Cement stone on the basis of quartz-ash-cement binder

Автор: Kosach A.F., Kuznetsova I.N., Rashupkina M.A., Pedun G.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Study of properties of nanomaterials

Статья в выпуске: 2 Vol.14, 2022 года.

Бесплатный доступ

Introduction. One of the promising areas related to formation of concrete structure on the basis of a mineral binder with specified performance properties employs the addition of ultradispersed fillers (nanomodifiers) to the binder composition. Wastes of quartz and hydro-removal ash are used as nanomodifiers. The presence of nanoparticles in the binder can significantly change the processes of hydration and hardening of the concrete mix. Materials and methods. Hydro-removal ash from Omsk combined heat and power plant 5 (CHPP-5), cement and quartz waste obtained from the production of highly pure quartz concentrate which acted as an enhancer of pozzolanic activity to hydro-removal ash were used as materials for cement stone on the basis of a quartzash- cement binder. Nanomodifier was obtained as a result of mechanical, mechanohydraulic (water) and mechanohydrochemical (water + Megalit S-3ML additive) activations. Activation of the quartz-ash mixture was carried out in a continuous-action rotary mill. The mechanical method provides only mechanical activation, and the mechanohydraulic method provides mechanical, hydraulic, turbulent and acoustic activations. The mechanohydrochemical method provides all actions of hydraulic activation including chemical one. Results. The article investigated cement stone on the basis of quartz-ash-cement binder (activated quartz waste and hydraulic ash from Omsk CHPP-5, cement). The technologies of activation of the quartz-ash mixture by increasing the specific surface of the dispersed phase for the production of quartz-ash-cement binder are considered. The obtained results of the weight distribution of particles of hydro-removal ash and quartz before and after activation show that the average size of the nanoparticle diameter is from 25 μm to 1.5 μm and specific surface is 967–7729 cm2/g. Conclusions. The use of nanoparticles in a quartz-ash mixture allows increasing the strength characteristics of cement stone from 23 to 59%. The use of quartz waste from the production of high-purity quartz concentrate and ash hydraulic removal from Omsk CHPP-5 power plant with the introduction of the proposed technologies for their activation allows increasing the formation of cement stone on a quartz-ash-cement binder by increasing the package density and chemical activity of nanoparticles in the processes of phase formation of hydrate compounds, which will reduce intergranular space between non-hydrated cement grains and will improve physical and mechanical characteristics of cement stone.

Quartz, hydrotreatment ash, quartz-ash-cement binder, cement stone, nanoparticle, nanomodifier, nanofiller

Короткий адрес: https://sciup.org/142231189

IDR: 142231189 | DOI: 10.15828/2075-8545-2022-14-2-83-88

Текст научной статьи Cement stone on the basis of quartz-ash-cement binder

Original article

O ne of the promising areas aimed at studying formation of concrete structure on mineral binder with the specified performance properties is introduction of ultradispersed fillers (nanomodifiers) into the composition of binder. The effect of introduction of nanoparticles into concrete is expressed in the fact that not only an additional phase interface appears in the system, but also a carrier of quantum-mechanical manifestations emerges [1, 2, 3].

From the nanoscale point of view, the particles possess qualitative effects determined by the dependence of chemical and physical properties on the ratio of the num- ber of atoms in the near-surface and internal volumes of the particles. Such particles and their ensembles acquire a different physicochemical and mechanochemical activity that can radically change the processes of structure formation synthesis and change the thermodynamic and energy situation in a dispersed system, such as the structure of a cement stone on a quartz-ash-cement binder [2, 3, 4]

Artificial nanotechnology creates nanosystems in both ways: “top-down” and “bottom-up”. It is already well-known phenomena of nanostructured objects self-organization which involve the processes of self-organization of substances at the atomic-molecular level, that makes it possible to create unique objects without external influence. [5].

STUDYING THE PROPERTIES OF NANOMATERIALS

Cement hydration products in the form of tiny particles – submicrocrystals – with sizes less than 0.1 microns create a colloidal system in the interlayers between hydrated cement grains: tobermorite gel. Coagulation contacts appear between the particles, which leads to the formation of a coagulation structure. A feature of these contacts is the obligatory presence between the particles of a thin stable layer of film water (disperse medium) [6, 7].

The physical contacts of the coagulation structure of the cement gel result in a migration of atoms, there are more signified attraction forces between the atoms, which leads to a tendency of self-organization of cluster structures [8, 9].

The presence of nanoparticles in the system can significantly change the processes of hydration and hardening of the concrete mix. When choosing a system of requirements for nanoparticles as concrete structure modifiers, we can distinguish: structure-forming and technological aspects, reflecting the phenomena and mechanisms of formation of the structure of high-strength concretes, explaining the effects of nanomodification and characterizing the impact of nanomodifiers in the structure of concrete; structure-forming participation and modifying effect of nanosized particles, which increase package density of capillary-bound and free water, as well as a significant chemical participation of nanosized particles in heterogeneous processes of phase formation of hydrated compounds. At the same time, during the colloidizing and nucleation stages and phase formation, nanoparticles are mainly defined by specific surface energy, nanoscale particles are determined mainly by the specific surface energy, which is a function of the particle size and the specific surface area of their surface.

In the general formulation of the problem concerning the development of a nanosystem, one should consider structure-forming and technological aspects that reflect the processes and mechanisms of structure formation, as well as the compatibility of the surface energy of nanoparticles with chemical additives and the technology for introducing nanomodifiers into the structure of a concrete mixture, which is the result of an increase in the packing density of nanodispersed particles and chemical participation of nanoparticles in heterogeneous processes of phase formation of hydrate compounds and self-organization of substances at the atomic-molecular level [10].

This possibility is determined both by the chemical-mineralogical composition of the particles and by the high values of their specific surface area and, as a consequence, by the specific surface energy. This will fill the microporosity of the cement stone, but also significantly reduce the amount of capillary-bound and free water, while compacting the nanosystem of hydrate formations. [11, 12].

At the stage of the coagulation period, nanoquartz particles act as a substrate of crystalline seeds of crystallization centers. The most important factors in the implementation of these mechanisms are the physicochemical properties of nanoparticles and their size, which determines the duration of the mechanisms and the concentration of nanoparticles per unit volume of the hardening system of cement stone on a quartz-ash-cement binder [13].

METHODS AND MATERIALS

The optimal raw material resource for the production of building materials in Omsk is the ash from the hydraulic removal of Omsk CHPP. More than 75 million tons of hydraulic ash have been accumulated on ash dumps with a total area of 755 hectares. On the territory of Omsk, three CHP plants of six operate with Ekibastuz coal, the ash content of which reaches 65%, consisting of chemical elements (carbon, hydrogen, oxygen, nitrogen) and mineral parts (clay minerals, which include oxides of silicon and metals, hydroxides metals, silicates Al, Mg carbonates Fe, Mg, Ca).

The main requirement for the successful use of hydroremoval ash CHPP-5 is the stability of their physicochemical parameters and the ability to exhibit pozzolanic activity with cement hydration products, the ability to bind calcium hydroxide at ordinary temperatures with the formation of insoluble compounds [14, 15].

In this regard, the purpose of the research is to obtain a cement stone with high physical and mechanical properties due to a nanomodifier obtained by mechanical, mechanohydraulic (H2O) and mechanohydrochemical (H2O + Megalit S-3ML additive) activation, based on ultrafine ash from the hydraulic removal of Omsk CHPP-5 and quartz waste as an enhancer of pozzolanic activity to hydro-removal ash [16].

In studies quartz waste from the production of highly pure quartz concentrate and hydro-removal ash from Omsk CHPP-5 was used as a material for cement stone on the basis of quartz-ash-cement binder. The content of hydro-removal ash oxides and quartz waste is presented in Table 1.

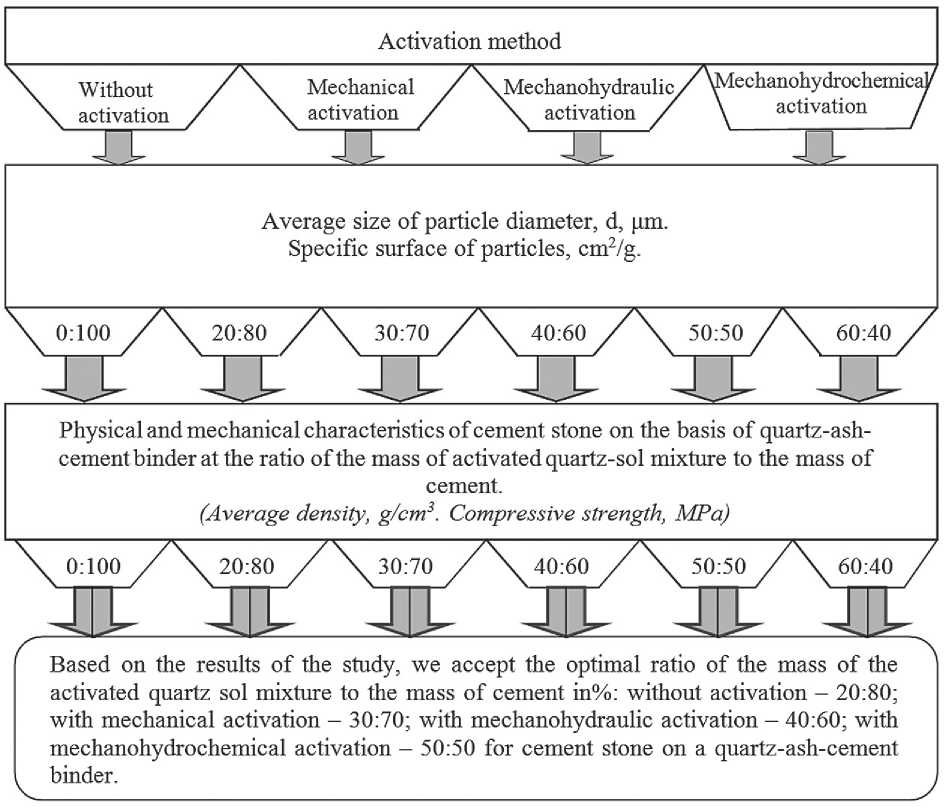

The block diagram of the study of the physical and mechanical properties of cement stone on a quartz-ash-cement binder is shown in Figure 1.

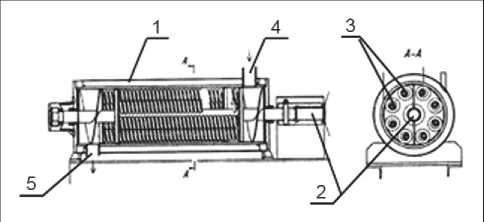

Activation of the quartz-sol mixture was carried out in a continuous rotary mill “Vyuga-3”, shown in fig. 2.

Mechanical method provides only mechanical activation. The mechanohydraulic method provides (ρH O = 1kg/m3) mechanical, hydraulic, turbulent and acoustic activations. The presence of finely ground active dust in a solution of film water obtained from the activation of quartz waste and hydro-removal ash is also involved in the processes of structure formation synthesis. With the mechanohydrochemical method, respectively,

STUDYING THE PROPERTIES OF NANOMATERIALS

Table 1

Oxide content, % mass

|

Name |

SiO2 |

Al 2 O 3 |

Fe 2 O 3 |

СаО |

MgO |

P 2 О 5 |

Na2O |

К2O |

ppp |

|

Quartz waste |

98–99 |

0.1–0.3 |

0.1–0.2 |

0.1–0.3 |

0.0–0.1 |

– |

0.2–0.3 |

0.2–0.5 |

2.1–3.0 |

|

Ashes of hydroremoval |

51–60 |

24–32 |

3.5–8.3 |

1.1–2.1 |

0.2–1.5 |

0.4–0.7 |

0.1–1.4 |

0.3–0.7 |

5.2–5.5 |

Fig. 1. Block diagram of the study of the physical and mechanical properties of cement stone on a quartz-ash-cement binder all methods of hydraulic activation and chemical, which affects the mechanisms of cement hydration, being in a solution of film water, contribute to a more active participation in the processes of formation of the crystalline ordered structure of cement stone at the atomic and molecular level. The plasticizing additive Megalit S-3 ML in an aqueous solution was used as a chemical reagent (ρH2O+C-3MЛ = 1.15 kg/m3) [17–22].

To determine the content and size of ultrafine particles of quartz waste and hydro-removal ash particles obtained as a result of activation, a laser analyzer “MicroSizer 201” was used.

STUDYING THE PROPERTIES OF NANOMATERIALS

Fig. 2. Continuous rotary mill “Vyuga-3”. Grinding bodies arrangement: 1 – cylindrical body, 2 – cylindrical grinding bodies – cylindrical spirals (8 pcs.), 3 – shaft with vertical plates for fastening cylindrical spirals (8 pcs.), fixed in the body with bearings, 4 – loading window , 5 – window for dispensing activated material

RESULTS AND DISCUSSION

The obtained results of the weight distribution of particles of hydroremoval ash and quartz after activation show that the average particle size is from 25 µm to 1.5 µm (nanoparticles) with a specific surface area from 967 to 7729 cm2/g. Dispersion and particle content of activated hydro-removal ash are shown in the figure in the article [23].

Based on the results of the study, we accept the optimal ratio of the mass of the activated quartz sol mixture to the mass of cement in%: without activation – 20:80; with mechanical activation – 30:70; with mechanohydraulic activation – 40:60; with mechanohydrochemical activation – 50:50 for cement stone on a quartz-ash-cement binder.

The strength of the cement stone was determined on samples prepared from quartz-ash-cement dough of normal density, 2×2×2 cm in size, for each composition according to the structural scheme of the study. The tests were carried out in accordance with the requirements of GOST 10180-2012. The compressive strength of the samples was determined on a “Matest” press. The physical and mechanical parameters of the obtained samples were determined at the age of 28 days and are presented in table 2.

The obtained results of the strength of samples of cement stone on a quartz-ash-cement binder with respect masses of activated quartz sol mixture to the mass of cement: without activation (20:80) – durability increases by 23%; with mechanical activation (30:70) – strength increases by 31%; with mechanohydraulic activation

Table 2

Physical and mechanical properties of cement stone on quartz-ash-cement binder

|

Activation method |

Physical and mechanical properties of samples |

Attitude masses of activated quartz sol mixture to the mass of cement for cement stone,% |

|||||

|

0:100 |

20:80 |

30:70 |

40:60 |

50:50 |

60:40 |

||

|

without activation, average particle diameter – d = 25 µm, specific surface area – 967 cm2/g |

average density, kg/m3 |

2399 |

2447 |

2454 |

2445 |

2449 |

2455 |

|

100% |

102% |

102.3% |

101.9% |

102.1% |

102.5% |

||

|

compressive strength, MPa |

62.9 |

77.3 |

76.7 |

74.8 |

72.3 |

71.1 |

|

|

100% |

123% |

122% |

119% |

115% |

110% |

||

|

mechanical activation, average particle diameter – d = 6 µm, specific surface – 2911 cm2/g |

average density, kg/m3 |

2400 |

2435 |

2450 |

2455 |

2458 |

2474 |

|

100% |

101.5% |

102.1% |

102.3% |

102.4% |

103.1% |

||

|

compressive strength, MPa |

63.08 |

79.1 |

82.8 |

80.3 |

78.4 |

76.5 |

|

|

100% |

125.1% |

131% |

127% |

124% |

121% |

||

|

Mechanohydraulic activation ρzh = 1g/cm3the average size of the particle diameter is d = 3 µm, specific surface area 5491 cm2/g |

average density, kg/m3 |

2411 |

2435 |

2447 |

2451 |

2453 |

2452 |

|

100% |

101% |

101.5% |

101.8% |

102% |

101.9% |

||

|

compressive strength, MPa |

63.03 |

80.2 |

83.1 |

87.8 |

85.3 |

82.1 |

|

|

100% |

127% |

133.1% |

139% |

135% |

130% |

||

|

Mechanohydrochemical activation (water + chemical additive) ρl = 1.15 g/cm3, the average size of the particle diameter is d = 1.5 µm, specific surface 7729 cm2/g |

average density, kg/m3 |

2419 |

2453 |

2470 |

2479 |

2489 |

2504 |

|

100% |

101.4% |

102.1% |

102.5% |

102.9% |

103.5% |

||

|

compressive strength, MPa |

63.07 |

82.8 |

90.36 |

97.38 |

100.45 |

96.67 |

|

|

100% |

131% |

143% |

154% |

159% |

153% |

||

STUDYING THE PROPERTIES OF NANOMATERIALS

(40:60) – strength increases by 39% and with mechanohydrochemical activation (50:50) – strength increases by 59%.

CONCLUSION

The use of nanoparticles in a quartz-sol mixture makes it possible to increase the strength characteristics of cement stone from 23 to 59%.

The use of quartz waste from the production of highly pure quartz concentrate and hydraulic ash from Omsk CHPP-5, using the proposed technologies for their activation, will improve the structure of the cement stone by increasing the package density and chemical activity of nanoparticles in the processes of phase formation of hydrated compounds, this will reduce intergranular space between non-hydrated cement grains and improve the physical and mechanical characteristics of the cement stone. The use of activated quartz waste with increased specific surface energy, like a highly reactive pozzolana, contributes to the production of a stronger and more durable cement stone. The hydraulic ash from the Omsk CHPP-5 on the optimal quartz-ash-cement binder for industrial and civil construction can contribute to significant investments in the Omsk region, which will positively affect the economic, social and environmental situation in the district.

At present, the wide application of quartz sol raw materials in construction can be considered as practically achievable and economically viable measures. The implementation of a quartz-ash-cement binder with rational grain composition makes it possible to increase the homogeneity of the concrete mix, reduce the consumption of cement, and also solve the problem of recycling quartz waste and hydraulic ash.

Список литературы Cement stone on the basis of quartz-ash-cement binder

- Gusev B.V. The strength of a polydisperse composite material, such as cement concrete, and the features of the stressstrain state of such a material under the action of compressive loads. Moscow: TsISN; 2003.

- Gusev B.V. Concrete with fillers of various dispersion and their nanomodification. Nanotechnologies in Сonstruction. 2019; 10(4): 384–393. Available from: doi: 10.15828/2075-8545-2019-11-4-384-393.

- Gusev B.V. Development of nanoscience and nanotechnologies. In: Proceedings of International scientific and technical conference “Composite building materials. Theory and practice”. Penza: Volga House of Knowledge; 2007. p. 70–73.

- Gusev B.V. [and others] Formation of the structure of composite materials and their properties. Moscow: Nauch. world; 2006.

- Baloyan B.M., Kolmakov A.G., Alymov M.I., Krotov A.M. Nanomaterials. Classification, features of properties, application and production technologies: textbook. Moscow; 2007.

- Kosach A.F., Kuznetsova I.N., Pedun G.A., Prezhin S.E. The use of activated waste on the physical and mechanical properties of cement stone. In the collection: “Modern Engineering Problems of Key Industries. Modern tasks of engineering sciences”. Collection of scientific papers of the International Scientific and Technical Symposium and the III International Kosygin Forum. Moscow, 2021; p. 175–186.

- Vavrenyuk S.V., Orentlicher L.P., Alikovsky A.V. Cement-polymer coatings based on “cryptoheterogeneous” water-soluble polymers for the secondary protection of enclosing structures. Vestnik RAASN. 2005; 9: 145–147.

- Lesovik V.S. On the development of the scientific direction “Nanosystems in building materials science”. Building materials. 2006; 28: 18–20.

- Voronkov M.G., Maletina E.A., Rollan A.K. Heterosiloxanes. The science. Novosibirsk; 1984.

- Vavrenyuk S.V., Orentlicher L.P., Alikovsky A.V. Cement-polymer coatings based on “cryptoheterogeneous” water-soluble polymers for the secondary protection of enclosing structures. Vestnik RAASN. 2005; 9: 145–147.

- Kosach A.F., Kuznetsova I.N., Pedun G.A., Gutareva N.A. Development of sand concrete composition based on slurry-cement binders. Construction materials, equipment, technologies of the XXI century. 2020; 1-2(252-253): 34–37.

- Kuznetsova I.N., Darulis M.A., Kosach A.F. Technology of foam concrete production with ultradispersed quartz waste. In: IOP Conference Series: Materials Science and Engineering. 2019. 012031.

- Batrakov V.G. Modified concrete. Moscow: Stroyizdat; 1998.

- Kosach A.F., Rashchupkina M.A., Kuznetsova I.N., Darulis M.A. Influence of ultradisperse filler based on hydroremoval ash on the properties of cement stone. Bulletin of the Tomsk State University of Architecture and Civil Engineering. 2019; 21(1): 150–158.

- Kuznetsova I.N. The influence of quartz waste addition on the porosity of cement stone. Journal of Physics: Conference Series. 2021; 1989: 012042.

- Sivkov S.P. Modern aspects of the processes of structure formation during the hydration of cements. In: Proceedings of the MNTK “Science and technology of silicates”. Moscow; 2003.

- Darulis M.A., Kuznetsova I.N., Kosach A.F. Structure and properties of the cement stone modified by ultradispersed quartz waste. In: IOP Conference Series: Materials Science and Engineering. 2019. 012032.

- Kosach A.F., Kuznetsova I.N., Kurbanova R.B., Pedun G.A., Prezhin S.E. Evaluation of the impact of quartz waste on the physical and mechanical properties of cement stone. News of higher educational institutions. Construction. 2020; 10(742): 17–26.

- Ivanov L.A., Muminova S.R. New technical solutions in the field of nanotechnology. Part 1. Nanotechnologies in construction. 2016; 8(2): 52–70. Available from: doi: 10.15828/2075-8545-2016-8-2-52-70.

- Ivanov L.A., Muminova S.R. New technical solutions in the field of nanotechnology. Part 3. Nanotechnologies in Construction. 2016; 8(4): 93–110. Available from: doi: 10.15828/2075-8545-2016-8-4-93-110.

- Kuznetsova I.N. Influence of the chemical and mineral composition of cement on the thermal insulation properties of foam concrete. [dissertation]. Novosibirsk; 2009.

- Kuznetsova I.N. The technology for concrete production using an activated mixture of wood procession waste and sand. In: IOP Conference Series: Materials Science and Engineering. 2021. 1093 012018.

- Kosach A.F., Rashchupkina M.A., Pedun G.A., Kurbanova R.B. Evaluation of the influence of highly dispersed ash-mineral raw materials on the physical and mechanical properties of cement stone. News of higher educational institutions. Construction. 2020; 11(743): 42–50.