Anti-icing coating based on silicone resin SILRES® MSE100

Автор: Valentina I. Loganina, Svetlana N. Kislitsyna, Evgenia V.Tkach, Irina V. Stepina

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 3 Vol.15, 2023 года.

Бесплатный доступ

Introduction. The study is aimed at obtaining an anti-icing coating for building structures by creating a hydrophobic surface layer, which is regulated by surface energy and surface topography. Materials and methods. Acrylic resins A-01 and DEGALAN®, high-chlorinated polyethylene resin HCPE and silicone resin SILRES® MSE 100 were used in the research. Aerosil R 972 nanoparticles were used as a filler. The anti-icing properties of the coating were evaluated by the contact angle of the water drop with the coating, the static and dynamic contact angle, the wetting hysteresis, and the adhesion of ice to the superhydrophobic surface. Results and discussions. We have found that coatings based on acrylic resins A-01, DEGALAN®, high chlorinated polyethylene resin HCPE and silicone resin SILRES® MSE100 20% concentration do not provide superhydrophobic properties. The superhydrophobic effect is retained by coatings based on SILRES® MSE100 silicone resin 5% and 10% concentration. The force of detachment of a drop from a coating based on SILRES® MSE100 silicone resin at a 10% concentration is 3 times less, which ensures an easier rolling of a water drop from the surface and its anti-icing properties. The amount of ice on an untreated surface is 0.59 kg/m2, and on a surface treated with a composition based on SILRES® MSE100 silicone resin, it is 0.15 kg/m2. Conclusions. An anti-icing coating composition based on SILRES® MSE100 silicone resin has been developed. The proposed composition forms a coating characterized by anti-icing properties that remain in operation.

Superhydrophobic coating, aerosil nanoparticles, contact angle, anti-icing properties, freezing, adhesion

Короткий адрес: https://sciup.org/142238286

IDR: 142238286 | DOI: 10.15828/2075-8545-2023-15-3-211-219

Текст научной статьи Anti-icing coating based on silicone resin SILRES® MSE100

Original article

T he formation of icicles on the pitched roofs of houses and their subsequent fall can lead to serious and tragic consequences. Superhydrophobic coatings are used to protect building structures and facilities. Various compositions of anti-icing coatings are presented on the domestic market [1–3]. The purpose of anti-icing coatings is to reduce the adhesion of ice to the surface. Such coatings significantly reduce freezing and ensure rapid ice melting during repeated freeze-thaw cycles [4–6].

Despite the large number of proposed compositions, the problem of icing remains relevant. Some anti-icing coatings have low adhesion to ice, however, however, the coatings do not retain anti-icing properties for a long time [7–10].

The adhesive strength of ice to the coating is a function of its surface energy [11, 12]. With an increase in the difference between the values of surface tension σw of water and surface tension σcr of the coating, the spreading of water over the surface layer of the coating decreases, which leads to a reduction in the contact area between frozen water and the coating and, as a result, to a decrease in ice adhesion to the coating [13–15].

For most polymeric materials, adhesion with ice is more than 0.100 MPa. Practice shows that polymers should be used to combat icing, the thermodynamic characteristics of which meet the following requirements: σcr < 25 mJ / m2, contact angle of wetting with water more than 900. In this case, the adhesion strength of ice to the surface will not exceed 0.030 MPa.

CONSTRUCTION MATERIALS SCIENCE

Real surfaces are rough. With complete wetting of the surface irregularities by the liquid, the value of the wetting angle θ′ is determined by the Wenzel equation:

cosθ ′ = rcosθ, (1)

where r is the surface roughness, which is defined as the ratio of the true and apparent surface areas.

In a heterogeneous wetting regime, a liquid drop does not wet the entire surface, but only the tops of the surface relief. The value of the contact angle is determined by the Cassie-Baxter equation:

cosθ ′ = –1 + Ф s ( cosθ + 1), (2)

where Ф s is the fraction of the surface area in contact with the water drop.

Therefore, superhydrophobic surfaces should have a small fraction of the surface area in contact with the surface of the water drop. Thus, the mechanism of antiicing action is directly related to the hydrophobicity of the surface layer, which is regulated by the surface energy, and the surface topography [16–20].

The use of hydrophobic aerosil R-972 nanoparticles as a filler is promising. which has surface hydrophobic methyl groups.

Based on the foregoing, the development of the formulation of the anti-icing composition consisted in the selection of a binder and filler and their optimal content. In this case, we proceeded from obtaining the topography of the coating surface, which provides a heterogeneous wetting regime.

MATERIALS AND METHODS

The following types of resins were used in the work: A-01 acrylic resin, DEGALAN® acrylic resin, HCPE high-chlorinated polyethylene resin and SILRES® MSE100 silicone resin. Aerosil R 972 with a density of ρ = 2360 kg/m3, particle size 16 nm was used as a filler and specific surface Ssp = 12 000 m2/kg.

The degree of hydrophobicity was assessed by the value of the contact angle (θо) of a water drop from the coating. The contact angle was determined by the drop projection method. A drop of liquid on a horizontal test surface was projected onto a screen, and the angle θ was determined from the figure along the height (h) of the drop and the radius of the contact area of the drop with the test surface (r) using the formula:

at θ < 90о cosθ = (r2– h2) / (r2+ h2), (3)

at θ > 90о cosθ = (1–h)/r. (4)

Additionally, the contact angle was determined after wetting the coatings for 72 hours.

To characterize the anti-icing properties of the coatings, we used the value of the static and dynamic (advancing and receding) wetting angle, as well as the wetting hysteresis, for which the advancing angles θad and receding angles θrec were measured.

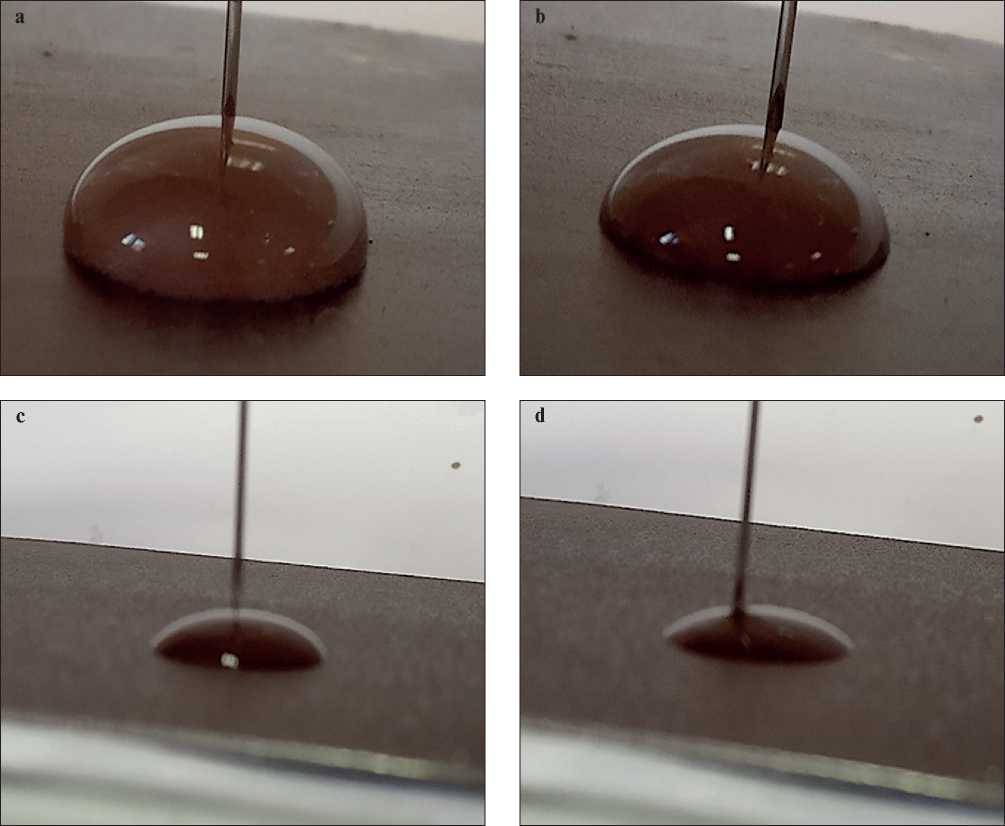

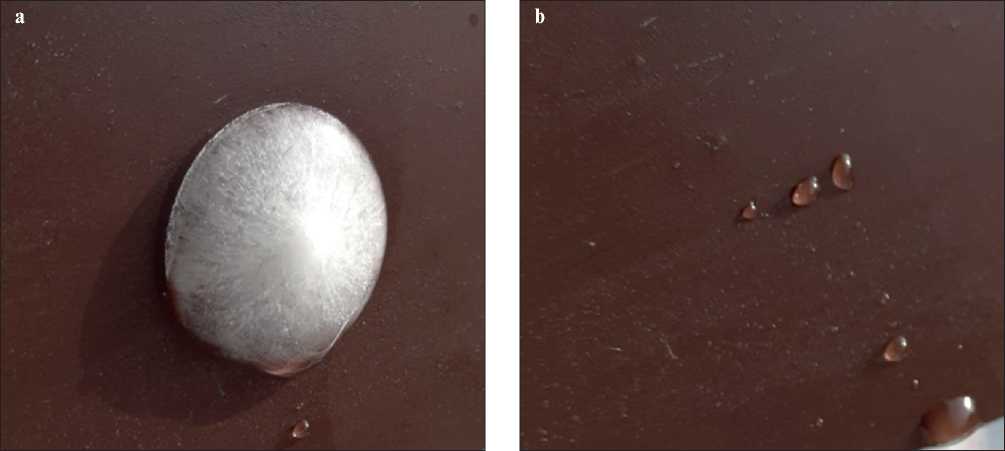

The dynamic contact angle was determined by the sessile drop method. To do this, a drop of water was placed on the surface of the coating using a syringe, the drop diameter was 2 to 5 mm. During the measurement of the incoming angle (θad), the syringe needle remained in the drop throughout the entire experiment. The receding angle (θrec) was measured when the droplet size decreased due to the suction of water through a syringe (Fig. 1). Wetting hysteresis was determined from the difference between the incoming angle and the outflowing angle.

The method for determining the critical angle at which a drop of water began to roll down from an inclined surface was as follows. A drop of water was placed on a metal plate, which gradually began to tilt. Metal plates of profiled roofing “MR-20” with a polymer coating were used as substrates. The composition of the anti-icing coating was applied to the plate, after curing of which a drop of water was applied to the surface. The static contact angle was determined by the sessile drop method using the formula (4).

The relative viscosity of the polymer solution was determined using a VZ-4 viscometer. The adhesion of the coatings to the substrate was evaluated by the lattice notch method in accordance with GOST 15140-78 “Paint-and-lacquer materials. Methods for determining adhesion”.

To evaluate the interaction between the film former and aerosil nanoparticles, an FSM 1201 FT-IR spectrometer (OOO Infraspek, Russia) was used with a MATTR36 multiple total internal reflection violation attachment with a ZnSe prism and a PZO10 specular reflection attachment. The measurements were carried out in the spectral range 650–3950 cm–1 with a resolution of 4 cm–1.

Resin was applied to aluminum foil substrates, which acted as a reference sample. Aerosil samples, which are ultrafine powder, were measured using the ATR method in the spectral range 650–4250 cm–1 with a resolution of 4 cm–1 without additional sample preparation.

The calculation of the optimal content of the filler was carried out according to the formula:

_ ______Pbulk______ т Л8$ррИС1 a , (5)

РИСТХ 6

where Ssp is the specific surface area of the filler.

The specific surface area was determined using a PSKh-12 instrument.

CONSTRUCTION MATERIALS SCIENCE

Fig. 1. Photo of a water drop on a metal surface: a, b – on a superhydrophobic surface; c, d – on the hydrophilic surface; a, c – leakage; b, d – outflow

RESULTS

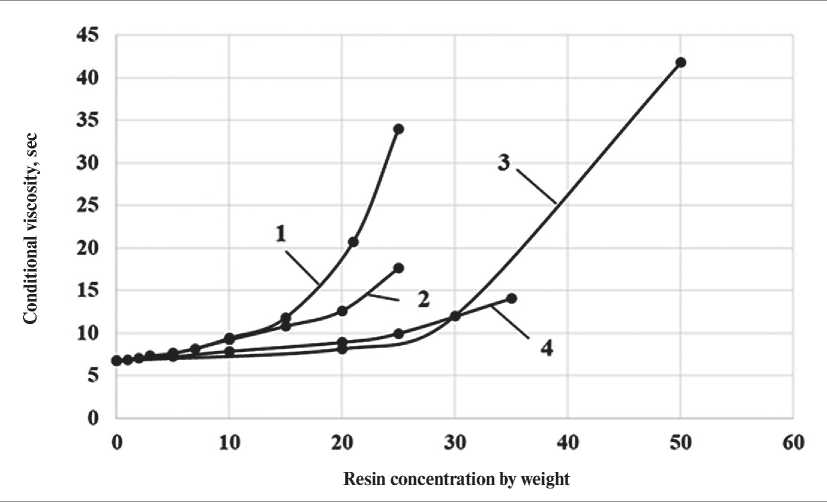

Fig. 2 shows the dependence of the viscosity of the resin solution on its concentration in the solvent (xylene).

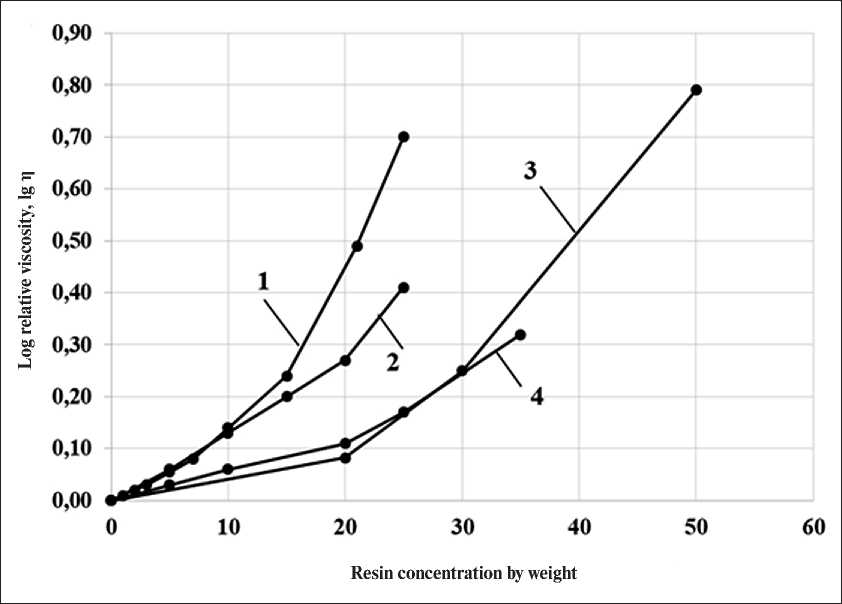

Representing the dependence of the viscosity of the polymer solution in semilogarithmic coordinates (Fig. 3), we obtain two intersecting lines. The point of intersection, projected onto the x-axis, will represent the critical concentration of the polymer in solution.

It has been established that the critical concentration of the polymer solution in xylene is 12% for highly chlorinated polyethylene resin HCPE, 20% for acrylic resin A-01, silicone resin SILRES® MSE100, acrylic resin DEGALAN (Fig. 3). For further studies, the concentration of resins in the solution was taken to be less than the critical one, since the practical concentration of the polymer in the solution should be lower than the critical one.

It has been established that the optimal content of Aerosil R 972 nanoparticles for acrylic resin A-01, high-chlorinated polyethylene resin HCPE is V = 0.008, for silicone resin SILRES® MSE100 – 0.009, for acrylic resin DEGALAN – 0.012. In Table 1 shows the contact angle values for various formulations.

Analysis of the data given in Table 1 indicate that coatings based on A-01 acrylic resins, DEGALAN® and high chlorinated polyethylene resin HCPE do not provide super hydrophobic properties after wetting. The contact angle of wetting is less than 150 degrees and is 81–86 degrees (on a metal substrate) and 104–124 degrees (on a solution substrate). Coatings based on SILRES® MSE100 20% silicone resin, although having a higher contact angle, are also not superhydrophobic. The contact angle of wetting on metal and mortar substrates is less than 150 degrees.

The superhydrophobic effect was retained by coatings based on SILRES® MSE100 5% silicone resin and

CONSTRUCTION MATERIALS SCIENCE

Resin concentration by weight

Fig. 2. The dependence of the nominal viscosity of the polymer solution on the concentration of the resin: 1 – highly chlorinated polyethylene resin HCPE; 2 – acrylic resin A-01; 3 – silicone resin SILRES® MSE100; 4 – acrylic resin DEGALAN

Fig. 3. The dependence of the viscosity of the polymer solution on the concentration of the resin in semi-logarithmic coordinates: 1 – high chlorine HCPE polyethylene resin; 2 – acrylic resin A-01;

3 – silicone resin SILRES® MSE100; 4 – acrylic resin DEGALAN

CONSTRUCTION MATERIALS SCIENCE

10% concentration – the wetting angle on the solution substrate was more than 150 deg. Adhesion of coatings to the substrate after wetting is 1 point.

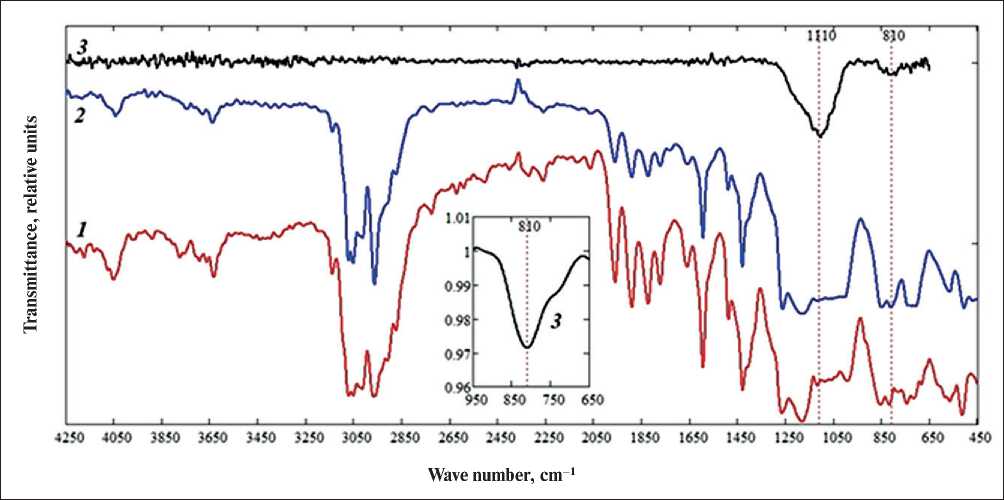

Fig. 4 presents the results of spectroscopic studies of the organosilicon binder type SILRES MSE100 with and without the addition of aerosil, and for comparison, the IR transmission spectrum of aerosil is shown separately.

Analysis of the presented IR spectra shows that Aerosil powder is chemically pure (within the resolution of the method) silicon dioxide, which is characterized by the presence of vibrational modes at 810 and 1110 cm–1. The first of the modes corresponds to the twisting vibrations of Si2O, and the second can be reliably attributed to the stretching symmetric and asymmetric vibrations of the bridging oxygen of the Si–O–Si bonds.

The introduction of an aerosil additive into the structure of the SILRES MSE100 organosilicon binder does not lead to a significant change in its qualitative composition, which can be judged by almost identical IR transmission spectra (Fig. 4). In this case, new types of vibrations corresponding to the chemical bonding of SiO2 and organosilicon are not observed, which, apparently, is due to the physical mechanism of interaction between aerosil and the binder. However, the decrease in the intensity of the absorption peaks at 1650 and 3640 cm–1, as well as in the spectral range 1750–2000 cm–1, observed in the IR spectra, allows us to conclude that aerosil nanoparticles have some effect on the SILRES MSE100 condensation process, in particular, on the removal from its structures are water, simple alcohols, and cyclic anhydrites.

The dependence of the wetting characteristics during the spreading of a drop on the surface of the coat-

ing was studied on the basis of the proposed composition. The values of the contact angles are presented in Table 2 and clearly confirm the presence of hysteresis on the surface.

At an angle of inclination of the metal plate of 10o, a drop of water from the superhydrophobic surface begins to roll down (Fig. 5).

In addition, a calculation was made of the force at which a drop of water rolls down an inclined surface. The volume of a water drop was 0.05 ml and was the same for different surfaces. In this case, its mass was determined in accordance with the formula m = Vρ, (6)

where ρ is the density of water.

Rolling occurs when the trailing edge of the drop breaks off. The drop separation condition is determined by the expression

F = mqsin α, (7)

where m is the mass of a water drop, kg;

α is rolling angle, deg;

F is tear-off force, n.

The force F is the sum of the adhesion values of a water drop and the friction force.

Table 3 shows the values of the force F for a hydrophilic and superhydrophobic surface.

A 3-fold decrease in the force of detachment of a drop from an anti-icing coating was revealed, which ensures an easier rolling of a drop of water from the surface.

Table1

The value of the contact angle on the anti-icing coating based on various resins

|

Resin type |

Resin concentration, % |

Volume content of filler |

Contact angle (θо), deg,* |

|

|

on a mortar substrate |

on a metal substrate |

|||

|

High chlorinated polyethylene resin HCPE |

15 |

0.009 |

150 124 |

170 86 |

|

Acrylic A-01 |

20 |

0.008 |

151 103 |

175 81 |

|

DEGALAN® Acrylic resin DEGALAN® |

20 |

0.012 |

152 110 |

154 83 |

|

Silicone resin SILRES® MSE100 |

20 |

0.009 |

152 104 |

176 104 |

|

Silicone resin SILRES® MSE100 |

5 |

0.009 |

160 151 |

– |

|

Silicone resin SILRES® MSE100 |

10 |

0.004 |

162 153 |

– |

Note. * Above the line are the values of the contact angle before wetting, under the line – after 72 hours of wetting

CONSTRUCTION MATERIALS SCIENCE

Fig. 4. IR transmission spectra: 1 – organosilicon binder SILRES MSE100; 2 – organosilicon binder with the addition of aerosil; 3 – aerosil

Table 2

Contact angle for water on a surface

|

Surface type |

Static wetting angle |

Off angle |

Leak angle |

Wetting hysteresis |

|

silicone resin coating SILRES® MSE100 |

164 |

162.8 |

166.5 |

3.7 |

|

hydrophilic |

25.4 |

21.1 |

45 |

23.9 |

Fig. 5. Photo of a water drop on the surface of an anti-icing coating on a metal surface: a – in its original state; b – after 1 second of rolling; c – after 2 seconds of rolling

Table 3

Rolling angle of a water drop from the surface

|

Surface type |

Rolling angle, degree |

Breakaway force, n |

|

roofing corrugated sheets “MR-20” (hydrophilic surface) |

31 |

2.55•10–4 |

|

MR-20 corrugated roofing sheets are treated with a composition based on SILRES® MSE100 silicone resin |

10 |

0.85•10–4 |

CONSTRUCTION MATERIALS SCIENCE

Fig. 6. Photo image of ice rolling off a superhydrophobic surface: a – the beginning of ice rolling; b – after rolling

Fig. 7. Photo of an image of ice rolling from a hydrophilic surface (freezing temperature –10оC)

It has been established that the removal of ice from a superhydrophobic surface at room temperature at a plate inclination angle of 90 degrees begins after 1 minute 55 seconds, and after 3 minutes the ice has fallen from the plate (Fig. 6). Removal of ice from the hydrophilic surface is not observed; after 6 minutes of being at room temperature, the ice melted (Fig. 7).

It was found that the amount of ice on the hydrophilic surface is 0.59 kg/m2, and on the surface treated with a composition based on SILRES® MSE100 silicone resin, it is 0.15 kg/m2.

CONCLUSIONS

An anti-icing coating composition based on 5% and 10% concentration SILRES® MSE100 silicone resin and R 972 aerosil nanoparticles has been developed. The composition is designed to protect building structures from icing. The results of the conducted studies indicate that the proposed composition forms a coating characterized by anti-icing properties that remain during operation.

Список литературы Anti-icing coating based on silicone resin SILRES® MSE100

- Shevchenko V.Ya., Shilova O.A., Kochina T.A., Barinova L.D., Belyi O.V. Resource saving and safety in transport through the introduction of environmentally friendly protective coatings. Physics and chemistry of glass. 2019; 45(1): 3-15. https://doi.org/10.1134/S0132665119010074

- Solovyanchik L.V., Kondrashov S.V., Nagornaya V.S., Melnikov A.A. Features of obtaining anti-icing coatings. Proceedings of VIAM. 2018; 6: 77-98. https://doi.org/10.18577/2307-6046-2018-0-6-77-98

- Liu J., Wang J., Mazzola L., Memon H., Barman T., Turnbull B. Development and evaluation of poly(dimethylsiloxane) based composite coatings for icephobic applications. Surface and coatings technology. 2018; 349: 980-985. https://doi.org/10.1016/j.surfcoat.2018.06.066

- Rongxian Qiu, Zhongxin Li, Zhilin Wu. Enhanced anti-icing and anti-corrosion properties of wear-resistant superhydrophobic surfaces based on Al alloys. Materials research express. 2019; 6(4): article 045059. https://doi.org/10.1088/2053-1591/aatdf1

- Boinovich L.B. Superhydrophobic coatings are a new class of polyfunctional materials. Bulletin of the Russian Academy of Sciences.2013; 8(1): 10-22. https://doi.org/10.7868/S0869587313010039

- Kreder M.J., Alvarenga J., Kim P., Aizenberg J. Design of anti-icing surfaces: smooth, textured or slippery? Nature Reviews Materials. 2016;1(1): 15003. https://doi.org/10.1038/natrevmats.2015.3

- Boinovich L.B., Emelianenko A.M. Hydrophobic materials and coatings: principles of creation, properties and application. Advances in chemistry. 2008; 77: 619-638). https://doi.org/10.1070/RC2008v077n07ABEH003775

- Rajiv S., Kumaran S., Sathish, M. Long-term-durable anti-icing superhydrophobic composite coatings. Journal of applied polymer science. 2018;136(7): 47059. https://doi.org/10.1002/app.47059

- Zheng Shunli, Bellido-Aguilar, Daniel Angel; Wu Xinghua. Durable Waterborne Hydrophobic Bio-Epoxy Coating with Improved Anti-Icing and Self-cleaning performance. Acs sustainable chemistry & engineering. 2019; 7(1): 641-649. https://doi.org/10.1021/acssuschemeng.8b04203

- Rongxian Qiu, Zhongxin Li, Zhilin Wu. Enhanced anti-icing and anti-corrosion properties of wear-resistant superhydrophobic surfaces based on Al alloys. Materials research express. 2019; 6(4): article 045059. https://doi.org/10.1088/2053-1591/aatdf1

- Piscitelli F., Tescione F., Mazzola L. On a simplified method to produce hydrophobic coatings for aeronautical applications. Applied surface science. 2019; 472(SI): 71-81. https://doi.org/10.1016/j.apsusc.2018.04.062

- Xinghua Wu, Silberschmidt Vadim V., Zhong-Ting Hu. When superhydrophobic coatings are icephobic: Role of surface topology. Surface & Coatings technology. 2019; 358: 207-214. https://doi.org/10.1016/j.surfcoat.2018.11.039

- Boinovich L.B., Emelianenko A.M. Hydrophobic materials and coatings: principles of creation, properties and application. Chemistry Advances. 2008; 77(7): 619–638. https://doi.org/10.1070/RC2008v077n07ABEH003775

- Loganina V.I. Study of the kinetics of freezing of a water drop on a superhydrophobic surface of coatings. Bulletin of MGSU. 2019;14(4):311-317. https://doi.org/10.22227/1997-0935.2019.4.435-441

- Loganina V.I., Kislitsyna S.N., Sergeeva K.A. Comparative evaluation of ice adhesion to superhydrophobic and hydrophilic coatings. Izvestiya vuzov. Construction.2019;4: 28-34.

- Zhang H.Y., Yang Y.L., Pan J.F. Compare study between icephobicity and superhydrophobicity. Physica b-condensed matter. 2019;556:118-130. https://doi.org/10.1016/j.physb.2018.12.014

- Nosonovsky M., Bhushan B. Superhydrophobic Surfaces and Emerging Ap-plications: Nonadhesion, Energy, Green Engineering. Current opinions coll. interface sci. 2009; 14: 270–280. https://doi.org/10.1016/j.cocis.2009.05.004

- Venkateswara Rao A., Latthe S.S., Nadargi D.Y., Hirashima H., Ganesan V. Preparation of MTMS based transparent superhydrophobic silica films by sol-gel method. J. colloid interf. Sci. 2009; 332(2):484–490. https://doi.org/10.1016/j.jcis.2009.01.012

- Shilova O.A., Proskurina O.I., Antipov V.N., Khamova T.V., Esipova N.E., Pugachev K.E., Ladilina E.Yu., Kruchinina I.Yu. Sol-gel synthesis and hydrophobic properties of anti-friction coatings for use in high-speed miniturbo generators. Physics and Chemistry of Glass. 2014; 40(3): 419–425.

- Shen Yizhou, Wu Yu, Tao Jie. Spraying Fabrication of Durable and Transparent Coatings for Anti Icing Application: Dynamic Water Repellency, Icing Delay, and Ice Adhesion. Acs applied materials & interfaces. 2019; 1: 3590-3598. https://doi.org/10.1021/acsami.8b19225