Biopolymers and its application as electroactive polymers

Автор: Olvera Bernal Rigel Antonio, Uspenskaya M.V., Olekhnovich R.O.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Химическая технология

Статья в выпуске: 1 (87), 2021 года.

Бесплатный доступ

Smart materials are a group of materials that exhibit the ability to change their composition or structure, their electrical and/or mechanical properties, or even their functions in response to an external stimulus such as heat, light, electricity, pressure, etc. Some of the advantages of these materials are: lightweight, flexibility, low cost of production, high energy density, fast response and compact size. One of the promises in the area of smart materials can be found in “smart polymer”. Polymers have many attractive characteristics, such as: lightweight, inexpensiveness, fractures tolerant, and pliable. Furthermore, they can be configured into almost any conceivable shape and their properties can be tailored according to the required needs. The capability of electroactive polymers (EAPs) to respond to electrical stimuli with a mechanical response, is attracting the attention of the scientific community from a wide range of disciplines. Biopolymers in recent decades have been studied as potential electroactive materials. These groups of polymers are extracted from a natural source; thus, they are eco-friendly, additionally they stand as a cheaper solution for the development of smart materials.The present manuscript will explore some of its applications as EAPs.

Biopolymers, eaps, hydrogels, electrorheology, electroactive films

Короткий адрес: https://sciup.org/140257333

IDR: 140257333 | DOI: 10.20914/2310-1202-2021-1-270-277

Текст научной статьи Biopolymers and its application as electroactive polymers

Electroactive polymers (ЕАРs) is a general term for all organic polymers which exhibit mechanical response to an electrical stimulus, as a result, these polymers show a change of shape or dimensions [1]. When talking about ЕАРs it is possible to classify them into two major groups depending on their mechanical response for actuation (figure 1). In the first group there are electronic ЕАРs (which are driven by electric field or coulomb forces); in the second group are ionic ЕАРs (which change shape by mobility or diffusion of ions and their conjugated substances) [2]. The actuation mechanism that these polymers possess, has enable engineers and scientist to establish novel approaches in the development of new technologies based on natural systems, the concept of copying or imitating biological systems is known as “Biomimicry”, which in recent decades has been use for the development of new technologies [3], as an example, the use of ЕАРs, are used to produce bio-inspired actuators, commonly known as artificial muscles. The application of these new technologies has been already implemented in many different fields such as, soft robots, steering mechanisms, braille displays, miniature grippers, loudspeakers, active diaphragm and pumps, toys, as well as many others. [4]. Other applications that ЕАРs can have, is to be used as sensors and power generators.

Figure 1. Electroactive polymers classification

Biopolymers are groups of polymers produced by living beings; for instance, plants, animals, bacterias, and fungi [5]. The term biopolymer stands in its literal sense as biological derived and biodegradable polymer, but there are some exceptions, among the group of biopolymers, we can find a type of polymers that are synthetized through chemical processes, these are called synthetic biopolymers [6].

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International License

Table 1, shows a general classification of biopolymers [7]. The attention on the use of these materials is due to their renewability, sustainability, nontoxicity and biodegradability. There are three main sources from which biopolymers are being extracted. The first source is found in plants, the polymers extracted are starch, soy protein, and cellulose; chitosan, keratin, and silk are polymers obtained from an animal source; and microbial fermented polymers such as polyhydroxyalkanoates (PHA) and polyhydroxybutyrate (PHB). Moreover, the applications that these polymers have make them very attractive for the scientific community, such applications are, biocompatibility, biodegradation to non-toxic end products, high bio-activity, low antigenicity, capability to support cell growth. Suitable material in the field of medicine, such as drug delivery systems, surgical implant devices, and bruise closing and healing products [8].

Table 1.

Biocompatible olymers classification [7]

|

Вiосоmраtiblе polymers |

Natural |

Proteins Silk Collagen Fibrinogen Soy protein Polysaccharides Cellulose Chitin Starch Hyaluronic acid Starch |

|

Synthetic |

PGA (Polyglycolic) PLA (Polylactic acid) PDS (Polydioxanone) PEG (Polyethyleneglycol) PP (Polypropylene) PVC (Polyvinyl chloride) PMMA (Polymethylmethacrylate) PTFE (Polytetrafluoroethylene) |

This manuscript aims to explore the approach on the use of biopolymers as electroactive polymers. In recent decades, the use of biopolymers as smart materials has been of great interest as a novel procedure to develop technologies that can be eco-friendly as well as their production process.

Electrorheological fluids

Electrorheological fluids or ЕRFs, are one of the most used smart materials and can be described as a class of colloidal dispersions that exhibit a reversible change in their rheological behavior as a response to an external electric field, with a huge potential application in many different fields, many researchers’ works focused on the use of these materials in the automotive industry, aerospace industry, robotics, medicine, and so on. As an example, in the automotive industry ЕRFs are implemented as shock absorbers, brakes, clutches, and smart structures. The change in their rheological behavior is due to a dramatic increase in the flow resistance, which depends on the flow regime and the composition of the fluid. One of the most attractive characteristics inherent in ЕRFs, is their fast response to electrical stimulus, which makes them suitable as an actuating device [9].

A wide variety of biopolymers have been used as fillers for the development of ЕRFs. Cellulose, corn starch and chitosan, were reported to be implemented as biopolymeric dispersoids for ЕRFs biocompatible systems [10].

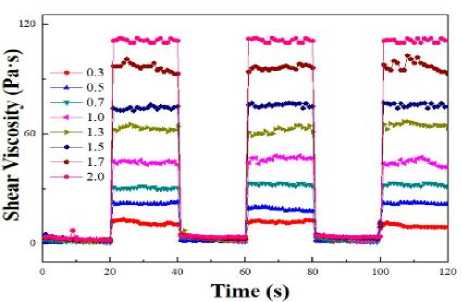

Choi et al., in their manuscript [11], reported a novel electrorheological material, by the use of microfibrillated cellulose (MFC), which was synthesized by a low-pressure delignification process. The MFC-based ER fluid was synthesized by suspending MFC particles (10 vol%) in an insulating silicone oil (100 сS). The MFC-ER fluid showed a change in its rheological properties when an electrical field was applied, the MFC-ER fluid showed a non-Newtonian fluid property. The plateau region of shear stresses was widened along with increased electrical field strength of up to 2.0 kV/mm. In order to know the speed response that MFC-ER fluid has, an on-off test was carried on, the test analyzed the shear viscosity behavior, which was measured at a fixed shear rate (= 1 s 1 ) and square voltage pulse (20 s), at various voltages (0.3–2.0 kV/mm). The shear stress grew quickly when the electrical field was applied and dropped to zero when the electrical field was turned off, as shown in figure 2.

Figure 2. Shear viscosity behavior as response to an electrical field [4]

Plateau behavior is originated by an attraction between the polarized particles, which build a chain structure. In addition, it is mentioned that the shear viscosity of the ER fluid increased as a response to the increasing of the electrical field. This can be explained due to interfacial polarization under an external electric field causes electrostatic forces between particles, leading to the chain structural formation. A dynamic oscillation measurement of the MFC ER fluid was performed to estimate the linear viscoelastic (LVE). The loss moduli was slightly higher than the storage moduli, indicating that the MFC particle-based ER suspension possessed a liquid-like property without electrical field strength. However, the storage moduli became higher than the loss moduli as electrical field strength was applied, indicating that the phase characteristics of the ER suspension moved from fluid-like to solid-like by the electrical field strength.

Same as cellulose, chitosan has been explored as a suitable biopolymer for the development of elec-trorheological fluids. Chitosan is a linear polysaccharide and an N-deacetylated form of chitin, which is the second most abundant natural biopolymer in the world. The main sources of chitin and hence chitosan are the cell walls of fungi, shrimp and crabs, exoskeleton of arthropods and some parts of insects. Among numerous attractive applications of chitosan, one of its most remarkable uses is as a filler for smart materials, for example electrorheological fluids.

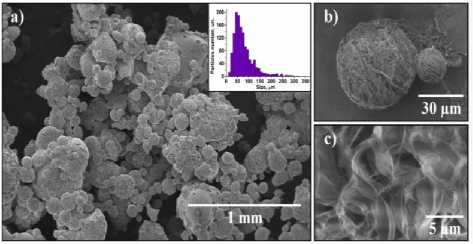

Kuznetsov et al. [12] examined the electro-rheological behavior that porous chitosan particles have when are immersed in an insulating liquid. In their work it was observed that porous chitosan particles, in suspensions of polydimethylsiloxane (silicone oil), exhibit a remarkable electrorheological effect. Porous chitosan particles were fabricated from chitosan via freeze drying technique. In figure 3, we can observe the morphology of the particles. The reason for the extraordinary electrorheological behavior is due to the high porosity of the particles, which resulted in an increase of yield stress and allows to reach the same efficiency at lower weight fillings, due to increase in volume fraction. The preparation of chitosan particles is as follows; chitosan (1 g) was dissolved in 100 mL of 1 wt% acetic acid. Electrorheological fluid with chitosan content of 0.1, 0.5 and 1.0 wt% were prepared by mixing porous particles with polydimethylsiloxane during 48 h by a magnetic stirrer and following ultrasonic treatment for 20 min before measurements.

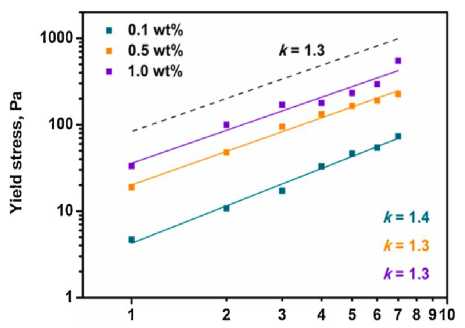

The results of their experiments show that, when the electric field is turned on, the shear stress of fluids increases instantaneously and drops rapidly when the electric field is turned off. These features may be related to primary aggregation processes, which happens when individual particles are polarized and form a percolation network. Similar behavior was observed during switching the electric field at constant level. Such tests clearly demonstrate the possibility of cyclic operation and show reversible and reproducible performance even at high electric fields. The yield stress dependence was also analyzed. Samples are persistent over a wide range of electric fields and exhibit a stable response up to fields of at least 7 kVmm 1 An increase in the yield stress can be observed, when the electrical field increases as well. At a concentration of 1 wt%, the yield stress reached up to 540 Pa, at electrical field of 7 kVmm 1 (figure 5). Is important to mention that if we consider the real volume concentration of particles, we can notice that it is low. Hence, the yield stress value observed is extremely high.

Figure 3. SEM images of porous chitosan particles (a, b); porous particle structure. The graph shows particle size distribution [12]

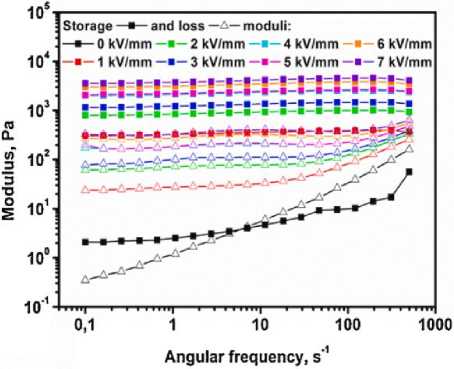

It can be seen in figure 4 that, without electric field the storage modulus exceeds the loss modulus at low frequencies and an increase in the frequency leads to the moduli crossover at frequency value of 6 s 1 . Thus, the sample behaves like a solid body at low frequencies and exhibits a viscous response with frequency increasing. The main reason of such strong electrorheological behavior is in the percolation network formation from fragments of the chitosan porous structure and its strength is determined by the contacts at the individual particles boundaries.

Electric field, kV/mm

Figure 4. Yield stress as a function of electric field for suspensions of porous chitosan particles in polydimethylsiloxane at various concentrations. Dashed line indicates the slope [12]

Figure 5. Frequency dependencies of storage and loss moduli [12]

Electroactive films

Ionic polymer actuators are a type of ЕАРs, which are structured by the use of a layer of polymer electrolyte sandwiched in between electrodes. Ionic polymer actuators, in literature are also referred as electroactive films, which, due to their electroactive and mechanical characteristics, have become a promising material for the development of soft actuators. The principle working mechanism that rules in the actuation of these materials can be described as follows. When the electric field is applied to the actuator film, the ions move from one surface to the other electrode surface in the form of ion-water clusters, leading to a bending motion of the actuator.

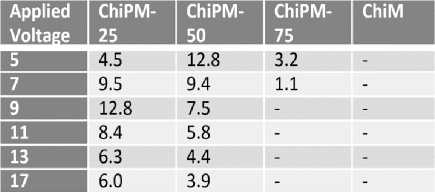

Altınkaya E. et al. [13], analyzed the bending mechanism of an ionic actuator by the use of chitosan combined with poly (diallyldimethylammonium chloride) (PDAD), at different concentrations. It is reported that four samples were prepared, including 0, 0.25, 0.50, and 0.75 mL of PDAD were called as СhiМ, СhiРМ-25, СhiРМ-50, and СhiРМ-75. The film samples were wrapped with gold leaves to fabricate electroactive polymeric actuators. One of the most important observations made in this work is that crosslinked-chitosan film having no PDAD does not move when an electrical excitation is applied. On the other hand, loading of certain amounts of PDAD converts crosslinked chitosan-film into an actuator which responds to applied electrical voltage with a bending motion. The greatest tip displacement value for СhiРМ-25 was obtained as 12.8 mm under the excitation voltage of 9 V. СhiРМ-75 also exhibited a great displacement of 3.2 mm under the excitation voltage of 5 V. Results reveal that СhiРМ-25 and СhiРМ-50 actuators have similar bending motion capabilities and motion ranges from 3.9 to 12.8 mm and from 4.5 to 12.8 mm, respectively (Table 2).

Table 2.

Tip displacement of СhiРМ-25, СhiРМ-50, СhiРМ-75 and СhiМ. [13]

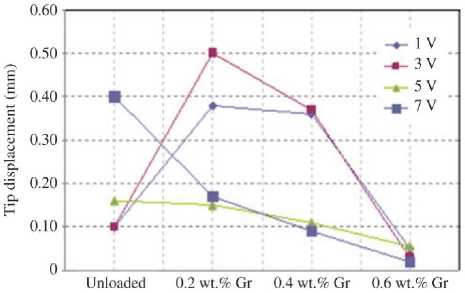

Figure 6. Tip displacement of multilayer graphene-loaded cellulose-based actuator, at different grapheme concentrations [14]

Electroactive hydrogels

Hydrogels are three-dimensional polymeric networks possessing hydrophilic characteristics and high water absorption capacities. Due to their high-water content, porosity and soft consistency, they can mimic natural living tissue better than any other class of synthetic biomaterials. It is because of their porous networks and highwater content that allows the transportation of small solutes, additionally, hydrogels present ionic conductivity, especially in the case of polyelectrolytes [15].

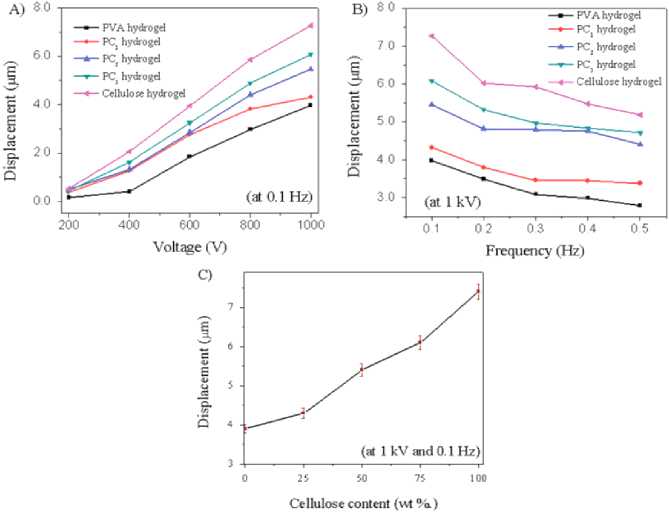

Jayaramudu et al. [16], have reported the preparation of polyvinyl alcohol/cellulose-based electroactive hydrogels for actuator applications. The polyvinyl alcohol/cellulose electroactive hydrogels were obtained by physical crosslinking of polyvinyl alcohol and cellulose. The studies reveal that the cellulose is uniformly reacted with hydroxyl groups of polyvinyl alcohol by intermo-lecular bond formation. The displacement behavior on the electroactive polymer is influenced by three main factors which are cellulose content, voltage and frequency. The actuation test was carried out by applying AC voltage and the use of a laser displacement sensor (Keyance LK-G85, Tokyo, Japan), in which a high voltage connected to a function generator (33220А, Agilent) in an environmental chamber and Labview software. Before conducting the test, the hydrogels samples (1010×4 mm3) were put into deionized water for 24 h. The swollen hydrogels were kept between two electrodes. The experiment was conducted in an environmental chamber and the chamber temperature and humidity was maintained at a constant temperature of 25 °C and a RH of 95%, throughout the experiment. The displacement of the PVA, cellulose and polyvinyl alcohol-cellulose (PC) hydrogels at 1 kV, were reported as follows; PVA ~4μm; cellulose hydrogel ~7.5μm and PC hydrogels 4–6μm. The displacement output increases by increasing the voltage. Note that the PC hydrogel shows higher displacement than the PVA hydrogel. In addition, it was reported that frequency plays an important role in the displacement of the actuator. The displacement decreases with increasing the actuation frequency. When the frequency increased from 1 Hz up to 5 Hz, the samples exhibit a lower displacement response: PVA from ~4μm to ~2μm; Cellulose from ~7.5μm to ~5.5μm; and PC from ~6μm to ~5μm, respectively, these parameters are shown in figure 7.

Figure 7. Actuation test of hydrogels prepared: (a) electrical voltage dependent displacement at 0.1 Hz, (b) displacement output with frequency change, and (c) cellulose content effect on displacement output [16]

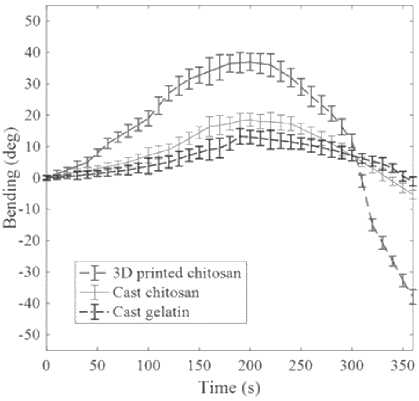

3D printing has become one of the most popular technologies in recent years. Due to its efficiency and flexibility, 3D printing has been implemented in many different fields, from the aerospace industry to the medical area. Zolfagharian et al. [20], made use of 3D printing technology, in their paper, they proposed a novel application of 3D printing for the production of soft robotics. In their study, chitosan was employed as a biopolymer for the development of the actuator. The paper focuses on the comparison of the actuation performance between 3D printed chitosan, conventional cast film gelatin and chitosan (figure 8). The results demonstrated that the rectilinear hollows made by 3D printing improve the functionality of actuation in chitosan, as shown in figure 9, where it is possible to observe the maximum bending (deg) for each sample.

It can be deduced that the porosity from the layer-by-layer 3D printing, contributes to higher bending and actuation rate. Despite the existing discrepancy between the actuation rate of cast gelatin and chitosan, they follow quite similar trends compared to the 3D printed chitosan.

Figure 8. 3D printed chitosan, cast chitosan and cast gelatin, from left to right; a) samples before actuation b) samples after actuation [17]

Figure 9. 3D printed chitosan versus cast gelatin and chitosan actuators [17]

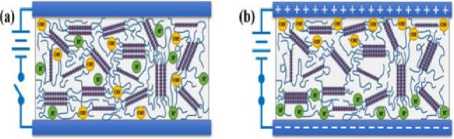

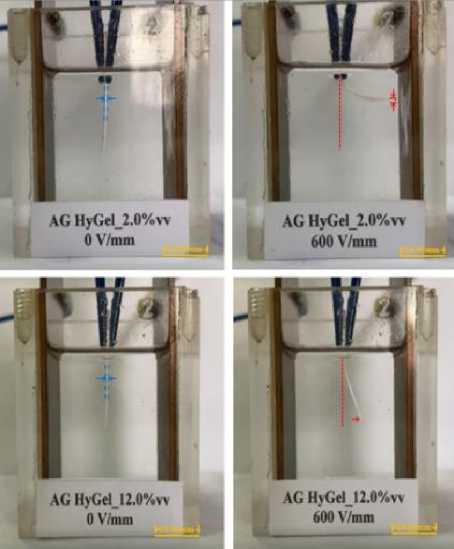

Chitosan and cellulose are not the only biopolymers used as electroactive materials. Recently Rot-janasuworapong et al. [18], have reported the use of agarose for the production of an electro-responsive material. In their work, agarose (AG) was used to fabricate the AG hydrogels through a simple solvent casting method. Generally, the formation of agarose hydrogel mostly depends on two factors namely temperature and concentration. For the experiment four hydrogels’ samples were prepared with 2.0, 4.0, 8.0, and 12.0%v/v agarose concentration. The electrostrictive response mechanism of the AG hydrogel can be described as the alignment in the same direction of the dipole molecules, as a response to an electrical field, such phenomenon is called orientation polarization, the representation of such phenomenon is shown in figure 10.

Figure 10. Proposed the electrostrictive response mechanism of the AG hydrogel [18]

It is mentioned that the highest dielectric constant was obtained from the sample with 2%v/v. This result can be explained due to the higher concentration of water molecules within the hydrogel. It can be compare the dielectric constant with other electroactive material, such as, cellulose ionogel (Phy gel) [19] and thermoplastic elastomer polyurethane (TPE-PU) [20], the present results show that the Phy gel exhibit a higher dielectric constant (~31) than the AG HyGel_2.0%v/v (~22), on the other hand, AG HyGel_2.0% has a higher dielectric constant than the TPE-PU (~4). The electromechanical properties tests show that, the AG HyGel_12.0%v/v possessed the highest storage modulus (G') and storage modulus relative response (AG 7 G '0) of 4.48x106 Pa and 1.07, respectively under applied electric field strength of 800 V/mm. The storage modulus AG 'I G '0 monotonically increases with increasing agarose concentration. The highest A G'/ G '„ with a value of 1.07, was obtained from the AG HyGel_12.0%v/v. It can be summarized that a higher agarose concentration with a higher number of polarizable groups (-OH groups) predominantly enhances the electromechanical response. The highest deflection distance of 15.30 mm at 600 V/mm was obtained from the AG HyGel_2.0%v/v (figure 11). The AG HyGel 8.0%v/v has the highest dielectrophoresis force density (0.17 mN I mm3).

Table 3.

Comparison of the bending performance of the AG HyGels [18]

|

Sample |

Voltage/ mm |

Volume (mm3) |

Deflection angle (degree) |

Deflection distance (mm) |

|

AG HyGel_2.0 %v/v |

500 |

27.27 |

74.60+1.02 |

15.30+0.43 |

|

AG HyGeL4.0%v/v |

600 |

27.83 |

56.11+3.67 |

10.92+0.69 |

|

AG HyGel_8.0 %v/v |

600 |

34.54 |

30.05+2.93 |

7.36+0.78 |

|

AG HyGel_12.0%v/v |

600 |

31.74 |

17.74+6.47 |

4.31+1.57 |

Table 3 summarizes the performance parameters obtained from the samples. The main advantages of the present agarose hydrogels are the ease and cost in fabrication without using a toxic chemical crosslinker or additive.

Figure 11. Bending performance of AG HyGel_2.0% and AG HyGel_12.0% [10]

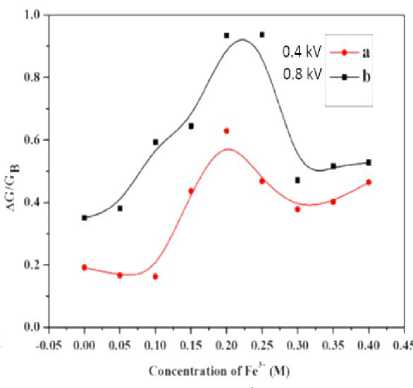

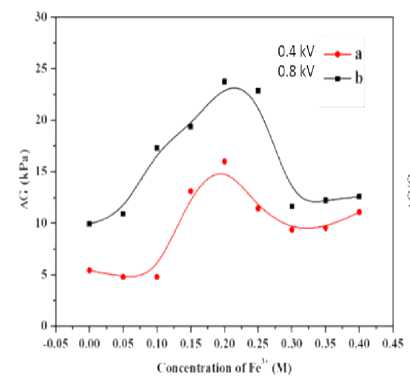

Starch is a biopolymer widely used for the preparation for electrorheological fluids. Starch also can be implemented for the preparation of electroresponsive hydrogels as reported at Wang et al., article [21]. They studied the effect that Fe(III) combined with starch can have in the look for an enhancement in the electro responsive properties of the hydrogel. The starch-Fe(III) hydrogels were prepared through two cross link procedures. Firstly, starch was dissolved in water at 60 °C, then, glutaraldehyde (GA) as the dominating cross-linker. Secondly, FеСl 3 solution with different concentrations (from 0.00 to 0.40 with step 0.05 M) as the auxiliary cross-linker. The hydrogel named A-hydrogels cured under a DC electric field (0.4 and 0.8 kV mm-1) for the first 1.5 h, the other hydrogel sample called B-hydrogels cured with no DC electric field was.

The two mixtures were gelation-cured synchronously. The results obtained after experimentation showed that there is a coordinate bond between Fe(III) with -OH of starch which leads to a stronger three-dimensional network structure and higher thermal stability of the starch-Fe(III) hydrogel. Furthermore, when the Fе3 + concentration is 0.15 ~ 0.25 M under the electric field of 0.8 kV mm 1 starch-Fe(III) hydrogels have the strongest electro-response, the maximum value of modulus increment (ΔG) is 24 kРа, and the modulus increment sensitivity (ΔG/GB) is about 90% (figure 12). It was shown that the addition of Fe(III) particles as composites to the starch hydrogel, represented an improvement in its electro-responsive behavior.

Figure 12. The storage modulus increment (ΔG) and increment sensitivity (ΔG/) of the hydrogels as a function of concentration under [21]

Conclusion

The present manuscript aimed to summarize some of the works that have been done in the last decade, by the use of biopolymers as electroactive materials, going from electrorheological fluids to electroactive hydrogels. The application that biopolymers are having in the field of smart materials has been increasing, expanding the fields of their application, from industry to medicine.

It is also important to mention that some of the drawbacks that this new proposal have is the use of high voltages in order to perform the actuation, which reduces their practical implementation. Nevertheless, biopolymers promise to be a potential material for the development of new technologies. There is still a long way to go before bringing them to large-scale production but, without any doubt, these polymers, are becoming the materials of the future.

Список литературы Biopolymers and its application as electroactive polymers

- Jean-Mistral C., Basrour S., Chaillout J. J. Comparison of electroactive polymers for energy scavenging applications. Smart Materials and Structures. 2010. vol. 19. no. 8. pp. 085012.

- Romasanta L. J., Lopez-Manchado M. A., Verdejo R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective. Progress in Polymer Science. 2015. pp. 188-211. doi: 10.1016/j.progpolymsci.2015.08.002.

- Lurie-Luke E. Product and technology innovation: What can biomimicry inspire? Biotechnology Advances. 2014. vol. 32. no. 8. pp. 1494-1505. doi: 10.1016/j.biotechadv.2014.10.002

- Bar-Cohen Y. EAP from 1999 to 2020: highlights from chairing the EAPAD conference for 22 years. Electroactive Polymer Actuators and Devices (EAPAD) XXII. International Society for Optics and Photonics. 2020. vol. 11375. pp. 1137502. doi: 10.1117/12.2559735

- Augustine R., Rajakumari R., Cvelbar U., Mozetic M. et al. Biopolymers for health, food, and cosmetic applications. Handbook of Biopolymer-Based Materials: From Blends and Composites to Gels and Complex Networks. 2013. pp. 801-849.

- Balaji A.B., Pakalapati H., Khalid M., Walvekar R. et al. Natural and synthetic biocompatible and biodegradable polymers. Navinchandra Gopal Shimpi. Biodegradable and biocompatible polymer composites. 2018. pp. 3-32.

- Wankhade V. Animal-derived biopolymers in food and biomedical technology. Biopolymer-Based Formulations. 2020. pp. 139-152. doi: 10.1016/b978-0-12-816897-4.00006-0

- Ahmed S., Kanchi S., Kumar G. Handbook of Biopolymers: Advances and Multifaceted Applications. CRC Press, 2018.

- Sohn J.W., Kim G.W., Choi S.B. A state-of-the-art review on robots and medical devices using smart fluids and shape memory alloys. Applied Sciences. 2018. vol. 8. no. 10. pp. 1928. doi: 10.3390/app8101928

- Choi K., Gao C.Y., Nam J. Do, Choi H.J. Cellulose-based smart fluids under applied electric fields. Materials. 2017. vol. 10. no. 9. pp. 1060. doi: 10.3390/ma10091060

- Choi K., Nam J. Do, Kwon S.H., Choi H.J. et al. Microfibrillated Cellulose Suspension and Its Electrorheology. Polymers. 2019. vol. 11. no. 12. pp. 2119. doi: 10.3390/polym11122119

- Kuznetsov N.M., Zagoskin Y.D., Vdovichenko A.Y., Bakirov A.V. et al. Enhanced electrorheological activity of porous chitosan particles. Carbohydrate Polymers. 2021. vol. 256. pp. 117530. doi: 10.1016/j.carbpol.2020.117530

- Altinkaya E., Seki Y., Çetin L., Gürses B.O. et al. Characterization and analysis of motion mechanism of electroactive chitosan-based actuator. Carbohydrate polymers. 2018. vol. 181. pp. 404-411. doi: 10.1016/j.carbpol.2017.08.113

- Akar E., Sever K. Electromechanical characterization of multilayer graphene-reinforced cellulose composite containing 1-ethyl-3-methylimidazolium diethylphosphonate ionic liquid. Science and Engineering of Composite Materials. 2017. vol. 24. no. 2. pp. 289-295. doi: 10.1515/secm-2015-0038

- Palza H., Zapata P. A., Angulo-Pineda C. Electroactive smart polymers for biomedical applications. Materials. 2019. vol. 12. no. 2. pp. 277. doi: 10.3390/ma12020277

- Jayaramudu T., Ko H., Zhai L., Li Y. et al. Preparation and characterization of hydrogels from polyvinyl alcohol and cellulose and their electroactive behavior. Soft Materials. 2017. vol. 15. no. 1. pp. 64-72. doi: 10.1080/1539445X.2016.1246458

- Zolfagharian A., Kaynak A., Khoo S.Y., Kouzani A.Z. Polyelectrolyte soft actuators: 3D printed chitosan and cast gelatin. 3D Printing and Additive Manufacturing. 2018. vol. 5. no. 2. pp. 138-150. doi: 10.1089/3dp.2017.0054

- Rotj anasuworapong K., Thummarungsan N., Lerdwij itj arud W., Sirivat A. Facile formation of agarose hydrogel and electromechanical responses as electro-responsive hydrogel materials in actuator applications. Carbohydrate Polymers. 2020. vol. 247. pp. 116709. doi: 10.1016/j.carbpol.2020.116709

- Kunchornsup W., Sirivat A. Physically cross-linked cellulosic gel via 1-butyl-3-methylimidazolium chloride ionic liquid and its electromechanical responses. Sensors and Actuators A: Physical. 2012. vol. 175. pp. 155-164. doi: 10.1016/j.sna.2011.12.045.

- Petcharoen K., Sirivat A. Electrostrictive properties of thermoplastic polyurethane elastomer: Effects of urethane type and soft-hard segment composition. Current Applied Physics. 2013. vol. 13. no. 6. pp. 1119-1127. doi: 10.1016/j.cap.2013.03.005.

- Wang Y., Lin M., Dai W., Zhou Y. et al. Enhancement of Fe (III) to electro-response of starch hydrogel. Colloid and Polymer Science. 2020. vol. 298. no. 11. pp. 1533-1541. doi: 10.1007/s00396-020-04736-y