An early iron age foundry at Kargat-4, Southwestern Siberia

Автор: Durakov I.A., Kobeleva L.S.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.47, 2019 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145446

IDR: 145145446 | DOI: 10.17746/1563-0110.2019.47.3.048-054

Текст статьи An early iron age foundry at Kargat-4, Southwestern Siberia

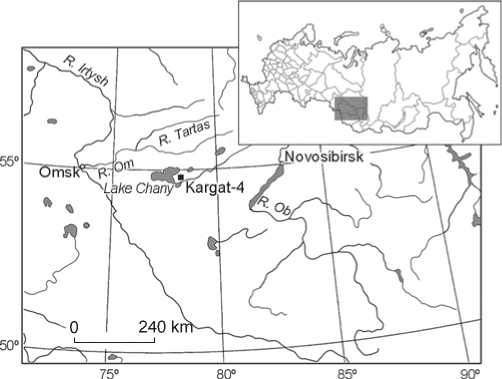

The settlement of Kargat-4 is located on a cape formed by the bank of the Kargat River and floodplain terrace of Lake Chicha, which in ancient times was a part of Lake Chany, 3.8 km to the west-northwest of the village of Zdvinsk, in the Zdvinsky District of the Novosibirsk Region (Fig. 1). The site was discovered in 1975 by V.A. Zakh (Molodin, Novikov, Sofeikov, 2000: 60) and was investigated in 1981 by an expedition from the Institute of History, Philology, and Philosophy of the Siberian Branch of the USSR Academy of Sciences (today IAET SB RAS) led by N.V. Polosmak*. The most striking and extraordinary feature of the settlement was an industrial complex for manufacturing metal products, which consisted of a melting-furnace and several utility pits. Therein, features of bronze-casting production were found, including fragments of clay casting-molds, crucibles, and drops of spilt bronze.

Archaeological context of finds

Visually, the settlement looked like a row of three shallow depressions located along the shoreline of Lake Chicha. According to pottery evidence, it was attributed to the Bolshaya Rechka culture of the Early Iron Age, representing one of the most western sites of that type. The settlement was dated to the 5th– 3rd centuries BC (Polosmak, 1987: 90). Two dwellings from the settlement have been investigated (Ibid.: 46–50). Traces of intense bronze-casting have been found only in dwelling No. 2.

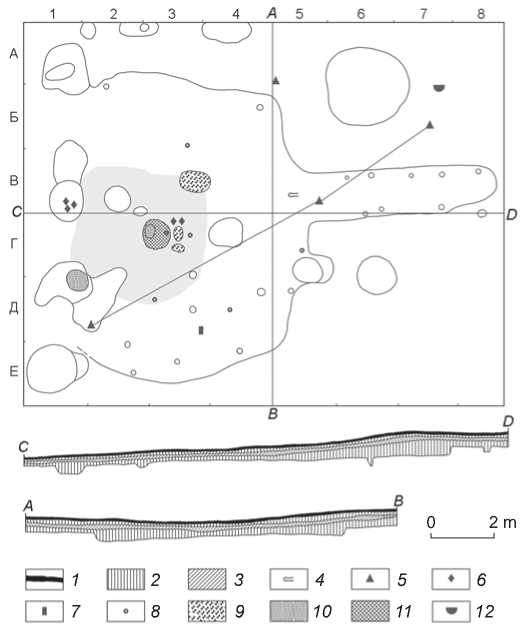

Dwelling No. 2 was a subrectangular pit oriented to the cardinal points (Fig. 2) and measuring 8.2 × 9.4 m. The walls were vertical; the bottom was even. The depth from the level of sterile soil was 0.25 m. The pit was filled with black sandy loam. On the eastern side, a corridor-shaped exit 7 m long and 1 m wide was adjacent to the dwelling; its depth from the level of sterile soil was 0.3 m. Rows of post pits, which used to support the frame of the walls, were 0.15–0.25 m in diameter and 0.1–0.27 m deep. These were found along the walls of the pit in the dwelling and corridor. Two pits remaining from the supporting posts of the roof were in the center of the pit. The dwelling could have been a frame-and-post structure. Its filling contained a stone flake, two bone arrowheads, a horn clasp, an iron clip, and clay spindle whorls (Ibid.: Fig. 69, 2 , 5–7 , 77, 2–5 ). Traces of production activities were found in the form of slag, copper splashes, and also fragments of crucibles and casting-molds.

The production complex consisted of a meltingfurnace located in the central part of the pit, and several utility pits. The furnace was a rounded depression 0.85 m in diameter and 0.25–0.28 m in depth from the floor level, filled with calcined soil with inclusions of burnt bones and lenses of ash. A clay spindle whorl was also found in the infill (Fig. 3, 4 ). At the edge of the northeastern wall of the furnace, two drops of split bronze and another spindle whorl were found (Fig. 3, 5 ). The composition of the findings suggests that the furnace had multiple functions: it was used not only for cooking and lighting, but also for melting metal and

Fig. 2 . Bronze-casting area in dwelling No. 2 in plan view and in cross section.

1 – sod layer; 2 – black sandy loam; 3 – whitish layer (mineral salts); 4 – bronze tongs; 5 – fragment of a mold; 6 – drop of bronze; 7 – whetstone; 8 – spindle whorl; 9 – accumulation of animal bones; 10 – ash; 11 – furnace;

12 – fragment of a crucible.

firing technical ceramics. Notably, a large number of spindle whorls (at least 6 items) were found in the bronze-casting area, while the neighboring dwelling No. 1 contained none. Since the opinion about the connection of the spindle and thread with the furnace and forge and metal-casting cult has already been suggested in the literature (Chindina, 2000: 271), it is impossible not to mention the presence of spindle whorls in priestly male burials of the Bolshaya Rechka culture (Troitskaya, 1987: 59–62; Troitskaya, Borodovsky, 1994: 80).

Fig. 1. The settlement of Kargat-4.

Two pits filled with bones and located in the center of the dwelling were also a part of the bronze-casting complex. The first pit was located 0.14 m east of the furnace; it was an oval depression elongated along the

Mi,

Fig. 3. Finds from bronze-casting area in dwelling No. 2. 1 , 2 – stone whetstones; 3 – fragment of a stone hammer;

4 , 5 – clay spindle whorls.

north–south and measuring 0.21 × 0.42 m with a depth of 0.21 m. The second pit also had oval shape, and was oriented west–east. Its size was 0.16 × 0.35 m.

The production complex also included the third pit filled with animal bones. This was located 1.14 m northeast of the furnace. The pit had an oval shape elongated along the east-west axis. Its size was 0.64 x 1.0 m; the depth from floor level was 0.23 m. In the metalworking of the Early Iron Age in Siberia, animal bones were often used as high-temperature fuel (Grishin, 1980: 94–95; Troitskaya, Borodovsky, 1994: 54); they could have also been used as flux (CaO) lowering the melting temperature (Beltikova, 1986: 74– 75). Accordingly, pits with bones were typically present at the production sites of the time. The total mass of the stocked bones was often significant, ranging from 3-5 to 10 kg. At the Bolshaya Rechka sites of the Upper Ob region, for example, at the settlement of Ordynskoye-9, in dwellings No. 1 and 7, such pits have been found near the melting-furnaces (Troitskaya, Durakov, 1999: 132; Troitskaya, 2005: 65, fig. 1, g ).

Judging by the infill (fragments of molds, drops of bronze, ash), two utility pits that served as garbage containers were also associated with the bronze-casting area. One was found 2 m west of the furnace; it had an elongated oval shape and measured 2.56 × 1.0 m, and 0.28 m deep. The pit was filled with black sandy loam with inclusions of ash and soot. Three bronze splashes were also found there. The second pit was located 1.2 m southwest of the furnace. It had irregular shape, and measured 2.25 × 2.1–1.0 m and 0.3 m deep. The pit was filled with black sooty loam with large lenses of ash. Fragments of ceramics, animal bones, and a fragment of a mold for the casting of celts were found in the pit.

On the territory of the bronze-foundry, items belonging to production equipment were discovered, including a fragment of a nozzle, bronze tongs, and fragments of at least five molds and three crucibles.

Description and analysis of bronze-casting equipment

Bronze tongs of the spring type were found at the floor level in the pre-entrance part of the dwelling. The tongs were 22 cm long and were made of a bent forged bronze rod, square in cross-section and measuring 0.4 × 0.6 cm in the middle part.

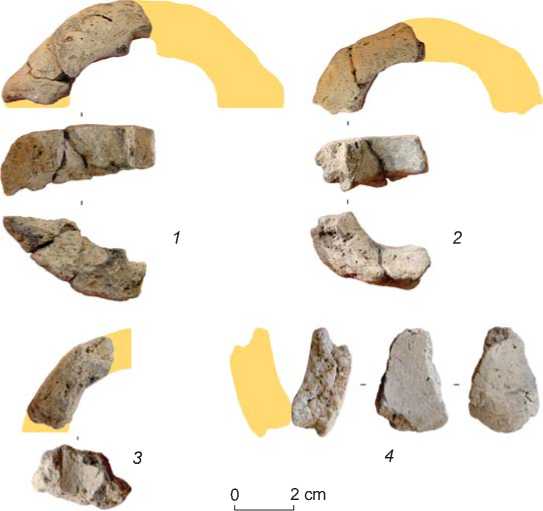

Casting-molds included 12 fragments of not less than five items. All of these were intended for casting-celts.

Only the upper halves of two molds have survived. One of these was intended for the casting of celts with oval sockets (Fig. 4, 2 ). The size of the half was 4.5–5.5 × 2.2–2.4 cm. The thickness of the wall along the upper edge of the socket was 0.5 cm.

Celts were also cast in the second mold. The imprint of a socket and a short sprue, square in cross-section, have been preserved (Fig. 4, 1 ). The size of the socket was 4.0 × 2.2 cm. The length of the sprue channel was 1 cm; its cross-section was 0.6 × 0.3 cm. Both of the above molds were made of clay with added organic material.

A third mold has come down to us in the form of a small fragment of the middle part of its body (Fig. 4, 3 ). It was intended for the casting of celts octagonal in cross-section. Judging by the imprint of wood structure surviving on the inner surface of the working chamber, the mold was made according to the wooden model.

Fourth mold is represented by a fragment of the lower part of the mold half with the imprint of a semicircular wedge-shaped blade of celt (Fig. 4, 4 ). The convergence angle of the blade planes reached 30°.

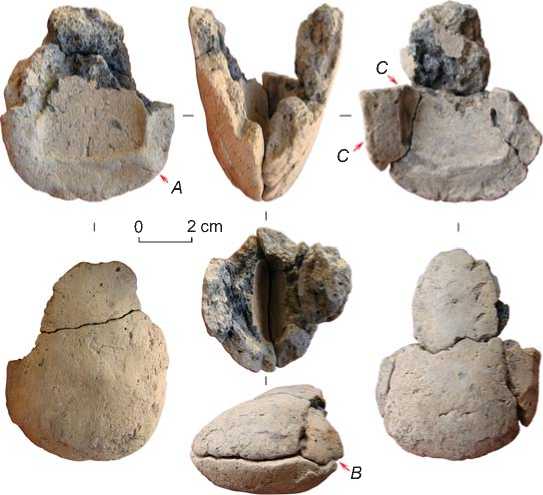

The fifth mold (the best preserved) consists of two halves (Fig. 5). Its fragments were found inside the dwelling in the utility pit, at the exit, and outside in the accumulation of garbage at the eastern wall. The dispersion of mold fragments may indicate the main directions of movements by the dwelling’s inhabitants in the course of their economic activities (see Fig. 2).

Judging by the negative space of the working chamber, a wedge-shaped celt with a sub-oval socket was cast in the mold. The width of the blade was 3.7 cm. The height of the preserved part was 6.3 cm. The size of the socket was 4.5 × 2.2 cm. Celts of this type are known from the materials of the Bolshaya Rechka culture of the Upper Ob region (Troitskaya, Borodovsky, 1994: Pl. XXIII, 2 ).

Their manufacture by the Bolshaya Rechka artisans is evidenced by the find from the settlement of Verkh-Tula (Ibid.: Pl. XI, 4 ). The halves of the mold were made of clay with the addition of organic material. The outer surface was covered with a layer of liquid clay applied using fingers and wood chips—fingerprints and elongated parallel grooves left by the wood chips can be seen.

All the molds of the Kargat-4 bronze-casting complex were made of clay fabric of the same composition. The stability of the recipe most likely indicates a high degree of production specialization. The recipe of clay + organic material in the bronze foundry of the population of the Ob-Irtysh forest-steppe is traditional. It has been found in this region at the sites of the Late Bronze Age and transitional period (Mylnikova, Durakov, 2008: 66).

The molds found on the territory of the production area were most likely made in the following way. First, the lower half was shaped: the model of the future product was pressed into a piece of molding material. The mold on the back and the parting were evened up and packed down by hands, which resulted in a protuberance of extruded molding-material formed around the working chamber. The parting of the mold acquired a distinctive convex uneven surface with traces of smoothing of plastic material (see Fig. 5, A ). The half was dried, after which the model was again inserted inside and pieces of clay were placed over and around the model, thus producing the second half. The surface of the parting in the second half was completely determined by the configuration of the first half; therefore, the place of their joint often had an uneven wavy shape (see Fig. 5, B ) with a distinctive lapping of moldingmaterial (see Fig. 5, C ).

This molding-method required careful drying, since in the case of uneven shrinking, or the slightest warping, the halves would not fit together. When assembling the mold, the displacement of its parts along the plane of the parting was practically eliminated. At the final stage of the work, the outer side of the mold was covered with a thin layer of liquid clay, which might have held the halves together. The finished mold was fired in a reducing mode in closed furnace.

Fig. 4. Fragments of clay molds from bronze-casting area in dwelling No. 2.

Fig. 5 . Mold for casting celts.

A – parting of the mold with traces of smoothening of plastic material; B – uneven wavy joint of mold halves; C – lapping of molding material formed during making the second half.

The above technology was used in manufacturing a part of the molds discovered in the foundry at the settlement of Blizhnie Elbany XII, located in the Upper Ob region and belonging to the Biysk stage of the Bolshaya Rechka culture (Gryaznov, 1956: 88–89, pl. XXIII, 4–10 , XXIV,

1–6 , 9 ). Notably, such technology was fundamentally different from the production methods typical of the cultures inhabiting the Ob-Irtysh interfluve. For example, a series of molds made on the model plate was discovered in a foundry of the Early Iron Age at the settlement of

Sergino-2 on the Om River (Kobeleva et al., 2015: 269– 270). This particular method had a centuries-old tradition in the Ob-Irtysh interfluve and was the main method in both the Late Bronze Age in the Irmen (Mylnikova, Chemyakina, 2002: 20, 61–62, fig. 10, 2 , 3 , 5 ; Mylnikova, Durakov, 2008: 63–66) and Late Irmen metal production (Chicha…, 2009: 228; Kobeleva, Durakov, 2016: 308), and in the earlier times in the Samus and Krotov metal production (Durakov, Kobeleva, 2017: 23).

In its origin, the method of molding used in the foundry at the Kargat-4 settlement is associated with western or southwestern territories. For instance, it was used in northern Kazakhstan in the Early Scythian period by the artisans of the Novoshulbinskoye settlement (Ermolaeva et al., 1998: 41–42, fig. 1, 2 , 3 ). In the Ishim region, the same production technique appeared in the materials of the Zhuravlevo complex at the Borki-1 fortified settlement (Zakh et al., 2015: 12). It also appears in the Trans-Urals at the sites of the Itkul culture. Clay molds of Itkul bronze foundries have uneven wavy line connecting the halves, and traces of wooden spatula (Beltikova, 1993: 70). In northern Kazakhstan and the Trans-Urals, such molding was used in the Late Bronze Age by the carriers of the Berlik and Krasnoozerka cultures.

The molding-method under consideration appeared in the central Baraba only during the transitional period from the Bronze to the Iron Age, as evidenced by the Berlik and Krasnoozerka materials (Chicha…, 2009: 229). The method of processing the outer surface of castingmolds and some crucibles from Kargat-4 with liquid clay over dried surface shows similarities to the method of “roughing” the surface of the Berlik pottery.

0 2 cm 2 4

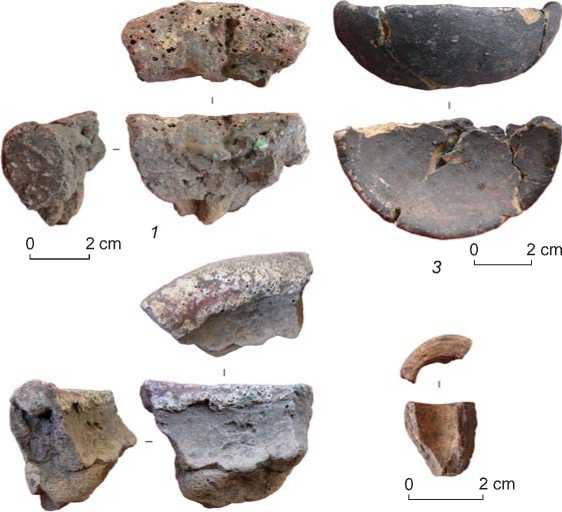

Crucibles . Fragments of three crucibles have been found. The first fragment was a round thick-walled cup (Fig. 6, 2 ). Only a part of the slagged wall 2.5 cm thick has been preserved. The rim was round; its inner part was strongly slagged. The outer surface was covered with a layer of liquid clay coating applied with wood chips. The reconstructed diameter of the vessel in the area of the rim was 10 cm. The volume of the cup was at least 100 cm3. The crucible was made of clay with the addition of small amount of organic materials. Sand that was present in clay fabric in small amounts was most likely a natural admixture in the clay.

Only a fragment has survived from the second crucible (Fig. 6, 1 ). The inner part was highly fire-damaged and had inclusions of metal drops. The wall’s thickness was 1.5 cm; the reconstructed diameter was 9.0–9.5 cm. The usable volume was not less than 75–80 cm3. According to the composition of the clay fabric, the second crucible was very different from the first crucible: it was made of clay with the addition of large amount of sand. The use of such a composition can be explained by the desire to obtain a heat-resistant material and prevent destruction of the crucible during overheating.

The third crucible can be completely reconstructed (Fig. 6, 3) as a cup with a round bottom and a diameter of 7.5 cm. The thickness of the walls was 0.5 cm. The reconstructed usable volume was 75–77 cm3. The crucible was made of clay with an artificial addition of sand. Thin-walled crucibles are not typical of the Bolshaya Rechka metalworking industry, but have been found in the Sargatka bronze foundry workshop at the settlement of Om-1 (Mylnikova, Chemyakina, 2002: 61–62). Given the presence of the Sargatka pottery in dwelling No. 1 at Kargat-4 (Polosmak, 1987: 101–102, fig. 79; Molodin, Novikov, Sofeikov, 2000: 175), it can be assumed that the local artisans were familiar with the foundry traditions of the carriers of the Sargatka culture.

Nozzle is represented by a small fragment of a clay tube (Fig. 6, 4 ). The length of the preserved part was 1.9 cm. Wall-thickness varied from 0.3–0.5 cm. The reconstructed diameter of the nozzle was 2.6 cm. The diameter of the channel for air injection was 1.6–1.7 cm. The nozzle was made on a template from one piece of clay. Judging by the traces of strong thermal impact, the item was calcined to a red-brick color.

It should be mentioned that all technical ceramics of the workshop (molds, crucibles,

Fig. 6 . Foundry equipment of production area in dwelling No. 2.

1–3 – fragments of crucibles, 4 – fragment of clay nozzle.

and nozzle) were made of molding-materials of a special composition that were not used for producing household utensils.

Three stone whetstones belonged to the set of production equipment for bronze casting area. The first and largest whetstone is a slate plate with traces of abrasive activities (see Fig. 3, 1 ). On one side, there is weak damage: apparently, the item occasionally served as an anvil. The length of the plate was 9.5 cm; its width was 5.4 cm, and its thickness 0.9–1.5 cm. The second whetstone, of trapezoidal shape, was also made of slate (see Fig. 3, 2 ). The length of the trapezoid along the midline was 5 cm; its width was 6.3–4.0 cm, and its thickness 0.5–0.9 cm. Traces of wear can be seen on all planes. The third whetstone was made of a fragment of a stone shaft-hole hammer (see Fig. 3, 3 ). Its length was 8.7 cm and its maximum width was 3 cm.

Conclusions

The settlement of Kargat-4 was undoubtedly one of the centers of bronze production in the Early Iron Age of Western Siberia. Traces of foundry activities at the Bolshaya Rechka sites are concentrated only in some dwellings or in the areas between the dwellings. This was observed in the Baraba forest-steppe at the settlement of Kargat-4, as well as in the Ob region at the settlements of Ordynskoye-9, Milovanovo-3A, and Blizhnie Elbany XII. Such a distribution of finds may reflect specialization and individual-and-family organization of production.

A group specialized in manufacturing metal could have emerged from the main collective of the community. Owing to specific aspects of production, such a group existed separately, but was included in constant economic relations not only with the inhabitants of the village, but also with the neighboring collectives, including those composing the carriers of the Sargatka culture.

The materials of the bronze casting-complex under consideration confirm the specialized nature of production. This is indicated by a large number of molds intended for casting similar items (celts), the use of spacious crucibles (75–100 cm3) and specialized tools (blacksmith tongs, molding models), and the stable composition of moldingmaterials.

The molding-technology observed at the Kargat-4 settlement looks similar to the production traditions of the cultures of northern Kazakhstan and the Trans-Urals. It was most likely brought to the central Baraba from the area inhabited by the carriers of the Bolshaya Rechka culture. As a result, at least in the initial period of that expansion, two bronze foundry traditions coexisted on the territory of the Ob-Irtysh interfluve, which differed in their method of manufacturing casting-molds. One (indigenous) tradition involved molding according to the model on the model board. The other tradition, brought from the neighboring territories, was aimed at producing molds according to the model without the model board, with subsequent bonding of the halves with coating on the outside.