An Energy-Efficient Wireless Sensor Network (EE-WSN) for Hazard and Crack Detection in Coal Mines

Автор: Kakelli Anil Kumar, Saurav Ranjan, Gudla Mohan Sathwik, Tanmay Agrawal, Riiju Jagetiya

Журнал: International Journal of Wireless and Microwave Technologies @ijwmt

Статья в выпуске: 4 Vol.14, 2024 года.

Бесплатный доступ

This paper presents a detailed study focused on the utilization of energy-efficient wireless sensor networks (WSNs) specifically designed for hazard and crack detection in coal mines. The primary objective of this research is to develop a WSN system that operates on low power consumption, enabling real-time monitoring of hazardous conditions and cracks within coal mines. The proposed system incorporates energy-efficient methods and protocols to minimize power usage and prolong the lifespan of sensor nodes. The study encompasses the complete design and implementation of a prototype WSN system, followed by a thorough evaluation of its performance within a simulated environment. The obtained results demonstrate the effectiveness of the proposed system in detecting hazards and cracks in real-time while consuming minimal power. Consequently, this research underscores the potential of energy-efficient WSNs to enhance the safety and efficiency of coal mining operations. Moreover, the findings of this study have broader implications, as they can serve as a foundation for the development of similar systems applicable to other hazardous environments, including oil rigs, nuclear power plants, and forest fires. By adopting the energy-efficient WSN approach outlined in this research, these industries can benefit from improved safety measures and enhanced operational efficiency.

Wireless sensor networks, Rime stack, ZigBee, Energy harvesting, Cooja simulator, Flooding algorithm, Broadcast

Короткий адрес: https://sciup.org/15019262

IDR: 15019262 | DOI: 10.5815/ijwmt.2024.04.02

Текст научной статьи An Energy-Efficient Wireless Sensor Network (EE-WSN) for Hazard and Crack Detection in Coal Mines

-

A. Theoretical Background

The mining industry holds significant economic importance in India, making substantial contributions to the country's overall economy. However, it is also an industry fraught with risks and high accident rates, making safety a crucial consideration for national integrity and reputation. Mining operations have a profound impact on a country's pride, as they showcase the variety and abundance of minerals or natural resources available, as well as the efficiency and responsible practices employed in their extraction. The mining sector's contribution to India's GDP ranges from 2.2% to 2.5%, but when compared to the entire industrial sector, it accounts for approximately 10% to 11%. Even small-scale mining activities contribute around 6% to the overall cost of mineral production. The mining industry provides employment opportunities to approximately 700,000 individuals in India. Unfortunately, between 2017 and 2020, there were 583 major accidents and multiple casualties reported in coal mines operated by SCCL (Singareni Collieries Company Limited) across various states like Telangana, Chhattisgarh, and Jharkhand [1].

-

B. Motivation

The mining industry is widely recognized as being prone to accidents, with numerous incidents occurring regularly. Mechanical failures, including issues related to battery life and wired communication, are commonly identified as the primary causes of mining accidents. Consequently, the implementation of software solutions or safety models becomes crucial in minimizing such accidents. However, existing mining conditions present additional challenges, such as network message transmission latency and the presence of mesh wires in cellular networks, which pose risks and discomfort to workers. Furthermore, the limited battery life of wireless sensor nodes hampers the efficiency of sensor networks. In this context, underground wireless sensor networks (WSNs) assume a significant role in mining operations.

-

C. Aim of the proposed work

Mining is an inherently hazardous industry, posing numerous technical and health challenges for miners. Our objective is to leverage IoT (Internet of Things) technology to enhance the mining process, making it safer and more convenient for miners. In this endeavor, we propose the utilization of a comprehensive system consisting of sensors, communication devices, and added features to monitor cracks, detect chemical levels, and assess the mine environment. The system collects data at regular intervals and transmits it to a server, enabling real-time monitoring of the miner's location and methane levels at specific points. Furthermore, our proposed model strives to optimize the battery efficiency of the Wireless Underground Sensor Network (WUSN). To achieve seamless integration, all these components will be incorporated into a smart helmet, creating a unified and user-friendly solution.

-

D. Objectives(s) of the Paper

The research objectives of the proposed work have been listed below.

a. Develop an energy-efficient wireless sensor network (EE-WSN) architecture specifically tailored for hazard and crack detection in coal mines.

b. Investigate and select appropriate low-power sensing technologies and algorithms for hazard and crack detection within the coal mining environment.

c. Design and implement energy-efficient communication protocols and algorithms for seamless data transmission and coordination among the sensor nodes in the EE-WSN.

d. Explore novel techniques for optimizing power consumption in the sensor nodes, including duty cycling, adaptive sensing, and data compression.

e. Conduct a comprehensive analysis of the environmental factors and conditions in coal mines that impact the effectiveness and efficiency of hazard and crack detection using the EE-WSN.

f. Evaluate the performance and reliability of the proposed EE-WSN system in real-time hazard and crack detection scenarios within coal mines through extensive field trials and data collection.

g. Investigate the integration of machine learning and data analytics techniques to enhance the accuracy and efficiency of hazard and crack detection in the EE-WSN.

h. Assess the scalability and adaptability of the EE-WSN system for deployment in different coal mine environments with varying geological and operational conditions.

i. Conduct a comparative analysis of the proposed EE-WSN system with existing hazard and crack detection methods in terms of power consumption, detection accuracy, and response time.

j. Explore the potential for using the EE-WSN system as a foundation for developing similar solutions for other hazardous environments, such as oil rigs, nuclear power plants, and forest fires.

2. Background Study

According to the findings presented in [2], a Zigbee-based helmet has been developed for hazard detection. The helmet incorporates a gas sensor and a smoke sensor to identify hazardous gases and smoke, respectively. To ensure user safety, the helmet is equipped with an LED light and an alarm that activate in the event of danger. The alert signal is wirelessly transmitted to a remote-control unit using the Zigbee communication protocol. This innovative helmet proves beneficial for individuals working in hazardous environments, including firefighters and industrial workers.

In another study described in [3], a smart rover designed for coal mine monitoring is introduced. The rover employs LabVIEW and wireless sensor networks to facilitate its operation. Equipped with sensors for temperature, gas, and humidity monitoring, the rover is remotely controlled through LabVIEW. Real-time data transmission from the rover to the control unit is facilitated by the wireless sensor network, enabling effective monitoring and control of the coal mine environment. The proposed system holds great potential for enhancing the safety and efficiency of coal mining operations. Moreover, the utilization of LabVIEW and wireless sensor networks makes the system cost-effective and easy to implement.

Furthermore, it has been argued in [4] that underground wireless sensor networks (WSNs) play a crucial role in continuous environmental monitoring. Sensor nodes located throughout the underground mines, actively collect and transmit data to the base station. To address power supply limitations in underground mines, a Wake-on-Radio (WOR-MAC) protocol based on a MAC practice cycle has been proposed. This protocol substantially reduces power consumption in individual sensors. Notably, a significant reduction of 66% in the end-to-end delay was observed with the implementation of this protocol. In [5], the proposal of MGSA-ORS suggests that it can reduce the power consumption of the collection head and transmission hub by 30%. This multi-purpose approach of MGSA-ORS achieves high power efficiency with minimal network overhead. Reference [6] emphasizes the need to control the main components that consume power in sensor nodes to save energy. Additionally, [7] identifies work cycles, data logging, and navigation as the three primary types of energy-saving strategies for WSNs. By employing a predictability algorithm and conducting a detailed analysis of WSN deployment sites, sleep hours for nodes can be planned effectively. In [8], it is noted that the decline rate of battery performance is influenced by the measurement interval and transmission power. Particularly, a rapid decrease in voltage occurs when soil temperature increases by 0.3 meters below the surface. The study also highlights that lithium-ion batteries are available, but overheating during recharging is a drawback.

Furthermore, [9] introduces MI-WUSN as a solution for sensor networks in environments like underground mines, where the charging source cannot be positioned near the sensor area. This implementation significantly enhances the system's efficiency. Additionally, [10] discusses the applicability of MIWI Pro as a communication protocol in WSNs, highlighting its feasibility and reliability. The work in [11] proposed the two-way ranging (TWR) method with the trilateration positioning algorithm as an efficient technique that can be used in underground WSN design. The work proposed in [12] is a good energy-efficient routing scheme using the Selection and Data transmission phase that considers the node density, cluster compactness, remaining energy in the sensor node, and energy prediction. This scheme outperforms LEACH and I-LEACH. The work presented in [13] used other protocols, such as the Virtual Grid-based Distributed Clustering (VGDC) protocol, to provide a solution that reduces network energy usage while improving data transmission between sensor nodes, cluster heads, and data sinks for the MWSN. Reference described [14]18 different ultralow-power methods for prolonging the EH-WSN lifespan.

In their study [15], the authors have addressed the issue of continuous monitoring, which results in aggressive power consumption and increased sensor maintenance, consequently limiting the battery life of the sensor. To optimize power consumption and functionality of the sensor node, the authors propose calculating the energy harvested and adjusting settings such as sampling rate, transmission power, packet routing choice, and duty cycle accordingly. This approach enables the optimization of power consumption while maintaining desired functionality. When it comes to communication with miners, radio broadcast is identified as the most preferred mode [1]. It utilizes frequencies that allow for navigation through mine shafts using waveguides. Zigbee has also been employed [16] due to its ease of deployment and low power consumption compared to other technologies. DASH-7, on the other hand, offers a lower data rate but a simple direct energy-bandwidth relationship, which results in improved energy efficiency and a potentially longer range. This technology presents an opportunity for better energy efficiency in communication. In terms of measuring battery life, the T-KiBaM model [17] is considered ideal, especially when battery life depends on the operating environment. Additionally, T-KiBaM offers the advantage of accommodating different battery models, such as Ni-MH or Li-ion, providing flexibility in battery selection.

In scenarios where the underground sensors [18] are not deeply positioned, the Unmanned Aerial Base Station (UABS) can be utilized to gather data from these sensors. LTE technology can be employed for backhaul connections, facilitating communication between the drones and core networks. Power consumption in soil moisture and air networks plays a crucial role. The Peplinski policy was utilized to calculate the ideal soil transfer rate [19]. This calculation takes into account factors such as the dielectric properties of the soil, volumetric water content, as well as the sand and clay components. For power prediction on a sensory timescale, the EMWA algorithm [20] proves to be highly effective. It enables accurate power estimation. Zigbee and IEEE 802.15.1 Bluetooth [21] are efficient communication mediums extensively used in WSNs to ensure reliable data transfer and operational efficiency. Off-the-shelf nodes for WSNs are highly efficient [22]. They utilize radio transmission to facilitate communication between sensors, ensuring seamless connectivity. Additionally, a cryptographic library called TinySec has been developed to maintain data integrity and security.

In [23], the development of a digital device using Zigbee technology for environmental monitoring in underground mines is described. This device incorporates a gas sensor, temperature sensor, and humidity sensor to monitor the mine environment. Utilizing the Zigbee communication protocol, the device wirelessly transmits data to a central monitoring system. The proposed system aims to enhance safety and productivity in underground mining operations. The cost-effectiveness of the system is achieved through the utilization of Zigbee technology, and the compact design of the device allows for easy installation within the mine. By implementing this system, the potential for accidents can be reduced, and working conditions for miners can be improved. Furthermore, [24] proposes the use of wearable wireless sensor networks for the detection of hazardous gases in industrial applications. The system involves a gas sensor module and a wireless sensor node attached to a worker's clothing. The sensor node collects data, which is then transmitted wirelessly to a remote-control unit. The intended outcome of this system is to enhance safety in industrial environments by providing real-time gas monitoring to workers. The use of wearable wireless sensor networks offers convenience and comfort to workers. By implementing this system, the potential for accidents can be mitigated, and the working conditions of industrial workers can be improved.

3. Our Proposed Work and Model

Energy harvesting offers an environmentally friendly solution to address the battery power crisis in WUSN (Wireless Underground Sensor Network) networks, which play a vital role in achieving a sustainable society in the next generation. In WUSNs, battery power, and signal strength are significant concerns, as both are essential for proper network functioning. Without sufficient battery power and strong signals, the network is at a significant disadvantage. To optimize battery usage and ensure efficient utilization of limited power, an effective algorithm is required. This algorithm should enable the accomplishment of tasks using minimal battery power and provide timely alerts to users when a sensor's battery is running low. Manually replacing batteries in numerous sensor nodes within a WUSN can be a tedious and time-consuming task.

Unfortunately, many existing studies on WUSN models have focused primarily on high battery consumption rates, overlooking the importance of battery management for maintaining network quality. Consequently, the overall lifespan of the network is severely limited, making it unsuitable for underground mining applications. However, the development of an energy-efficient WUSN network holds great potential for enhancing safety and communication in critical mining areas, making thousands of underground mines safer. Additionally, this proposed WUSN model can find applications in other fields where communication is challenging in unmanned areas, offering a preferred solution for such scenarios.

We propose a smart helmet/device designed to detect methane levels in the surrounding region, providing timely alerts to miners regarding the presence of potentially hazardous compounds and enabling them to take necessary precautions. Our model utilizes MQ series sensors to detect methane or other hazardous components like sulfur levels in the immediate vicinity. These sensors transmit the collected data over a Zigbee network. With the help of ATmega family microcontrollers, this data can be broadcasted to the network, empowering miners to gain insights into their surrounding environment. Additionally, we monitor temperature and other natural variables in mining fields and adjacent areas to gather comprehensive information about the conditions and how mining activities may be impacted by different weather conditions. By employing machine learning technologies, we assess, analyze, and compare the conditions surrounding the mine, generating valuable data from the miner's device. This aids in the discovery and evaluation of mine sites.

For concrete structures, we introduce a crack-detection light sensor that can accurately identify fractures on the surface. During regular maintenance, the light source is connected to various connectors on optical fiber cables, allowing for visual inspection of multiple locations in succession. This inspection technique eliminates the need for an on-site power supply. The small and lightweight nature of the light source ensures safe and convenient performance. This approach offers several advantages, including simple fault detection, as the checker does not require knowledge about structure management or control systems. The sensor's luminescence enables the identification of fracture growth, even in scenarios where visual inspection is challenging, such as at great heights or in darkness. Figure 1 illustrates the safety helmet for the miner attached to the proposed sensor node. This node consists of a 500mAh battery, and the components listed above. The circuitry of the same is explained in the next section. In this helmet, notification functionality is added for instant alerts; for example, if an emergency is detected by the helmet, it can notify the user.

Fig. 1. Proposed Model of the helmet with the Sensor Node

Vibration motors or alarms were used to implement this feature in our helmets. This enhances user safety. Subsequently, a WSN node network is created in which all helmets communicate with each other and transfer data to each other. If any sensor picks ambiguous data, it alerts both the main server and its nearby sensor nodes. We also implemented button functionality to interact with the server so that a user can easily communicate with the administrator.

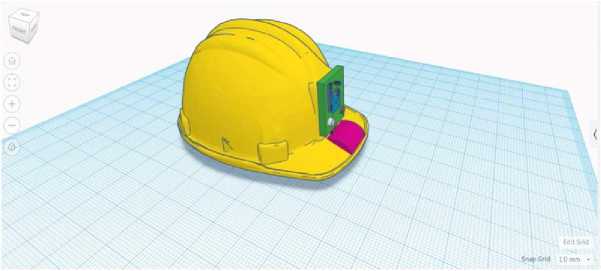

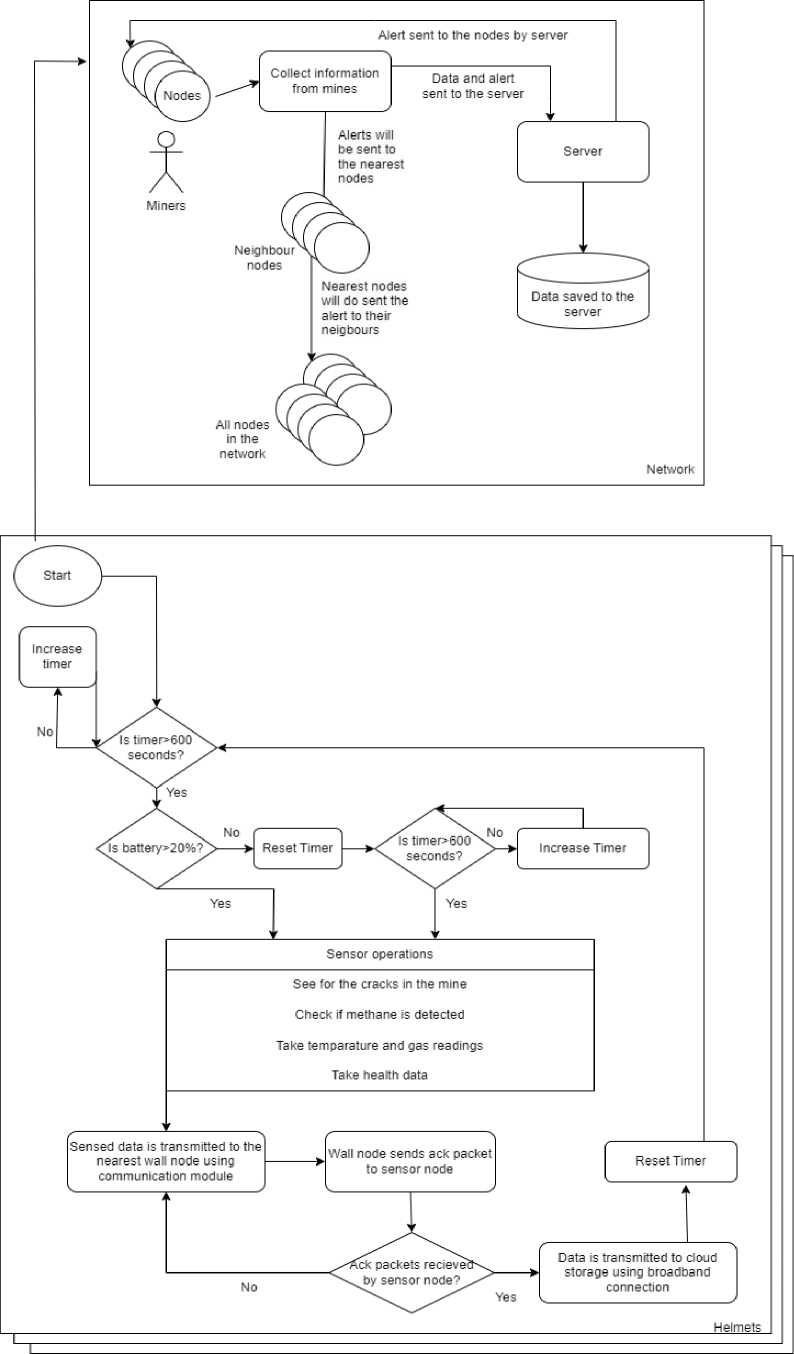

Fig. 2. Data Flow of the proposed work

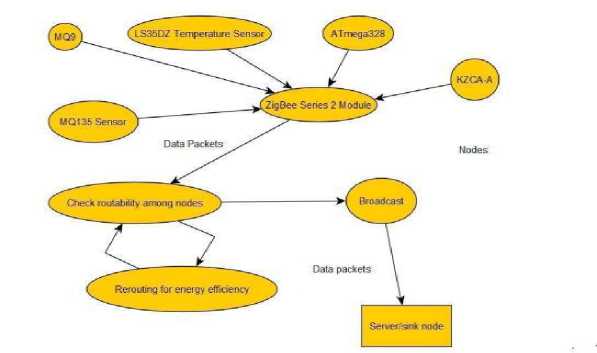

Figure 2 illustrates the proposed flow diagram. Sensor LS35DZ (temperature), MQ-9(gas sensor), and MQ-135(air quality sensor) will be deployed with the Zigbee series –two modules with integrated antennas together from the Sensor Node, and this module is deployed by attaching it to the worker's safety helmet. This sensor node senses and collects data. Thereafter, the values were transferred to ZigBee for data transition. After this process, the sensor node goes into sleep mode for 10 min to conserve power consumption. Each sensor node is connected to the wall node, which is in the range of Zigbee series-1 and transmits the data to the wall node. After data transmission, Zigbee sleeps until the next set of sensor data is received from the sensors. The wall node was a Zigbee series –2 modules with an integrated antenna with power and broadband connections. The wall node gathers data from all the sensor nodes and transmits data values to the cloud, which is accessed by the end user in real time. In this flowchart of figure 3, a process of working model is described for sensor nodes in a wireless sensor network.

a. Timer Check: At regular intervals of 600 seconds (10 minutes), the timer at the sensor node is checked to initiate data collection and transmission.

b. Battery Level Check: Before taking any readings, the battery level of the sensor node is evaluated. If the battery level is above 20%, the sensor proceeds with data collection; otherwise, it waits until the battery level is sufficient.

c. Data Collection: Once the battery level is above 20%, the sensor node measures the gas concentration and temperature readings from its environment. These readings represent important environmental parameters that need to be monitored.

d. Data Transmission: The collected data is then sent from the sensor node to the ZigBee module. The ZigBee module is equipped with an integrated antenna, allowing it to wirelessly transmit data.

e. Communication with Wall Node: The ZigBee module sends the data to the nearest wall node in the network. It waits for an acknowledgment from the wall node to ensure successful transmission. If the acknowledgment is received, the process continues to the next step. If no acknowledgment is received, the ZigBee module retransmits the data to the nearest wall node.

f. Data Capture by Wall Node: Once the data reaches the wall node, it is captured and stored locally. The wall node acts as an intermediate point for data aggregation and forwarding.

g. Cloud Storage: The captured data from the wall node is then sent to cloud storage. This is achieved using a broadband connection established within the mine. The cloud storage serves as a centralized repository for storing and analyzing the collected data.

h. Battery Level Below 20%: If the battery level of the sensor node drops below 20% during the process, the entire data collection and transmission process is repeated after a longer interval of 1200 seconds (20 minutes), instead of the usual 600 seconds. This extended interval allows the battery to recharge or be replaced, ensuring continuous operation of the sensor node.

4. Implementation of the Proposed Work

By following this process, the sensor nodes in the network collect and transmit data at regular intervals, ensuring the monitoring of gas concentration and temperature in the mine environment while considering the battery life of the sensor nodes.

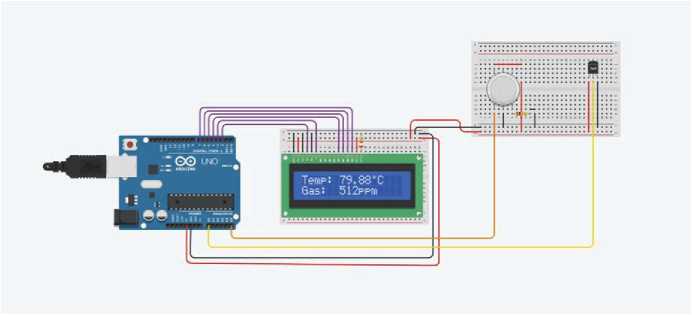

Fig. 3. Flowchart for the proposed system

The work is divided into two parts: the first part is related to making a hardware prototype helmet in which a wide variety of sensors are used and the second part is a wireless sensor network using the COOJA simulator, where each node acts as a helmet. An Arduino Uno board was used to integrate the sensors in the first part of creating the helmet prototype. Environmental parameters such as temperature, pressure, and humidity levels, and a vibration sensor were added to the board to alert the miner; toxic gas sensors such as the MQ sensor were used to detect harmful leaked gases in the mine environment, and a crack detection sensor was used to detect cracks on the mine walls. Therefore, to integrate the above properties, an LM35DZ temperature sensor, which is an integrated circuit analog sensor that can be used to measure the temperature with an electrical output proportional to the temperature (this is why it is an analog sensor). It can measure the temperature more accurately than a thermistor can. The sensor circuitry was sealed and was not subjected to oxidation. The MQ9 sensor is a glove Gas Sensor (MQ9) module that is useful for gas leakage detection (in the home and industry). This method is suitable for the detection of LPG, CO, and CH4. Owing to its high sensitivity and fast response time, measurements can be performed as soon as possible.

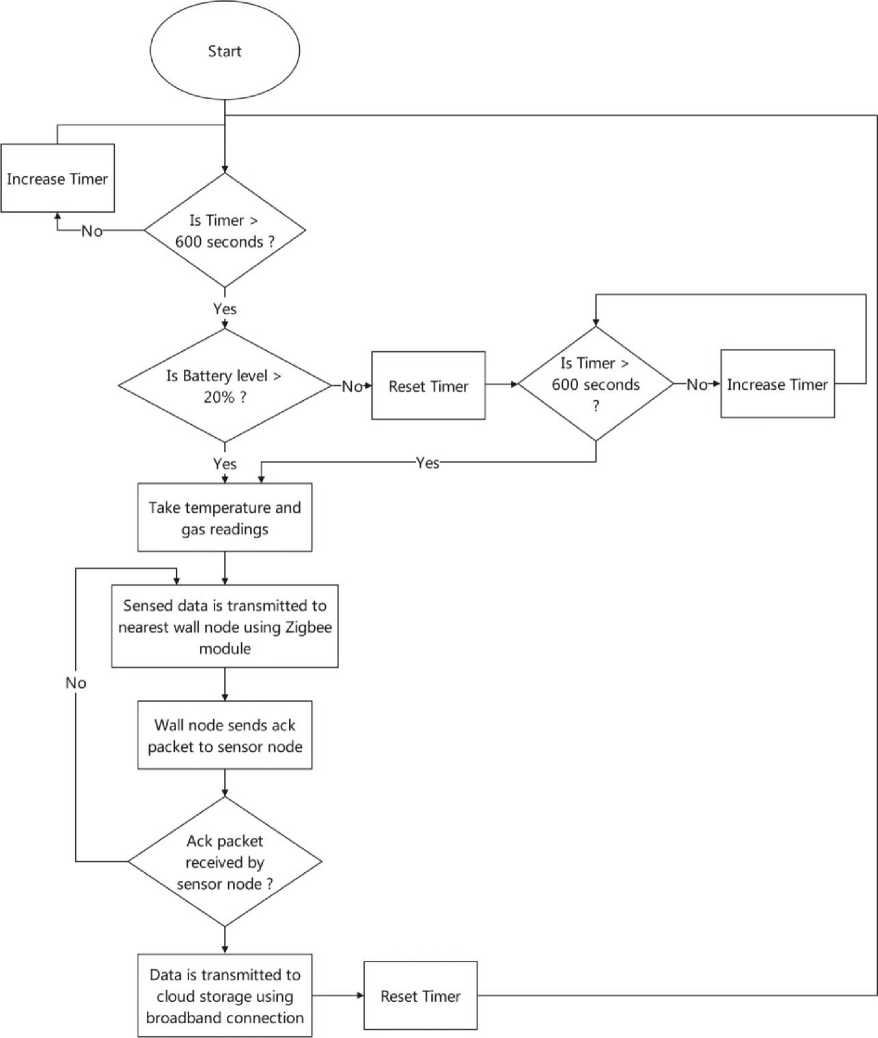

Fig. 4. The Proposed System Architecture

From Table 1, the following values were calculated.

• Load Current consumption: 150 + 150 + 0.012 + 19 + 12 = 331.012 mA

• Standby Current consumption: 0.05 + 0.05 + 0.001 + 19 + 0.002 = 19.103mA

In this research, the focus was on detecting cracks in the mine for which a KZCA-A sensor was used to facilitate the easy and accurate detection of cracks developed on the surface of concrete structures due to deterioration. The sensors were previously bonded onto a concrete structure, and the wirings were completed. At the time of regular checks, the light source was connected to one optical fiber cable connector to perform visual observation of multiple points in order. No power supply was required at the site. The light source itself is exceedingly small and light, and a checking job can be performed securely. The detection accuracy of crack widths can be selected from 0.05 / 0.1 / 0.2 / 0.3 mm, allowing use for the detection of cracks at the initial stage or repaired cracks.

Table 1. Power consumption of components

|

Components |

Standby Current |

Load Current |

|

MQ-135 |

50microA |

150mA |

|

MQ-9 |

50microA |

150mA |

|

LM35DZ |

1microA |

12microA |

|

ATMEGA328 |

19mA |

|

|

Zigbee Module |

2microA |

12mA |

Fig. 5. Sensor Node Circuit Simulation

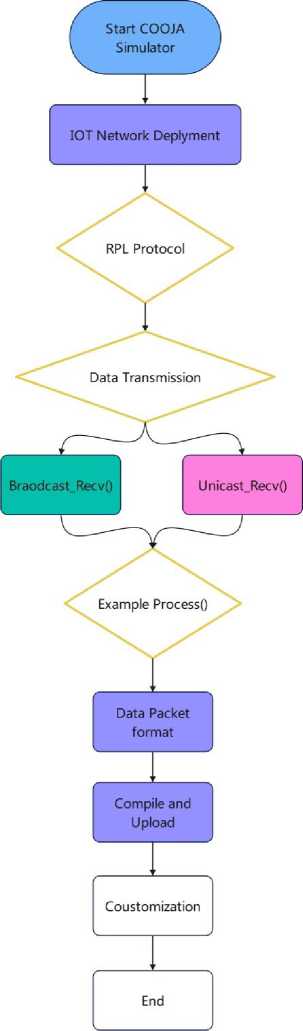

Figure 5 depicts the user end of the generated data, synchronized with the clouds. The interface is accessible to the mine supervisor or security guard, enabling them to monitor the mine's environment. The location of the mine and wall nodes is illustrated, showing each node's position on the map along with average temperature and gas levels. This facilitates easy access to environmental data. Communication between nodes, the server, and alerts transfer to nearby nodes requires a communication module. In this proposed methodology, the ZigBee module is utilized to transfer alerts to nearby nodes, creating a cascading effect until reaching the end of the network. The Internet plays a crucial role in transmitting data sensed by integrated sensors, which is valuable for future work. In the second part, a wireless sensor network is simulated using the COOJA simulator. Multiple nodes represent individual helmets, communicating with each other to transmit essential information such as temperature, humidity, and AQI for miners' well-being. The COOJA simulator enables the recreation of a WSN scenario, where data is transmitted between nodes and reaches the nearest nodes, ultimately covering the entire network. The following steps are followed to establish a WSN in the Contiki Cooja simulator. Define the network topology by specifying the number of nodes, their positions, and communication range. The COOJA simulator facilitates creating and placing nodes.

-

- Define the application layer, selecting the Rime stack as the lightweight communication protocol for WSNs. Specify the message format, including the data payload and destination address.

-

- Implement the data transmission logic, utilizing the flooding algorithm. Nodes forward data packets to all neighbors.

-

- To prevent loops and redundant transmissions, a sequence number or hop count can be included in the packet header. Test the WSN by simulating different scenarios.

-

- The COOJA simulator to visualize network behavior and analyze data transmission efficiency.

-

A. Network Topology

For our scenario, the recommended network topology is flat, where all nodes are on the same level and can directly communicate. This topology suits small, dense networks where all nodes are within range of each other. Nodes can send messages to immediate neighbors, who in turn forward them to their neighbors until reaching all nodes. A flooding algorithm can be employed to ensure message delivery across the network.

-

B. Application Layer

The application layer is defined using a lime stack. The Rime stack is a lightweight communication protocol for wireless sensor networks that provides a reliable and efficient communication mechanism. To define the application layer using the Rime stack, the following steps were followed to establish data transmission in the network:

-

- Define the message format, including the data payload and destination address. The payload can be any data type, and the broadcast address ensures message delivery to all nodes.

-

- Specify the data transmission protocol, such as the flooding algorithm. Nodes forward data packets to neighbors, preventing loops using sequence numbers or hop counts in the packet header.

-

- Implement the data transmission logic using the Rime stack. Nodes send messages to immediate neighbors, which propagate the message further until it reaches all nodes in the network.

-

C. Implementing data transmission logic

Implementing the data transmission logic using the Rime stack using the following steps.

-

a. Create a message buffer to hold the data payload and destination address.

-

b. Initialize the message buffer with the data payload and the destination address.

-

c. The message buffer is sent to the next-hop neighbor using the rime stack.

-

d. When a node receives a message, it checks its destination. If the destination address matches its address, the message is processed. Otherwise, it forwards the message to its neighbors.

-

e. To avoid loops and redundant transmissions, a sequence number or hop count can be used in the packet header.

The following steps were used in the simulation:

-

• Add sensor nodes to the simulation using the "Mote" option in the "Add" menu.

-

• Configure the radio parameters of each node by selecting the appropriate radio model (e.g., CC2420 or Z1) in the "Mote Type" tab.

-

• Define the network topology by creating a network in the simulation, utilizing the "Create new simulation" option.

-

• Select a routing protocol (e.g., Rime or Contiki MAC) that enables data transmission between nodes.

-

• Write a program in C using the Contiki API to enable nodes to collect and transmit data (e.g., using a

flooding algorithm).

-

• Compile and upload the program to the nodes in the simulation.

-

• Run the simulation and observe data transmission within the network.

The algorithm/flowchart described for the Contiki Cooja Simulator enables nodes in the network to collect and transmit data. Here's a detailed explanation of the different components and functions mentioned:

-

a. Data Transmission: The algorithm allows data to be transmitted from one node to the nearest nodes within the network. This means that each node can forward data packets to its neighboring nodes, thereby enabling data propagation throughout the entire network.

-

b. Rime Routing Protocol: The algorithm utilizes the Rime routing protocol for data transmission. Rime is a lightweight communication protocol specifically designed for wireless sensor networks (WSNs). It provides a reliable and efficient way to route data packets between nodes in a network.

-

c. Functions:

-

- broadcast_recv() function: This function is responsible for receiving broadcast messages. When a node receives a broadcast message, it can process the message or forward it to its neighbors if necessary.

-

- unicast_recv() function: This function is responsible for receiving unicast messages. Unlike broadcast messages, unicast messages are directed to a specific node. When a node receives a unicast message, it can process the message or forward it to its neighbors if needed.

-

- example_process: This process periodically sends data packets using the broadcast_send() function. The example_process can be customized according to specific requirements, such as the frequency of data transmission and the data to be sent.

d. Data Packet Format: The struct data_packet defines the format of the data packet. It includes fields like node ID and data value. This structure specifies how the data is organized within each data packet

e. Compilation and Upload: The program, which includes the algorithm and the defined functions, is compiled using the Contiki compiler. Once compiled, the program is uploaded to the nodes in the Contiki Cooja Simulator. This allows the simulation to run, and data transmission can be observed within the network.

f. Customization: The algorithm can be customized to suit specific network topologies and requirements. This means that the flowchart and functions can be modified or extended based on the specific needs of the wireless sensor network being simulated.

5. Results and Discussion

By following this algorithm/flowchart, the Contiki Cooja Simulator enables data collection and transmission within the network, utilizing the Rime routing protocol. The simulation allows for observation and analysis of data transmission behavior, and the algorithm can be adapted to different network scenarios as needed.

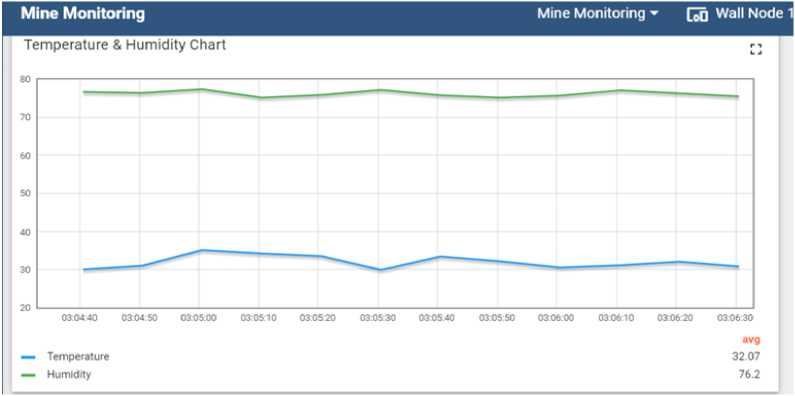

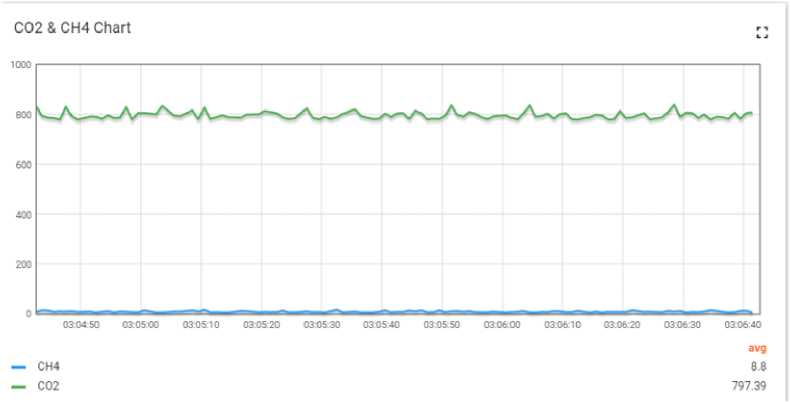

Fig. 6. The working model and its execution of the Proposed Work in the COOJA simulator

Through the COOJA simulator, a network is created to simulate the behavior of a wireless sensor network (WSN). In this network, each node can transmit alerts to their nearest nodes and data to the server. The simulation allows for the analysis of various aspects, including power consumption, data transfer between nodes and the server, and the design of the network used in mines. The analysis conducted on the simulated network focuses on the power consumption of each node in the WSN. Power consumption is a critical factor in WSNs as it directly impacts the battery life and overall efficiency of the nodes. By examining the power consumption, insights can be gained into how efficiently data and alerts are transferred between nodes and the server. Figures 7 and 8 in the analysis represent real-time graphs of temperature, humidity, and gas sensor readings. These graphs provide a visual representation of the fluctuations in these parameters over time. By monitoring these graphs, anomalies or abnormalities in the mine environment can be detected. The real-time graphs serve as a valuable record for end users to observe and assess the working conditions of the mine.

By thoroughly analyzing the data and optimizing the sensor module for battery efficiency, the battery life of a sensor node in the network was extended to approximately 20 hours. This extension in battery life significantly reduces the number of battery cycles required, enhancing the overall lifespan of the sensor node. The analysis further reveals that with an expected efficiency of 60% after 4000 battery cycles, the sensor network can achieve a battery life of 12 hours. This longevity of the sensor node leads to improved battery life estimation for the sensor module, enabling better planning and management of the WSN. In summary, the COOJA simulator facilitated the creation and analysis of a WSN, allowing for the examination of power consumption, data transfer, and network design. Real-time graphs provided valuable insights into the fluctuations of environmental parameters, while optimization efforts resulted in an extended battery life for the sensor nodes, enhancing the overall efficiency and reliability of the network.

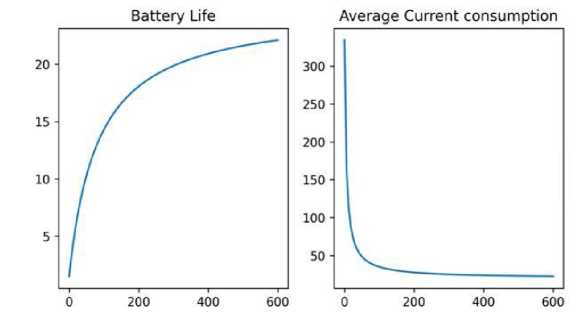

In Figure 9, two graphs provide insights into the relationship between standby time, battery life, and average current consumption. Graph 1 depicts the relationship between standby time (in seconds) and battery life (in hours). The x-axis represents the standby time, while the y-axis represents the battery life. By analyzing this graph, it was observed that the battery life increases exponentially as the standby time increases. In other words, a longer standby time leads to a longer battery life for the circuit. This relationship suggests that increasing the standby time can significantly improve the overall battery performance of the system. Graph 2 shows the relationship between standby time (in seconds) and average current consumption (in mA). The x-axis represents the standby time, while the y-axis represents the average current consumption. The average current consumption includes the current load during both the standby and active states of the circuit. Upon analyzing this graph, a drastic decrease in the average current consumption was observed between 0 seconds and 100 seconds of standby time. This means that there is a significant reduction in power consumption during this initial period of standby time. As the standby time increases, the average current consumption continues to decrease. This suggests that increasing the standby time leads to lower power consumption, which is beneficial for prolonging the battery life of the circuit.

Fig. 9. Estimation of Battery Life (1) and Average current consumption (2)

Based on the analysis of both graphs, it can be concluded that a standby time of more than 100 seconds is desirable. The graphs indicate that with a standby time of 600 seconds (10 minutes), the circuit achieves a good balance between battery life and power consumption. Therefore, 600 seconds is determined as the fixed standby time for the system. In summary, the analysis of the two graphs reveals that increasing the standby time results in an exponential increase in battery life while reducing the average current consumption. Based on these findings, a standby time of 600 seconds is chosen as it offers a suitable trade-off between battery life and power consumption for the system.

6. Conclusion and Future Works

Our proposed model aims to revolutionize miner safety and communication through the implementation of an energy-efficient wireless underground sensor network (WUSN). By optimizing energy consumption and enabling seamless data and alarm transmission between sensor nodes and the server, we have successfully extended the battery life of sensor nodes to meet desired levels. This breakthrough allows for continuous, real-time monitoring of critical environmental parameters such as temperature, humidity, crack width, and gas concentration, providing a live feed that facilitates effective mine monitoring and the detection of abnormal behavior.

Our research demonstrates the immense potential of WUSN and IoT technologies in enhancing the security and productivity of mining operations. By integrating hardware design, advanced modeling techniques, and data analysis, we have achieved significant energy savings, created highly efficient networks, and accurately estimated battery life. It is worth noting that the implications of our study extend beyond the construction industry, as sectors lacking safety, communication, and sustainability measures can also benefit from our findings. To further advance this field, future research should focus on refining the energy consumption algorithm for helmets, exploring emerging technologies, and conducting extensive field testing. There is vast potential for improving helmet design to enhance portability and usability, thereby enhancing the overall effectiveness of the system. In summary, our innovative approach presents a paradigm shift in miner safety and communication through the implementation of an energy-efficient WUSN. Our research showcases the transformative impact of integrating hardware design, modeling, and data analysis, paving the way for improved energy savings, efficient networks, and accurate battery life estimation. With further exploration and development, our findings can extend beyond the construction industry, benefiting sectors where safety, communication, and sustainability are lacking.

Список литературы An Energy-Efficient Wireless Sensor Network (EE-WSN) for Hazard and Crack Detection in Coal Mines

- Chehri, A., Saadane, R., Hakem, N., & Chaibi, H. (2020). Enhancing Energy Efficiency of Wireless Sensor Network for Mining Industry Applications. Procedia Computer Science, 176, 261-270.

- Catherine, J. R., Priyanka, R., Alagusabai, A., & Renuka, K. (2021, March). Zigbee-Based Hazard Detecting Helmet. In IOP Conference Series: Materials Science and Engineering (Vol. 1084, No. 1, p. 012069). IOP Publishing.

- Udeshna, D., & Nipan Kumar, D. (2021). Coal Mine Monitoring Smart Rover Using LabVIEW and Wireless Sensor Network. In Applications of Artificial Intelligence in Engineering (pp. 217-224). Springer, Singapore.

- Qiu, L., Salcic, Z., Kevin, I., &cheng Wang, K. (2019, July). Adaptive Duty Cycle MAC Protocol of Low Energy WSN for Monitoring Underground Pipelines. In 2019 IEEE 17th international conference on industrial informatics (INDIN) (Vol. 1, pp. 41-44). IEEE.

- Veshala, M., & Srinivasulu, T. (2021, April). Improving the Energy Efficiency of the WSNs by Optimal Relay Node Selection using Modified Gravitational Search Approach. In 2021 5th International Conference on Computing Methodologies and Communication (ICCMC) (pp. 276-283). IEEE.

- Engmann, F., Adu-Manu, K. S., Abdulai, J. D., & Katsriku, F. A. (2021). Applications of prediction approaches in wireless sensor networks. In Wireless Sensor Networks-Design, Deployment and Applications. IntechOpen.

- Engmann, F., Katsriku, F. A., Abdulai, J. D., Adu-Manu, K. S., & Banaseka, F. K. (2018). Prolonging the lifetime of wireless sensor networks: a review of current techniques. Wireless Communications and Mobile Computing, 2018.

- Levintal, E., Ganot, Y., Taylor, G., Freer-Smith, P., Suvocarev, K., & Dahlke, H. E. (2022). An underground, wireless, open-source, low-cost system for monitoring oxygen, temperature, and soil moisture. Soil, 8(1), 85-97.

- Kisseleff, S., Chen, X., Akyildiz, I. F., & Gerstacker, W. H. (2016). Efficient charging of access limited wireless underground sensor networks. IEEE Transactions on Communications, 64(5), 2130-2142.

- Ge, R., Pan, H., Lin, Z., Gong, N., Wang, J., & Chen, X. (2016, May). RF-powered battery-less Wireless Sensor Network in structural monitoring. In 2016 IEEE international conference on electro information technology (EIT) (pp. 0547-0552). IEEE.

- Cheng, J., Jin, J., Huang, Y., & Yu, P. (2020, October). Design of Positioning System for Underground Personnel and Electromechanical Equipment Using WSN. In 2020 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD) (pp. 1-2). IEEE.

- Sheth, S. D., Verma, Y., Kaur, G., & Chanak, P. (2021). An energy optimized routing algorithm for IoT-enabled WSN. In 2021 Fourth International Conference on Computational Intelligence and Communication Technologies (CCICT) (pp. 308-312). IEEE.

- Ismat, N., Qureshi, R., & Mumtaz ul Imam, S. (2019). Adaptive power control scheme for mobile wireless sensor networks. Wireless Personal Communications, 106(4), 2195-2210.

- Mazunga, F. (2021). Ultra-low power techniques in energy harvesting wireless sensor networks: Recent advances and issues. Scientific African, 11, e00720.

- Mohamed, M. I., Wu, W. Y., & Moniri, M. (2011, April). Power harvesting for smart sensor networks in monitoring water distribution system. In 2011 International Conference on Networking, Sensing and Control (pp. 393-398). IEEE.

- Minhas, U. I., Naqvi, I. H., Qaisar, S. B., Ali, K., Shahid, S., & Aslam, M. A. (2018). A WSN for Monitoring and Event Reporting in Underground Mine Environments. IEEE Systems Journal, 12(1), 485-496.

- Rodrigues, L., Leao, E., Montez, C., Moraes, R., Portugal, P., & Vasques, F. (2018). An advanced battery model for WSN simulation in environments with temperature variations. IEEE Sensors Journal, 18(19), 8179-8191.

- Castellanos, G., Deruyck, M., Martens, L., & Joseph, W. (2020). System assessment of WUSN using NB-IoT UAV-aided networks in potato crops. IEEE Access, 8, 56823-56836.

- Akkaş, M. A., & Sokullu, R. (2015). Wireless underground sensor networks: channel modeling and operation analysis in the terahertz band. International Journal of Antennas and Propagation, 2015.

- Adu-Manu, K. S., Adam, N., Tapparello, C., Ayatollahi, H., & Heinzelman, W. (2018). Energy-harvesting wireless sensor networks (EH-WSNs) A review. ACM Transactions on Sensor Networks (TOSN), 14(2), 1-50.

- Soomro, A. H., & Jilani, M. T. (2020, February). Application of IoT and artificial neural networks (ANN) for monitoring of underground coal mines. In 2020 international conference on information science and communication technology (ICISCT) (pp. 1-8). IEEE.

- Stajano, F., Hoult, N., Wassell, I., Bennett, P., Middleton, C., & Soga, K. (2010). Smart bridges, smart tunnels: Transforming wireless sensor networks from research prototypes into robust engineering infrastructure. Ad Hoc Networks, 8(8), 872-888.

- Lee, W. H., Kim, H., Lee, C. H., & Kim, S. M. (2022). Development of Digital Device Using ZigBee for Environmental Monitoring in Underground Mines. Applied Sciences, 12(23), 11927.

- Vallathan, G., Shiny, X. A., & Loga, K. (2020, July). Detection of hazardous gas using wearable wireless sensor networks for industrial applications. In 2020 International Conference on System, Computation, Automation and Networking (ICSCAN) (pp. 1-6). IEEE.