Application of nanotechnology in oil well cementing – an overview of the challenges associated with well cementing in difficult conditions

Автор: Abusal Yousef А.Y., Mohammedameen A.I., Ismakov R.А., Muftakhova E.D., Yahin A.R.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 6 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Nanotechnology has received a lot of attention in the oil and gas industry as an effective means of improving properties and increasing production rates, especially in harsh environments such as ultra-deep and shallow gas fields, deviated and horizontal wells, geothermal zones, and high pressure/high temperature (HPHT) areas. These environments present numerous economic, technical, operational, and HSE challenges that need to be addressed.Cementing operations play a critical role in these environments, as the cement sheath serves as a barrier to meet the different well conditions, including pressure, temperature, and the flow of liquids or gases. The use of nanomaterials as additives to cement has been credited with improving its properties and performance under these complicated conditions. Methods and materials. The study presents an analysis of the effect of pressure and temperature on the behavior and complexity of cementing operations in high-pressure wells. Analytical performance of the main characteristics of nanoclay (structural and mechanical) and evaluation of its effect on the durability and strength of cement slurry during well construction are presented. Results and Discussion. The results of the study allow us to conclude that nanoclay can be widely used as an additive to improve the durability and properties of cement-based materials under difficult conditions. Conclusions. The results of this study provide valuable information to researchers, engineers and practitioners in the field of cementing oil and gas wells, especially in solving problems related to providing the most favorable conditions for well operation with the long-term use of more durable cement slurry.

High pressure/high temperature wells (HPHT), Portland cement, Nanomaterials, Nano-clay, well cementing, Rheological properties

Короткий адрес: https://sciup.org/142242747

IDR: 142242747 | DOI: 10.15828/2075-8545-2024-16-6-555-566

Текст научной статьи Application of nanotechnology in oil well cementing – an overview of the challenges associated with well cementing in difficult conditions

Original article

Abusal Yousef А.Y., Mohammedameen A.I., Ismakov R.А., Muftakhova E.D., Yahin A.R. Application of nanotechnology in oil well cementing – an overview of the challenges associated with well cementing in difficult conditions. Nanotechnologies in Construction. 2024; 16 (6): 555–566. – EDN: REARCK.

Exploration and extraction processes are being pushed into previously unexplored, hazardous and costly regions because to rising demand and decreasing proved reserves. As an example, consider environments like those found in the ultra-deep and shallow gas fields, deviated and horizontal wells, geothermal zones, and high pres-sure/high temperature (HPHT) areas. Wells of this sort involve unique difficulties that mostly not observed in routine drilling operations. As a result, additional measures made during the planning stage may assist alleviate some of the key challenges encountered during drilling [1–3].

The key challenges of these non-conventional wells are casing and cementing during drilling operations. Extent to which this stage is successful has a significant impact on the long-term durability and efficiency of well produc-

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES tion rates. Since casing cover the wellbore during tubing operation, the annulus between the pipe string and well rock (Formation) must filled with a cement grout mix during the cementing stage to prohibit fluid from moving across zones inside the formation and to ensure long-term zonal isolation. Cementing operations must also provide a solid link from shock loads and corrosion between the casing and the formation [4].

Changes in downhole temperatures and pressures conditions in (HPHT) wells, leads to cement mechanical failure caused by varies stresses, due to; (1) Pressure rise as result of gas production (2) Changes in mud weight following cement placement (3) Temperature changes. These stresses prepare the wellbore mechanically fail in different scenarios; (a) Tensile stresses at the casing-cement interface and the cement-rock interface will likely cause de-bonding and opening of fluid pathways at the interface. (b) Tensile stresses inside the cement or the rock can cause tensile fracturing if the stresses reach the tensile strength of the material. (c) Shear stresses inside the cement or the rock can cause shear fractures to form, which be enough to destroy the cement sheaths integrity (plastic deformation, cracking, and deboning). The resulting of these scenarios cause long-term gas migration, sustained annular pressure, hazardous rig, and lost revenue from production. Furthermore, operations like; Hydrocarbon production, Hydraulic fracturing and Perforating, Hydration of cement, Injection of fluid, Gas lift, Drilling resuming, Casings slips setting and testing, Acid treatments, Extracting blowout preventers (BOP) and Rig animating are the another reason for changing downhole pressure and temperature that could exert stress on the cement sheath damage [5–10].

To prevent cement sheath damage in HPHT wells, required that, the cement slurry had to be pumpable long enough to allow placement, have enough density to compensate for the underground formation pressure and thermal loads, desired compressive strength, which has a significant impact on the cement sheath durability and long-term integrity. The permeability should be low, so that, no fluid can pass through the cement. In addition, the cement slurry should be environmentally friendly and not harm underground formations. Since it, Ordinary Portland Cement (OPC) is the most commonly used cementing material in the extraction of petroleum and geothermal resources to seal the wellbore annulus between casing and formation. Thence mixing conditions for cement slurries and their impact on slurries properties are of great importance. Although the use of additives (particularly retarders) is widespread, the number of additives available for HPHT applications is limited. The homogeneity of additive concentration, quality, and quantity is critical in well slurries [10–14].

To avoid the limitation of using additives in HPHT and other non-conventional wells, the terms “Nanosci- ence” or “Nanotechnology” has used as cement reinforcement and modification in oil-gas industry. Nanomaterials provide high strength, large surface area, low density, high corrosion resistance, and interesting chemical-physical properties are potentially improving the performance and reliability of drilling – completion materials, drilling equipment, and surface facilities. The nano composite materials are more stable in (HTHP) environments. In cementitious materials, nanoparticles with high surface area, providing a high chemical reactivity, fill the voids between cement grains, and resulting denser material. These impacts are according to several simultaneous mechanisms contribute to the effect of nanoparticles on fresh and hardened cement properties; Due to their small size; fillers improve microstructure and packing density. Due to the “nucleation” effect, they can accelerate the hydration of cement. According to researchers, cement hydration Calcium Silicate Hydrate (C–S–H) diameter is approximately 10 nm. The formation of additional C–S–H has a chemical or pozzolanic effect, because of the reaction between the nanomaterials and calcium hydroxide Ca(OH)2 (nanoparticles can react with calcium hydroxide, a by-product of cement hydration, to create extra C–S–H). If the cement-replacing powder particles are inert, there may be a dilution effect. Nanoparticles can also be hydrophobic, hydrophilic or amphiphilic [15–18].

One of the most important applications of nanomaterials in cementing operations is the using of nanoclay materials. Nano-clay improves the stiffness, strength, fatigue resistance, and thermal stability of materials. Because of its high aspect ratio, nano-clay has a larger interfacial area, which greatly improves its reinforcement properties.Nano-clay increased the elastic modulus of hybrid composites [19, 20]. Research results shown in the table 1, elucidated the effectiveness of nano clay on cement slurry for both construction and oil-gas industry.

In drilling fluid, Nano clays shown to be effective at modifying static yield stress by acting as inorganic rheology modifiers include yield stress and filtration loss. C. Vipulanandan et al. [21, 22] illustrated and studied the effect of temperature on rheology and electric resistivity for water base drilling mud, addition of nano clay in rang (0.6–1%) with the bentonite decreased the electrical resistivity and fluid loss of drilling mud with increasing bentonite content, nanoclay content and temperature, increased the yield point, plastic and apparent viscosity.

The motivation of this study summarizes (table 1) an overview behind the effect of pressure and temperature in HPHT wells on cementing behavior and it challenges. Then an overview of the use of nanoclay as additive to enhanced the durability of cement-based materials and its properties under these complicated condition.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Table 1

Nanoclay effectiveness on cement slurry for both construction side and oil industry

|

Nano-clay type |

Addition rate % BWOC |

Cement type |

Curing time days |

Effects |

Ref. |

|

Metakaolin (NMK) |

6% + 0.02% CNTS |

OPC |

28th |

Enhanced compressive strength by 18% and enthalpy C–S–H |

[23] |

|

Metakaolin (NMK) |

1% |

OPC |

28th |

Amended pore frame and frost resistance of cement materials. Reduce porosity, mass and strength loss of cement slurry via freeze-thaw cycles. |

[24] |

|

Nano-clay |

0.33% |

OPC with fly ash |

24th hours |

Affect the instant solidity, Flocculation. Reduced pressure form-work in SelfConsolidating Concrete CSS. |

[25] |

|

Halloysite |

3% and 2% |

OPC with 5% silica fume |

7th and 28th |

Enhanced compressive strength up to 24%, reduce the flowability and permeability by 65% and 56% respectively |

[26] |

|

Montmorillonite |

1% |

OPC with 2.5% HempFabric |

56th |

Reinforcement the uplift density, flexural strength, fracture toughness and influence strength. Reduced porosity and water absorption and improved the thermal stability. |

[27] |

|

Montmorillonite |

2% |

OPC (class G) |

28th with (37°, 50°, 60°, 80° and 90° C) |

Improved rheological characterization and provided high shear stress, increased plastic viscosity and yield strength and enhanced the stability of cement slurry. |

[28] |

|

Montmorillonite |

1% |

OPC (class H) |

24th hours, 7th and 28th day with (25, 55 and 85 °C) |

Weight loss decreased to 1.03%, yield stress increased, Plastic viscosity increased by 13%, maximum shear stress increased by 15%, ultimate shear stress increased by 5% to 50%, the compressive strength increased by 43% and the density increased by 0.8% |

[29] |

RESULTS AND DISCUSSION

High pressure / High temperature Well Cementing Challenges

Deep Trek (US Department of Energy) defines an HPHT drilling operation as one in which the borehole static temperature (BHST) reaches 177° C (350 °F) and the pressure is in excess of 25,000 Psi. Drilling conditions will get harsher as the depth of the wells continues to rise, with temperatures reaching 315 °C (600 °F) and 40,000 Psi pressures [18]. In United Kingdom, the interpretation of HPHT wells definition is the bottomhole temperature utmost 300° F (149 °C) and porous formation is to be drill at a maximum pore pressure of 0.8 Psi/ft according to the Department of Trade and Industry. Norwegian Petroleum Directorate depicted HPHT well is one that has a pressure more than or equal to 690bar (10,000 Psi) and a temperature in excess of 150 °C (302 °F) [30].

HPHT wells present numerous economic, technical, operational, and HSE challenges. The majority of these issues related to material manufacturing characteristics and excessive loads. Research shows that the following list of parameters influenced in HPHT wells [31–36]:

-

1. High costs and budget, due to; harsh environments, specific required equipment, great cement and/or mud volumes, unscheduled events, long time rig operation, more fishing jobs, stuck pipe increased by 30% from conventional drilling, higher frequently kicks (2 times/well) and bigger Non-productive time (NPT) by 3 times from ordinary drilling.

-

2. The narrow margin between pore pressure and fracture gradient and sometimes it may not even exist present many challenges; over-pressured formations where kicks are easily taken, accurate modeling of drilling fluids, well control incident is between 100% and 200% with abnormal pressures.

-

3. Thermal effect, high temperature in HPHT wells can significantly influence wellbore stability and cause high reduction in yield strength of casing [hydrostatic wellbore pressure (inner pressure) acting on the inner walls of the casing, in addition to the increase in temperature]; thus, casing will undergo substantial thermal expansion. Depending on the rigidity of the rock, a 1 °F change in temperature causes 3–8 psi of tensile or compressive stress. In HPHT wells with a stress change of more than 1000 Psi, cooling or heating by 100–120 °F is possible.

-

4. Lost circulation as a result of bottomhole pressure and high equivalent circulating density (ECD).

-

5. In HPHT wells, static and/or dynamic barite sag is a common issue. This phenomenon is caused by a loss of circulation, torque and drag, ECD fluctuations, and other operations that require the mud to remain static for an extended period of time.

-

6. To avoid surge pressure in HPHT wells, it is critical to record the pressure required for gel breaking. If mud circulation resumed too quickly, circulation may be lost. In addition to the continuous circulation, keeping the casing at the bottom of the open hole at all times may completely prevent mud gelation.

-

7. Low cleaning efficiency and heavy solids content which is very critical issue because of long circulation times.

-

8. To push the limits of logging technologies, HPHT wells have required continuous improvement. Well logging equipment in these wells faces numerous challenges due to pressures and temperatures. Particularly when combined with the presence of H2S gas.

-

9. Casing connections in HPHT wells must thoroughly investigated. Especially between the trapezoidal threads root and crest, Lubricants are currently blocking this phenomenon, but at high temperatures and pressures, the lubricant may skip within the helical path, causing a leak.

-

10. Casing wear, torque, and drag can all be significant issues in highly deviated and horizontal wells through highly compacted formations.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Quite evident, all these parameters have an impact by one way or more on cementing operation. O.A. Sa-nuade et al. [36], Fatemeh et al. [14], Al-Bagoury et al. [37] illustrated that, in HPHT conditions, with higher concentrations of high hydrocarbons (e.g., methane, propane, and ethane) pose significant challenges to the oil and gas industries. This is due to the fact, that these hydrocarbons are more volatile than liquid hydrocarbons. As a result, they can enter the micro-annuli, or cracks in the cement sheath. As a result, the pressure will change, which may jeopardize the wells safety. Predominantly, HPHT cementing requires effective additives. Filtration additives that also reduce gas migration risk and improve cement bonding are in great demand. As well as obtaining adequate zonal isolation with cement might be difficult at times. Mechanical failure, chemical assaults, durability concerns, prolonged casing pressure, shrinkage, and leakage are all challenges associated with well integrity.

In other hand, mud cake may cause a weak cementformation link, compromising the integrity of well cement. To address this challenge, Sairam et al. [38] mentioned that, during cementing operations, it is critical to prepare the casing surface and the wellbore to accept cement slurry. Before cementing, a clean and water-wet casing surface is ticklish for ensuring perfect shear bond strength (SBS) and long-term wellbore integrity. Prior to cement application, spacer fluids are frequently circulated to clean the casing and wellbore surfaces and to assist minimize direct contact between cement and muds.

Al-Bagoury et al. [39], Jupe et al. [40] and Siwei et al. [41] studied the thermal effect on cement mortar. At temperatures, over 110 °C and pressures up to 51 Mpa (7400 Psi) a process known as “strength retrogression” occurs, causing the strength of calcium silicate cement quickly diminish owing to the metamorphosis of calcium silicate hydrate gel. An increase in cement permeability is caused by the crystallization of the Ca-rich phase into denser phases, such as α-C2SH [Ca2 (HSiO4) OH] or hillebrandite [Ca2 SiO3 (OH)2] which shrink, and subsequently the cement loses its integrity. The use of crystalline silica to reduce the CaO/SiO2 (C/S) molar ratio in Portland cement to less than 1.5 gps (gallon per sack) recommended and effectively applied to minimize strength retrogression. The inclusion of silica flour (35–40% BWOC) ensures consistent compressive strength and low permeability at temperatures up to 250 °C, Fig. 1. Whereas Qin et al. [12] explained that, when the temperature exceeds 150 °C, 40% silica flour appears insufficient to mitigate strength retrogression, and several recent studies have recommended increasing the silica flour dosage (50–65% BWOC or more) at temperatures above 200 °C.

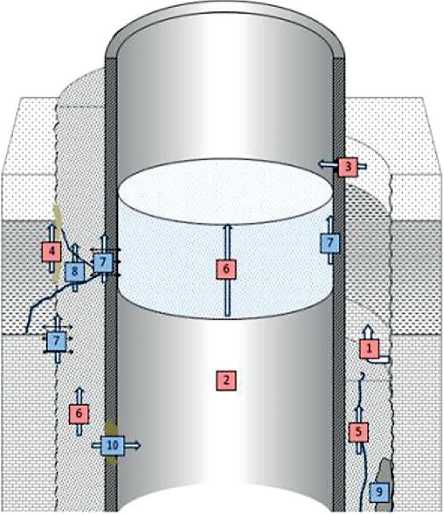

Eventually, Weideman et al. [42] demonstrated in figure 2 the possible leakage channels vicinity of the wellbore, rely upon circulation temperature, internal casing pressure, and cement hydrostatic pressure as operating conditions. Depending on their location, leaks classified as either primary or secondary. The activities and circumstances that occur during primary cementing cause main leakage channels, while secondary leakage paths occur after primary cementing completed. It is possible for fluid to seep into the wellbore or annulus via any of these leakage path-ways compromise the wellbore integrity. In certain cases, temperature variations during cementing operations might result in fluid loss, formation cracks, or formation fluid influxes in the near term. A minor fluid pressure modification may have a long-term impact on the wellbore’s ability to handle future loads and stresses, resulting in a significantly more robust wellbore.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES о о о о о о о

5 0 5 0 5 0 5

3 3 2 2 1 1

о 。) alnmaduml

Xonotlite

Truscottite

Gyrolite y-C2S hydrate

Hillebrandite

Z-phase 11 ATobermorite

Afwillite a-C2s hydrate

14 ATobermorite

Ca(H3SiO4)2 C-S-H (I) C-S-H (II)

0,5 1 1,5 2 2,5

CaO/SiO2 mole ratio

Fig. 1. Portland cement/Calcium silicate phases as a function of temperature [39]

Nanoclay Particles Modification Additives in HPHT Wells

Nanoclay Structure

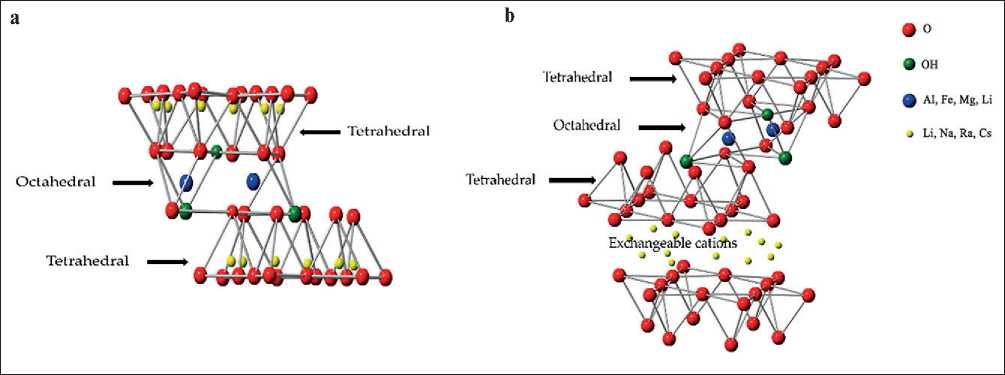

Nano-clay is a pozzolanic material used to improve cement properties. Comprises of eight – layered (octahedral) design of alumina (AlO6) embedded between four layers (tetrahedral) of silicon (SiO2) known as (Platelets structure). The average dimensions are 1 nm thick and 70– 150 nm wide [43, 44]. Classified in three ratios; First 1:1 ratio, one octahedral and one tetrahedral layer are platelet together by Van Der Waals attractive forces and hydrogen bonds such as in Halloysite and Kaolinite. Water cannot permeate between the layers due to the strength of the hydrogen bond; hence, kaolinite is normally non-swelling in water. The outer surface of the halloysite nanotubes resembles SiO2, while the inner cylinder core resembles Al2O3, which may improve the cement matrix [26, 45].

Second ratio is 2:1; two plates of tetrahedral sandwiching in one octahedral plate such as Sepiolite and Montmorillonite. Montmorillonite is a crystalline hydrous phyllosilicate with a permanent negative charge that balanced by interlayer exchangeable inorganic cations (Na+, Ca+2). When water molecules penetrate and ingest water molecules, the outer layers of montmorillonite become swollen, loosely held together by weak Van Der Waals forces. As a result, before be employed in cement-based mixtures containing water, nanosized montmorillonite is commonly chemically treated to become hydrophobic by cation exchange. Third, 2:1:1 attribution (chlorite), which not estimated as clay fig 3. Clays and clay min- erals (allophane, kaolinite, and montmorillonite) have found applications in many fields due to their abundance (in soils and sediments), low cost, and environmentally friendly nature [45–48].

Nanoclay effect in HPHT wells

Cementitious operations represent the barrier to meet the different conditions of wells such as pressure, temperature, liquids or gases flowing. When crossing the temperature barrier 110 °C, the hydration phase of Portland cement loses a significant amount of compression resistance, which caused decrease of the compressive strength over time and increased permeability [49]. C–S–H gel and Portlandite (CH) crystals, which chemically interact with each other when heated, are the primary sources of compressive strength in cement paste. The properties of cement paste after heat treatment are primarily affected by changes in water content, as well as mineral decomposition and fusion. at temperatures above 250 °C, most of the hydrate bonded water containing Al2O3 and Fe2O3 is lost, along with approximately 20% of the bonded water in the C–S–H gel, compressive and flexural strengths decrease appreciably [50, 51]. To address this challenge, clay nanoparticles have the endurance to mitigate this issue notably. Nanoclay can used to create an internal water reservoir. This is due to nanoclay ability to retain water. This provides internal water for more hydration, enhancing autogenous healing [36].

In view of this approach, Researchers agreed that Nanoclay has the ability to improve cement resistance to carbonation in geologic carbon storage (GCS) appli-

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

PRIMARY

-

1. incomplete annular cementing job, does not reach seal layer

-

2. Lack of cement plug or permanent packer

-

3・ Failure of the casing by burst or collapse

-

4. Poor bonding caused by mudcake

-

5. Channeling in the cement

-

6・ Primary permeability in cement sheath or cement plug

-

7. De-bonding due to tensile stress on casing-cement-formation boundaries

-

8. Fractures in cement and formation

-

9. Chemical dissolution and carbonation

-

10. Wear or corrosion of the casing

SECONDARY

of cement

Fig. 2. Wellbore leakage route [42]

Fig. 3. Clay mineral crystal structures: (a) Halloysite 1:1 ratio; (b) Montmorillonite 2:1 ratio [48]

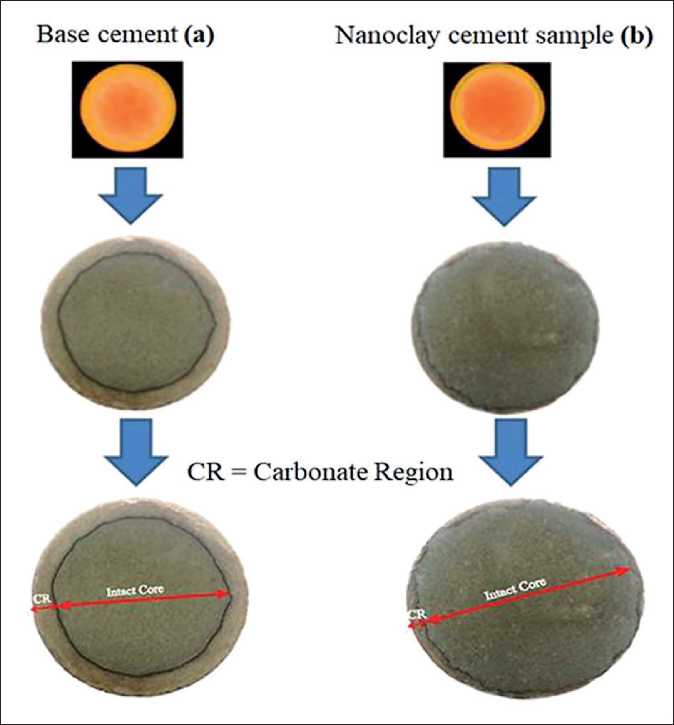

cations such as CO2 migration to other formations and defilement groundwater. This ability approved through the laboratory work by Elkatatny et al. [52–54]. They noted that, 1% montmorillonite with OPC (class G) and 0.5 M (NaCl) submerged in CO2 saturated brine for 5, 10, 20, 30 days (carbonation time) under 95 °C, 130 °C and 10 Mpa (1450 Psi) conditions, decreased the decline in compressive and tensile strength, then, increased by decrease the carbonation depth inside the cement sheath. The mechanism of nanoclay to improve carbonation re- sistance confirmed a decrease in Portlandite (CH) content and cement permeability, followed by an increase in the most thermodynamically stable calcium silicate hydrates (C–S–H) for the sample containing 1% NC. Fig 4

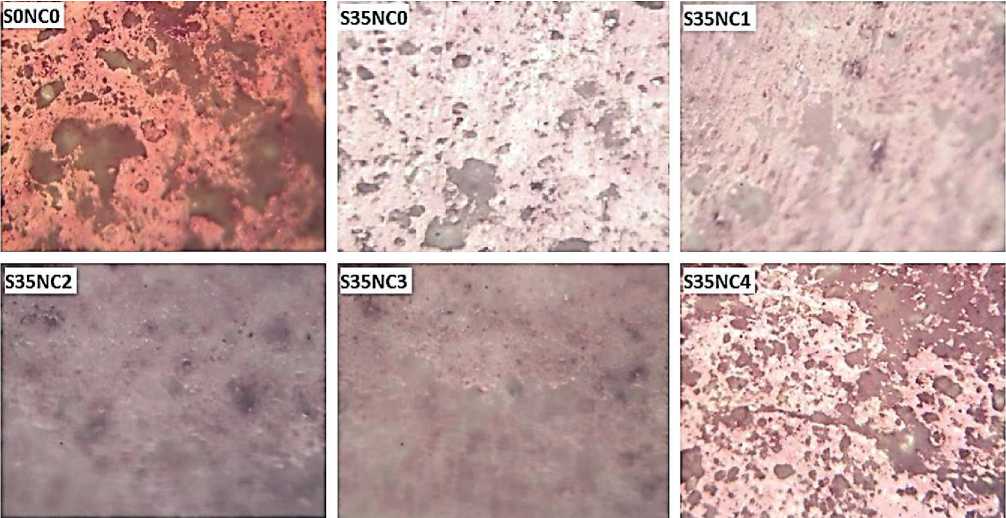

The use of nanoclay in high concentrations will result in nanoparticle agglomeration in the mixes. Because of these aggregations, weak zones form, which, prevents homogeneous hydrate formations from forming and drastically reduces cement strength retrogression resistance at high temperatures. Particularly in wells subjected to

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Fig. 4. Nanoclay decrease the carbonation region outward in the cement samples: (a) Cement sample with 0% nanoclay; (b) Cement sample with 1% nanoclay [52]

steam injection for enhanced oil recovery (EOR) applications, because the injected steam can reduce oil viscosity, increasing mobility and, ultimately, oil production. This was the subject of the two papers presented by Mahmoud et al. [55, 56]. Pointed out, through six cement samples (4 samples incorporating 1, 2, 3, and 4% BWOC of nanoclay with 35% BWOC silica flour, one sample cement with 35% silica flour and last sample without nanoclay and silica flour) for (7 and 28 days) curing under the (38 °C and 300 °C) temperature. The outcomes uncovered that the utilization of nanoclay (up to 3% BWOC) can forestall the oil well cement disintegration under amazingly high temperature conditions. Fusing over (3% BWOC) of nanoclay seriously harmed the concrete lattice microstructure because of the agglomeration of the nanoparticles. Consolidation of nanoclay particles expanded all the concrete slurry rheological properties. The microscope images confirmed that, nanoclay with (≤ 3% BWOC) improved to fill cement matrix pore space, while with (≥ 3% BWOC) affected on the cement structure by increasing the concentration of the pore space and increase in the permeability (Fig 5).

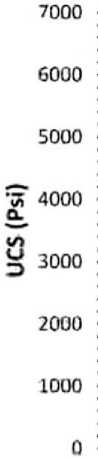

Nanoclay has the power for early developing the compressive strength and makes it robust. Cement rheology affected with addition of clay nanoparticles especially plastic viscosity PV (high PV made the cement ability more suitable to mud displacement), yield point YP (cement pumping become more sufficient with high YP) and Gel strength (a measure of the attractive forces between particles that cause gelation when flow is interrupted). It also describes the force required to restart circulation after it stopped). Researchers proved that, addition of nanoclay in amount (1–3% BWOC) enhanced the compressive strength to the value that, sufficient enough to support the steel casing prior to resuming the drilling operation under pressure 3000 Psi and temperature 140 °C. At the same conditions plastic viscosity, yield point and gel strength increased with nanoclay [57]. Table 2 and 3

It showed that, nanoclay particles have the ability to reduce fluid loss and prevent breakthrough for a longer period by blocking the pores in cement slurry at comparing with calcined clay. Nevertheless, in case of compressive Strength, plastic viscosity and yield points calcined clay more effective if compared with nanoclay. This approved

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Fig. 5. Optical microscopy images of the cement samples exposed to 300 °C. Where S is Silica Flour, NC is NanoClay [56]

Table 2

Cement rheology admixed with nanoclay at (3000 Psi and 140 °C)

|

Properties |

Glass G |

Base Mix |

1% NC |

2% NC |

3% NC |

|

Plastic Viscosity (cp) |

32.2 |

131.1 |

205.5 |

229 |

244.6 |

|

Yield Point (Ibf/100ft2 |

16.4 |

9.6 |

9.4 |

12.6 |

16.4 |

Table 3

Gel strengths for cement admixed with nanoclay

CONCLUSION

This review presented the summarized and highlighted of HPHT well cementing challenges along with nanoclay influencing under these conditions. HPHT wells display numerous economic, technical, operational, and HSE challenges such as pressure, temperature, loss of circulation, high equivalent circulating density (ECD), low cleaning efficiency, logging tools, and casing wear. It known that, all these parameters have an impact by one way or more on cementing operation failure. Thermal effect causes strength retrogression for the slurry when crossing the temperature barrier 110° C, the hydration phase of Portland cement loses a significant amount of compression resistance by changes in water content, which caused decrease of compressive strength over time and increased permeability. While the narrow margin between the pore pressure and the fracture gradient reason for abnormal pressures and introduce a different Tensile stresses at the casing-cement and the cement-rock interface.

According to the researchers articles, clay nanoparticles have the endurance to mitigate the issue of thermal and pressure effect in HPHT wells notably. Nanoclay can used to create an internal water reservoir. This is due to nanoclay ability to retain water, which provides internal water for more hydration, enhancing autogenous heal-

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Fig. 6. Uniaxial Compressive Strength results of calcined clay (CC) and nanoclay (NC) based cement slurries cured for 5 days ing, and encouraging in upgrading mechanical properties (nanoclay has the power for early developing the compressive strength and makes it robust) and rheological properties especially (plastic viscosity, yield point, and Gel strength) for cement slurry. Furthermore, nanoclay has the ability to improve cement resistance to carbonation in geologic carbon storage (GCS) applications such as CO2 migration to other formations and defilement groundwater. It can also act as a plasticizer due to the presence of silicon in its chemical composition. In addition, have the ability to reduce fluid loss and prevent breakthrough time for a longer period by blocking the pores in cement slurry.

Generally, HPHT wells continue to present numerous difficult challenges and hazards that have not addressed by conventional drilling methods. The constant debate is about the critical need for new methodologies and remarkable advancements in the tools and equipment used in these harsh environments. Even with the use of nanomaterials, it is difficult to determine the optimum amount of nanoparticles to use as a rule in these environments, but it almost universally agreed that small amounts must use. All of the methodologies developed to date for HPHT wells are unable to solve the complex equation of cost, safety, and performance.

Список литературы Application of nanotechnology in oil well cementing – an overview of the challenges associated with well cementing in difficult conditions

- Pubudu Gamage, Jay Deville (2013, February). Self-Degrading Gel for Downhole Applications in High Temperature Reservoirs. American Association of Drilling Engineers (AADE) National Technical Conference and Exhibition, Oklahoma; 2013. AADE-13-FTCE-13.

- Wade Wise, William Gusler, Nels Hansen, Brian Teutsch, Dominic Thomas (2010, April). HP/HT Well: Fluid Selection, Planning and Lessons Learned. American Association of Drilling Engineers (AADE) Fluids Conference and Exhibition, Houston, Texas; 2010. AADE-10-DF-HO-38.

- Mohamed Al-Bagoury, Martin Urraca, Tarek Fattah, Ben Wang (2019, April). Micronized Weighting Agents for Ultra-High-Density Oil Well Cementing. American Association of Drilling Engineers (AADE) National Technical Conference and Exhibition, Denver, Colorado; 2009. AADE-19-NTCE-027.

- Mojtaba Labibzadeh, Behzad Zahabizadeh, Amin Khajehdezfuly (2010, January). Early-age compressive strength assessment of oil well class G cement due to borehole pressure and temperature changes. Journal of American Science. 2010; 6(7).

- Phillip D. McElroy, Hossein Emadi, Marshall C. Watson, Habib K. Menouar (2020, April). Improving Cement Wellbore Integrity with Fiber Hybridization: Based on Response Surface Methodology. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2020. AADE-20-FTCESPP-09.

- A.S. Al-Suwaidi, A. Abou Soliman, K. Jammeli, M. Arif, B. Elatrache, T. Fattah, M. Agnani, E. Voon (2008, November). A New Cement Sealant System for Long-Term Zonal Isolation for Khuff Gas Wells in Abu Dhabi. Society of Petroleum Engineers., Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi; 2008. SPE 117116.

- K. Ravi, M. Bosma, O. Gastebled (2002, February). Improve the Economics of Oil and Gas Wells by Reducing the Risk of Cement Failure. Society of Petroleum Engineers, IADC/SPE Drilling Conference, Dallas, Texas; 2002. IADC/SPE 74497.

- Runar Nygaard, Saeed Salehi, Benjamin Weideman (2012, April). Cement Failure and Potential Wellbore Leakage Induced by Injection Loads. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas 2012; AADE-12-FTCE-35.

- Kris Ravi, David E. McMechan, B.R. Reddy, Ron Crook (2004, June). A Comparative Study of Mechanical Properties of Density- Reduced Cement Compositions. Society of Petroleum Engineers; 2004. SPE Annual Technical Conference and Exhibition, Houston., SPE 90068.

- Joseph Huwel P.E., Faustino Villarreal, Russel Roberts (2014, April). Cement Compressive Strength Development Drastically Affected by Testing Procedure. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2014. AADE-14-FTCE-22.

- M. K. Rahman, W. A. Khan, M. A. Mahmoud (2016, March). MWCNT for Enhancing Mechanical and Thixotropic Properties of Cement for HPHT Applications. Offshore Technology Conference, Kuala Lumpur, Malaysia; 2016. OTC-26465-MS.

- Jiankun Qin, Xueyu Pang, Guodong Cheng, Yuhuan Bu, Huajie Liu (2021, October). Influences of different admixtures on the properties of oil well cement systems at HPHT conditions. Elsevier, Cement and Concrete Composites. 2021; 123:104202. https://doi.org/10.1016/j.cemconcomp.2021.104202

- M.A. Shahri, J.J. Schubert, M. Amani (2005, November). Detecting and Modeling Cement Failure in High-Pressure/High-Temperature (HP/HT) Wells, Using Finite Element Method (FEM). International Petroleum Technology Conference, Doha, Qatar; 2005. IPTC 10961.

- Fatemeh K. Saleh, Catalin Teodoriu (2017, February). The mechanism of mixing and mixing energy for oil and gas wells cement slurries: A literature review and benchmarking of the findings. Journal of Natural Gas Science and Engineering. 2017; 38: 388-401. https://doi.org/10.1016/j.jngse.2016.12.017

- Jiang Yang, Sixue Ji, Ran Li, Wenlong Qin, Yongjun Lu (2015, June). Advances of nanotechnologies in oil and gas industries. Energy Exploration and Exploitation. 2015; 33 (5): 639–657.

- C. Vipulanandan, A. Mohammed (2015, November). Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Materials and Structures. IOPscience. 2015; 24 (12): 125020. https://iopscience.iop.org/article/10.1088/0964-1726/24/12/125020

- Ines Dejaeghere, Mohammed Sonebi, Geert De Schutter (2019, October). Influence of nano-clay on rheology, fresh properties, heat of hydration and strength of cement-based mortars. Elsevier. Construction and Building Materials. 2019; 222: 73-85. https://doi.org/10.1016/j.conbuildmat.2019.06.111

- Sushant Agarwal, Phuoc Tran, Yee Soong, Donald Martello, Rakesh K. Gupta (2011, April). Flow Behavior of Nanoparticle Stabilized Drilling Fluids and Effect of High Temperature Aging. American Association of Drilling Engineers (AADE) National Technical Conference and Exhibition, Houston, Texas,. AADE-11-NTCE-3.

- Muhammad Hasibul Hasan, Md. Sazib Mollik (2015, November). Mechanical Performance of Montmorillonite Dispersed Jute Reinforced Composite. Advanced materials and properties. International Conference on Material Science and Engineering Technology (ICMSET). 2015; 30: 01007. https://doi.org/10.1051/matecconf/20153001007

- Hugo Varela, Gonzalo Barluenga, Irene Palomar, Alberto Sepulcre (2021, September). Synergies on rheology and structural build-up of fresh cement pastes with nanoclays, nanosilica and viscosity modifying admixtures. Elsevier. Construction and Building Materials. 2021; 308: 125097. https://doi.org/10.1016/j.conbuildmat.2021.125097

- Cumaraswamy Vipulanandan, Ahmed Mohammed (2016, April). Nanoclay Modified Drilling Muds for HPHT Applications. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2016. AADE-16-FTCE-85.

- C. Vipulanandan, A. Mohammed (2018, May). Fluid Loss Control in Smart Bentonite Drilling Mud Modified with Nanoclay and Quantified with Vipulanandan Fluid Loss Model. Offshore Technology Conference, Houston, Texas; 2018. OTC-28947-MS.

- M.S. Morsy, S.H. Alsayed, M. Aqel (2011, January). Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar. Elsevier. Construction and Building Materials. 2011; 25(1): 145-149. https://doi.org/10.1016/j.conbuildmat.2010.06.046

- S. Zhang, Y. Fan, N. Li. Pore structure and freezing resistance of nanoclay modified cement based materials. Materials Research Innovations. 2014; 18 (sup 2). https://doi.org/10.1179/1432891714Z.000000000434

- Shiho Kawashima, Pengkun Hou, David J. Corr, Surendra P. Shah (2013, February). Modification of cement-based materials with nanoparticles. Elsevier. Cement and Concrete Composites. 2013; 36: 8-15. https://doi.org/10.1016/j.cemconcomp.2012.06.012

- A. Hakamy, F. U. A. Shaikh, I. M. Low (2013, November). Thermal and mechanical properties of hemp fabricreinforcednanoclay–cement nanocomposites. Springer. Journal of Materials Science. 2013; 49: 1684–1694. https://link.springer.com/article/10.1007/s10853-013-7853-0

- Zeeshan Tariq, Mobeen Murtaza, Mohamed Mahmoud (2020, July). Development of New Rheological Models for Class G Cement with Nanoclay as an Additive Using Machine Learning Techniques. American Chemical Society. ACS Publications. 2020; 5 (28): 17646–17657. https://doi.org/10.1021/acsomega.0c02122

- Ahmed S. Mohammed (2018, September). Vipulanandan model for the rheological properties with ultimate shear stress of oil well cement modified with nanoclay. Elsevier. Egyptian Journal of Petroleum. 2018; 27(3): 335-347. https://doi.org/10.1016/j.ejpe.2017.05.007

- Paul Fredericks, Ossama Sehsah, Fernando Gallo, Corrado Lupo. Practical Aspects and Value of Automated MPD in HPHT Wells. American Association of Drilling Engineers (AADE) National Technical Conference and Exhibition. New Orleans. Louisiana; 2009. AADE 2009NTCE-04-04.

- Amr Radwan, Moji Karimi (2011, October). Feasibility Study of Casing Drilling Application in HPHT Environments; A Review of Challenges, Benefits, and Limitations. SPE/IADC Middle East Drilling Technology Conference and Exhibition, Muscat, Oman; 2011. SPE/IADC 148433.

- H. Rabiaah Well Engineering and Construction Handbook; 2010.

- Mohammed Reza Amighi, Khalil Shahbazi (2010, January). Effective Ways to Avoid Barite Sag and Technologies to Predict Sag in HPHT and Deviated Wells. SPE Deep Gas Conference and Exhibition, Manama, Bahrain; 2010. SPE 132015.

- Aberdeen Drilling Schools and Well Control Training Center. High Pressure High Bottom Hole Temperature. https://www.aberdeendrilling.com/

- Tom Proehl, Fred Sabins (2006, June). Drilling and Completion Gaps for HPHT Wells in Deep Water Final Report. U.S. Department of the Interior Minerals Management Service Offshore Minerals Management Technology Assessment and Research Program. Deep Star, 2006; CTR 7501.

- Oluseun A. Sanuade, Salaheldin Elkatatny (2018, April). Cement Failure Modeling for High Pressure High Temperature Wells: Case Studies. SPE Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia; 2018; SPE-192232- MS.

- Mohamed Al-Bagoury (2018, April). Micro-composite as a Fluid Loss Additive for Oil Well Cementing. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2018. AADE-18-FTCE-065.

- Venkata Gopala Rao Palla, Abhimanyu Deshpande (2014, April). Is the Wellbore Prepared “Enough” for Cementing? Finding Answers using Electrochemical Impedance Spectroscopy. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2014. AADE-14-FTCE-40.

- Mohamed Al-Bagoury, Philippe Revil, Atle Kastad (2016, April). Silica Dispersion for HT Oil Well Cement. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2016. AADE-16-FTCE-57.

- Andrew C. Jupe, Angus P. Wilkinson, Karen Luke, Gary P. Funkhouser (2008, May). Class H cement hydration at 180 °C and high pressure in the presence of added silica. Elsevier. Cement and Concrete Research. 2008; 38 (5): 660-666. https://doi.org/10.1016/j.cemconres.2007.12.004

- Siwei Ma, Shiho Kawashima (2019, August). A rheological approach to study the early-age hydration of oil well cement: Effect of temperature, pressure and nanoclay., Elsevier, Construction and Building Materials. 2019; 215:119-127. https://doi.org/10.1016/j.conbuildmat.2019.04.177

- Benjamin Weideman, Runar Nygaard (2014, April). How Cement Operations affect your Cement Sheath Short- and Long-Term Integrity. American Association of Drilling Engineers (AADE) Fluids Technical Conference and Exhibition, Houston, Texas; 2014. AADE-14-FTCE-20.

- Gajanan Bhat, Raghavendra R. Hegde, M.G. Kamath, Bhushan Deshpande (2008, September). Nanoclay Reinforced Fibers and Nonwovens. Journal of Engineered Fibers and Fabrics. 2008; 3 (3). https://doi.org/10.1177/155892500800300303

- Antonella D Alessandro, Annibale Luigi Materazzi, Filippo Ubertini. Nanotechnology in Cement-Based Construction. Jenny Stanford Publishing Pte. Ltd.; 2020. https://www.jennystanford.com/

- Shiho Kawashima, Kejin Wang, Raissa Douglas Ferron, Jae Hong Kim, Nathan Tregger, Surendra Shah (2021, September). A review of the effect of nanoclays on the fresh and hardened properties of cement based materials. Elsevier. Cement and Concrete Research. 2021; 147: 106502. https://doi.org/10.1016/j.cemconres.2021.106502

- M. Calabi Floody, B. K. G. Theng, P. Reyes, M. L. Mora (2009, June). Natural nanoclays: applications and future trends – a Chilean perspective. The Mineralogical Society. Clay Minerals. 2009; 44 (2): 161–176. https://doi.org/10.1180/claymin.2009.044.2.161

- Mohammad Jawaid, Abou el Kacem Qaiss, Rachid Bouhfid. Nanoclay Reinforced Polymer Composites Nanocomposites and Bionanocomposites. Springer Science and Business Media Singapore. Pte Ltd.; 2016.

- Feng Guo, Saman Aryana, Yinghui Han, Yunpeng Jiao (2018, September). A Review of the Synthesis and Applications of Polymer–Nanoclay Composites. MDPI. Applied Sciences. Appl. Sci. 2918; 8(9): 1696. https://doi.org/10.3390/app8091696

- U. T. Bezerra, A. E. Martinelli, D. M. A. Melo, M. A. F. Melo, V. G. Oliveira (2011, June). The strength retrogression of special class Portland oilwell cement. Ceramica. 2011; 57 (342): 150-154. https://www.researchgate.net/publication/262595843

- M.S. Morsy, Y.A. Al-Salloum, H. Abbas, S.H. Alsayed (2012, October). Behavior of blended cement mortars containing nano- metakaolin at elevated temperatures. Elsevier. Construction and Building Materials. 2012; 35: 900-905. https://doi.org/10.1016/j.conbuildmat.2012.04.099

- Wei-Chien Wang (2017, August). Compressive strength and thermal conductivity of concrete with nanoclay under Various High- Temperatures. Elsevier. Construction and Building Materials. 2017; 147: 305-311. https://doi.org/10.1016/j.conbuildmat.2017.04.141

- Ahmed Abdulhamid Mahmoud, Salaheldin Elkatatny (2019, August). Mitigating CO2 reaction with hydrated oil well cement under geologic carbon sequestration using nanoclay particles. Journal of Natural Gas Science and Engineering. 2018; 68. (102902). https://doi.org/10.1016/j.jngse.2019.102902