Antistatic polymer materials

Автор: Pavel A. Yudaev, Bakary Tamboura, Evgeniy M. Chistyakov

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 2 Vol.15, 2023 года.

Бесплатный доступ

Introduction. In connection with the growing demand for living and working conditions in civil and industrial construction, there is an increasing need for high-quality building materials with the required set of performance properties. Polymer reinforced composite materials are promising materials in the construction industry due to their high strength, durability, reliability and economy. Polymers such as polyvinyl chloride, polyurethanes, polyacrylates, epoxy resins, polypropylene are used in construction for the manufacture of decorative elements, self-leveling floors, coatings for appliances and equipment. However, the use of polymeric materials creates risks of electric shock due to the generation of static charge. The use of electrically conductive nanomaterials as fillers makes it possible to reduce the resistivity of polymeric materials and slow down the flow of electric charges. Main part. This review article presents the benefits and drawbacks of antistatic additives for polymer materials used in industry and in the construction industry. Conclusion. An analysis of the literature has shown that over the past seven years, the largest number of relevant papers has been devoted to carbon materials as antistatic additives (8 articles), metal and metal oxide nanoparticles (7 articles), ionic liquids (7 articles), and polyaniline (7 articles). The most studied characteristics of antistatic polymer materials are the specific surface RS and volume RV resistances. According to the reviewed articles, metal and metal oxide nanoparticles are the most suitable antistatic additives to polymeric materials, since they are well dispersed in the polymer matrix. However, further research is needed to eliminate the negative effect of nanoparticles on the mechanical properties of polymeric materials.

Nanoparticles, static electricity, carbon nanotubes, graphene oxide, ionic liquids, construction industry

Короткий адрес: https://sciup.org/142237970

IDR: 142237970 | DOI: 10.15828/2075-8545-2023-15-2-139-151

Текст научной статьи Antistatic polymer materials

Review article

Static electricity is a serious problem for industrial production [1], industrial and civil construction, hospital wards [2]. This is explained by the fact that static charges create a fire and explosion hazard [3, 4]. Static electricity is caused by accumulation of positive or negative charges on the surface of polymer coatings and paintwork materials, for example, an excess of electrons due to surface friction upon contact with dust [5, 6]. Instruments, equipment and packaging used at industrial plants are made of polymeric materials with high surface resistivity, which is about 1011–1014 Ω/cm2 [7]. To eliminate static electricity at industrial plants and in the household, it is necessary to develop antistatic coatings for measuring instruments and equipment, panels of internal and external walls of buildings, which, unlike polymers, have high electrical conductivity and allow safe discharge of excess charge into the ground [8]. To remove the charge, the coating must have an electrical resistivity in the range of 103–1010 Ω/ cm2 [9]. With a lower resistivity, the risk of electric shock to the human body increases [10].

Conductive ionic liquids [11], metal [12] and metal oxide [13] nanoparticles, carbon nanotubes [14], graphene oxide nanosheets [15], conductive polymers (polyaniline, polythiophene, polypyrrole) [16], and surfactants [17] are used as additives to polymer coatings that endow them with antistatic properties.

Nanomaterials are widely used in the construction industry. Nanoparticles are added to paints and varnishes to make them antistatic and scratch resistant and to protect them against dust and fog. The adhesives used for the manufacture of antistatic floors based on nanomaterials have a high electrical conductivity [18]. Coatings containing nanomaterials reduce dust adhesion on photovoltaic panels that are placed on the roofs of eco-buildings [19].

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

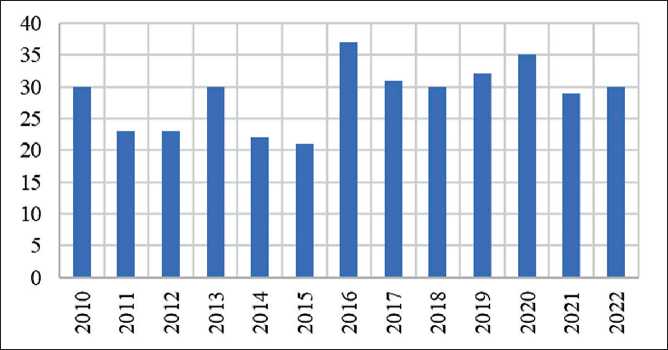

Fig. 1. Number of articles according to the Scopus database (search query: antistatic coatings)

The development of antistatic additives for polymer coatings is a promising area of research, as evidenced by a large number of articles published in the period of 2010– 2022, according to the Scopus database (Figure 1). From the above data, it can be seen that the greatest interest in this topic was observed in 2016, while the smallest interest was expressed in 2015. In 2022, the number of publications has decreased with respect to 2016, but the interest in antistatic coatings is still high (30 articles per year).

CARBON-BASED ANTISTATIC ADDITIVES

Carbon-based conductive fillers include carbon black [20, 21], carbon fibers [1, 22], carbon nanotubes [13, 23–26], graphite [27], graphene [28, 29], and graphene oxide (GO) [30, 31].

Carbon nanotubes

Carbon nanotubes, particularly multi-walled carbon nanotubes (MWCNTs), are used most widely due to their low weight, large aspect ratio, good mechanical properties, chemical stability, and electrical conductivity comparable to that of metals [32].

The main disadvantage of using carbon nanotubes in antistatic polymer coatings is their low degree of dispersion in polymer matrices, especially in highly crystalline polymers, due to their entanglement and aggregation into bundles [33, 34]. This is caused mainly by high energy of van der Waals interactions and electrostatic forces in MWCNTs. To improve the dispersion of MWCNTs in the polymer, the nanotubes are treated with stabilizing compounds using covalent and non-covalent (or ultrasonic) modification [35, 36].

The non-covalent modification without the formation of chemical bonds between MWCNTs and the stabilizer is the method of choice, since the covalent modification may cause rupture into shorter segments [37]. For example, Yan W. et al. used environmentally friendly and cheap tannic acid as a stabilizer. The authors attributed the stabilizing effect to the formation of non-covalent π-π bonds between the aromatic phenol rings of tannic acid and graphene structures of the nanotubes [38].

Liu L. et al. [39] used MWCNTs (Seoul, Korea, 10– 20 nm in diameter, 20–100 µm long) stabilized with environmentally friendly poly(tannin urethane) to produce an antistatic coating based on poly(vinyl chloride) (PVC).

When MWCNTs were added to the polymer, the surface resistance decreased from 1016 to 108 Ω/cm2. Moreover, the content of the antistatic additive was low and amounted to 0.5 wt. %. Poly(tannin urethane) showed an excellent dispersing ability for MWCNTs. Considering the poly(tannin urethane) structure, the authors concluded that the aromatic rings of poly(tannin urethane) were attached to the MWCNT surface via π–π interactions, which promoted disaggregation [40].

The authors [39] compared the characteristics of the fabricated PVC coating with the coatings based on polyurethane-containing MWCNTs and found that the coating showed similar surface resistivity characteristics [39, 41].

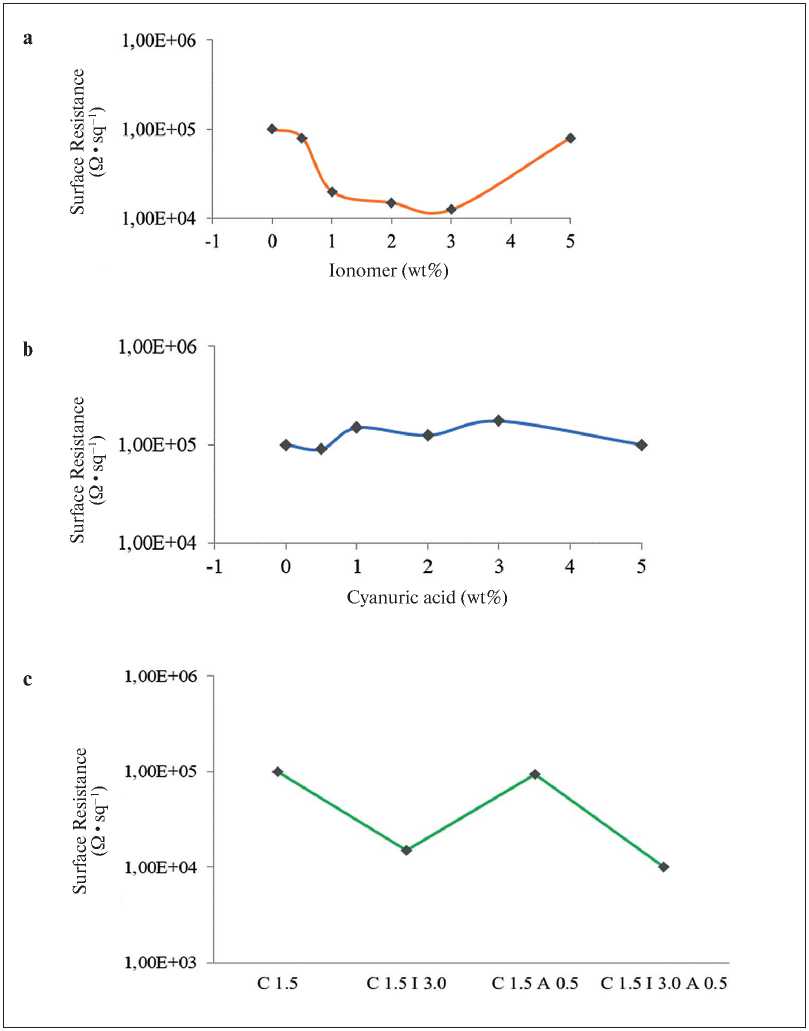

Cyanuric acid and an ionomer based on the ethylene-co-acid-co-sodium acid copolymer were used to enhance the MWCNT dispersion in the polyoxymethylene matrix and to improve the electrical properties (electrical conductivity, surface resistance) of the polymer nanocomposite [42]. As a result, the surface resistance of the composites was reduced by an order of magnitude compared to pure polyoxymethylene (Figure 2). It was found that the most pronounced decrease in the surface resistance is achieved at an ionomer concentration of 3 wt. % (Figure 2 a) and cyanuric acid concentration of 0.5 wt. % (Figure 2 b). The authors explained the MWCNT stabilization by non-covalent π-π interaction with the external surface of the nanotube (wrapping of nanotubes) for cyanuric acid and cation-π interaction for the ionomer.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 2. Surface resistance of composites containing MWCNTs the surface of which is coated with ionomer (a), cyanuric acid (b), and ionomer and cyanuric acid (c) vs. concentration of the additive. С are nanotubes, I is ionomer, A is cyanuric acid [42]

However, the disadvantage of polymeric materials obtained in [39, 42] is weak adhesion, which leads to a short service life and environmental pollution, as well as to low tensile strength and impact strength.

Reduced graphene oxide as an antistatic additive

Reduced graphene oxide (rGO) nanosheets, like carbon nanotubes, have high mechanical strength, large specific surface area, and high electrical conductivity, which makes them promising for use in polymer composites as antistatic agents [43–46]. However, the disadvantage of graphene oxide nanosheets, unlike nanoparticles of metals and metal oxides, is their poor dispersibility in the polymer matrix, which makes it difficult to create electron-conducting paths [47, 48]; one more drawback is low stability. To improve the dispersibility, graphene oxide is coated in situ with chemical modifiers, in particular surfactants [49, 50] or polymers

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

-

[51 ]. For example, polydopamine with catechol, amino, and imino functional groups covalently grafted to GO surface provides good dispersibility with polyurethane due to improved interfacial adhesion [52]. The poor dispersibility and tendency to aggregation and exfoliation of reduced graphene oxide nanosheets is due to van der Waals forces at the nanosheet interface [53].

The chemical modification of graphene oxide with dimethylformamide and carboxylic acids generated a positive charge on graphene sheets with a zeta potential of about 20 mV [54]. The addition of rGO to water-based polyurethane coatings made it possible to reduce the surface electrical resistance by five orders of magnitude. In the presence of 3 wt. % rGO, the surface electrical resistance was 5.4 109 Ω/cm2, which is sufficient for the manufacture of antistatic coatings. The authors attributed this fact to sp2 hybridization in the rGO structure. The use of rGO nanohybrids with conductive polymers, in particular polyaniline, reduced the surface resistivity down to 106 Ω/cm2 [54]. According to the authors [54], this was a result of the synergistic effect of rGO and polyaniline caused by the conjugated structure of polyaniline.

However, the authors [54] did not provide a detailed explanation of how the conducting paths are formed in the polyurethane matrix, which is a significant drawback of the study.

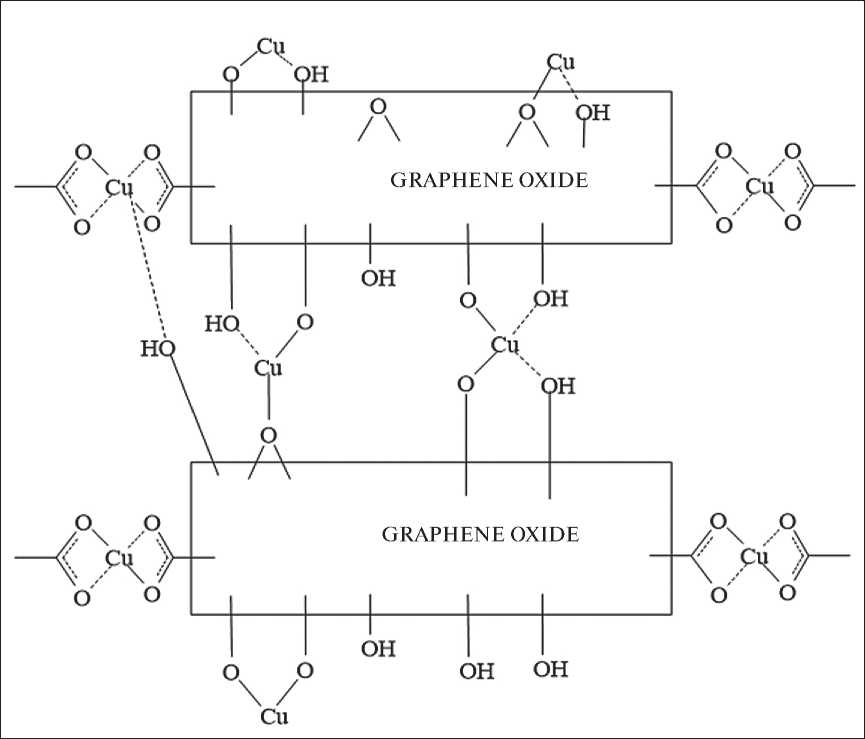

In another work [55], rGO nanosheets and copper nanoparticles were introduced into a polyurethane coating (the content of the additives was 3 wt. %). This resulted in a decrease in the surface resistivity of polyurethane from 1014 Ω/cm2 to 109 Ω/cm2. The authors suggested that the synergistic antistatic effect was due to the formation of conducting paths by copper nanoparticles, which acted as conductors between the rGO nanosheets (Figure 3).

Thus, small amounts of carbon-based additives reduce the surface resistivity of polymeric materials by several orders of magnitude. However, carbon-based fillers can deteriorate the mechanical properties and increase the water uptake of polymer coatings [54]. The main problem associated with the use of carbon materials in industry is the difficulty of their dispersion in polymers and the need to endow polymer fibers and textiles with hydrophilicity needed for their processing [56]. Carbon fillers deteriorate the film transparency of films, which requires the use of

Fig. 3. Structure resulting from the reaction of rGO and copper(II) sulfate [55]

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION layer-by-layer assembly. For example, in order to maintain the film transparency [57], poly-L-lactide films were successively treated with two types of polyelectrolytes: positively charged chitosan or polyethyleneimine and negatively charged GO. This method allows deposition of multiple bilayers on the film.

Surfactants as antistatic additives

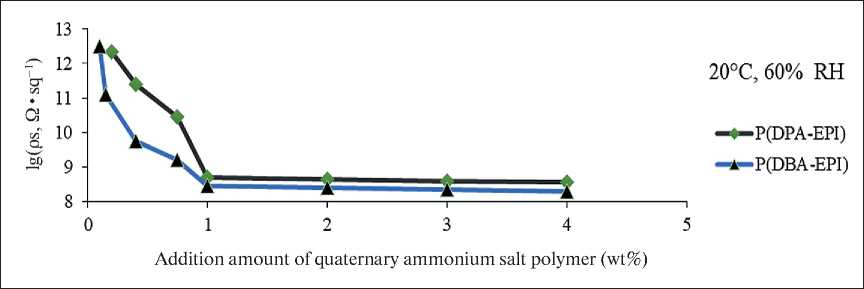

The surfactants applicable as antistatic additives include compounds containing hydrophilic groups and lipophilic hydrocarbon groups. This makes it easy to combine surfactants with epoxy resins [58], PVC [59], and textile fibers based on polyesters [60]. Cationic surfactants, that is, quaternary ammonium salts, are used most widely as antistatic agents, since they are readily soluble in epoxy resins and are easily adsorbed on negatively charged polyester fibers without damaging them [61]. For example, antistatic coatings based on epoxy resin (E-51), polyetheramine (hardener), and quaternary ammonium salts of poly(di-n-propylamine-co-epichlorohydrin) P(DPA-EPI) and poly(di-n-butylamine-co-epichloro-hydrin) P(DBA-EDI). The coatings were deposited on a polypropylene substrate. The coatings retained their transparency when the surfactant was added. To achieve the antistatic effect, only 1 wt. % surfactant was required (Figure 4). As a result, the surface resistivity decreased by four orders of magnitude (from 1012 to 108 Ω/cm2). According to the authors, this was due to the adsorption of air moisture by the surfactant and the formation of a conductive hygroscopic layer by the polar hydroxyl and quaternary ammonium groups of the surfactant.

In addition, the surface resistivity of the coatings with P(DBA-EDI) decreased to a higher extent than that of the coatings containing P(DPA-EPI). Thus, the length of the hydrocarbon chain at the nitrogen atom affects the antistatic properties of epoxy coatings.

However, a drawback of surfactants is their migration to the surface of the polymer material over time, which leads to the loss of antistatic properties [62]. In addition, the hardness of epoxy coatings decreases upon the addition of surfactants, despite good adhesion [56]. Therefore, the interest in the use of surfactants in antistatic polymeric materials is declining.

Nanoparticles as antistatic additives

Nanoparticles of metals and metal oxides provide electrically conductive structures for polymer coatings [63]; unlike carbon particles, they are easily dispersed in the polymer matrix [64], generating a long-term antistatic effect; unlike surfactants, they do not migrate to the surface of the polymer material and are not leached [65, 66]; in addition, they improve the UV resistance of polymer fibers [64, 67–69].

Zhang. J. et al. [70] fabricated an antistatic coating based on polypropylene decorated with silver nanoparticles incorporated in the porous structure of coal gasification slag microbeads. Due to the small particle size, low density, and large specific surface area, silver nanoparticles were easily built into microbeads, and the filler was easily dispersed in the polypropylene matrix. Upon the addition of 10 wt. % of microbeads into the polypropylene matrix, the volume resistivity was 3.35•105 Ω•cm; this fits into the range required for antistatic properties. However, the filling deteriorated the mechanical properties of polypropylene. In particular, the mechanical strength of polypropylene decreased, which was explained by an increase in stress concentration at the polymer-filler interface. However, a shortcoming of this study is the lack of explanation why silver nanoparticles were used in microbeads rather than by themselves.

Nanoparticles of metal oxides, for example, aluminum(III) oxide, zinc(I) oxide, iron(III) oxide, and zirconium oxide (IV), are environmentally benign, chemically stable, and inexpensive antistatic additives for polymer coatings and fibers [63, 71, 72].

Fig. 4. Change in the surface resistivity of the epoxy coating with increasing surfactant content.

RH is air humidity [58]

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

The introduction of aluminum oxide nanoparticles (particle size of 20–40 nm) into polypropylene was shown to increase the electrical conductivity of polypropylene [73]. The modified polypropylene was meant for the use as an antistatic coating for tools and instrumental equipment. It was reported that an increase in the nanoparticle concentration from 1 to 5 wt. % led to a decrease in the surface resistivity of the modified samples. When the concentration of nanoparticles in the composite was low (below 5 wt. %), the modification resulted in increasing tensile strength. However, when the concentration of nanoparticles in the polypropylene bulk was 30 wt. %, the mechanical and surface properties of polypropylene are deteriorated. Electron irradiation of modified polypropylene samples slightly increased the conductivity (on average, by 5–6%). The authors interpreted this fact by assuming that polypropylene chains break on exposure to radiation, resulting in an increase in the number of free radicals and unsaturated bonds and in the formation of conjugated double bonds.

The application of 6 wt. % zirconium dioxide nanoparticles with a size of 20–50 nm and a spherical shape in polyurethane coatings makes it possible to dissipate the electrostatic charges and reduce the surface resistivity to 109 Ω/cm2. In addition, an advantage of zirconium dioxide nanoparticles over other nanoparticles is their ability to improve the adhesive strength of a polyurethane coating and form a rough structure on the coating surface, which prevents dust accumulation [74].

However, there are no data in the literature [63, 71– 74] on the mechanism of the antistatic action of metal oxide nanoparticles.

Despite the fact that metal and metal oxide nanoparticles are better dispersed in the polymer matrix than carbon materials, higher concentrations of nanoparticles compared to the concentrations of carbon materials are required to attain the antistatic effect; this results in deterioration of mechanical properties. In addition, metal nanoparticles (copper, silver) are prone to oxidation, which necessitates their additional processing, in particular, alloying [75].

Ionic liquids as antistatic additives

Ionic liquids (ILs) are salts with high thermal stability and low combustibility [76]. They represent a promising alternative to nanosized powdered inorganic fillers of polymeric materials due to their environmental safety and the possibility of using renewable natural raw materials for their manufacture [77–83]. Ionic liquids can reduce the resistivity of polymer coatings in both wet and dry states. For example, Mudzakir A. et al. [84] tested an ionic liquid, cis-oleylimidazolinium iodide, as an antistatic agent in ceramic and wooden floor coverings. The ionic liquid was mixed with polyurethane. The surface resistivity of the coating with IL (2–9 wt. %) was in the range from 106 to 109 Ω/cm2, which allows slow and safe discharge of the electrical charge into the ground. According to the authors [84], the antistatic properties of IL were due to the electrical conductivity of iodide ions and to the ability to attract less dust. The resulting coating can be used in the construction industry for floor treatment and as a decorating element. A disadvantage of the reported coating and of the study as a whole is the yellow color of the resulting

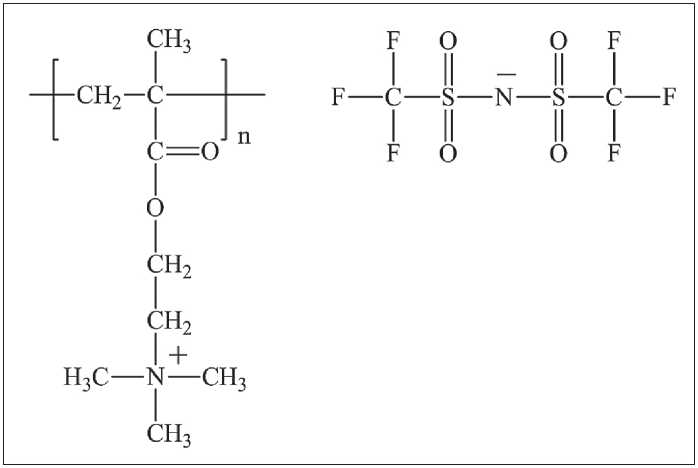

Fig. 5. Polymerized bis(trifluoromethanesulfonimide) [2-(methacryloyloxy)ethyl] trimethylammonium [85]

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Table 1

Specific surface RS and volumetric RV electrical resistances of polyurethane films containing IL

To eliminate this drawback, a iodine-free IL, that is, polymerized bis(trifluoromethanesulfonylimide) [2-(methacryloyloxy)ethyl]trimethylammonium was utilized as a filler for polyurethane films [85] (Figure 5).

Owing to the use of IL, it was possible to reduce the surface and volume resistivity of polyurethane by two to three orders of magnitude at a low filler concentration of only 1000 ppm (Table 1). The film retained transparency upon addition of IL. The authors interpreted the mechanism of the antistatic action of IL by assuming that IL dissociates in the polyurethane matrix and [Tf2N]-anions migrate along the fluctuations of polyurethane chains [84]. This IL was not washed away from the film in a methanol solution. However, a disadvantage of this IL is the fact that it is a solid, which complicates its dispersion in the polymer matrix.

The incorporation of ILs into poly(methyl methacrylate) and poly(butyl methacrylate) films and polyurea-based coatings made it possible to reduce their resistivity without loss of transparency [86–88]. Lower-viscosity ILs containing shorter alkyl chains have better antistatic properties [86, 88]. This is explained by the fact that an elonga- tion of the IL alkyl chain leads to an increase in the van der Waals forces and a decrease in the ion mobility [89–91]. However, ILs based on imidazolium and ammonium cations are better compatible with the acrylate matrix than phosphonium cations, which is due to their better solubility [86]. Therefore, the compatibility of ILs with polymers is greatly affected by the hydrophobicity of the cations.

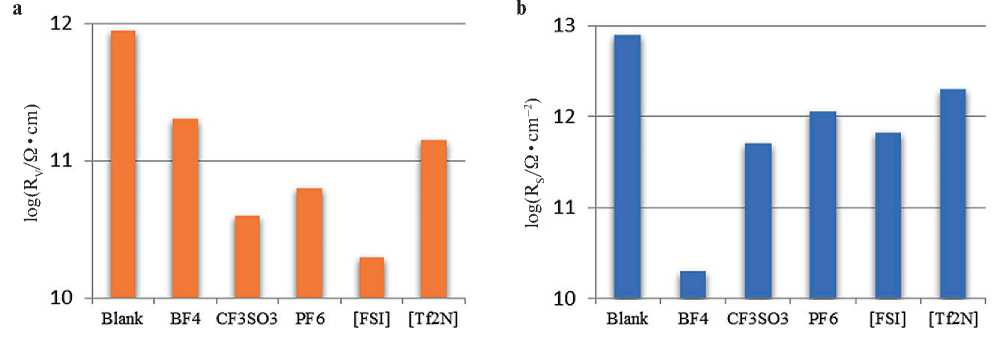

Ionic liquid anions also affect the conductivity. Tsurumaki A. et al. [86] compared the volume and surface resistivity of poly(butyl methacrylate) films (Blank) containing ionic liquids based on imidazolium cations [C4mim]+ and [BF4]–, [CF2SO3]–, [PF6]–, [FSI]–, and [Tf2N]– anions. The most pronounced decrease in the surface resistivity was attained for the IL with the [BF4]– anion, while the smallest decrease was observed for the IL with the [Tf2N]– anion (Figure 6). The authors attributed the decrease in the resistivity to the plasticizing effect of IL and to the formation of a continuous conductive path in the polymer matrix. However, the influence of the type of anion on the resistivity was left without a proper explanation, which is a significant shortcoming of the work.

The addition of low-viscosity IL in low concentrations to polymer materials makes it possible to obtain antistatic polymer films and coatings. In particular, to reduce the resistivity of polyurea by five orders of magnitude, it is sufficient to introduce 2 wt. % potassium hexafluorophosphate [11, 87]. At the same time, the transparency of the coatings is preserved, unlike that upon the addition of carbon fillers. However, ionic liquids are more expensive antistatic additives than graphene, aluminum and copper powder. For example, the price of potassium hexafluorophosphate IL is 46 euro per kg; meanwhile, carbon black costs approximately $1000 per ton. It is also possible that the mechanical properties of coatings based on polyurea can be deteriorated upon the addition of IL, in particular, the tensile strength may decrease due to IL migration to the surface [87].

Fig. 6. RV (orange) and RS (blue) of poly(butyl methacrylate) films containing 10 wt. % IL [86]

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Conductive polymers as antistatic additives

Conductive polymers, mainly polyaniline, are inexpensive and readily available alternatives to ILs. Conductive polyaniline was dispersed in methylpyrrolidone and added to polyurethane-acrylate latexes [92]. Polyaniline was added to improve the electrical insulation of damping coatings used in railway trains. As the content of polyaniline increased, the resistivity of the films decreased, while the electrical conductivity increased. When the content of polyaniline was 10 wt. %, the volume resistivity was 3.19•105 Ω•cm, and the best antistatic characteristics of the films were observed at a polyaniline dispersion content of 45 wt. %.

An advantage of polyaniline over nanoparticles is its controlled electrical conductivity due to the possibility of doping [93]. In particular, polyaniline was doped [93] with an acrylic ester grafting epoxy resin (A-g-EP) with carboxyl functional groups, which, in the opinion of the authors, provided conductive bridges between the polyaniline domains. As a result, the surface resistivity of the coatings decreased by 6 orders of magnitude compared to A-g-EP (from 1.6•1011 Ω/cm2to 2.4•105 Ω/cm2). Gao X. et al. [94] showed that the addition of 3 wt. % polyaniline doped with dodecylbenzenesulfonic acid to polyurethane increases the electrical conductivity of the polyurethane film. The disadvantage of the works [92, 93] is the lack of data on the effect of polyaniline on the mechanical properties of polymer composites.

However, a disadvantage of polyaniline is the difficulty of its dispersion in the polymer matrix due to its aggregation, which this deteriorates the conductivity and complicates the formation of a conductive network in the coating; the lack of solubility in most organic solvents [95]; the need to use high concentrations to attain an antistatic effect (20 wt. % polyaniline was added to natural rubber in [96]); and lower electrical conductivity compared to titanium dioxide nanoparticles [97].

A high content of polyaniline in the matrix can lead to poor mechanical stability of the final product. To avoid deterioration of mechanical properties, polyaniline is mixed with nanoparticles [98]. Mirmohseni A. et al.

-

[98 ] inserted a nanohybrid of polyaniline, copper, and zinc oxide into the water base of a polyurethane dispersion. The resulting polyurethane coating had an increased adhesive strength to steel and scratch resistance compared to a coating without nanoparticles. The authors explained this fact by charged hydrophilic surface of the coating. Furthermore, the addition of the nanohybrid provides a better antistatic effect of polyurethane compared to single additives. The developed nanohybrid polyurethane coating is in demand in modern industrial construction for dedusting of soft steel and in hospital operating rooms.

CONCLUSION

Carbon nanotubes are promising antistatic additives to polymer coatings based on polyvinyl chloride for the manufacture of decorative finishing materials in construction and to composites based on polyoxymethylene intended for fixing devices for electronic equipment and gadgets (mobile phones, displays). However, further research is needed to improve the mechanical and adhesive properties of filled polymeric materials.

Graphene oxide nanosheets can only be used as additives in water-based polyurethane coatings as synergistic mixtures with metal nanoparticles or conductive polymers. The coatings can be used in civil engineering as decorative elements.

Metals and metal oxide nanoparticles, due to their good dispersibility in the polymer matrix, can be used as additives to polypropylene and polyurethane industrial coatings for devices and equipment.

Ionic liquids are promising additives in polyurethane coatings and polyacrylate films that can be used in civil and industrial construction and in electronics.

Surfactants are washed away from polymer coatings, and, therefore, they are not of interest to researchers.

Polyaniline is of interest as a cheap additive to waterbased polyurethane coatings for the use in health care institutions (wall and floor coatings in hospitals, dental offices, etc.) only in combination with metal and metal oxide nanoparticles.

Список литературы Antistatic polymer materials

- Yadav R., Tirumali M., Wang, X., Naebe M., Kandasubramanian B. Polymer composite for antistatic application in aerospace. Defence Technology. 2020;16(1):107-118. https://doi.org/10.1016/j.dt.2019.04.008

- Kalender-Smajlović S., Kukec A., Dovjak M. The problem of indoor environmental quality at a general Slovenian hospital and its contribution to sick building syndrome. Building and Environment. 2022;214:108908. https://doi.org/10.1016/j.buildenv.2022.108908

- Jeong M.Y., Byung-Yoon A.H.N., Sang-Koul L.E.E., Won-Ki, L.E.E., Nam-Ju, J.O. Antistatic coating material consisting of poly (butylacrylate-co-styrene) core-nickel shell particle. Transactions of Nonferrous Metals Society of China. 2009;19:119-123. https://doi.org/10.1016/S1003-6326(10)60258-0

- Chou H.C., Yeh C.T., Shu C.M. Fire accident investigation of an explosion caused by static electricity in a propylene plant. Process Safety and Environmental Protection. 2015; 97:116-121. https://doi.org/10.1016/j.psep.2015.02.007

- Baytekin H.T., Baytekin B., Hermans T.M., Kowalczyk B., Grzybowski B.A. Control of surface charges by radicals as a principle of antistatic polymers protecting electronic circuitry. Science. 2013; 341(6152):1368-1371. https://doi.org/10.1126/science.1241326

- Al-Badra M.Z., Abd-Elhady M.S., Kandil H.A. A novel technique for cleaning PV panels using antistatic coating with a mechanical vibrator. Energy Reports. 2020; 6:1633-1637. https://doi.org/10.1016/j.egyr.2020.06.020

- Amsc N., Reli A. Military handbook electrostatic discharge control handbook for protection of electrical and electronic parts, assemblies and equipment (excluding electrically initiated explosive devices) (metric). 1991.

- Bhardwaj P., Grace A N. Antistatic and microwave shielding performance of polythiophene-graphene grafted 3-dimensional carbon fibre composite. Diamond and Related Materials. 2020;106; 107871. https://doi.org/10.1016/j.diamond.2020.107871

- ESD Association (2020) Part 6: ESD Standards. https://www.esda.org/esd-overview/esd-fundamentals/part-6-esd-standards/. Accessed 13 Dec 2022.

- ESD Flooring-Definition, Types, Applications, Antistatic Resistance Standard & Best Options. Available online: https://www.accessfloorstore.com/news/228--esd-flooring-definition-types-applications-antistatic-resistancestandard--best-options. (Accessed on 13 May 2021).

- Kosiński S., Rykowska I., Gonsior M., Krzyżanowski P. Ionic liquids as antistatic additives for polymer composites–A review. Polymer Testing. 2022;112(1); 107649. https://doi.org/10.1016/j.polymertesting.2022.107649

- Memon H., Wang H., Yasin S., Halepoto A. Influence of incorporating silver nanoparticles in protease treatment on fiber friction, antistatic, and antibacterial properties of wool fibers. Journal of Chemistry. 2018. https://doi.org/10.1155/2018/4845687

- Rahman M.M. Polyurethane/zinc oxide (PU/ZnO) composite-synthesis, protective property and application. Polymers. 2020; 12(7); 1535. https://doi.org/10.3390/polym12071535

- Tian Y., Zhang X., Geng H.Z., Yang H.J., Li C., Da S.X., Lu X., Wang J., Jia S.L. Carbon nanotube/polyurethane films with high transparency, low sheet resistance and strong adhesion for antistatic application. RSC advances. 2017; 7(83):53018-53024. https://doi:10.1039/C7RA10092B.

- Sangermano M., Marchi S., Valentini L., Bon S.B., Fabbri P. Transparent and conductive graphene oxide/poly (ethylene glycol) diacrylate coatings obtained by photopolymerization. Macromolecular Materials and Engineering. 2011; 296(5):401-407. https://doi.org/10.1002/mame.201000372

- Saini P., Choudhary V., Dhawan S.K. Improved microwave absorption and electrostatic charge dissipation efficiencies of conducting polymer grafted fabrics prepared via in situ polymerization. Polymers for Advanced Technologies. 2012;23(3):343-349. https://doi.org/10.1002/pat.1873

- Zheng A., Xu X., Xiao H., Li N., Guan Y., Li S. Antistatic modification of polypropylene by incorporating Tween/modified Tween. Applied surface science. 2012; 258(22):8861-8866. https://doi.org/10.1016/j.apsusc.2012.05.105

- Wei Y., Jiang S., Li C., Li J., Li X., Li J., Fang Z. Organic-inorganic hybrid network to enhance the electrostatic shielding of multifunctional soybean meal-based adhesive. Industrial Crops and Products. 2022; 189:115850. https://doi.org/10.1016/j.indcrop.2022.115850

- Elnozahy A., Abd-Elbary H., Abo-Elyousr F.K. Efficient Energy Harvesting from PV Panel with Reinforced Hydrophilic Nano-materials for Eco-buildings. Energy and Built Environment. 2022. https://doi.org/10.1016/j.enbenv.2022.12.001

- Karmankar R.G. Extraction of Carbon Black from The Coconut Shell. International Research Journal of Engineering and Technology (IRJET). 2016; 3(1):1286-1291.

- Choi H.J., Kim M.S., Ahn D., Yeo S.Y., Lee S. Electrical percolation threshold of carbon black in a polymer matrix and its application to antistatic fibre. Scientific reports. 2019; 9(1):1-12. https://doi.org/10.1038/s41598-019-42495-1

- Ezquerra T.A., Connor M.T., Roy S., Kulescza M., Fernandes-Nascimento J., Baltá-Calleja F.J. Alternatingcurrent electrical properties of graphite, carbon-black and carbon-fiber polymeric composites. Composites science and technology. 2001; 61(6):903-909. https://doi.org/10.1016/S0266-3538(00)00176-7

- Zhang M., Zhang C., Du Z., Li H., Zou W. Preparation of antistatic polystyrene superfine powder with polystyrene modified carbon nanotubes as antistatic agent. Composites Science and Technology. 2017;138:1-7. https://doi.org/10.1016/j.compscitech.2016.11.010

- de Souza Vieira L., dos Anjos E.G.R., Verginio G.E.A., Oyama I.C., Braga N.F., da Silva T.F. Passador F.R. Carbon-based materials as antistatic agents for the production of antistatic packaging: a review. Journal of Materials Science: Materials in Electronics. 2021;32(4):3929-3947. https://doi.org/10.1007/s10854-020-05178-6

- Wang Q., Wang T., Wang J., Guo W., Qian Z., Wei T. Preparation of antistatic high‐density polyethylene composites based on synergistic effect of graphene nanoplatelets and multi‐walled carbon nanotubes. Polymers for Advanced Technologies. 2018; 29(1):407-416. https://doi.org/10.1002/pat.4129

- Ying F., Cui Y., Xue G., Qian H., Li A., Wang X., Jiang, D. Preparation and properties of an antistatic UVcurable coating modified by multi-walled carbon nanotubes. Polymer Bulletin. 2016;73(10):2815-2830. https://doi.org/10.1007/s00289-016-1623-5

- Imiołek P., Kasprowicz K., Laska J. Antistatic polyethylene free-standing films modified with expan ded graphite–technological aspects. Polimery. 2020;65(4):275-279. https://doi.org/10.14314/polimery.2020.4.3

- Park G.H., Kim K.T., Ahn Y.T., Lee H.I., Jeong H.M. The effects of graphene on the properties of acrylic pressure-sensitive adhesive. Journal of Industrial and Engineering Chemistry. 2014;20(6):4108-4111. https://doi.org/10.1016/j.jiec.2014.01.008

- Zhang Y., Li T.T., Shiu B.C., Sun F., Ren H.T., Zhang X.F., Lin J.H. Mass production and effect of polyurethane/graphene coating on the durability and versatile protection of ultralight nylon fabrics. Polymer International. 2021;70(3):308-316. https://doi.org/10.1002/pi.6135

- Fan L., Tan Y., Amesimeku J., Yin Y., Wang C. A novel functional disperse dye doped with graphene oxide for improving antistatic properties of polyester fabric using one-bath dyeing method. Textile Research Journal. 2020;90(5-6):655-665. https://doi:10.1177/0040517519877464

- Meng Z., Lu S., Zhang D., Liu Q., Chen X., Liu W., Ke Y. Grafting macromolecular chains on the surface of graphene oxide through crosslinker for antistatic and thermally stable polyethylene terephthalate nanocomposites. RSC advances. 2022;12(51):33329-33339. https://doi:10.1039/D2RA06725K

- Li C., Liang T., Lu W., Tang C., Hu X., Cao M., Liang J. Improving the antistatic ability of polypropylene fibers by inner antistatic agent filled with carbon nanotubes. Composites Science and Technology. 2004; 64(13-14):2089-2096. https://doi:10.1016/j.compscitech.2004.03.010

- Ma P.-C., Siddiqui N.A., Marom G., Kim J.-K. Dispersion and Functionalization of Carbon Nanotubes for Polymer-Based Nanocomposites: A Review. Compos. Part A. Appl. Sci. Manuf. 2010;41:1345-1367. https://doi:10.1016/j.compositesa.2010.07.003

- Tanabi H., Erdal M. Effect of CNTs Dispersion on Electrical, Mechanical and Strain Sensing Properties of CNT/Epoxy Nanocomposites. Results Phys. 2019;12:486-503. https://doi.org/10.1016/j.rinp.2018.11.081

- Tasis D., Tagmatarchis N., Bianco A., Prato M. Chemistry of Carbon Nanotubes. Chem. Rev. 2006; 106:1105-1136. https://doi:10.1021/cr050569o

- Zhao X., Ye L. Structure and Mechanical Properties of Polyoxymethylene/Multi-Walled Carbon Nanotube Composites. Compos. Part B Eng. 2011; 42:926-933. https://doi.org/10.1016/j.compositesb.2011.01.002

- Skákalová V., Kaiser A.B., Dettlaff-Weglikowska U., Hrnčariková K., Roth S. Effect of Chemical Treatment on Electrical Conductivity, Infrared Absorption, and Raman Spectra of Single-Walled Carbon Nanotubes. J. Phys. Chem. B. 2005; 109:7174–7181. https://doi: 10.1021/jp044741o

- Yan W., Shi M., Dong C., Liu L., Gao C. Applications of tannic acid in membrane technologies: A review. Advances in Colloid and Interface Science. 2020; 284:102267. https://doi:10.1016/j.cis.2020.102267

- Liu L., Yu P., Wu M., Wu Q., Liu J., Yang J., Zhang J. Poly (tannin urethane)-stabilized multiwalled carbon nanotube aqueous dispersion for antistatic coating. Industrial & Engineering Chemistry Research. 2021; 60(33):12353-12361. https://doi.org/10.1021/acs.iecr.1c02880

- Wang Z., Liu C., Liu Z., Xiang H., Li Z., Gong Q. π-π Interaction enhancement on the ultrafast third-order optical nonlinearity of carbon nanotubes/polymer composites. Chem. Phys. Lett. 2005; 407:35–39. https://doi:10.1016/j.cplett.2005.03.038

- Pilch-Pitera B., Czachor D., Kowalczyk K., Pavlova E., Wojturski J., Florczak Ł., Byczyński Ł. Conductive polyurethane-based powder clear coatings modified with carbon nanotubes. Prog. Org. Coat. 2019; 137:105367. https://doi:10.1016/j.porgcoat.2019.105367

- Yun S.S., Shin D.H., Jang K.S. Influence of Ionomer and Cyanuric Acid on Antistatic, Mechanical, Thermal, and Rheological Properties of Extruded Carbon Nanotube (CNT)/Polyoxymethylene (POM) Nanocomposites. Polymers. 2022;14(9):1849. https://doi.org/10.3390/polym14091849

- Long H., Harley‐Trochimczyk A., Pham T., Tang Z., Shi T., Zettl A., Maboudian R. High surface area MoS2/graphene hybrid aerogel for ultrasensitive NO2 detection. Advanced Functional Materials. 2016;26(28):5158-5165. https://doi.org/10.1002/adfm.201601562

- Canal-Rodríguez M., Arenillas A., Rey-Raap N., Ramos-Fernández G., Martín-Gullón I., Menéndez J.A. Graphene-doped carbon xerogel combining high electrical conductivity and surface area for optimized aqueous supercapacitors. Carbon. 2017;118:291-298. https://doi.org/10.1016/j.carbon.2017.03.059

- Wen S., Wang Z., Zheng X., Wang X. Improved mechanical strength of porous chitosan scaffold by graphene coatings. Materials Letters. 2017; 186:17-20. https://doi.org/10.1016/j.matlet.2016.09.040

- Yilmaz Dogan H., Altin Y., Bedeloğlu A.Ç. Fabrication and properties of graphene oxide and reduced graphene oxide reinforced Poly (Vinyl alcohol) nanocomposite films for packaging applications. Polymers and Polymer Composites. 2022;30. https://doi.org/10.1177/09673911221113328

- Vieira L.D.S., dos Anjos E.G.R., Verginio G.E.A., Oyama I.C., Braga N.F., da Silva T.F., Passador F.R. A review concerning the main factors that interfere in the electrical percolation threshold content of polymeric antistatic packaging with carbon fillers as antistatic agent. Nano Select. 2022;3(2):248-260. https://doi.org/10.1002/nano.202100073

- Zhao Y., Yao W., Wang Y., Wang Q., Lou F., Guo W. High-performance antistatic acrylic coating by incorporation with modified graphene. Journal of Materials Research. 2019;34(4):510-518. https://doi.org/10.1557/jmr.2018.436

- Lotya M., King P. J., Khan U., De S., Coleman J. N. High-concentration, surfactant-stabilized graphene dispersions. ACS nano. 2010;4(6):3155-3162. https://doi.org/10.1021/nn1005304

- Mohamed A., Ardyani T., Bakar S. A., Brown P., Hollamby M., Sagisaka M., Eastoe, J. Graphene-philic surfactants for nanocomposites in latex technology. Advances in colloid and interface science. 2016; 230:54-69. https://doi.org/10.1016/j.cis.2016.01.003

- Tang C., Long G., Hu X., Wong K. W., Lau W. M., Fan M., Hui D. Conductive polymer nanocomposites with hierarchical multi-scale structures via self-assembly of carbon-nanotubes on graphene on polymer-microspheres. Nanoscale. 2014;6(14):7877-7888. https://doi.org/10.1039/c3nr06056j

- Zhang S., Zhang D., Li Z., Yang Y., Sun M., Kong Z., Dong W. Polydopamine functional reduced graphene oxide for enhanced mechanical and electrical properties of waterborne polyurethane nanocomposites. Journal of Coatings Technology and Research. 2018;15(6):1333-1341. https://doi.org/10.1007/s11998-018-0082-3

- Luo X., Zhong J., Zhou Q., Du S., Yuan S., Liu Y. Cationic reduced graphene oxide as self-aligned nanofiller in the epoxy nanocomposite coating with excellent anticorrosive performance and its high antibacterial activity. ACS applied materials & interfaces. 2018; 10(21):18400-18415. https://doi.org/10.1021/acsami.8b01982

- Mirmohseni A., Azizi M., Dorraji M.S.S. Cationic graphene oxide nanosheets intercalated with polyaniline nanofibers: A promising candidate for simultaneous anticorrosion, antistatic, and antibacterial applications. Progress in Organic Coatings. 2020; 139:105419. https://doi.org/10.1016/j.porgcoat.2019.105419

- Mirmohseni A., Azizi M., Dorraji M.S.S. Facile synthesis of copper/reduced single layer graphene oxide as a multifunctional nanohybrid for simultaneous enhancement of antibacterial and antistatic properties of waterborne polyurethane coating. Progress in Organic Coatings. 2019;131:322-332. https://doi.org/10.1016/j.porgcoat.2019.02.031

- Abdel-Halim E.S., Abdel-Mohdy F.A., Al-Deyab S.S., El-Newehy M.H. Chitosan and monochlorotriazinyl-β-cyclodextrin finishes improve antistatic properties of cotton/polyester blend and polyester fabrics. Carbohydrate Polymers. 2010;82(1):202-208. https://doi.org/10.1016/j.carbpol.2010.04.077

- Li K., Fina A., Marrè D., Carosio F., Monticelli O. Graphite oxide nanocoatings as a sustaibale route to extend the applicability of biopolymer-based film. Applied Surface Science. 2020;522:146471. https://doi.org/10.1016/j.apsusc.2020.146471

- Gao W., Dang Z.C., Liu F.S., Wang S., Zhang D.W., Yan M. X. Preparation of antistatic epoxy resin coatings based on double comb-like quaternary ammonium salt polymers. RSC advances. 2020;10(71):43523-43532. https://doi.org/10.1039/d0ra07479a

- Bao L., Lei J., Wang J. Preparation and characterization of a novel antistatic poly (vinyl chloride)/quaternary ammonium based ion-conductive acrylate copolymer composites. Journal of Electrostatics. 2013; 71(6):987-993. https://doi.org/10.1016/j.elstat.2013.09.001

- Yang W., Cao Y., Ju H., Wang Y., Jiang Y., Geng T. Amide Gemini surfactants linked by rigid spacer group 1, 4-dibromo-2-butene: Surface properties, aggregate and application properties. Journal of Molecular Liquids. 2021;326: 115339. https://doi.org/10.1016/j.molliq.2021.115339

- Fan Y., Shen J., Xu H. Synthesis and dilute aqueous solution properties of cationic antistatic surfactant functionalized with hydroxyl and ether groups. Tenside Surfactants Detergents. 2022. https://doi.org/10.1007/s00396-014-3233-9

- Si J., Tang P. Influence of antistatic agent encapsulated into functionalized mesoporous silica on antistatic properties of polystyrene. International Journal of Polymeric Materials and Polymeric Biomaterials. 2018;67(12):745-753. https://doi.org/10.1080/00914037.2017.1376201

- Kuo Y.C., Lee C.H., Rajesh R. Iron oxide-entrapped solid lipid nanoparticles and poly (lactide-co-glycolide) nanoparticles with surfactant stabilization for antistatic application. Journal of Materials Research and Technology. 2019; 8(1):887-895. https://doi.org/10.1016/j.jmrt.2018.04.022

- El-Dessouky H.M., Lawrence C.A. Nanoparticles dispersion in processing functionalized PP/TiO2 nanocomposites: distribution and properties. Journal of Nanoparticle Research. 2011;13(3):1115-1124. https://doi.org/10.1007/s11051-010-0100-6

- Wang Y., Zhang C., Du Z., Li H., Zou W. Synthesis of silver nanoparticles decorated MWCNTs and their application in antistatic polyetherimide matrix nanocomposite. Synthetic metals. 2013; 182:49-55. https://doi.org/10.1016/j.synthmet.2013.09.006

- Li R., Si J., Tang P. Enhancement of electrostatic charge dissipation properties of polymers by a sustained‐release effect of mesoporous silica nanoparticles. Polymers for Advanced Technologies. 2016;27(5):615-622. https://doi.org/10.1002/pat.3728

- Kumar A.P., Depan D., Tomer N.S., Singh R.P. Nanoscale particles for polymer degradation and stabilization—trends and future perspectives. Progress in polymer science. 2009; 34(6):479-515. https://doi.org/10.1016/j.progpolymsci.2009.01.002

- Chiu C.W., Lin C.A., Hong P.D. Melt-spinning and thermal stability behavior of TiO2 nanoparticle/polypropylene nanocomposite fibers. Journal of Polymer Research. 2011;18(3):367-372. https://doi.org/10.1007/s10965-010-9426-0

- Hassan M.M., Koyama K. Multifunctional acrylic fibers prepared via in-situ formed silver nanoparticles: Physicochemical, UV radiation protection, and antistatic properties. Dyes and Pigments. 2018;159:517-526. https://doi.org/10.1016/j.dyepig.2018.07.013

- Zhang J., Zuo J., Yuan W., Fu W., Zhang J., Wei C. Synthesis and characterization of silver nanoparticledecorated coal gasification fine slag porous microbeads and their application in antistatic polypropylene composites. Powder Technology. 2022; 410:117891. https://doi.org/10.1016/j.powtec.2022.117891

- Wasim M., Khan M.R., Mushtaq M., Naeem A., Han M., Wei, Q. Surface modification of bacterial cellulose by copper and zinc oxide sputter coating for UV-resistance/antistatic/antibacterial characteristics. Coatings. 2020;10(4):364. https://doi.org/10.3390/coatings10040364

- Thennakoon C.A., Rajapakshe R.B.S.D., Rajapakse R.M.G., Rajapakse S. Anti-stain and durable superhydrophobic/antistatic dual functionality surface for fabric materials based on F-ZnO/TiO2 composite. Journal of Sol-Gel Science and Technology. 2022;101(3):529-538. https://doi.org/10.1007/s10971-022-05734-y

- Mikhailov M.M., Goronchko, V.A. Changes in the Electrical Conductivity of Polypropylene Modified with Nanoparticles of Oxide Compounds. Journal of Surface Investigation: X-ray, Synchrotron and Neutron Techniques. 2022; 16(3):343-346. https://doi.org/10.1134/S1027451022030284

- Yousefi E., Dolati A., Najafkhani H. Preparation of robust antistatic waterborne polyurethane coating. Progress in Organic Coatings. 2020;139: 105450. https://doi.org/10.1016/j.porgcoat.2019.105450

- Shang Q., Hao S., Wang W., Fu D., Ma T. Preparation and characterization of antistatic coatings with modified BaTiO3 powders as conductive fillers. Journal of adhesion science and technology. 2013;27(24):2642-2652. https://doi.org/10.1080/01694243.2013.798926

- Amde M., Liu J.F., Pang L. Environmental application, fate, effects, and concerns of ionic liquids: a review. Environmental science & technology. 2015;49(21):12611-12627. https://doi.org/10.1021/acs.est.5b03123

- Coleman D., Gathergood N. Biodegradation studies of ionic liquids. Chemical Society Reviews. 2010;39(2):600-637. https://doi.org/10.1039/b817717c

- Welton T. Ionic liquids in green chemistry. Green Chemistry. 2011;13(2):225-225. https://doi.org/10.1039/C0GC90047H

- Sadjadi S. Magnetic (poly) ionic liquids: A promising platform for green chemistry. Journal of Molecular Liquids. 2021;323:114994. https://doi.org/10.1016/j.molliq.2020.114994

- Kapitanov I.V., Jordan A., Karpichev Y., Spulak M., Perez L., Kellett A., Gathergood N. Synthesis, selfassembly, bacterial and fungal toxicity, and preliminary biodegradation studies of a series of L-phenylalanine-derived surface-active ionic liquids. Green Chemistry. 2019; 21(7):1777-1794. https://doi.org/10.1039/C9GC00030E

- Chiappe C., Marra A., Mele A. Synthesis and applications of ionic liquids derived from natural sugars. Carbohydrates in sustainable development II. 2010; 295: 177-195. https://doi.org/10.1007/128_2010_47

- Gomes J.M., Silva S.S., Reis R.L. Biocompatible ionic liquids: fundamental behaviours and applications. Chemical Society Reviews. 2019;48(15):4317-4335. https://doi.org/10.1039/C9CS00016J

- Chen J., Xie F., Li X., Chen L. Ionic liquids for the preparation of biopolymer materials for drug/gene delivery: a review. Green Chemistry. 2018;20(18):4169-4200. https://doi.org/10.1039/C9CS00016J

- Mudzakir A., Jafarian M. B., Widyaningsih M., Nandiyanto A.B.D., Ragadhita R. Fatty Acid Based Ionic Liquids: A New Antistatic Agent For Floor Coating. Moroccan Journal of Chemistry. 2022;10:591-605. https://doi.org/10.48317/IMIST.PRSM/morjchem-v10i3.33146

- Tsurumaki A., Iwata T., Tokuda M., Minami H., Navarra M.A., Ohno H. Polymerized ionic liquids as durable antistatic agents for polyether-based polyurethanes. Electrochimica Acta. 2019; 308:115-120. https://doi.org/10.1016/j.electacta.2019.04.031

- Tsurumaki A., Tajima S., Iwata T., Scrosati B., Ohno H. Evaluation of ionic liquids as novel antistatic agents for polymethacrylates. Electrochimica Acta. 2017; 248:556-561. https://doi.org/10.1016/j.electacta.2017.07.181

- Seki Y. O. L. D. A. Ş., Yıldız N., İnce M., Şengül S., Sever K., Sarıkanat M., Dikici, T. U. N. C. A. Y. The investigation of antistatic effects of 1-ethyl-2, 3-dimethylimidazolium ethyl sulphate for acrylic-based polymer film. Plastics, Rubber and Composites. 2016; 45(8):362-367. https://doi.org/10.1080/14658011.2016.1201258

- Ueno K., Fukai T., Nagatsuka T., Yasuda T., Watanabe M. Solubility of poly (methyl methacrylate) in ionic liquids in relation to solvent parameters. Langmuir. 2014; 30(11): 3228-3235. https://doi.org/10.1021/la404797g

- Kosiński S., Gonsior M., Krzyżanowski P., Rykowska I. New Hybrid Polyurea-Polyurethane Elastomers with Antistatic Properties and an Influence of Various Additives on Their Physicochemical Properties. Molecules. 2021;26(19):5778. https://doi:10.3390/molecules26195778

- Stoppa A., Zech O., Kunz W., Buchner R. The Conductivity of Imidazolium-Based Ionic Liquids from (−35 to 195) oC. A. Variation of Cation’s Alkyl Chain. Journal of Chemical Engineering Data. 2010; 55(5):1768–1773. https://doi.org/10.1021/je900789j

- Rahman, M.B.A., Jumbri K., Basri M., Abdulmalek E., Sirat K., Salleh A.B. Synthesis and Physico-Chemical Properties of New Tetraethylammonium-Based Amino Acid Chiral Ionic Liquids. Molecules. 2010;15:2388–2397. https://doi.org/10.3390/molecules15042388

- Liang X., Deng Y., Li S., Wu J., Zhang H., Zhang Z. Waterborne polyurethane‐acrylate‐polyaniline: Interfacial hydrogen bonding for enhancing the antistatic, damping, and mechanical properties. Polymers for Advanced Technologies. 2022; 33(9): 2667-2681. https://doi.org/10.1002/pat.5722

- Zhu A., Wang H., Sun S., Zhang C. The synthesis and antistatic, anticorrosive properties of polyaniline composite coating. Progress in Organic Coatings. 2018;122:270-279. https://doi.org/10.1016/j.porgcoat.2018.06.004

- Gao X., Chu F. Fabrication of High Conductivity Polyurethane/Polyaniline Composite Coating Based on In-Situ Polymerization. In Advances in Graphic Communication, Printing and Packaging. Springer, Singapore. 2019; 958-963. https://doi.org/10.1007/978-981-13-3663-8_129

- Cao Y., Wang L., Gao Y., Sun T.J., Zhou Y., Hu H.Q., Dong X. Morphology and electric conductivity controlling of in situ polymerized poly (decamethylene dodecanoamide)/polyaniline composites. Journal of Applied Polymer Science. 2018;136(6):47041. https://doi.org/10.1002/app.47041

- Jose B., Sambhudevan S., Shankar B. Mechanical and Conducting Properties of Polyaniline Doped Natural Rubber Nanocomposites. Materials Today: Proceedings. 2019; 18:4901-4905. https://doi.org/10.1016/j.matpr.2019.07.481

- Mirmohseni A., Rastgar M., Olad A. PANI‐chitosan‐TiO2 ternary nanocomposite and its effectiveness on antibacterial and antistatic behavior of epoxy coating. Journal of Applied Polymer Science. 2019;136(23):47629. https://doi.org/10.1002/app.47629

- Mirmohseni A., Azizi M., Seyed Dorraji M.S.A promising ternary nanohybrid of Copper@ Zinc oxide intercalated with polyaniline for simultaneous antistatic and antibacterial applications. Journal of Coatings Technology and Research. 2019; 16(38):1411-1422. https://doi.org/10.1007/s11998-019-00223-4