Биомеханические свойства хирургических нитей с функциональным покрытием

Автор: Шилько С.В., Гракович П.Н., Хиженок В.Ф., Паркалов С.В.

Журнал: Российский журнал биомеханики @journal-biomech

Статья в выпуске: 2 (20) т.7, 2003 года.

Бесплатный доступ

С целью получения хирургического шовного материала исследуются фрикционно-механические свойства промышленно выпускаемых нитей на основе природных и синтетических волокон до и после модификации биоинертным полимерным покрытием на основе полипараксилилена (ППК). Проведены испытания образцов нитей на основе шелка, полиамида и полиэтилентерефталата в условиях одноосного растяжения и при трении по имитатору биоткани в сухом и влажном состоянии. Установлено, что, помимо улучшения биосовместимости, нанесение ППК-покрытия позволяет оптимизировать фиксирующие и манипуляционные свойства нитей.

Хирургические нити, функциональное покрытие, полипараксилилен, прочность, сила трения, биосовместимость

Короткий адрес: https://sciup.org/146215764

IDR: 146215764 | УДК: 531/534:57+612.7

Текст научной статьи Биомеханические свойства хирургических нитей с функциональным покрытием

Surgical threads are known to be most spread means of connecting biotissues during operations. In spite of a wide variety of natural and synthetic fibers they do not always comply with a set of requirements imposed on the suture material in surgical practice [1-3]. Soft plaited or lisle threads, especially natural ones (catgut, silk, cotton, and flax) display perfect handling parameters in contrast to insufficient neutrality to biological media because of structural porosity which may cause inflammation. In their turn, strongly popular at present synthetic monofilament threads showing high bioneutrality thanks to their smooth surface are much more rigid and necessitate incremented number of nodes to make fixation reliable.

In this connection, investigations in this field are directed to creation of a suture material with composite structure by applying functional, in the first place, polymer coatings on the elastic fibrous base.

The aim of the present investigation is evaluation of modification efficiency of commercial threads based on natural (silk) and synthetic (polyethylene terephthalate, polyamide) fibers via gas-phase polymerization of polyparaxylylene (PPX).

Formulation of quality criterion of surgical threads

Besides the requirement of biocompatibility with living tissues, the threads should acquire a specific complex of physical and mechanical (strength, deformation and friction) characteristics. These must become dominating parameters in relation to known in the experience quality parameters, namely handling characteristics (convenience for surgeons), atraumatic criteria and so on (Table).

a b c

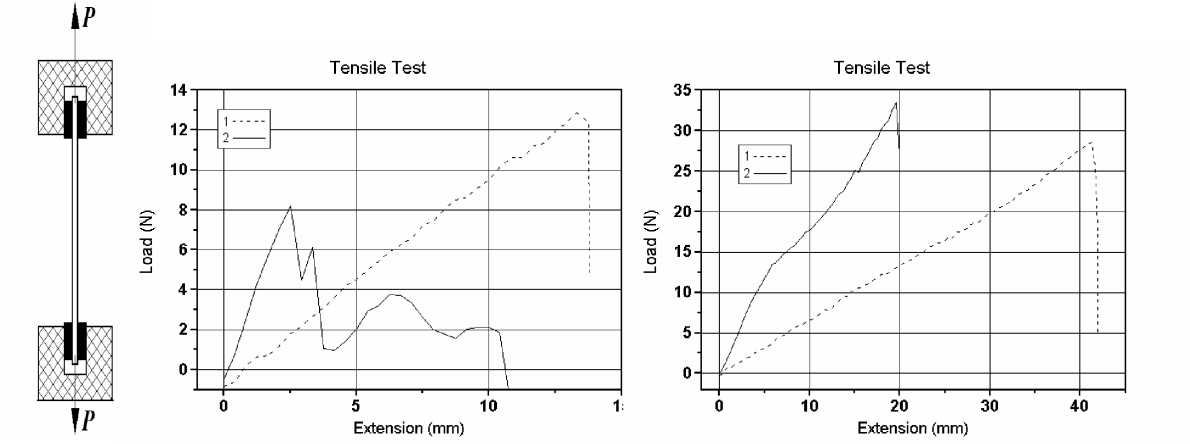

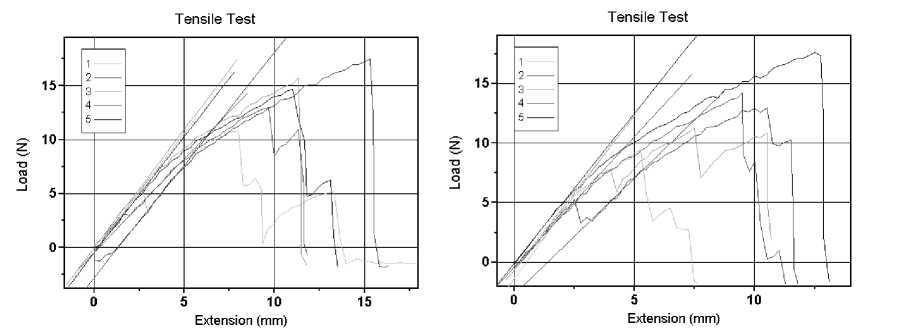

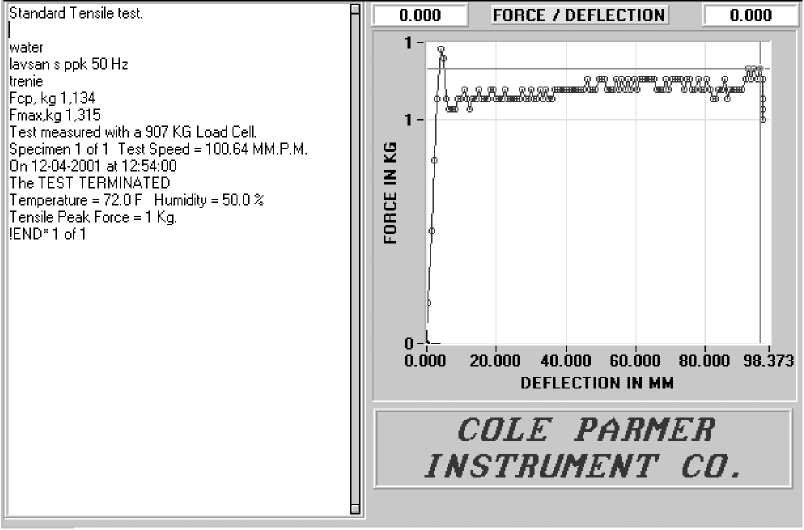

Fig. 1. Mechanical testing scheme (a) and tension diagrams of modified threads based on silk, (b) and Lavsan, (c) in the presence (dotted lines) and absence (solid lines) of nodes.

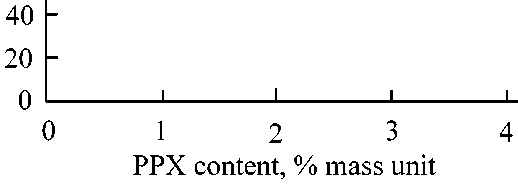

PPX content, % mass unit

№0> %

120 h

a b

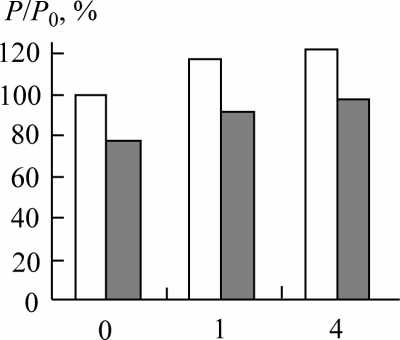

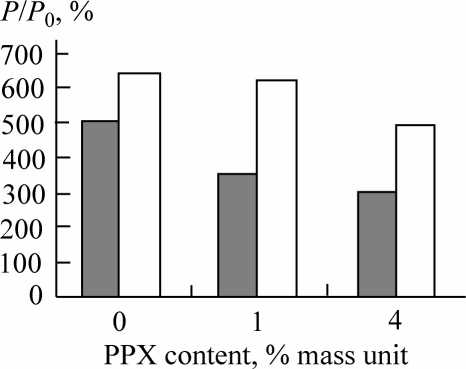

Fig. 2. The effect of coating thickness on breaking strength of silk threads (a) and Kapron (b) in dry (light bars and dashed line) and wet (dark bars and solid line) states.

Table. Interrelation of quality criteria and physical and mechanical characteristics of threads

|

Quality index |

Governing parameter |

|

High initial strength |

Strong defectless base |

|

Strength preservation at functioning |

Absence of capillary transport and destruction in biologically active medium |

|

Simplicity in node tying and its reliability |

Low contact and bending stiffness, high friction coefficient |

|

Atraumatic level at suture making |

Smooth mating and nearness of the thread friction coefficient and needle |

|

Atraumatic level of made suture |

Even surface and low friction coefficient of the thread |

In a number of cases the requirements to governing parameters turn to be contradictory. For example, high friction coefficient is beneficial for elevated reliability of the suture joint as a whole but traumatizes biotissues at stitching to a greater degree. As it can be seen, high quality parameters of surgical threads are ensured when the correlation of elastoplastic and frictional characteristics of a given sutural material is optimal.

Silk (regime 2)

Silk (regime 1)

Kapron (regime 1)

Kapron (regime 2)

Lavsan (regime 1)

Lavsan (regime 2)

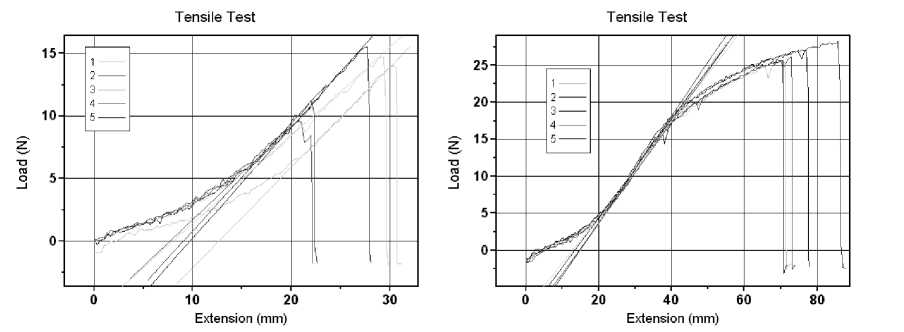

Fig. 3. Tension diagrams of modified threads for two regimes of PPX polymerization.

Characteristics of employed materials

Polyparaxylylene has been chosen out of other biocompatible polymers due to its uniqueness in the field of thin films. The technology of applying PPX presupposes the formation of sterile coatings of stable thickness on any accessible for the gas phase surface, including narrow gaps, capillaries and sharp edges. Polymerization in cold plasma is devoid of any energy action on both substrate and coating which excludes degradation of their physical and mechanical properties.

a

b

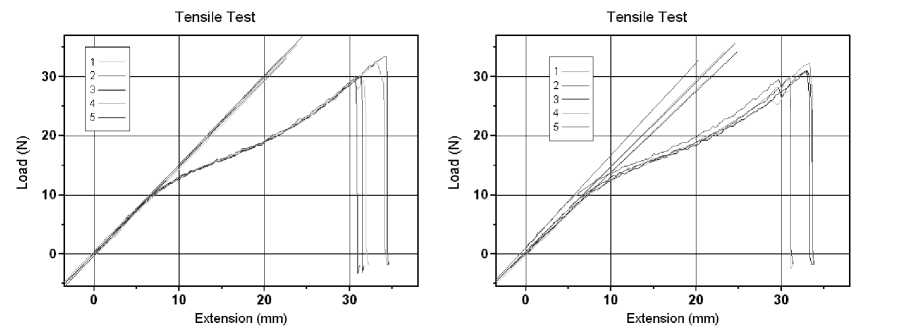

Fig. 4. Tribotesting scheme and kinetics of friction force.

a

№0, %

PPX content, % mass unit

b

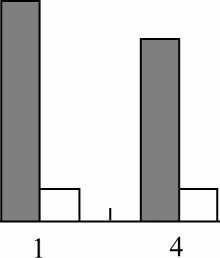

Fig. 5. The effect of coating thickness on incipient force (a) and mean drawing force (b) of Lavsan threads in dry (light bars) and wet (dark bars) states.

Four types of materials were used as the base, namely silk, polyamide (Kapron) of two grades and polyethylene terephthalate (Lavsan) with different coating thickness depending on PPX content 1 and 4% mass units.

Methods of investigation

PPX coating was applied during synthesis in the gaseous phase using a setup incorporating vacuum station VUP-4. The coating mass was equal to that with tens micrometers mean thickness.

Biomechanical investigations consisted of estimating strength of threads at tension with and without nodes, and drawing force of wet and dry threads prior and after modification. Automated test benches ComTen 94C [4] and INSTRON 5567 [5] were used to determine named characteristics. Indicated test benches are intended for high-precision measurement of mechanical characteristics of polymer materials under static loading.

For tests to rupture samples of threads were hooked in the lower and upper claws of the bench with elastic washers to exclude slippage and rupture of the thread near claw edges (Fig. 1a). Ten nodes at 1 cm interval were made to evaluate their strength. The initial distance between claws was set 6 cm and loading velocity was 1 cm/min.

During frictional tests the force needed to draw a sutural thread over a suede surface of dressed leather serving as a living biotissue sample was recorded (Fig. 4a). The tests kept to the following procedure: 40 mm in diameter cylindrical mandrel enveloped into a leather shred of 18 cm length was fixed horizontally between claws. As soon as one end of the thread was fixed in a movable claw of the test machine, a turn was produced around the mandrel and a weigh of 50g mass was hanged to the other end of the thread. Loading velocity was 10 mm/min.

Test results

Small enough amounts of PPX ensure nonwettability of the threads or their articles. Usage of water-repellent threads for outer sutures eliminates capillary transport of biological fluids over the thread, which meets antiseptic demands. This effect is specifically peculiar to silk threads that are falling into disuse of practical surgery due to their poor biocompatibility.

Mechanical characteristics

Characteristic deformation diagrams of lisle threads are presented in Figs. 1b, c and the results of strength comparison are illustrated in Figs. 2 and 3. It should be noted that nodes promote consolidation of fibers, linearize the diagram and eliminate rupture of individual fibers up to the moment the thread looses its strength resource. In contrast to the silk thread whose strength augments in the presence of nodes, that of a synthetic thread based on, e.g. Lavsan somewhat impairs (Fig. 1b, c).

The comparison of limiting loads at tension before and after PPX coating application of different thickness is shown in Fig. 2, where strength of the dry thread is taken 100%. It is evident that modification leads to a noticeable increase in thread strength in the dry state and what is more important, it preserves the thread in conditions of soaking from resorption. This effect is even more prominent for lisle silk threads which loose 25% of their strength at wetting. This is attributed to encapsulating effect of the coating, which hampers weakening of silk fibers under the effect of moisture and reduces the role of defects and damage probability of peripheral fibers. Deformation characteristics of threads and their test results with a coating applied at different generation frequencies of the installation are described in Fig. 3.

Improved handling characteristics of the threads are supported by the tests fulfilled with modified threads on test animals.

Frictional characteristics

In case a very fine PPX coating is applied (mass share – 1%) the friction force of threads in both dry and wet states diminishes (1.5 times for Lavsan) (Figs. 4, 5).

The effect of incipient sliding is exhibited in the fact that the friction at the rest exceeds that of thread sliding against a biotissue (Fig. 4b).

Incremented till 4 mass % coating thickness exerts a perceptible effect on the onset force in dry state and to a lesser degree in wet medium (Fig. 5a). The drawing force behaves otherwise at incremented coating thickness (Fig. 5b) which can be evidently attributed to retaining minimum PPX amount as a solid lubricant during kinetic friction of dry threads and its removal at friction in wet medium.

Besides, reduced friction is indirectly noticed at suture and node tying. The degree of damageability by sutural material, especially of silk, raises. In this case, valuable handling characteristics of the silk base are used. It is in fact non-stretched, shows stable strength and can be reliably fixed with just two nodes. However, silk threads formed by twisting of different thickness fibers are characterized by expressed capillary (wick) effect, which lowers their bioneutrality.

Polyamide and Polyethylene terephthalate based fibers acquire perfect frictional properties along with elevated bioneutrality thanks to relatively soft PPX coating.

Conclusions

Investigations performed have proved the modification efficiency of surgical suture threads on the base of natural and synthetic materials via application of polymer coatings, which raise strength and improve handling characteristics.