Assessment of the quality and safety of textile materials treated with a biocidal preparation

Автор: Alibekova M.A., Burkitbay A.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 3-1 (129), 2020 года.

Бесплатный доступ

The article presents research on the development of a biocidal preparation for the appret of cotton textile materials. The appret developed by the authors on the basis of salicylic acid and liquid glass provides high rates of biostability of cotton fabric, does not reduce quality indicators and meets the environmental requirements for appret compositions. The coefficient of resistance to microbiological destruction in cotton textile materials treated with a biocidal preparation in all cases was above 80%. The work also assessed the safety and quality of cotton materials treated with a new biocide.

Cotton fabric, appret, antimicrobial finishing, biocides, microbial damages

Короткий адрес: https://sciup.org/140256783

IDR: 140256783 | УДК: 64.29.29 | DOI: 10.48184/2304-568X-2020-3/1-38-43

Текст научной статьи Assessment of the quality and safety of textile materials treated with a biocidal preparation

The problem of biodeterioration is complex in scientific value and multi industrial in practical. Scientifically, it is based on knowledge of materials science, biology and chemistry.

Protection of textiles, leather and shoes, wood and paper, plastics and metals, optics and concrete, oil and fuel from biodeterioration is becoming as important goal as care of their economy and rational use [1].

One of the main areas of human biocidal protection using specially processed textile materials is the prevention of skin diseases, especially in the professional field. According to experts of the committee of the World Health Organization, pustular skin diseases compose a third of the entire skin pathology and take 3-4 places in the overall structure of the incidence after influenza, respiratory and cardiovascular diseases [2].

The presence of cellulose, pectin, nitrogencontaining and other organic substances in cotton fiber, and their high hygroscopicity make it a breeding ground for abundant microflora.

Cotton is infected with microorganisms during assembly, transportation and storage. When machine-assembled raw cotton is strongly clogged with foreign impurities. It contains a large number of particles of leaves and boxes with a higher humidity than the fiber. Such foreign particles create a wet macro zone around themselves, in which microorganisms multiply intensively.

A favorable condition for the destruction of cotton fibers by microorganisms is the moisture content of the fiber above 9%.

Destruction of textile materials by microorganisms depends on the degree of wear, type and origin, organic composition, temperature and humidity conditions, degree of aeration, etc.

Over the past decades, due to the sharp deterioration of the environment, the development of measures aimed at reducing the risk of spreading viral diseases has become an increasingly urgent topic. The level of humidity, temperature, the presence of dust, dirt and greasy spots in textile materials create a favorable environment for the propagation of bacteria and microorganisms [3, 4].

It should be noted the most basic criteria that were established in the practice of creating and using a biocidal preparation: ease of processing the fabric with this composition in a minimum concentration of preparation for biostability to a wide range of microorganisms, low price, no change in the properties of the fabric for the worse and the effect on human skin.

The relevance of the problem of protecting textiles from bio-damage coincides with the task of preventing and minimizing the transmission of microorganisms/diseases, acting as a physical barrier between the source of infection and the person.

Materials and research methods

The object of study in the work is: cotton fabric of 1553 (1030) article group. The following reagents were used for the experiments:

Salicylic Acid is a beta hydroxy acid that occurs as a natural compound in plants. It has direct activity as an anti-inflammatory agent and acts as a topical antibacterial agent due to its ability to promote exfoliation [5].

Salicylic acid is a monohydroxybenzoic acid that is benzoic acid with a hydroxy group at the ortho position. It is obtained from the bark of the white willow and wintergreen leaves. It has a role as an antiinfective agent, an antifungal agent, a keratolytic drug, an EC 1.11.1.11 (L-ascorbate peroxidase) inhibitor, a plant metabolite, an algal metabolite and a plant hormone. It is a conjugate acid of a salicylate [6].

Uses in manufacturing. Salicylic acid is used in the production of other pharmaceuticals, including 4-aminosalicylic acid, sandulpiride, and landetimide (via Salethamide). Salicylic acid is used as a food preservative, a bactericidal and an antiseptic.

Liquid glass is an aqueous alkaline solution of sodium and/or potassium silicates Na 2 O(SiO 2 ) n or K 2 O(SiO 2 ) n . It is available commercially as a thick liquid solution or in solid form. Liquid glass has many applications. It is used in construction to make concrete structures water- and moisture-resistant. Liquid glass impregnation helps prevent flammable materials such as fabrics, wood, and cardboard from catching fire. It is also often used to glue paper and cardboard [7].

Liquid glass is also commonly known as silicate glue (trade name).

Preparation of the appret solution. Before experimental work the bleached, unapproved cotton fabric promotes in distilled water in order to completely remove the remains of the bleaching bath. CaCl 2 to determine the exact sample of the sample.

Fabric samples 200×200 mm in size, after determining the exact mass on an analytical balance are impregnated for two minutes, with a solution of a hydrophobizing compound (Liquid

Glass), and then on a laboratory two-shaft plus with a 90% extraction, drying is carried out in a cabinet with a temperature regulator at 100°C for 3-4 minutes. Then, fabric samples are impregnated for one minute with an aqueous solution of Salicylic Acid (SA), after that, on a laboratory two-shaft plus with 90% extraction, drying is carried out at 100°C for 3-4 minutes and heat treatment at 145°C for one minute. After drying and heat treatment, the samples are being washed in distilled water, and then dried at room temperature (Fig.1).

Na 2 O(SiO 2 ) n t=2', T=300

Extraction 90 %

Drying t=3-4', T=1000

Heat treatment t=1', T=1450

Drying t=3-4', T=1000С

Extraction 90 %

Washing at 45oC

C 7 H 6 O 3 t=1', T=600

Washing at 35oC

Drying at room temperature

Figure 1. Scheme of fabric treatment with a biocide preparation

Extraction 90 %

Washing at room temperature

Instrumental research methods

Research to determine the antimicrobial activity of textile materials was carried out in accordance with the standard "Methods of laboratory tests for resistance to microbiological destruction of GOST 9.060–75” [8].

Results and their discussion

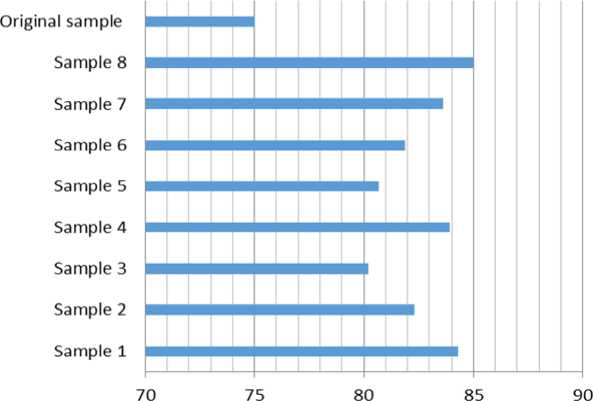

Researches have been carried out on the use of salicylic acid solution and liquid glass for appret of cotton fabric in order to give it antimicrobial and hydrophobic properties.The quality of the effect of antimicrobial appret characterizes the resistance of the material to microbiological destruction. The results of the estimates of the tests for material resistance to microbiological destruction are presented in table. 1.

Table 1 - Values of the coefficient of resistance to microbiological destruction (in percent), P (%).

|

№ |

LG, ml/l |

SA, g/l |

Resistance to microbiological destruction, p, % |

|

Sample 1 |

20 |

2 |

84,3 |

|

Sample 2 |

30 |

3 |

82,3 |

|

Sample 3 |

40 |

2 |

80,2 |

|

Sample 4 |

50 |

3 |

83,9 |

|

Sample 5 |

40 |

3 |

80,7 |

|

Sample 6 |

20 |

3 |

81,9 |

|

Sample 7 |

30 |

2 |

83,6 |

|

Sample 8 |

50 |

2 |

85,0 |

|

Original sample |

75 |

Resistance to microbiological destruction, p, %

Figure 2. Influence of component concentration on microbiological stability of cotton fabric.

Table 1 and Figure 2 show that the resistance indicators to microbiological destruction compared with the untreated sample increased significantly. In developing chemical means of protecting materials and products from biodeterioration, it is required to study the biocidal properties of both the compounds themselves and to verify their effectiveness of the material.

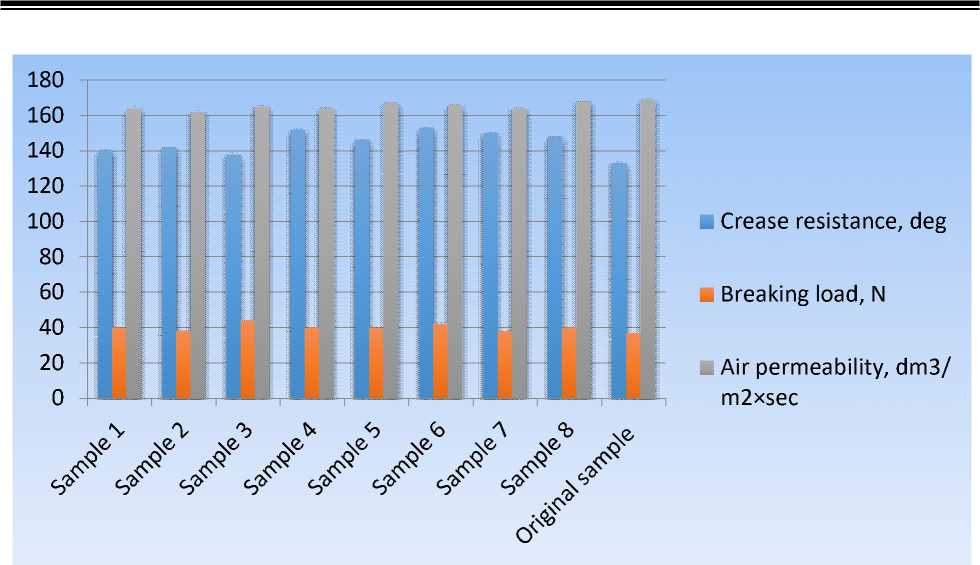

Assessment of air permeability, strength and crease resistance are presented in table 2.

Table 2 - Indicators of air permeability, breaking load and crease resistance of cotton fabric

|

Ns |

Component concaitration |

Crease resistance, deg |

Breaking load,N |

Ал-permeability, dm-’ m2xsec |

|

|

LG, mil |

SA,gl |

||||

|

Sample 1 |

20 |

2 |

140 |

40 |

164 |

|

Sample 2 |

30 |

3 |

142 |

38 |

162 |

|

Sample 3 |

40 |

2 |

138 |

44 |

165 |

|

Sample 4 |

50 |

3 |

152 |

40 |

164 |

|

Sample 5 |

40 |

3 |

146 |

40 |

167 |

|

Sample 6 |

20 |

3 |

153 |

42 |

166 |

|

Sample 7 |

30 |

2 |

150 |

38 |

164 |

|

Sample 8 |

50 |

2 |

148 |

40 |

168 |

|

Original Sample |

- |

- |

133 |

37 |

169 |

Figure 3. The influence of component concentration in terms of crease resistance, breaking load and air permeability cotton fabric.

Table 2 and Figure 3 show that the breaking load and crease resistance of cotton textile materials treated with this composition are increased compared with the original sample.

Also the air permeability coefficients of the textile material treated with the proposed composition are not significantly reduced.

Assessment of the capillarity of the processed cotton of the tests performed are presented in table 3.

Table 3 - Effect of the concentration of the composition components on indicators of capillarity of the cotton fabric

|

№ |

Component concentration |

Capillarity, mm |

|

|

LG, ml/l |

SA, g/l |

||

|

Sample 1 |

20 |

2 |

7.2 |

|

Sample 2 |

30 |

3 |

7 |

|

Sample 3 |

40 |

2 |

6,8 |

|

Sample 4 |

50 |

3 |

7,3 |

|

Sample 5 |

40 |

3 |

6,9 |

|

Sample 6 |

20 |

3 |

7,1 |

|

Sample 7 |

30 |

2 |

7 |

|

Sample 8 |

50 |

2 |

7,2 |

|

Original Sample |

- |

- |

8,5 |

Table 3 show that the water-repellent properties of cotton fabric treated with this biocide are increased compared with the original sample.

Thus, it is established that cotton fabric treated with a biocidal preparation based on salicylic acid and liquid glass has improved consumer and antimicrobial properties, as a result of which it does not overgrow mold fungi and is not destroyed by microorganisms under operating conditions.

The appret developed by the authors provides high indicators of low-wearability, strength, and biostability of cotton textile materials, does not reduce its hygienic properties, and meets the environmental requirements for applying compounds.

Conclusions

-

1. The resistance of processed samples to biodegradation increased by 1.2 times compared

-

2. Water-repellent properties of cotton fabric treated with this composition increase by 15% compared to the original sample.

-

3. Coefficients of air permeability of the fabric treated with the proposed composition are reduced by 4%.

to untreated samples, as evidenced by the growth of this indicator to 85%.

Список литературы Assessment of the quality and safety of textile materials treated with a biocidal preparation

- Razuvayev A. V. Final finishing of textile materials with biocidal preparations// News of higher educational institutions. Chemistry and chemical technology, Ivanova, 2010. №8. - P. 3-7..

- Pehtasheva E. L. Microbiological resistance of materials based on natural macromolecular: dissertation of Doctor of Technical Sciences: 05.19.08. -Moscow, 2004. - 312 p..

- Krichyevskyi G. E. Chemical Technology of Textile Materials: A Textbook for Universities in Three Volumes, Moscow, 2001. №3.- 298 p..

- Textile Fibers and Materials, 2006- Access mode. URL: http://biocides.ru/page637298 (date of application 12.05.2006)..

- Ding, P. & Ding, Y. Stories of Salicylic Acid: A Plant Defence Hormone// Trends in Plant Science. - 2020. №4 - P. 1921-1938..

- Pubchem National Library of Medicine, National Center of Biotechnology Information- Access mode. URL: https://pubchem.ncbi.nlm.nih.gov/compound/Salicylic-acid (date of application: 16.09.2004)..

- Liquid Glass Technology, Protecting the things you care about with eco-friendly liquid glass technology, 2017- Access mode. URL: https://www.liquidglassnanotech.com/2017/08/07/what-is-liquid-glass/ (date of application: 17.10.2017)..

- ST RK ISO 20743-2012 Textile. Determination of antibacterial activity of products with antibacterial treatment. State Standard of NurSultan: Publishing House of Standards, 2012. - 56 p..