Assessment of protective coatings adhesion on steel linear structures under laser nanostructuring

Автор: Shegolkov N.I., Komarova L.Yu, Lisienkova L.N., Budnikova O.A., Varfalovskaya V.V., Tsybin A.I.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The study of the properties of nanomaterials

Статья в выпуске: 5 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Due to the extensive use of steel linear structures, the standards for the surface quality of pipelines used for oil fluid production have been increased. In this case, studies of the interfacial boundary during the application and bonding of protective coatings are the interesting subjects to do. Recent research describes the potential of laser nanostructuring for steel surface pretreatment prior to polymer layer application. The introduction of laser technology into industry requires not only research on surface properties, but also an evaluation of operational characteristics. Usually, the semi-quantative criteria of mechanical strength of polymer bonding to metallic substrate is the adhesive strength. Methods and Materials. In this study, steel plates were used as a substrate for laser surface treatment with two pulsed ytterbium-doped fiber lasers. The polymer layer was based on epoxy-phenolic resin liquid paint. The liquid paint composition was applied via airless spraying. The curing process was carried out in a drying oven at 150 °C. Results and Discussion. In the process of the study, the surface of the metal plates was treated with laser irradiation to form nanostructures on the metallic surface. Following this treatment, increase in submicroscale surface roughness was up to 230–470% compared to the initial condition. Pull-of adhesion tests of polymer coating vary from 2.2 to 20.6 MPa. This depends on the type of laser irradiation and the type of equipment used. Conclusion. The test results demonstrated that the nanostructured surface facilitates the formation of an array of nano-scale asperities. This array enhances the adhesive bonding with the epoxyphenolic polymer layer and, consequently, improves the adhesive strength. A comparative analysis of the test results obtained using two different types of laser equipment confirmed the effectiveness of a laser system to perform combined polishing and nanostructuring of the metallic surface.

Nanostructuring, Submicro-roughness, Steel structures, Polishing, Adhesive strength, Metal-polymer composite

Короткий адрес: https://sciup.org/142246072

IDR: 142246072 | DOI: 10.15828/2075-8545-2025-17-5-518-529

Текст научной статьи Assessment of protective coatings adhesion on steel linear structures under laser nanostructuring

Original article

Щегольков Н.И., Комарова Л.Ю., Лисиенкова Л.Н., Будникова О.А., Варфаловская В.В., Цыбин А.И. Оценка адгезии защитных покрытий к линейным стальным конструкциям при воздействии лазерного наноструктурирования. Нанотехнологии в строительстве. 2025;17(5):518–529. – EDN: IJFDZX.

Pipelines, as linear construction structures in the oil and gas industry, are critical infrastructures that combine the functions of production, transportation, and storage of hydrocarbon resources. The global demand for such engineering is growing. As the number of operational pipelines increases, so does the need to optimize their design, manufacturing, and operation [1, 2].

The majority of operational challenges are associated with the corrosion degradation of linear structures. This type of damage leads to economic expenditures on maintenance and repair, amounting to 2–5% of the GDP for countries with developed economies [3–5].

Therefore, there is a need to investigate methods for enhancing the performance characteristics of epoxy-based protective coatings. In the present study, the microroughness of the steel surface and the adhesive strength of the polymer layer to the metallic substrate were selected as the key criteria under investigation.

The formation of stable adhesive bonds at the polymer-steel interface requires the creation of a nanotextured

THE STUDY OF THE PROPERTIES OF NANOMATERIALS surface area on the substrate. This process is based on the removal of surface contaminants and the formation of a developed microrelief, which is characterized by its roughness. The degree of microrelief development determines the contact area and the magnitude of the chemical and mechanical bonding between the polymer coating and the steel plate. This is a critical factor influencing the adhesive strength of the entire protective system in metal-polymer composite materials [6–8].

Among existing methods for steel surface preparation, shot blasting technology, which uses various abrasive materials, has gained the most widespread adoption. As researches shows [9-11], this method allows the formation of a steel surface morphology with a pronounced, deepened relief.

Despite its widespread use, shot blasting technology has a number of significant limitations. These include its negative environmental impact due to the generation of abrasive dust; low efficiency when processing surfaces with complex geometry; non-uniform surface deformation; and its dependence on the hardness and dispersity of the abrasive material [12, 13].

A promising alternative is laser surface treatment – a technology based on the use of high-energy laser radiation for the simultaneous removal of surface contaminants and the formation of a developed microrelief, extending to the nanoscale level. Compared to traditional steel surface cleaning methods, it offers the following advantages: environmental safety, high controllability precision, reproducible modification results, and the ability to process surfaces with complex geometry.

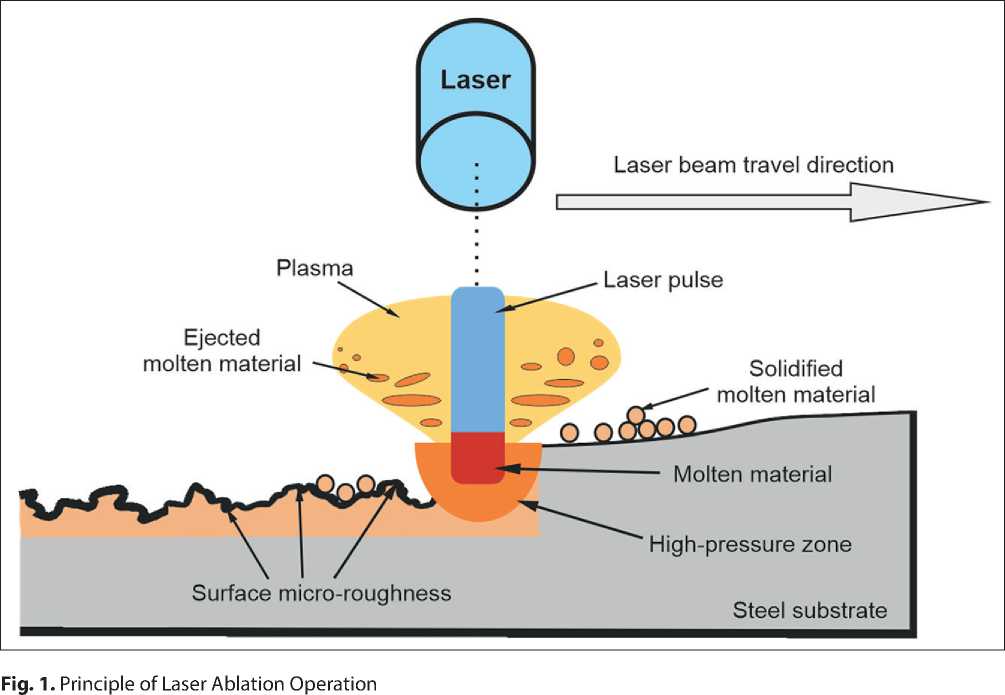

Laser cleaning technology is based on the mechanism of photothermal ablation, wherein a metallic surface is heated to the phase transition temperature, followed by partial evaporation of the surface layer. The processing involves three interrelated physical phenomena: localized laser exposure generates significant thermal stress; simultaneously, a plasma plume is formed, creating a zone of high internal pressure; and cyclic heating and cooling processes contribute to structural modification of the surface (Fig. 1) [14–18].

Scientific literature [19] discusses the prospects of laser ablation in both air and water environments. The experimental results demonstrate that nanostructuring in an aqueous medium facilitates the formation of surfaces with complex morphology; however, this method requires further investigation to optimize processing parameters. At the same time, the high efficiency of laser ablation in an air environment has been confirmed, enabling the creation of controlled nanotextures on steel surfaces.

As noted in studies [20, 21], laser cleaning technology demonstrates high efficiency. However, the authors

THE STUDY OF THE PROPERTIES OF NANOMATERIALS emphasize the lack of sufficient data on the corrosion resistance of modified surfaces in aggressive environments, such as saltwater conditions during marine transport operation and oilfield pipeline service.

The study [22] confirms the effectiveness of laser cleaning for turbine blades, which allowed for their surface preparation without damaging the component’s nanostructure. This demonstrates the potential of a method that combines high cleaning efficiency and process effectiveness with the preservation of material integrity.

Modern industry employs two main types of laser equipment: large-area surface processing systems and specialized devices for marking and texturing various materials.

Large-area cleaning systems are characterized by a relatively limited ability to configure the laser emitter, typically in terms of the following parameters: power, radiation frequency, and beam scanning speed. This type of equipment enables the modification of steel surfaces with high throughput rates — up to 10 cm²/s.

Laser systems for nanotexturing and marking are characterized by lower power and a compact work area. They provide a high degree of flexibility in controlling laser radiation parameters, including precise positioning and trajectory of the laser beam [23, 24].

Modern studies [25–30] have investigated the influence of laser emitter settings during surface nanotexturing on the micro-roughness, wettability, and chemical composition of the substrate after modification, which directly impacts the adhesive strength of the polymer layer.

Researchers employ various laser trajectories – concentric octagonal rings, intersecting ellipses, ordered crater arrays. Each of these generates a specific configuration of modifications and material melting zones, which ultimately affects the final microrelief of the steel surface.

With an increase in the degree of beam trajectory overlap, the micro-roughness grows. However, excessive overlap leads to superfluous material evaporation, which results in a reduction of the nanorelief development degree.

Despite a detailed examination of microrelief formation aspects in laser nanostructuring of steel surfaces, a scientific literature search has revealed a lack of systematic data reflecting the influence of laser texturing on the adhesive strength of epoxy resin-based polymer layers, as a common class of organic compounds used for the corrosion protection of metal structures.

This gap substantiates the relevance of the conducted research, which aims to explore the possibility of obtaining a protective polymer coating with enhanced adhesive strength through preliminary surface preparation using laser texturing.

The aim of the work was to investigate the influence of the developed microrelief, formed during the laser nanotexturing process and assessed through roughness param- eters, on the adhesive strength of a polymer layer based on epoxy-phenolic resins cross-linked with a polyamine-type hardener.

Within the framework of this study, two types of pulsed ytterbium fiber lasers were used to evaluate adhesive properties: an industrial-scale setup for large-area modification and a laser marker. The former is employed to study the effect of high-throughput laser texturing on the formation of adhesive bonds at the polymer-steel interface. The latter type of equipment enables surface nanostructuring of the metal, which is expected to enhance adhesive strength through a more prolonged modification process.

The research topic is highly relevant, and the obtained results will prove valuable for the implementation of laser surface modification technology in the production of metal-polymer structures.

METHODS AND MATERIALS

Metal plates made of Grade 20 steel were selected as experimental samples. The plate dimensions were 100×50×3.9 mm.

The initial condition of the studied surface corresponds to Type “A” according to the international standard ISO 8501-1:2007.

Two-component compositions were used as the polymer anti-corrosion layer, consisting of a base – epoxy-phenolic resin and a polyamine-type hardener. These compositions are applied for the internal protection of pipes transporting aggressive and abrasive environment.

To implement the laser texturing process of the steel surface, two types of pulsed ytterbium fiber lasers were utilized. The wavelength of the emitters is 1064±5 nm.

Laser No. 1 is an industrial-scale setup for large-area surface modification. It is characterized by high power and limited flexibility in adjusting processing parameters. These features make this type of equipment an optimal choice for high-volume production that requires surface processing with standard parameters.

Laser System No. 2 is designed for marking and producing nanostructured surfaces with the capability for fine-tuning all radiation parameters. It is characterized by lower power and throughput.

The specifications of the laser equipment are presented in Table 1.

Ten plates were treated with each type of laser. For more detailed investigation, a selection of four specimens was made.

A control sample without surface modification was included in the tests for characteristics comparison.

Prior to laser surface treatment, each specimen underwent an additional stage of ultrasonic degreasing in a bath with chemically pure acetone for 60 seconds.

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Table 1. Characteristics of Laser Systems No. 1 and No. 2

|

Laser System Characteristic |

Laser Systems No. 1 |

Laser Systems No. 2 |

|

Radiation power, W |

100 |

20 |

|

Pulse frequency, kHz |

100–500 |

1–4000 |

|

Pulse duration, ns |

100 |

2–350 |

|

Pulse energy, mJ |

1 |

up to 4 |

|

Scanning speed, mm/s |

2000–2500 |

up to 8000 |

Specimens No. 1 – No. 4 were modified using Laser No. 1 with fixed emitter settings:

-

- Radiation power: 100 W;

-

- Pulse frequency: 100 kHz;

-

- Laser spot area: 180 mm²;

-

- Scanning speed: 2500 mm/s;

-

- Pulse duration: 100 ns.

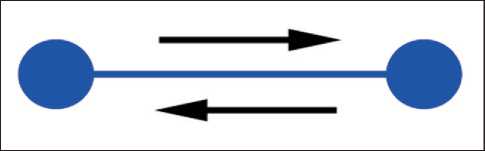

The laser spot trajectory pattern for Laser No. 1 is shown in Figure 2.

The average surface modification processing time with Laser No. 1 was 16 seconds.

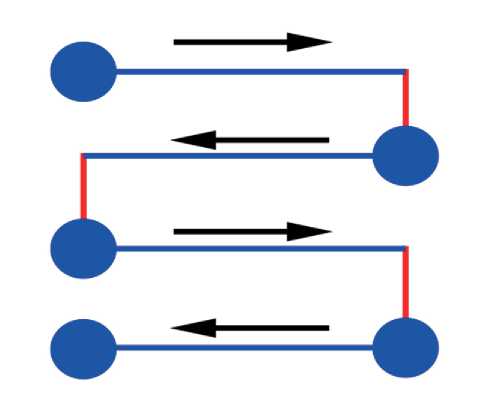

During nanostructuring of the steel plates' surface using Laser No. 2, various modification regimes were tested. Across all regimes, the laser beam trajectory remained unchanged, as shown in Figure 3.

The average surface modification time with Laser No. 2 averaged 220 seconds.

Below is the algorithm for the nanostructuring process of steel plates using Laser System No. 2, along with the equipment configuration settings.

Specimen No. 5. A grid-like nanostructure was formed. Three laser passes were performed in one direction, followed by three passes in the mutually perpendicular direction. The beam movement was parallel to the plate edges. This specimen was nanostructured using laser radiation parameters similar to those applied to subsequent experimental surfaces, thus establishing it as a baseline reference specimen.

Emitter configuration settings:

-

- Radiation power: 15 W;

-

- Pulse frequency: 20 kHz;

-

- Laser spot area: 0.03 mm²;

-

- Scanning speed: 500 mm/s;

Fig. 2. The trajectory of the laser beam No. 1

-

- Pulse duration: 200 ns;

-

- Trajectory line spacing: 0.5 mm.

Specimen No. 6. The emitter configuration and nanostructuring algorithm were similar to those of the baseline specimen. Additionally, three passes were performed parallel to the plate edges, resulting in the formation of a more highly-developed grid nanostructure. The emitter settings for the additional passes differed only in the trajectory line spacing, which was set to 0.02 mm.

Specimen No. 7. The morphology formation was implemented similarly to the baseline specimen. The difference consists in the diagonal beam movement from one to the opposite corner of the rectangular plate.

Specimen No. 8. Creation of a structure identical to Specimen No. 7. Subsequently, a polishing process was initiated over the formed grid microstructure to remove residual contaminating compounds, characterized by the following emitter settings:

-

- Radiation power: 15 W;

-

- Pulse frequency: 300 kHz;

-

- Laser spot area: 0.03 mm²;

-

- Scanning speed: 1000 mm/s;

Fig. 3. Trajectory of the laser beam No. 2

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

-

- Pulse duration: 3 ns;

-

- Trajectory line spacing: 0.04 mm.

On each plate, after the modification process, surface micro-roughness was assessed at five points using a “Time Group Inc TR220” profilometer. The measurement baseline was 0.8 mm. The result was recorded as the arithmetic mean value for Rz and Ra parameters.

The protective coating was applied using laboratory equipment operating on the airless spray principle, where the liquid polymer composition is atomized into a fine aerosol through mechanical rotation of the applicator, driven by an air turbine.

Polymerization of the protective layer was carried out in a drying oven with natural convection at a temperature of 150±5 °C for 60 minutes.

The measurement of the polymer coating thickness was carried out using a “Konstanta K5” geometric parameter measuring instrument. The average protective coating thickness on the specimens was 170±5 µm and corresponds to the recommended value used for paint coatings with high solid content.

The adhesive strength of the polymer layer was determined by the normal pull-off method according to ISO 4624:2002. Two tests were performed on each steel plate specimen with polymer coating to determine the adhesive strength. The arithmetic mean of all measurements was taken as the result.

RESULTS AND DISCUSSION

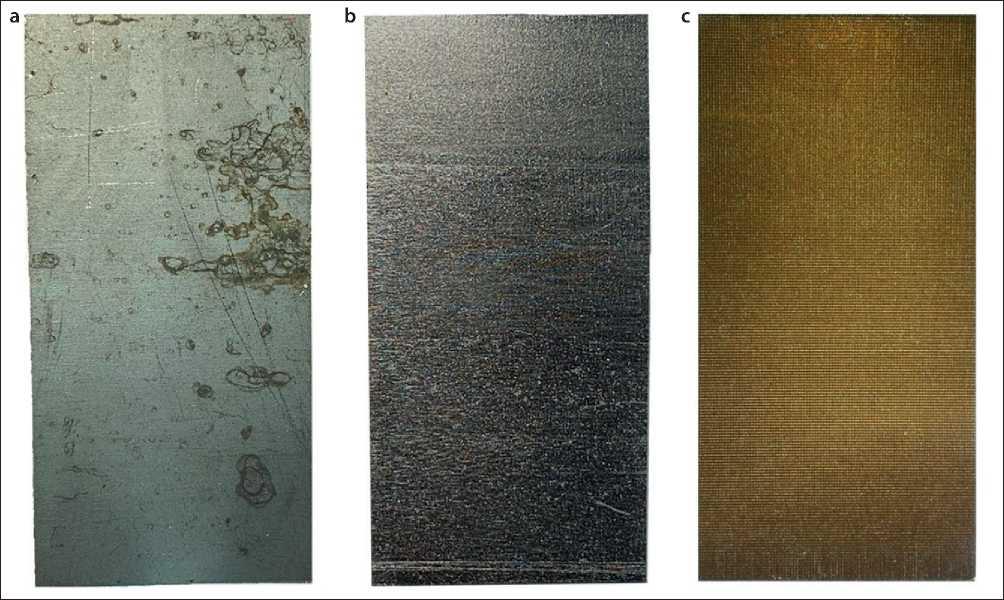

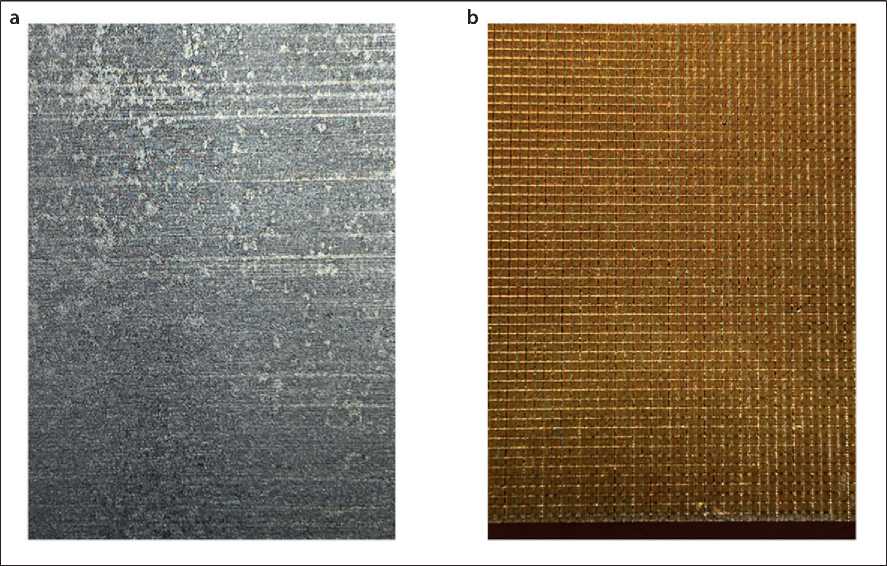

The appearance of the experimental specimen's surface before and after the nanostructuring process is shown in Figure 4.

The initial state of the steel surface is characterized by the presence of tightly adherent mill scale and low content of corrosion products.

On the surface of the steel plate subjected to nanostructuring with Laser No. 1, removal of local corrosion process centers and formation of an uneven linear microstructure of gray shade are observed.

After the laser nanostructuring process with Laser No. 2, elimination of local corrosion areas and presence of a uniform grid microstructure were recorded.

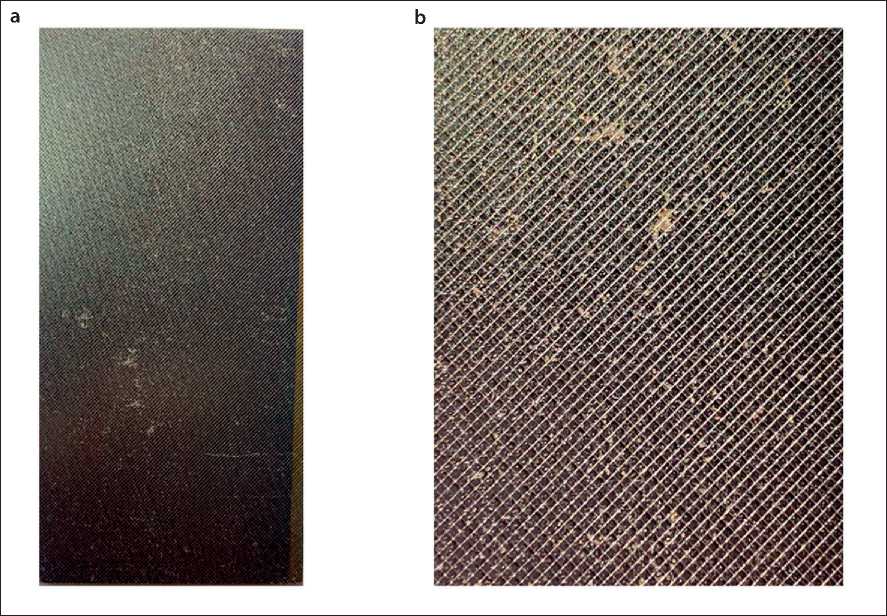

A more detailed examination and comparison of the surface structure after modification with 2.5× photographic magnification is presented in Figure 5.

The surface of specimens treated with Laser No. 2 acquired a brown-yellow tint, which is presumably associated with the formation of oxide compounds during prolonged ablation. To eliminate these oxidation products, additional laser polishing was performed on Specimen No. 8, with results shown in Figure 6.

The specimen surface shows complete removal of brown-yellow oxidation products, while the processed nanostructured surface acquired a uniform gray shade.

Fig. 4. Photographs of the steel plate's surface appearance before and after the nanostructuring process: a – unmodified; b – structured with Laser No. 1; c – structured with Laser No. 2

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 5. Surface structure of steel plates after modification: a – structured with Laser No. 1; b – structured with Laser No. 2

Fig. 6. Appearance and surface structure of Specimen No. 8 after additional laser polishing process: a – general view of specimen surface; b – magnified 1.6× view of this surface structure

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

The initial and formed surface micro-roughness parameters of plates after laser modification are presented in Table 2.

On average, the profile irregularity height (Rz) increased by a factor of 2.3 and 4.7 for Laser No. 1 and No. 2, respectively.

An increase in the arithmetic mean deviation of the profile (Ra) by 15.4% is observed after texturing with Laser No. 1, while the increase of this parameter for Laser No. 2 is significantly greater at 76.9%.

It is worth noting separately the microrelief evaluation results for Specimen No. 8, which underwent an additional polishing process. Its micro-roughness measured 13.9 µm and 2.3 µm for Rz and Ra parameters, respectively. Meanwhile, the baseline specimen is characterized by values of 13.6 µm and 1.8 µm, respectively.

Thus, the polishing process did not significantly affect the degree of microrelief development. At the same time, the absence of oxide film on the nanostructured surface contributes to increased area and improved quality of polymer-steel contact, which is important for composite service life.

Such difference in the degree of substrate surface microstructure development can be explained by different radiation intensities of both lasers, as well as by specific features of the laser beam trajectory.

Radiation intensity characterizes the power density per unit area of the laser beam. Its magnitude determines the capability to influence the nanorelief of the steel surface.

According to equation (1), the radiation intensity of Laser No. 1 is 0.5 W/mm², while for Laser No. 2 this parameter reaches 500 W/mm². Despite the lower average power of System No. 2, its high intensity enables deep and precise modification of the surface nanorelief. This also contributes to increased processing time due to the small laser spot area.

I = P/A, (1)

where: I – laser radiation intensity, W/mm²; P – laser emitter power, W; A – laser spot area, mm².

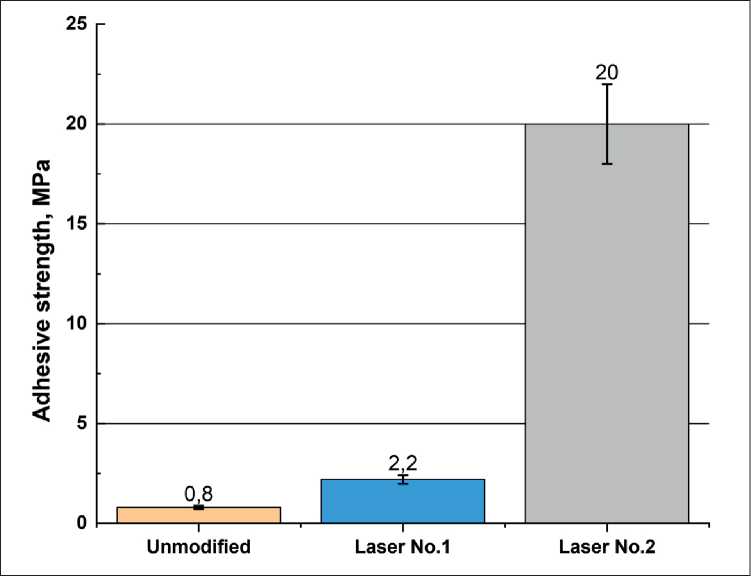

Figure 7 presents a histogram with the mean values of adhesive strength of the polymer layer for the considered types of laser systems.

Fig. 7. Adhesive strength of the polymer layer to the steel surface

Table 2. Initial and formed micro-roughness parameters of substrate surface after laser modification

|

Roughness Laser Systems |

Rz, µm |

Ra, µm |

|

Unmodified |

3.1 |

1.3 |

|

Laser Systems No. 1 |

7.2 |

1.5 |

|

Laser Systems No. 2 |

14.7 |

2.3 |

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

The highest adhesive strength is observed on specimens of steel plates subjected to nanostructuring with Laser No. 2, reaching 20 MPa. This parameter demonstrates a 25-fold increase compared to the control specimen.

A 2.7-fold increase in adhesive strength was recorded after surface modification with Laser No. 1.

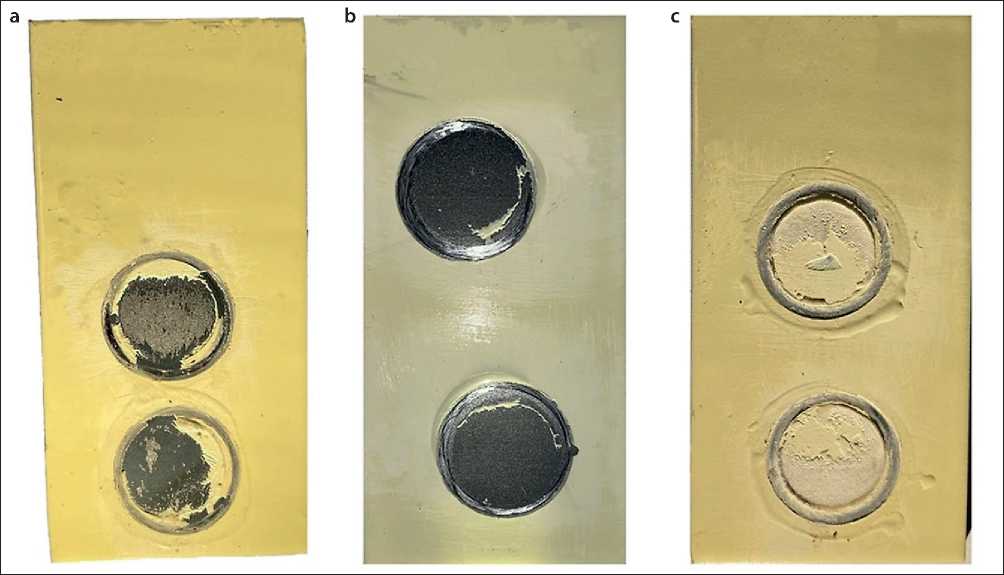

Figure 8 demonstrates the failure mode of coatings using the normal pull-off method during adhesive strength testing.

Analysis of the failure mode revealed that due to the low degree of microrelief development on the unmodified specimen and after texturing with Laser No. 1, the adhesive failure component dominates at the interface.

The polymer coating formed on the steel surface prenanostructured with Laser No. 2 exhibited a cohesive failure mode, indicating a high degree of chemical-mechanical bonding of the polymer layer over the tested polymer-steel contact area.

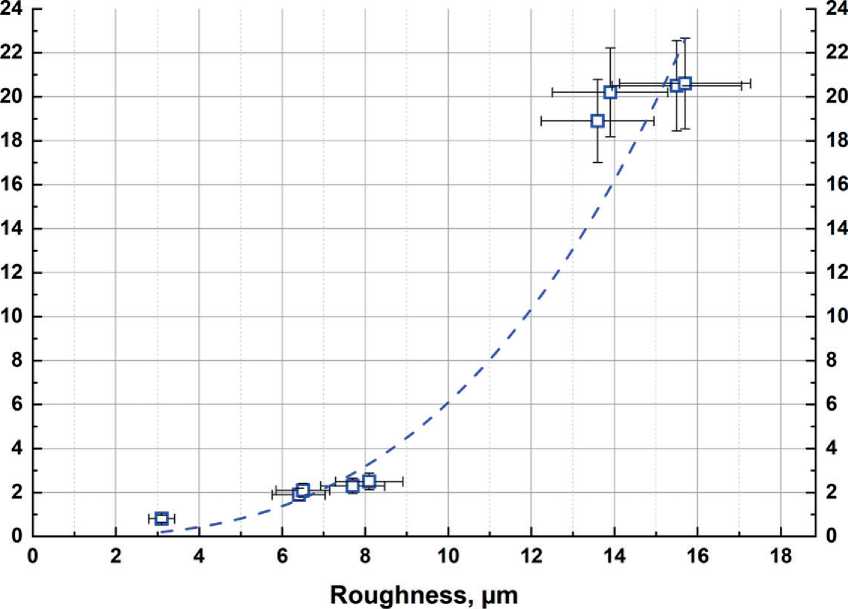

The influence of micro-roughness on the adhesive strength of the polymer layer is presented in Figure 9.

The initial values on the graph correspond to the untextured control specimen with values of 3.1 µm and 0.8 MPa.

The data points on the graph within the Rz microroughness range of 6 to 9 µm correspond to texturing with Laser No. 1. After structuring with Laser No. 2, the micro-roughness on the graph falls within the range of 12 to 16 µm.

This difference in adhesive strength is explained by the variation in the degree of submicro-roughness development and, consequently, the formation of different surface energy magnitudes. Equation (2) shows that the internal energy of the surface layer depends on the interfacial surface area, i.e., the contact area between the liquid polymer composition and the micro-relief state of the steel surface.

^S ^ T S , (2) s \dT/J where: σ – surface formation energy per unit area, J/m²; T – temperature, K; dσ/dT – temperature coefficient, J/(m²•K); S – interfacial surface area, m².

CONCLUSION

When implementing metal surface texturing with Laser No. 1, designed for large-area processing, it was possible to remove corrosion inclusion sites and achieve a 2.3-fold increase in adhesive strength compared to the control specimen.

After surface treatment with Laser No. 2, more thorough cleaning of corrosion areas and point defects was recorded, with significant development of the surface nanostructured area and a 4.7-fold increase in roughness parameters compared to the control plate. Such roughness enhancement leads to the formation of a

Fig. 8. Failure mode during adhesive strength determination of the polymer layer: a – unmodified; b – structured with Laser No. 1; c – structured with Laser No. 2

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 9. Effect of micro-roughness on adhesive strength of the polymer layer to the steel surface

greater number of intermolecular bonds, which provided a 10-fold increase in adhesive strength relative to the same parameter after Laser No. 1 treatment. This enables the formation of strong polymer layer adhesion ensuring long-term anticorrosion protection for pipeline structures.

It has been established that the additional polishing mode for plates modified with Laser No. 2 offers the advantage of absent metal corrosion compounds while maintaining comparable micro-roughness values and adhesive strength.

The test results demonstrated that the developed texture of steel surface microrelief influences the adhesive strength of the epoxy-phenolic polymer layer and, consequently, will increase the service life of metal-polymer structures.

Based on the research results, two types of pulsed ytterbium fiber lasers have been compared. The study demonstrated the advantage of using a laser with texturing and marking functionality, which simultaneously removes tightly adherent mill scale and corrosive micro-deposits while facilitating the formation of nano-relief, thereby increasing the surface area.