Conference Series: Materials Science and Engineering, Institute of Physics Publishing, 890. https://doi.org/10.1088/1757-899X/890/1/012037.

- Fang, Y., Chen, P., Huo, R., Liang, Y., Wang, L. and Liu, W. (2018) Hygrothermal Ageing of Polymeric Sandwich Structures Used in Structural Engineering. Construction and Building Materials, Elsevier, 165, 812–824. https://doi.org/10.1016/J.CONBUILDMAT.2018.01.072.

- Ferdous, W., Manalo, A. and Aravinthan, T. (2017) Bond Behaviour of Composite Sandwich Panel and Epoxy Polymer Matrix: Taguchi Design of Experiments and Theoretical Predictions. Construction and Building Materials, Elsevier, 145, 76–87. https://doi.org/10.1016/J.CONBUILDMAT.2017.03.244.

- Yuan, G., Bai, Y., Jia, Z., Lau, K. tak and Hung, P. yan. (2019) Structural Deformation Performance of Glass Fiber Reinforced Polymer Composite Beam Actuated by Embedded Indented SMA Wires. Composites Part B: Engineering, Elsevier, 159, 284–291. https://doi.org/10.1016/J.COMPOSITESB.2018.09.101.

- Biryukov, A.N., Dudurich, B.B. and Gricuk, A.P. (2018) Application of Polymer Lining Sheets for Repairs and Reconstructions of Operating Military Infrastructure Facilities [Primenenie Polimernyh Futerovochnyh Listov Dlya Provedeniya Remontov i Rekonstrukcij Ekspluatiruemyh Ob"ektov Voennoj Infrastruktury]. Current state of operational maintenance of barracks and housing stock of the Russian Defense Ministry and innovative ways of prospects for its development [Sovr. sost. ekspluatac. soderzhaniya kazarmenno-zhilishch. fonda MO Rossii], 261–268. https://www.elibrary.ru/item.asp?id=35623859.

- Galushko, M.M., Vasyutkin, E.S., Beloglazov, A.P. and Chernyavskij, V.L. (2020) Application of Cellular Structures from Polymeric Composite Materials for Reinforcement of Ice Massives. Current problems of military scientific research [Aktual'nye problemy voenno-nauchnyh issledovanij], 11(12), 505–514. https://www.elibrary.ru/item.asp?id=41558854.

- SP 32.13330.2018 Sewerage. Pipelines and Wastewater Treatment Plants. URL: Https://Docs.Cntd.Ru/Document/554820821.

- Recommendations for Calculating Systems for the Collection, Disposal and Purification of Surface Runoff from Residential Areas, Enterprise Sites and Determining the Conditions for Its Release into Water Bodies [Rekomendacii Po Raschyotu Sistem Sbora, Otvedeniya i Ochistki Poverhnostnogo Stoka s Selitebnyh Territorij, Ploshchadok Predpriyatij i Opredeleniyu Uslovij Vypuska Ego v Vodnye Ob"ekty]. M. 2014. https://files.stroyinf.ru/Data2/1/4293769/4293769496.pdf.

- Abbood, I.S., Odaa, S.A., Hasan, K.F. and Jasim, M.A. (2021) Properties Evaluation of Fiber Reinforced Polymers and Their Constituent Materials Used in Structures – A Review. Materials Today: Proceedings, Elsevier, 43, 1003–1008. https://doi.org/10.1016/J.MATPR.2020.07.636.

- Gopalakrishnan, T. and Chandrasekaran, M. (2023) Analysis of Low Velocity Impact Response of Glass Fiber Reinforced Epoxy Resin Composite with Shape Memory Alloy Incorporation. Materials Today: Proceedings, Elsevier. https://doi.org/10.1016/J.MATPR.2023.05.338.

- Han, Z., Jeong, S., Noh, J. and Oh, D. (2020) Comparative Study of Glass Fiber Content Measurement Methods for Inspecting Fabrication Quality of Composite Ship Structures. Applied Sciences 2020, Vol. 10, Page 5130, Multidisciplinary Digital Publishing Institute, 10, 5130. https://doi.org/10.3390/APP10155130.

- Chen, R.S., Muhammad, Y.H. and Ahmad, S. (2021) Physical, Mechanical and Environmental Stress Cracking Characteristics of Epoxy/Glass Fiber Composites: Effect of Matrix/Fiber Modification and Fiber Loading. Polymer Testing, Elsevier, 96, 107088. https://doi.org/10.1016/J.POLYMERTESTING.2021.107088.

- Nayak, R.K., Mahato, K.K. and Ray, B.C. (2016) Water Absorption Behavior, Mechanical and Thermal Properties of Nano TiO2 Enhanced Glass Fiber Reinforced Polymer Composites. Composites Part A: Applied Science and Manufacturing, Elsevier, 90, 736–747. https://doi.org/10.1016/J.COMPOSITESA.2016.09.003.

- Manfredi, L.B., De Santis, H. and Vázquez, A. (2008) Influence of the Addition of Montmorillonite to the Matrix of Unidirectional Glass Fibre/Epoxy Composites on Their Mechanical and Water Absorption Properties. Composites Part A: Applied Science and Manufacturing, Elsevier, 39, 1726–1731. https://doi.org/10.1016/J.COMPOSITESA.2008.07.016.

- Gnanavelbabu, A., Saravanan, P., Rajkumar, K., Sabarinathan, P. and Karthikeyan, S. (2018) Mechanical Strengthening Effect by Various Forms and Orientation of Glass Fibre Reinforced Isopthalic Polyester Polymer Composite. Materials Today: Proceedings, Elsevier, 5, 26850–26859. https://doi.org/10.1016/J.MATPR.2018.08.167.

- Devi, P.A., Reddy, P.R. and Prasad, K.E. (2023) Hardness and Impact Testing of Glass Epoxy Nanoclay Composites. Materials Today: Proceedings, Elsevier. https://doi.org/10.1016/J.MATPR.2023.09.166.

- Bhat, R., Mohan, N., Sharma, S., Pratap, A., Keni, A.P. and Sodani, D. (2019) Mechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester Composites. Journal of Materials Research and Technology, Elsevier, 8, 3653–3661. https://doi.org/10.1016/J.JMRT.2019.06.003.

- Satkar, A.R., Mache, A. and Kulkarni, A. (2022) Numerical Investigation on Perforation Resistance of Glass-Carbon/Epoxy Hybrid Composite Laminate under Ballistic Impact. Materials Today: Proceedings, Elsevier, 59, 734–741. https://doi.org/10.1016/J.MATPR.2021.12.464.

- Saravanakumar, K., Subramanian, H., Arumugam, V. and Dhakal, H.N. (2019) Influence of Milled Glass Fillers on the Impact and Compression after Impact Behavior of Glass/Epoxy Composite Laminates. Polymer Testing, Elsevier, 75, 133–141. https://doi.org/10.1016/J.POLYMERTESTING.2019.02.007.

- Mirbagheri, M., Rahmani, O. and Mirbagheri, Y. (2022) Estimation of Residual Tensile Strength of Composite Laminate after Low-Velocity Impact Using Visually Inspection. Engineering Failure Analysis, Pergamon, 131, 105898. https://doi.org/10.1016/J.ENGFAILANAL.2021.105898.

- Yorseng, K., Rangappa, S.M., Pulikkalparambil, H., Siengchin, S. and Parameswaranpillai, J. (2020) Accelerated Weathering Studies of Kenaf/Sisal Fiber Fabric Reinforced Fully Biobased Hybrid Bioepoxy Composites for Semi-Structural Applications: Morphology, Thermo-Mechanical, Water Absorption Behavior and Surface Hydrophobicity. Construction and Building Materials, Elsevier, 235, 117464. https://doi.org/10.1016/J.CONBUILDMAT.2019.117464.

- Lu, J.J., Shi, Y.C., Guan, J.P., Dang, R.Q., Yu, L.C., Wang, H.Q., Hu, N. Di and Shen, X.J. (2023) Enhanced Mechanical Properties of Ramie Fabric/Epoxy Composite Laminates by Silicon Polymer. Industrial Crops and Products, Elsevier, 199, 116778. https://doi.org/10.1016/J.INDCROP.2023.116778.

- Arslan, C. and Dogan, M. (2018) The Effects of Silane Coupling Agents on the Mechanical Properties of Basalt Fiber Reinforced Poly(Butylene Terephthalate) Composites. Composites Part B: Engineering, Elsevier, 146, 145–154. https://doi.org/10.1016/J.COMPOSITESB.2018.04.023.

- Karaş, B., Smith, P.J., Fairclough, J.P.A. and Mumtaz, K. (2022) Additive Manufacturing of High Density Carbon Fibre Reinforced Polymer Composites. Additive Manufacturing, Elsevier, 58, 103044. https://doi.org/10.1016/J.ADDMA.2022.103044.

- Genna, S., Papa, I., Lopresto, V. and Tagliaferri, V. (2020) Mechanical Characterisation of CFRP Laminates with Recycled Carbon Fiber Obtained by Resin Infusion under Flexible Tooling (RIFT) Technology. Composites Science and Technology, Elsevier, 199, 108328. https://doi.org/10.1016/J.COMPSCITECH.2020.108328.

- Yu, L., Li, Y., Chen, L., Kang, C. and Zhang, T. (2015) Experimental Study on Mechanical Properties of FRP Components and Comparison of Steel Properties. Atlantis Press. https://doi.org/10.2991/ICADME-15.2015.317.

- Naseri Ghalghachi, R., Showkati, H. and Eyvazinejad Firouzsalari, S. (2023) Experimental, Numerical and Analytical Study on Axial Compression Buckling of Chopped Glass Fibre-Reinforced Polymer Cylindrical Shells. Structures, Elsevier, 58, 105368. https://doi.org/10.1016/J.ISTRUC.2023.105368.

- Liu, Z., Simonetto, E., Ghiotti, A. and Bruschi, S. (2023) Inter-Ply Friction Behaviour in the Temperature Assisted Forming of Magnesium/Glass Fibre Reinforced Thermoplastic Polymer Laminates. Composites Part A: Applied Science and Manufacturing, Elsevier, 173, 107635. https://doi.org/10.1016/J.COMPOSITESA.2023.107635.

- Tryasunov, V.S., Shultseva, E.L., Baganik, A.M. and Polyakova, Y. V. (2022) Properties of the Fiberglass Based on the Fire-Resistant Polyester Resins of Russian Brands Arkpol 40 M and Polymer 3088 Ta. Materials Science Issues [Voprosy materialovedeniya], FSUE CRISM Prometey, 0, 147–156. https://doi.org/10.22349/1994-6716-2022-109-1-147-156.

- Tryasunov, V.S., Lishevich, I. V., Nikolaev, G.I., Shultseva, E.L., Baruev, V.E. and Makhanko, A. V. (2020) On the Definition of Fire-Safety Characteristics for Three-Layer Composite Polymers in Shipbuilding Structures. Materials Science Issues [Voprosy Materialovedeniya], FSUE CRISM Prometey, 139–147. https://doi.org/10.22349/1994-6716-2020-101-1-139-147.

- Anisimov, A.V., Tryasunov, V.S., Shultceva, E.L., Sokolov, Ju.V. and Mudry, F.V. (2017) Epoxyvinylester Binder for Fire Resistant Marine Fiberglass Plastics. Materials Science Issues, 4(92), 120–130. http://www.crism-prometey.ru/science/editions/Russian4(92)2017.pdf.