Circular economy in recycling concrete and reinforced concrete waste

Автор: Graneva A.V., Lushin K.I., Pulyaev I.S., Kudryavtseva V.D.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Efficient use of recycled resources

Статья в выпуске: 1 Vol.16, 2024 года.

Бесплатный доступ

Introduction. In the process of demolition and dismantling of emergency buildings, as well as during construction and reconstruction, more than 70 million tons of construction waste are generated annually in Russia. The circular economy is based on the principle of resource renewal, recycling of secondary raw materials, technological measures to return waste to the repeated economic turnover. Nowadays the problem of saving natural resources and reducing construction waste is especially urgent. About 80% of construction waste is heavy and light reinforced concrete, from which can be produced secondary crushed stone, increasing the use of which is one of the tasks in the transition of linear economy to a circular economy. Materials and methods. The study of the implementation of a set of organizational, economic and technological solutions aimed at the reuse of construction waste was carried out. The analysis was carried out on the example of using secondary aggregates obtained from concrete scrap. Results and discussions. In the course of the research the necessity of concrete scrap involvement into repeated economic turnover was proved, as its use in construction fully meets the requirements of the set tasks in the field of energy and resource saving and environmental safety. Conclusion. Recycled crushed stone is a valuable resource that contributes to the sustainable development of the economy as a whole and reduces the harmful impact of the construction industry on the environment.

Recycling, circular economy, recycling concrete and reinforced concrete scrap, secondary crushed stone, construction production waste

Короткий адрес: https://sciup.org/142240526

IDR: 142240526 | DOI: 10.15828/2075-8545-2024-16-1-50-58

Текст научной статьи Circular economy in recycling concrete and reinforced concrete waste

Original article

With the development of industrial production, increasing rates and volumes of construction of buildings and structures, the level of natural resources decreases from year to year, and the process of their extraction becomes more complicated. With the increase in the level of consumption of the population, there is a growing need to erect residential buildings that meet environmental, thermophysical, aesthetic norms and citizens’ requirements for modern housing. To renew the housing stock, housing renovation programs are developed and implemented, which leads necessarily to the demolition of emergency as well as obsolete housing stock. The issue of using reinforced con- crete scrap is also relevant in connection with the demolition of destroyed buildings as a result of military operations. Not only in the process of demolition and dismantling of buildings, but also during construction, reconstruction, landscaping every year in Russia more than 70 million tons of construction waste is generated, of which less than 25% of the volume is sent for recycling. Since most construction elements are manufactured in ways that do not allow dismantling them at the end of their service life, they are mostly disposed of in landfills or incinerated [1]. In the best case, the remaining waste is sent to landfills, which negatively affects the ecological condition of the natural environment and leads to unsustainable waste of raw material stocks. Due to the low level of control over the formation,

EFFICIENT USE OF RECYCLED RESOURCES transportation and disposal of construction waste, negligent organizations allow spontaneous dumping of garbage in forests, near roads, on the territories of specially protected natural objects. In addition, the construction of buildings and structures leads to significant greenhouse gas emissions both directly on construction sites and during the production of construction materials such as cement and concrete. Thus, the construction industry is perceived as one of the largest industries in the world with a significant impact on the global environment, economy and society in terms of sustainable development [2]. In order to reduce the environmental impact, various methods are used: improving the energy efficiency of buildings, minimizing waste on construction sites, creating construction materials that require less energy in production and with the possibility of recycling or safe disposal after use, and improving waste management systems on construction sites.

THE NEED TO DEVELOP A CIRCULAR ECONOMYIN CONSTRUCTION

The linear economy in construction involves the use of natural resources for the production of materials, products and structures, followed by waste disposal after demolition or dismantling of buildings. Concrete, being the main construction material nowadays, consumes a large amount of non-renewable natural resources. It has been found that 2.5 tons of concrete per person, which corresponds to 17.5 billion tons per year for the entire world population, requiring 2.62 billion tons of cement, 1.75 billion tons of water, and 13.12 billion tons of aggregate [3]. Circular economy (or recycling) is an economy based on the principle of renewal of natural resources through recycling, utilization of renewable energy sources, reuse of waste through recovery and recycling, unlike linear economy [4].

From the scientific point of view, “recycling” is a system of organizational, economic and technological measures for the return of production and consumption waste into repeated economic turnover [5].

The Government of the Russian Federation Order No. 868-r dated May 10, 2016 approved the Strategy for the development of the construction materials industry for the period up to 2020 and further perspective up to 2030, which involves stimulating the development of the market of secondary material resources of anthropogenic ori-

Construction

Separation

Crushing J concrete

Construction > materials manufacturinf

Linear economy

Natural

Natural resources

、 Building /construction

Circular economy

К .

——\1

Demolition and X Disposal at the dismantling landfill

N , N .

\Operation of 'buildings and structures .

Fig. 1. Difference between linear economy and circular economy on the example of recycling scrap concrete and reinforced concrete

EFFICIENT USE OF RECYCLED RESOURCES gin and activation of the process of creating by-products at enterprises to process waste into finished products. The action plan approved by the Order of the Government of the Russian Federation No. 630-r dated April 6, 2017 in the development of the above strategy, in terms of the use of secondary resources is supposed to analyze the technologies of production of construction materials and products [4].

More and more regions of the Russian Federation are launching new rules for construction waste disposal. For example, in the Moscow region, a system has been created that reflects all information about companies transporting construction waste, which allows to exclude unauthorized waste disposal [6].

On the initiative of the Ministry of Natural Resources and Ecology of the Russian Federation, Federal Law No. 268-FZ dated 14.07.2022 “On Amendments to the Federal Law “On Production and Consumption Waste” and Certain Legislative Acts of the Russian Federation” was issued, which will regulate the involvement of wastes, including those from construction production, in secondary turnover. In 2024, it is planned to develop a register of materials and products in the production of which secondary resources will be used, and in the future, after 2030, the burial of secondary resources will be prohibited.

APPLICATION OF CIRCULAR ECONOMY IN CONCRETE AND REINFORCED CONCRETE PROCESSING

All conducted and planned activities on the use of closed cycle in construction waste utilization lead to the development of appropriate technologies.

The generated construction waste consists of scrap concrete, reinforced concrete, bricks, polymeric materi- als, bitumen, asphalt, and wood waste. About 80% of the waste is heavy and light reinforced concrete (approximately 4:1 ratio). Large scrap concrete and reinforced concrete is pre-destroyed, debris is removed, washed, sorted into fractions: 5–20, 20–40, 40–70.

The choice of the method of processing concrete debris is determined by a number of conditions, such as the possibility of access to the waste processing area, organization of the place for storage of equipment and materials, etc. There are three basic schemes for organizing the production of concrete and reinforced concrete products processing:

-

1 scheme – installation of technological equipment at the site of dismantling (demolition) of buildings and structures and obtaining aggregate with its subsequent transportation to the concrete plant or facility;

-

2 scheme – organization of production for processing of concrete scrap into crushed stone, production of concrete mix at the site of demolition of capital construction objects;

-

3 scheme – transportation of concrete debris to the enterprise for crushed stone production [7].

The so-called secondary crushed stone is used for flooring in non-residential buildings, roads with low traffic intensity, parking lots as drainage, as part of railway embankments, for backfilling of paths, construction of small architectural forms, as a means of ice control (sift, concrete or brick scrap of the smallest fraction (up to 10 mm) [8, 9].

Secondary crushed stone according to the main indicators meets the requirements of GOST 8267-93 “Crushed stone and gravel from dense rocks for construction works. Technical conditions (with Amendments N 1-4)» [10] Fig. 2.

The demolition of a four-unit residential building of the demolished series results in about 5.5 thousand

Table 1

Comparison of characteristics of secondary and granite crushed stone fraction 5-20

|

Item No. |

Сharacteristics |

Test results |

|

|

Secondary crushed stone |

Granite crushed stone |

||

|

1 |

The content of clay and pulverulent particles, % |

0.11 |

0.65 |

|

2 |

Content of grains of lamellar and needle-shaped, % |

6.7 |

7.5 |

|

3 |

Strength (crushability), % |

18.9% (grade 600) |

4.1% (grade 1400) |

|

4 |

Freeze-thaw resistance |

F25–F50 |

> F150 |

|

5 |

Presence of harmful organic impurities |

Not found |

Not found |

|

6 |

True specific gravity, kg/m3 |

2685 |

2718 |

|

7 |

Porosities and voidness, % |

51.1 |

47.5 |

|

8 |

Average bulk density, kg/m310 |

1219 |

1344 |

|

9 |

Water absorption |

6.22 |

0.57 |

EFFICIENT USE OF RECYCLED RESOURCES

Fig. 2. Compliance of secondary crushed stone characteristics with the requirements of GOST 8267-93

cubic meters of concrete slabs or blocks. During the renovation program at least 30 million cubic meters of construction waste will have to be generated additionally [11]. In 2022–2023 alone, 300 houses will be demolished. To produce 1 m3 of concrete of class B25 using recycled crushed stone, 960–1010 kg of recycled crushed stone of 5–20 mm fraction is required [12].

The advantages of using recycled crushed stone include the following factors:

-

– Recycling construction waste into crushed stone helps reduce the amount of waste sent to landfills;

-

– The use of recycled materials reduces the need to extract new natural raw materials;

-

– The economic benefit of using recycled crushed stone at the point of production plays an important role in the current economic situation;

-

– Reducing carbon emissions reduces the burden on the environment.

EXPERIMENTAL STUDIES OF PROPERTIESOF CONCRETE ON SECONDARY AGGREGATE

When performing experimental studies of the basic properties of concrete with recycled aggregate, raw materials were used: cement, sand for construction works, recycled aggregate, ash, chemical additives.

Cement of CEM I 42.5H GOST 30515-2013 was used as a binder. The main characteristics of cement are given in Table 2.

All indicators meet the requirements of GOST 31108 – 2016, GOST 30515 – 2013.

Natural quartz sand was used as fine aggregate (Table 3).

All indicators meet the requirements of GOST 8736-93

During the processing of concrete scrap at the crushing and screening complex “Satori” in Moscow city, the screenings of 5–10 mm fraction were obtained, which was used as coarse aggregate. Chemical mineralogical compositions of concrete scrap are given in Tables 4 and 5.

In order to study the physical and mechanical characteristics reflecting structural properties, the specimens were molded by casting method. Curing of concrete specimens was carried out at normal temperature and humidity. Compressive strength, average density, water absorption were determined according to standard methods as the average of six specimens of test results.

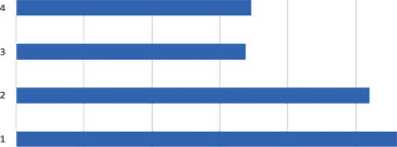

In compositions 1 and 2 granite crushed stone was used as coarse aggregate, in compositions 3 and 4 natural aggregate was replaced by secondary aggregate from concrete scrap.

The concrete specimens were tested in compression at the age of 28 days. The specimens on secondary aggregate showed a strength of 38.25 and 39.2 MPa, which corresponds to concrete class B30 (Fig. 3).

Despite the fact that the properties of recycled crushed stone differ from those of natural crushed stone, the production of concrete and reinforced concrete products from recycled concrete scrap fully meets the requirements of the set tasks in the field of energy and resource saving, environmental safety of capital construction projects.

INNOVATIVE TECHNOLOGIES IN CONSTRUCTION WASTE RECYCLING

Current research in the field of construction waste recycling focuses on the development of innovative technologies aimed at improving the efficiency and environmental friendliness of the processes.

EFFICIENT USE OF RECYCLED RESOURCES

Table 2

Main parameters of cement CEM I 42.5H [13]

|

Name of indicators |

Unit of measurement |

Actual figures |

|

Particle size distribution |

||

|

Maximum particle size d (0.9) |

micrometer |

84.423 |

|

Minimum particle size d (0.1) |

micrometer |

6.572 |

|

Average particle size d (0.5) |

micrometer |

31.984 |

|

Arithmetic mean diameter: D (1.0) |

micrometer |

0.67 |

|

Mean volumetric diameter: D (4.3) |

micrometer |

39.74 |

|

Average surface diameter: D (3.2) |

micrometer |

11.22 |

|

Physical indicators |

||

|

Normal density of cement dough |

% |

30 |

|

Beginning of setting |

h/min |

2 h 30 min. |

|

End of setting |

h/min |

4.5 ч |

|

Cone blur (at B/C = 0.4) |

mm |

110 |

|

Fineness according to the residue on the sieve (No. 008) |

% |

88 |

|

Tensile strength |

||

|

In compression (28 days) |

MPa |

55.6 |

|

At bending (28 days) |

MPa |

8.5 |

Table 3

Main indicators of sand from Krasnogorsk sand quarry [13]

|

Name of indicators |

Unit of measurement |

Actual figures |

|

Grain composition |

Total balances, % |

|

|

2.5 |

1.4 |

|

|

1.25 |

2.8 |

|

|

0.63 |

16.8 |

|

|

0.315 |

65.8 |

|

|

0.14 |

94.2 |

|

|

< 0.14 |

100 |

|

|

Coarseness modulus |

1.7 |

|

|

Clay content in lumps |

% |

no |

|

bulk density |

g/m3 |

1578 |

|

True density |

g/m3 |

2632 |

|

Dusty and clayey particles |

% |

1.1 |

|

hollowness |

% |

44 |

Table 4

Mineralogical composition of concrete scrap

|

Content, % |

|||||||

|

SiO2 |

CaCO3 |

Ca(OH)2 |

CaCO₃ • MgCO₃ |

KAlSi3 O8 |

NaAlSi3 O8 |

C3S |

Ca6Al2(SO4)3(OH)12 • 26H2O |

|

Silica |

Calcite |

Portlandite |

Dolomite |

Microcline |

Albit |

Tricalcium silicate |

Ettringite |

|

61 |

16 |

0.9 |

3 |

6.0 |

10.8 |

1.9 |

0.4 |

EFFICIENT USE OF RECYCLED RESOURCES

Table 5

Chemical composition of concrete scrap

|

Oxide |

Content, % |

|

SiO2 |

53.29 |

|

CaO |

31.17 |

|

Al 2 O 3 |

6.02 |

|

Fe 2 O 3 |

3.01 |

|

MgO |

2.23 |

|

K 2 O |

1.42 |

|

SO3 |

1.12 |

|

Na2O |

0.907 |

|

P 2 O 5 |

0.295 |

|

TiO2 |

0.268 |

|

Cl |

0.143 |

|

MnO |

0.0849 |

|

CuO |

0.012 |

|

Cr 2 O 3 |

0.0118 |

|

ZnO |

0.0113 |

|

Co 3 O 4 |

0,007 |

One of the promising directions is the use of nanotechnology to improve the properties of building materials. Various types of nanoparticles can be used as additives, including nanosilicates, nanoclay, carbonate nanotubes and metal nanooxides. Each of these types contributes to improving certain properties of concrete. For example, the introduction of nanosilica into concrete mixes can produce concretes with a denser structure and improved mechanical properties [14, 15], which can compensate for some deterioration in strength performance due to the use of secondary aggregate.

Another direction can be considered the development of methods for deep purification of waste from pollutants, which allows to improve the quality of the obtained secondary raw materials. This is especially relevant for waste containing heavy metals and other toxic substances. The application of advanced filtration and purification methods helps to eliminate these impurities, making materials safer for reuse.

Another direction may be the possibility of using artificial intelligence to optimize the sorting and recycling of construction waste. These technologies make it possible to identify different types of materials more efficiently and determine the most appropriate methods of their recycling [16].

Life cycle studies of secondary construction materials are also an important part of the research. This includes the analysis of environmental impact at all stages – from waste collection and processing to production and use

Fig. 3. Comparison of the main characteristics of concrete samples on natural aggregate (1, 2) and secondary aggregate (3, 4)

EFFICIENT USE OF RECYCLED RESOURCES

Table 7

Physical and mechanical characteristics of crushed stone

|

Main features |

Units of measurement |

Test results |

|

True density ρ ист |

kg/m3 |

2590 |

|

Bulk density ρ нас |

kg/m3 |

1205 |

|

Water demand Wp |

% |

4.8 |

|

Grain content of lamellar (flaky) grains |

% |

18.7 |

|

Dust content |

% |

1.2 |

|

Crushed stone crushability grade |

– |

600 |

|

Loss of weight when determining the crushability grade |

% |

10.0 |

|

Content of weak grains with strength less than 20 MPa |

% |

3 |

of final products. This approach allows us to assess the environmental feasibility and efficiency of recycling materials, which requires the formation of information systems for collecting engineering and environmental characteristics of the environment in places of production, use and utilization of construction materials, both in the form of information in environmental declarations and in an independent form [17, 18].

The above research and development areas offer great opportunities to improve environmental sustainability in

the construction sector, as well as to reduce the consumption of primary resources and construction waste.

The widespread implementation of the closed cycle economy through the introduction of rational processing schemes, application of new generations of equipment, technologies and innovative research will lead to improved quality and availability of secondary crushed stone, lowering its cost, which will ensure its competitiveness with natural aggregates [19, 20].

CONCLUSION

In fulfillment of the modern legislation, taking into account the positive properties and in connection with the currently significant and ever-increasing over time volume of demolished emergency, obsolete and conflictdamaged buildings, the issue of expanding the nomenclature of products from secondary concrete rubble is relevant. This can be not only a wider use of it as an aggregate for the production of new building materials and products, but also in the following cases:

– use as a permeable pavement for pedestrian walkways, driveways, in order to filter sediments and reduce the amount of wastewater to be discharged by the storm sewer system;

-

– as a base for rails on railroad tracks due to its resistance to dynamic loads;

-

– filling of wire gabions, which can serve not only for decorative purposes, but also as retaining walls, reinforcing the shorelines of water bodies, etc.;

-

– as a lining layer for new landfills to prevent harmful substances from entering the ground;

-

– as an aggregate for decorative plasters;

Table 6

Granulometric composition of crushed stone from concrete scrap

|

Names of balances |

Residues on sieves. % by weight |

||||||

|

12.5 |

10 |

7.5 |

5 |

2.5 |

1.25 |

Bottom |

|

|

Private |

0.1 |

1 |

58.0 |

28.0 |

11.6 |

0.9 |

0.4 |

|

Complete |

0.1 |

1.1 |

59.1 |

87.1 |

98.7 |

99.6 |

100 |

Table 8

Concrete mix compositions

|

No. of concrete mix composition |

Cement |

Coarse aggregate |

Fine aggregate Quartz sand |

Water |

||||

|

Natural |

Secondary |

|||||||

|

% |

kg |

% |

kg |

% |

kg |

% |

kg/m3 |

|

|

1 |

487 |

1094 |

100 |

– |

– |

625 |

100 |

180 |

|

2 |

487 |

1094 |

100 |

– |

– |

437.5 |

70 |

180 |

|

3 |

487 |

– |

– |

972 |

100 |

625 |

100 |

180 |

|

4 |

487 |

– |

– |

972 |

100 |

437.5 |

70 |

180 |

EFFICIENT USE OF RECYCLED RESOURCES

– as a component of composite binder from mechanically milled powders from waste concrete fractions with low residual strength characteristics and grindability [21].

The latest research and development contribute not only to improving environmental safety and efficiency of construction waste recycling, but also opens up ways to create new, more sustainable building materials and technologies, including those based on recycled crushed stone.

In general, recycled crushed stone is a valuable resource that contributes to the development of the economy as a whole and reduces the environmental impact of the construction industry, although its properties may differ from natural crushed stone. It is important to consider these differences when selecting a material for specific construction applications.

The addition of nanoparticles to secondary concrete is one of the promising directions in the field of construction materials, as it allows to significantly improve the properties of concrete and expand its application area. Nanoparticles can significantly increase the strength and resistance

[22] of secondary concrete to various external influences. This is achieved due to the fact that nanoparticles fill the micropores in concrete, improving its density and homogeneity. The introduction of nanotechnology into the concrete production process opens up new opportunities to improve its performance and extend its service life. The use of nanoparticles, such as nanosilicates, enhances the protective properties of concrete, preventing early aging and deterioration. This is particularly relevant for environments where concrete is exposed to corrosive environments such as salts or acids. Nanoparticles can significantly increase the chemical resistance of the material by preventing penetration and degradation by corrosive agents, making concrete more durable and reliable in service. The field of adding nanoparticles to concrete is being actively researched, and new data on the effect of various nanomaterials on concrete properties are regularly emerging. Nanotechnology in construction opens up new opportunities for improving the quality and durability of construction materials, including concrete obtained from secondary sources.

Список литературы Circular economy in recycling concrete and reinforced concrete waste

- Yeheyis M. et al. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technologies and Environmental Policy; 15 (81–91): 2013.

- Dewagoda K.G. et al. Driving systematic circular economy implementation in the construction industry: A construction value chain perspective. Journal of Cleaner Production; 381: 2022.

- Saimanova O.S. et al. Methods of organizing work on construction and demolition waste recycling. BIO Web of Conferences; 43 (8): 2022.

- Sysoeva E.A., Economy and ecology. Problems of Modern Economics; 2 (70): 2019. Available at: http://www.meconomy.ru/art.php?nArtId=6642

- Bannikova A.S., Chepeleva K.V., Pukhova V.V. Recycling in construction: problems and prospects for development in the territory of Eastern Siberia. Modern High Technologies; 10 (14-21): 2018.

- Vasileva A., Mertsalova A., Voronov A. Against the demolition there are techniques. Newspaper Kommersant; 24: 2022. Available at: https://www.kommersant.ru/doc/5206904

- Oleinik P.P., Oleinik S.P. Organization of the construction waste recycling system. Moscow State University of Civil Engineering; 250: 2009.

- Recommendations on the use of recycling products of substandard concrete and reinforced concrete products. Research Institute of Concrete and Reinforced Concrete; 9: 1984.

- Vaisberg L.A., Kameneva E.E. Study of the composition and physical-mechanical properties of secondary crushed stone from crushed concrete. Construction Materials; 6 (41-45): 2014.

- Beppaev Z.U. et al. Study of the dependence of grain composition and grade of recycling crushed stone on the crushability from the strength of the original utilized concrete. Bulletin of the Scientific Center of Construction; 3 (5-16): 2021. https://doi.org/10.37538/2224-9494-2021-3(30)-5-16

- Anfimova A.Y. Problems of construction waste disposal during renovation. Bulletin; 1 (2): 2019. Available at: https://vestnik.mi.university/journal/article.php?id=2152

- Kalgin A.A., Fakhratov M.A., Sokhryakov V.I. Experience in using waste crushed concrete in the production of concrete and reinforced concrete products. Construction Materials; 6 (32–33): 2010.

- Petropavlovskaya V.B. et al. Basalt dust removal product in the composition of the organomineral complex for the production of concrete mixes. Chemistry, Physics and Mechanics of Materials; 3 (26) (60-72): 2020.

- Flores-Vivian I. et al. Effect of SiO2 nanoparticles on the properties of cement materials. Bulletin of the Belgorod State Technological University named after V.G. Shukhov; 11 (6-16): 2018.

- Aleksandrova O.V. et al. The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete. Materials; 15 (8851): 2022. https://doi.org/10.3390/ma15248851

- Gorodnova N.V., The use of artificial intelligence in ‘SMART-ECOLOGY’ projects. Discussion; 105 (34-48): 2021.

- Zhuk P.M., Lavrusevich A.A. Geoecological aspects of the life cycle analysis of construction materials. Bulletin of the Perm National Research Polytechnic University. Applied Ecology. Urban Studies; 3 (99-111): 2020. https://doi.org/10.15593/2409-5125/2020.03.09

- Vigovskaya A., Aleksandrova O., Bulgakov B. Life cycle assessment (LCA) in building materials industry. XXI International Scientific Conference on Advanced in Civil Engineering Construction – The Formation of Living Environment (FORM 2018), Conference Series-Materials Science and Engineering; 106: 2017. https://doi.org/10.1088/1757-899X/245/5/052021

- Budzinsky P.A., Dyachkova O.N. Concrete disposal at the construction site during the renovation of urbanized territories. Potapov Readings: Proceedings of the All-Russian Scientific Conference dedicated to the memory of Doctor of Technical Sciences; 23-29: 2021. https://doi.org/10.22227/978-5-7264-2875-8.2021.23-29

- Larsen O., Naruts V., Aleksandrova O. Self-compacting concrete with recycled aggregates. Materials Today: Proceedings, International Conference on Modern Trends in Manufacturing Technologies and Equipment. ICMTMTE; 2023–2026: 2019. https://doi.org/10.1016/j.matpr.2019.07.065

- Aizenstadt A.M. et al. Integral indicators of quality of used concrete for secondary use. Nanotechnologies in Construction; 13 (5) (276–281): 2021. https://doi.org/10.15828/2075-8545-2021-13-5-276-281

- Artamonova O.V. Synthesis of nanomodifying additives for the technology of construction composites: monograph. Voronezh State University of Architecture and Civil Engineering, Voronezh; 100: 2016.