Artificial Neural Network Based Control Strategies for Paddy Drying Process

Автор: Shekhar F. Lilhare, N. G. Bawane

Журнал: International Journal of Information Technology and Computer Science(IJITCS) @ijitcs

Статья в выпуске: 11 Vol. 6, 2014 года.

Бесплатный доступ

Paddy drying process depends upon ambient conditions, paddy quality, temperature and mass of hot drying air. Existing techniques of paddy drying process are highly nonlinear. In this paper, a neural network based automated controller for paddy drying is designed. The designed controller manages the steam temperature and blower motor speed to achieve constant paddy drying time. A Layer recurrent neural network is adopted for the controller. Atmospheric conditions such as temperature and humidity along with the size of the paddy are used as input to the network. Experimental results show that the developed controller can be used to control the paddy drying process. Implementation of developed controller will help in controlling the drying time at almost constant value which will definitely improve the quality of rice.

Paddy, Drying Time, Neural Controller, Simulation, Control Strategies

Короткий адрес: https://sciup.org/15012188

IDR: 15012188

Текст научной статьи Artificial Neural Network Based Control Strategies for Paddy Drying Process

Published Online October 2014 in MECS

The variable temperature drying using fuzzy controller with features of non-linear, time variability and other variables during paddy drying process, improve the production efficiency of dryer and reduce drying cost of high moisture content paddy[6]. The work in [7, 8] propose an advanced control strategy used to design temperature, relative humidity and air velocity nonlinear tracking controllers, in order to overcome its highly nonlinear dynamics over whole drying operating conditions. In online quantitative feedback theory (QFT) based selftuning controller [9] for a conveyor belt type grain dryer plant a mathematical model of the grain dryer plant was obtained using system identification and real-time input/output data. QFT technique potentially has excellent solution towards this problem due to its well known capability to achieve robust performance regardless parameter variation such as long delay time, presence of disturbances and plant uncertainty. An automatic multi parameter processing system improve the tiresome procedure for grain drying in a deep fixed - bed dryer [10]. Drying experiments [11] conducted to assess the effects of inlet drying air temperature, feed mass flow rate, on energy efficiency, entropy generation, improvement potential rate, and sustainability index. Study conducted by researchers [12, 13, 14] show that the surface drying process can be controlled by three variables temperature, humidity rate, and direction of air flow rate from external source. Values of these variables should be optimized to obtain maximum efficiency and drying performance.

Dimensions are important factor of paddy to be studied for quantitative analysis of heat penetration and requirement. Paddy shape is treated cylindrical body for heat conduction purpose [20]. The weight of paddy is moisture dependent whereas equilibrium moisture contents (M e ) is dependent upon ambient temperature & relative humidity of environment and variety of paddy. To evaluate the required heat for drying, equilibrium moisture contents (Me), specific heat of moist paddy (Cg), specific heat of bone dry paddy (Cdr), total temperature rise during drying etc. are essential [3]. Accurate information of these factors are needed for successful simulation and optimisation of grain drying and aeration systems. Specific heat of moist paddy (Cg) is required, to calculate the total amount of heat to raise the temperature of paddy to a certain level. Specific heat of dry paddy (Cdr) for different size varies in range from 1.3 to 2.0 kJ/ kg within the moisture range 0 - 20% weight basis (w.b.). Moisture inside brown parboiled rice behaves almost like free water when moisture content is above 12% weight basis [1, 21]. Heat required for rising the temperature of water contents of paddy depending on bone dry paddy weight, its initial moisture contents and rise in temperature. The important physical properties such as shape, size, environment condition, volume, surface area, colour etc. of different grains is necessary for design of various separating, handling and drying systems [3]. Environmental condition comprises of ambient temperature and relative humidity varies with seasons and places. These variations do affect paddy drying characteristics as well as drying duration. The researches show that drying process depends on mass and temperature of drying air, ambient condition, quality of paddy and its feed rate etc. Proper combinations of motor speed and steam temperature have to be maintained to achieve the required mass & temperature of drying air. Grain moisture contents and its quality can be helpful in deciding the best possible drying conditions and drying duration. Experimental observations of drying characteristics and drying duration in various drying conditions for medium and thick quality paddy with constant feed rate shows that there are considerable difference in drying duration when processed under constant drying air temperature and mass.

Normally operator keeps constant temperature and flow rate of hot air (drying element) in all drying conditions irrespective of change in weather conditions. This constant flow and temperature of drying air is bound to get variable drying time with varying ambient conditions. The variable drying time is to be regulated or made constant by controlling temperature and mass of drying air within permissible limit. The required temperature and mass of drying air can be achieved by variations in blower motor speed and steam temperature and the proposed ANN controller would be helpful in these variations to regulate the drying time.

The research work is organized in two major stages. In first stage drying parameter data have been collected for maximum possible ambient conditions with traditional drying process, and in the second stage, motor speed and steam temperature have been changed to achieve the desired drying time. The details of paddy dryer system, present process control techniques (based on operator's skill), block diagram of existing and proposed changes in the process control using ANN are discussed in section 2. Methodology for design of controlled paddy drying process, real time observations as well as simulated drying parameters and drying duration, application of suitable integrated ANN to select new inputs for process control to change drying time are given in section 3. Experimental testing and results are given in section 4 and finally section 5 deals with Conclusion.

-

II. Paddy Drying System

The continuous flow mixing type LSU grain dryer consists of rectangular drying chamber (4.10 m ×2.35 m × 5 m), with 32 ton installed capacity located at SHRINATH rice processing plant Gondia (M.S) is chosen for experimentation. The dryer system is equipped with a blower, heat exchanger, duct and boiler. The 35 HP, 750 rpm GEC make squirrel cage Induction motor runs the blower at constant speed. An additional Lenz A. C. Frequency drive system has been connected to motor supply terminal for experimentation to vary motor speed. A blower of 0.95 m. fan diameter, 3000 m3/minute air blowing capacity is coupled by V belts with Motor. Sony make heat exchanger with 90 steam tubes of 1 meter length and 0.03 meter diameter has been used for drying air heating. VEE SON'S Energy system (Trichirapally make) steam boiler model FFF4 with rated working pressure 150 kg /cm2 and 2 Ton /hour capacity has been installed for steam supply in existing dryer plant.

-

A. Existing paddy drying process

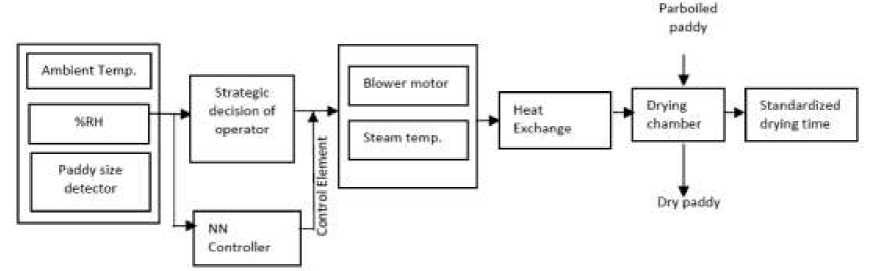

The strategic decision of operator is very important in existing paddy drying process for proper paddy drying.

His previous knowledge helps to decide the steam temperature circulated through heat exchanger steam tubes. A blower fan attached to motor blows the air at normal temperature and pressure in cross flow to steam tubes. The blown air comes in contact with heat exchanger's steam tubes and gets heated. This hot air supplied to drying chamber through duct in cross flow with paddy. The paddy flows from top to bottom with uniform flow rate, comes in contact of hot air and dry as shown in Fig.1 (without NN controller). Operator normally do not change blower motor speed and steam temperature as a result drying air at constant volume and temperature is supplied to dryer chamber. The supply of drying air at constant volume and temperature is taking different drying time, in different operating conditions which is undesirable. As a result frequent manual moisture measurement of the paddy is required to take the decision to stop drying air supply.

-

B. Proposed paddy drying process

Drying air temperature and flow rate is depending on blower motor speed and steam temperature. The objective of this study is to make constant or desired drying time for each size of paddy, irrespective of change in weather condition. To achieve this, drying air temperature and flow rate is estimated by simulating the prepared model.

The relation between blower motor speed and steam temperature is established with hot drying air temperature and flow rate at different atmospheric temperature and % relative humidity.

In the proposed modified process diagram sensors for environmental temperature and % relative humidity has been added. The size of the paddy is detected by camera (Fig.1). The detected size of paddy is classified in to thick and medium size. These sensed and detected data are fed to ANN controller to make decision of motor speed and steam temperature. According to output of ANN controller, motor speed and steam temperature have been varied. This varied motor speed, controls the mass of air which comes in contact with steam tubes and getting heated in heat exchanger. Heated drying air temperature and its mass is maintained (within permissible limit) in such a way so that drying period in all weather conditions are either constant or targeted one. There are numerous combinations of blower motor speed and steam temperature to achieve targeted drying period. Probabilities of mistakes are very high in selection of proper combination of motor speed and steam temperature which may cost more energy, over or under drying of paddy.

Fig. 1. Block diagram of proposed paddy drying process

To avoid all these difficulties we have developed the sensor unit and Neural Network controller. Proposed NN controller is trained and simulated by all possible combinations of ambient temperature, relative humidity and size of paddy as input parameter and required combinations of blower motor speed and steam temperature for making desired drying time in different ambient conditions as target to the NN. According to simulated output changes in motor speed and steam temperature is maintained for regulating the hot air temperature, coming out from heat exchanger to achieve desired or standardized drying period.

-

III. Methodology for Design of Controlled Paddy Drying Process

contents and temperature of paddy during drying, drying duration, blower motor speed (air flow rate), steam temperature, hot air temperature at entry and exhaust points for dryer chamber. Due care is taken to have real time observations for both types of paddy in most possible drying conditions. Out of 54 recorded data, 9 sample data of extreme conditions for both types of paddy are shown in table 1.

Table 1. Real time observations in normal drying condition

|

S.N. |

Paddy size |

.Ambient condition |

Normal Running Conditions |

|||||||

|

(motor speed is constant and steam temperature is changing) |

||||||||||

|

Temp. |

°oRH |

Drying time (hr) |

Motor speed |

Air Volin |

Steam Temp. |

Hot air temp. |

Simulate dhot air temp. |

|||

|

Real |

Simulate d |

(RPM) |

||||||||

|

1 |

м |

40 |

30 |

5.3 |

5.27 |

720 |

3000*60 |

115 |

78 |

76.23 |

|

2 |

м |

34 |

58 |

6.2 |

6 |

720 |

3000*60 |

115 |

7? |

74.61 |

|

3 |

м |

31 |

85 |

7.15 |

6.9 |

720 |

3000*60 |

115 |

73 |

71.88 |

|

4 |

м |

21 |

65 |

7.13 |

720 |

3000*60 |

125 |

75 |

73.34 |

|

|

5 |

т |

41 |

35 |

6.3 |

5.07 |

720 |

3000*60 |

115 |

78 |

76.52 |

|

б |

т |

30 |

85 |

7.3 |

7.15 |

720 |

3000*60 |

125 |

79 |

76.33 |

|

7 |

т |

25 |

90 |

7.55 |

84 |

720 |

3000*60 |

125 |

7? |

74.38 |

|

8 |

т |

21 |

63 |

8.3 |

7.9 |

720 |

3000*60 |

130 |

78 |

75.43 |

|

9 |

т |

17 |

69 |

845 |

8 6 |

720 |

3000*60 |

130 |

76 |

73.56 |

In present situations variation in drying duration is unavoidable and authentic documentation regarding drying durations at different atmospheric conditions are not available. Operators have to check the paddy moisture continuously to confirm the completion of drying process.

Sometimes paddy is over dried because of negligence due to physical tiredness or lack of operator's awareness. To overcome these practical difficulties it is felt that there is a need to develop the process model which must accommodate variable parameters such as ambient temperature, relative humidity, mass of paddy, its equilibrium moisture contents (M e ), specific heat of moist paddy (Cg), specific heat of bone dry paddy (Cdr) and total temperature rise during drying process. A suitable MATLAB simulink paddy drying process model [27, 28] able to incorporate above said parameters is developed. The developed model is simulated for real-time observed drying conditions and results are found very close to realtime observations as shown is table 1(refer real and simulated drying time). It is also observed that simulated and real time drying process durations are close to each other and within tolerable limits, which inspired us for experimentation on drying system.

-

A. Application of Artificial Neural Network

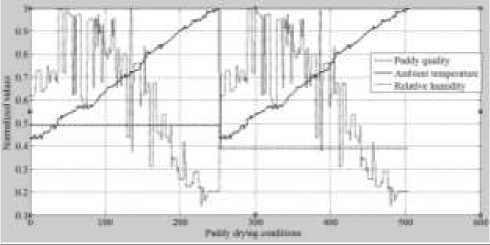

Total 504 different combinations for ambient temperature, relative humidity and size of paddy have been observed to perform the drying process. It is difficult for an operator to remember all these combinations and respective drying time data. Apart from this sometimes environment conditions changes in between drying process and make it complicated. These complications create lot of confusion in selection of operating conditions which may lead towards more erratic outputs. The applications of artificial neural networks are most widely used for solving such types of data analysis and control [29, 30]. A suitable ANN has to be design to change the operating conditions as per need. Feed-forward ANNs allow signals to travel one way from input to output only. There is no feedback i.e., the output of any layer does not affect that same layer. Feed-forward ANNs tend to be straight forward networks that associate inputs with outputs. Layer recurrent or feedback networks are powerful and found most suitable for classification of complicated and large number of data. Layer recurrent networks can have signals travelling in both directions by introducing loops in the network. In these networks, computations derived from earlier input are fed back into the network, which gives them a kind of memory. Feedback networks are dynamic, their state is changing continuously until they reach an equilibrium point. They remain at equilibrium point until the input changes and a new equilibrium needs to be found. A three layer recurrent NN is designed in this study. Total 504 set for input components (paddy quality, ambient temperature and relative humidity) are made as per need of drying conditions and their respective targeted outputs (motor speed and steam temperature) are obtained. A data bank is prepared to operate the dryer with controlled motor speed and seam temperature for constant drying time at all probable drying conditions. Graphical presentation of data (normalized) for input variables, and outputs (operating conditions) along with errors are given in subsequent section.

-

B. Input variables

-

(i) Paddy quality: - Drying time is depending on specific heat of paddy and specific heat is depending on size of paddy. Paddy is divided into thick and medium size. The specific heats of medium and thick size paddy

are 0.39 and 0.49 Kcal/kg°C. First assigned input to NN (for medium paddy = 0.39 and for thick paddy = 0.49) have been set for paddy quality (Fig. 2).

-

(ii) Ambient temperature: - The range of ambient temperature varies between 13 to 45°C at Gondia in Vidarbha region, India. Since paddy dryers are operated in day time only to minimize the energy consumption and labour related problems that's why the range of day time temperature (15 to 45°C) is taken. Normalized values of temperature are ranging from 0.4307 to 1 (Fig. 2) is the second input to NN.

-

(iii) Relative humidity: - The range of relative humidity is varying from 13 to 93% at Gondia in Vidarbha region, India. The normalized values of relative humidity are ranging from 0.139 to 1 (Fig. 2) is the third input to NN.

-

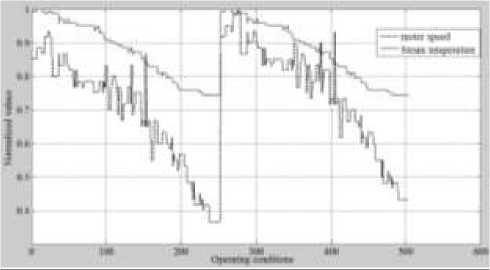

C. Target variables

-

(i) Motor speed: - The range of motor speed varies from 265 rpm to 720 rpm. The normalized range of motor speed has been taken 0.3673 to 1 as first output (Fig. 3) to train NN.

-

(ii) Steam temperature: - The range of Steam temperature varies from 105°C to 145°C. The normalized range of steam temperature has been taken 0.7447 to 1 (Fig. 3) as second output to train NN.

-

Three inputs, two outputs recurrent ANN having two hidden layers has been trained with random data division for above said inputs and outputs. The no. of neuron for first and second hidden layers are 10 and 6 respectively, while 500 epochs, TANSIG transfer function, 500 maximum fails are selected for training process of network. The best validation performance is achieved at 265 epochs while the simulated mean square error is 0.00097.

-

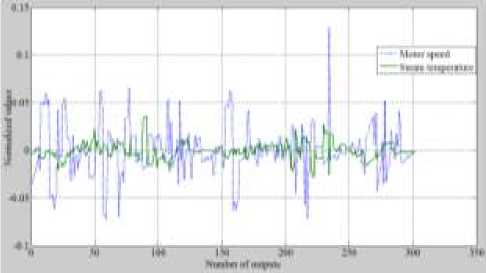

D. Errors

The supplied targets to NN and simulated outputs are very close to each other. Errors (mean) for motor speed and steam temperature are shown in Fig. 4.

-

(i) Error in motor speed: - The minimum error in the motor speed is - 7% while maximum error is found 12%. Mean error for motor speed is - 0.000007% while standard deviation in error is 2.6%. Lower percentage of standard deviation is indicating that most of the outputs are close to targeted motor speed.

-

(ii) Error in steam temperature:- The minimum error in the steam temperature is 2.8% while maximum error is found 3.5%. Mean error for steam temperature is – 0.06% while standard deviation is 0.9%. Lower percentage of standard deviation is indicating that almost all outputs are close to targeted steam temperature.

-

IV. Experimental Testing and Results

Testing and validation of any process is most important part of research activity. For drying process experimentation and testing with controlled conditions Mr. Krishnakant Khandelwal and Mr. Anil Jain proprietor of Shrinath paddy processing plant are requested to permit us for necessary experimentation.

Fig. 2. Input to neural network

Fig. 3. Target to neural network

Fig. 4. Errors in motor speed and steam temperature

After getting permission to experiment and man power assistance, Mr. Ramchand (operator) is contacted for necessary arrangement. With the help of operator a Lenz make A. C. frequency drive system is connected to motor supply terminal for getting variable motor speed. Variation in motor speed can be done by just changing the position of frequency drive system knob. Temperature of supplied steam can be changed by existing valve position. The new targeted drying time 5 hr. 45 minutes for medium size paddy and 6.0 hrs for thick size paddy have been fixed. To achieve these targeted drying time in all 34 experiments are performed as per controlled motor speed and steam temperature spreading over summer winter and rainy seasons. The controls of motor speed and steam temperature have been done according to the outputs of ANN manually. Out of these 34 experiments, 8 experiments could not be performed in single stage because of mechanical or electrical related failure. Observations of remaining 26 successful experiments are shown in table 2.

The real drying time for medium and thick paddy shown in table 2 are almost constant and close to targeted one (5 hrs. 45 min. and 6 hrs.) with controlled motor speed and steam temperature. The range of the motor speed is 390 rpm to 720 rpm (respective volume of blown air is 1600 kg/m to 3000 kg/m) and steam temperature is ranging from 110 to 145°C. These ranges are well within the operating ranges provided by manufacturers and previous researchers. The analysis obtained errors for motor speed show that, out of 504 input, 10 nos. of inputs are giving more than 6% error, 22 nos. of inputs are giving more than 5% error, 43 nos. of inputs are giving more than 4% error and remaining 227 nos. of inputs are giving less than 4% errors when compared with targeted motor speed. Analysis for steam temperature show that 15 nos. of inputs are giving more than 1% error while remaining inputs are giving less than this when compared with targeted steam temperature.

Table 2. Real time observations in controlled conditions by setting motor speed and steam temperature manually according to ANN output

|

SN |

Paddy size |

Ambient condition |

Controlled Drying Conditions |

||||||

|

Temp. “C |

%RH |

Drying tune (hrs) |

Motor (RPNf) |

Air voLf hr |

Steam Temp *C |

Hot an Temp “C |

|||

|

Targeted |

Real |

||||||||

|

1 |

0.39 |

40 |

35 |

5.45 |

5.45 |

460 |

1900*60 |

115 |

85 |

|

2 |

0.39 |

40 |

25 |

5.45 |

5.5 |

430 |

1800*60 |

115 |

85 |

|

3 |

0.39 |

36 |

80 |

5.45 |

5.4 |

720 |

3000*60 |

120 |

78 |

|

4 |

0.39 |

35 |

60 |

5.45 |

5.5 |

720 |

3000*60 |

120 |

78 |

|

5 |

0.39 |

33 |

40 |

5.45 |

5.45 |

625 |

2600*60 |

125 |

83 |

|

б |

0.39 |

31 |

80 |

5.45 |

5.45 |

525 |

2200*60 |

130 |

87 |

|

7 |

0.39 |

30 |

70 |

5.45 |

5.45 |

560 |

2400*60 |

130 |

84 |

|

8 |

0.39 |

28 |

60 |

5.45 |

5.55 |

720 |

3000*60 |

130 |

78 |

|

9 |

0.39 |

27 |

80 |

5.45 |

5.4 |

625 |

2600*60 |

135 |

84 |

|

10 |

0.39 |

22 |

70 |

5.45 |

5.4 |

675 |

2800*60 |

140 |

84 |

|

11 |

0.39 |

42 |

30 |

5.45 |

5.4 |

460 |

1900*60 |

110 |

82 |

|

12 |

0.39 |

44 |

20 |

5.45 |

5.5 |

460 |

1900*60 |

105 |

80 |

|

13 |

0.49 |

45 |

20 |

6 |

5.55 |

390 |

1600*60 |

110 |

86 |

|

14 |

0.49 |

43 |

30 |

6 |

6 |

550 |

2300*60 |

no |

79 |

|

15 |

0.49 |

42 |

40 |

6 |

6 |

450 |

1900*60 |

115 |

86 |

|

16 |

0.49 |

36 |

60 |

6 |

6.1 |

600 |

2500*60 |

127 |

84 |

|

17 |

0.49 |

29 |

90 |

6 |

6.15 |

650 |

2700*60 |

135 |

83 |

|

18 |

0.49 |

41 |

35 |

6 |

6 |

430 |

1800*60 |

117 |

85 |

|

19 |

0.49 |

30 |

85 |

6 |

6 |

650 |

2700*60 |

137 |

86 |

|

20 |

0.49 |

25 |

90 |

6 |

6.15 |

675 |

2800*60 |

142 |

85 |

|

22 |

0.49 |

35 |

50 |

6 |

5.1 |

720 |

3000*60 |

125 |

SO |

|

23 |

0.49 |

32 |

70 |

6 |

6 |

650 |

2700*60 |

130 |

83 |

|

24 |

0.49 |

22 |

70 |

6 |

5.5 |

700 |

2900*60 |

145 |

84 |

|

25 |

0.49 |

24 |

60 |

6 |

6.05 |

720 |

3000*60 |

140 |

82 |

|

26 |

0.49 |

21 |

63 |

6 |

6.15 |

700 |

2900*60 |

145 |

85 |

-

V. Conclusion

Varying ambient temperature and relative humidity have great effect on drying air temperature and paddy drying duration. Drying duration can be changed by changing drying air temperature and it's mass. The varying drying duration can be regulated or made constant by controlling temperature and mass of drying air. In this paper the concept of an integrated ANN has been developed to regulate motor speed and steam temperature according to paddy size to achieve the desired drying time irrespective of weather conditions. Experimental results show that drying time for medium size paddy is varying from 5 hrs. 30 min. to 7 hrs., while for thick paddy it is 6 hr. 30 min. to 8 hrs. 45minutes. It is observed that drying duration is less in summer season and more in winter seasons for both types of paddy.

The maximum difference between targeted and real time drying duration for medium and thick paddy are 10 minutes and 15 minutes i.e. 2.89% and 2.5%. The maximum hot air temperature in controlled condition is 87 °C, which is under tolerable limit of 90 °C [31].

It is also concluded that drying time is affected more by change in ambient temperature as compare to change in % relative humidity. Higher ambient temperature shortens drying time, while higher relative humidity longer the drying duration. Errors in motor speed are more as compare to steam temperature. On the basis of these results it is concluded that for better drying results, drying process duration should be control by varying steam temperature.

Acknowledgment

The authors would like to convey their sincere thanks to Mr. Krishnakant Khandelwal and Mr. Anil Jain proprietor SHRINATH rice processing industry for permitting necessary experimentations, real time observations and required changes in operating conditions. We are also thankful to Mr. Ramchand (operator) for his time to time co-operation in making necessary changes for successful experimentation.

Список литературы Artificial Neural Network Based Control Strategies for Paddy Drying Process

- M.H. Saifullah Saif, A. Dwayne, and Yubin Lan, "Effects of Processing Conditions and Environmental Exposure on the Tensile Properties of Parboiled Rice," Journal of Bio Systems Engineering, Vol. 89 (3), pp. 321–330, 2004.

- H. N. Larsen, "Glycaemic index of parboiled rice depends on the severity of processing," European Journal of Clinical Nutrition, Vol. 54(5), pp. 380 -385, 2000.

- A. Chakraborty and D. S. Dey, "Post Harvest Technology," Oxford and IBH Publishing Co. Pvt. Ltd, New Delhi, pp. 72, 94, 125, 2008.

- G. N. Tiwari, A. K. Singh, and P. S. Bhatia, "Experimental simulation of a grain drying system," Elsevier's, Energy conversion management, Vol. 35, No. 5, pp. 453-458, 1994.

- S. Somchart, "Fluidised Bed Grain Drying," School of Energy and Materials, King Mongkut’s University of Technology, Thonburi Suksawat, 48 , Bangkok , Thailand, pp. 54-71, 2010.

- J. Wang, "Researches on variable temperature drying technology and on-line control for high moisture content," New Technology of Agricultural Engineering (ICAE), International Conference, Zibo, pp. 27-29, 2011.

- N.B. Camila, N. S. J. Fernando, and A. F. Ferreira, "High performance controllers for drying processes, "Acta Scientiarum, Technology, Maringá," Vol. 35, No. 2, pp. 279-289, 2013.

- N.B. Camila, N.S. J. Fernando, A. F. Ferreirac, and M. P. S. Santosd, "Experimental Comparison Between Control Schemes for a Drying Process Dynamics," Advances in Mathematical and Computational Methods, ISSN 2160-0635, Vol. 2, No.1, 2012.

- Samsul, Bahari Mohd. Noor, Hasmah Mansor, Raja Kamil Raja Ahmad, and Farah Saleena Taip, "Online quantitative feedback theory (QFT) - based self-tuning controller for grain drying process," Scientific Research and Essays, Vol. 6(31), pp. 6520-6534, 2011.

- D. Wang, C. Li, J. Xu, and B. Zhang, "A control-parameter data collecting and processing system of grain drying in a deep fixed-bed," World Automation Congress (WAC), pp. 325-330, 2010.

- S. Atthajariyakul and T. Leephakpreeda, "Fluidized bed paddy drying in optimal conditions via adaptive fuzzy logic control," Journal of Food Engineering, Vol. 75, pp. 104–114, 2006.

- K. H. Lee and O. J. Kim, "Investigation on drying performance and energy saving of the batch –type heat pump dryer," Drying Technology, Vol. 27, pp. 565-573, 2009.

- W. C. Wang, R. K. Calay, and Y. K. Chan, "Experimental study on an energy efficient hybrid system for surface drying," Applied Thermal Engineering Vol. 31, pp. 425-431, 2011.

- S. S. Mohapatra and P. Mahanta, "Thermodynamic evaluation of natural convection paddy dryer," Developments in Renewable Energy Technology (ICDRET), 2nd International IEEE Conference , Dhaka , pp. 1- 4, 2012.

- S. Hung –Jung and Yi-Iuenchen, "Thin layer model for Intermittent Drying of Rough Rice," American Association of Cereal Chemists, Inc. Cereal chemistry Vol. 76, No. 4, pp. 577-581, 1999.

- J. F. Steffe and R. P. Singh, "Theoretical and practical aspects of rough rice tempering," American Society of Agriculture Engineering, Vol.23, pp. 775-782,1980.

- J. L. Parry, "Mathematical modelling and computer simulation of heat and mass transfer in agricultural grain drying," Journal Agriculture Engineering Research, Vol. 32, pp.1-29, 1985.

- A. Iguaz, M. B. San Martin, J. I. Mate, T. Fernandez, and P. Virseda, "Modelling Effective Moisture diffusivity of rough rice at low drying temperatures," Journal of food engineering, Vol. 59, pp. 253-258, 1994.

- X. Zheng and Y. Lan, "Effects of Drying Temperature and Moisture Content on Rice Taste Quality," Agricultural Engineering International: The CIGR E Journal Manuscript FP 07 023, Vol. 9, 2007.

- S. F. Lilhare and N. G. Bawane, "Simulation of Paddy Drying Characteristics Under Different Ambient Conditions," International Journal of Engineering Systems Modeling and Simulation, Vol. 1, Issue 7, pp. 1-4, 2012.

- N. S. Visen, J. Paliwal, D. S. Jayas, and N. D. G. White, "Specialist neural Networks for cereal Grain Classification," Elsevier Science, Bio systems Engineering, Vol. 82(2), pp. 151-159, 2002.

- S. F. Lilhare and N. G. Bawane, "Classification of paddy Varieties using Image processing," National Conference on Innovative Paradigms in Engineering and Technology, NCPIET-12, pp. 33-35, 2012.

- Y. Liu, F. Cheng, Y. b. Ying and X. Q. Rao, "Identification of rice seed varieties using neural network," Journal of Zhejiang university Science, Vol. 6b (11), pp. 1095-1100, 2005.

- B. T. Mazhar and B. Mohamed E.El, "ECG images classification using artificial neural network based on several feature extraction methods," IEEExplore International Conference on Computer Engineering & Systems (ICCES), pp.113-115, 2008.

- D. Malathi and N. Gunasekaran, "A Novel Neural Learning Algorithm for Separation of Blind Signals," Medwell Publishing, International journal of Soft Computing Vol. 4(1), pp. 1624, 2009.

- A. Goshvarpour, H. Ebrahimnezhad and A. Goshvarpour, "Shape classification based on normalized distance and angle histograms using PNN," Journal of Information Technology and Computer Science (IJITCS), Vol. 5, No. 9, 2013.

- F.F.G. Areed, M.S. El kasassy, and M. S. Mahmood, "Design of Neuro Fuzzy Controller for a Rotary Dryer," International Journal of Computer Application, Vol. 37, No. 5, pp. 34- 41, 2012.

- S. F. Lilhare and N. G. Bawane, "Modelling and simulation of control strategies for paddy dryer system," National Conference on Innovative Paradigms in Engineering and Technology, NCPIET-13, pp. 23-28, 2013.

- Koushal Kumar and Abhishek, "Artificial Neural Networks for Diagnosis of Kidney Stones Disease," International Journal of Information Technology and Computer Science (IJITCS), Vol. 4, No. 7, pp. 20-25, 2012.

- Koushal Kumar, Gour Sunder, and Mitra Thakur, "Advance Application of Neural Network and Artificial Intelligence: A Review," International Journal of Information Technology and Computer Science (IJITCS), 6, pp. 57-68, 2012.

- P. Somkiat, S. Somchart, Y. Mustafa, and W. Montri, "Prototype and commercialization of fluidized Bed Paddy Dryer," Research and Development, Journal of the Engineering Institute of Thailand, Vol. 6, No. 2, pp. 2, 1995.