Collagen based bio-additives in polymer composites

Автор: Baldanov A.B., Bokhoeva L.A., Shalbuev D.V., Tumurova T.B.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Creation of new functional materials

Статья в выпуске: 2 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Polymer composite materials (PCM) based on epoxy resins are widely used in the construction industry. They are applied in construction of bridge spans, roadway slabs, footwalk planks, in low-loaded structures, as well as for reinforcement of concrete structures, sheating, strengthening of metal and concrete structures. Various fillers of micro- and nanosizes are used to improve the performance properties of PCM. Interfacial interaction between the filler and the polymer matrix plays an important role in determining the strength of the created composite materials. Methods and materials. The article studies the properties of polymer matrix composites reinforced with collagen based bio-additives obtained from solid organic waste of the leather industry. We have developed a fundamentally new method for obtaining a bioactive collagen product at a relatively low price, described in patent RU No. 2272808. Tensile studies of the PCM samples were carried out by adding dry collagen powder to an epoxy binder. We analyzed the sections of samples made on a JSM-6510LVJEOL scanning electron microscope, and studied the changes in the structure of PCM with fillers. Results and discussion. When 1% collagen is added to the PCM matrix, the amount of chemical elements is increasing: carbon (C) by 2.93%, oxygen (O) by 1.61%, magnesium (Mg) by 0.11%. And the number of micropores on the surface of the matrix, which serve as a stress concentrator, is decreasing by 4.9%, and they are also diminishing in size. The tensile tests have shown that when 1% collagen is added to the PCM matrix, the bearing capacity of the samples is increasing by 15.57%. The results obtained can contribute to the expansion of collagen application, waste reduction in the leather industry due to recycling. Conclusion. A fundamentally new method has been developed for obtaining a bioactive collagen product from solid organic waste of the leather industry at a relatively low price. It has been established that a bioactive collagen product in a powder form has a low cost and can be used as a bio-additive for PCM.

Collagen, bio-additive, polymer composite material, testing, samples, strength

Короткий адрес: https://sciup.org/142231195

IDR: 142231195 | DOI: 10.15828/2075-8545-2022-14-2-137-144

Текст научной статьи Collagen based bio-additives in polymer composites

Original article

In recent years, polymer composite materials (PCM) have found application in various industries, due to their high strength and modulus of elasticity, low weight, processibility, resistance to aggressive external factors, moldability [1], etc. The basic material of polymer composites is a matrix made of polymer binder: epoxy, phenolic polyamide or other resins and reinforcing filler of carbon, glass, boron or other fibers. Their combination makes it possible to obtain high-strength structures with targeted properties. PCM are used for the reinforcement of concrete structures in the form of strips [2], rebars [3], in construction of foot bridges [4], open sheds and enclosing structures, as well as primary bearing members exposed to an aggressive environment [5]. The need for such materials mirrors in the developments aimed at the improvement of the physical and mechanical properties of PCM, such as stiffness, fracture toughness and loadbearing capacity. A significant number of recent studies have shown that adding of nanoparticles and nanofibers to the PCM epoxy matrix improves the mechanical properties of such materials [6–10]. Addition of carbon nanotubes in the form of dispersions leads to an increase in the tensile strength of bond joints, an improvement of the mechanical properties, and growth of the microhardness of samples [11]. The researchers [12] studied unidirectional glass fiber reinforced epoxy composite filled with nanosize alumina, silica and micron-size alumina trihydrate fillers. The tensile, flexural and impact strengths of 10 wt% (combined alumina, silica and alumina trihydrate)-filled glass fiber reinforced epoxy composite improved by 9, 20 and 28%, respectively, as compared to the unfilled and alumina/silica-filled glass fiber reinforced epoxy compos-

CREATION OF NEW FUNCTIONAL MATERIALS ites. The results of studies of nanocomposites with silicon dioxide published over the past ten years were presented in the works [13–15]. The inclusion of silica nanoparticles sharply increases the compressive strength and moderately increases the tensile strength. The maximum effect of nanoparticles inclusion in PCM is encountered when the particle size range from 10 to 25 nm [16].

According to research conducted by Abercade [17], nanoadditives can be divided into four groups: pure metal powders, mixtures, metal oxides, complex oxides. Powders of pure metals make up a significant share of the total production of nanopowders – 80%. Complex oxides and mixtures are available in limited quantities. The results of the tenacity testing of multilayer polymer composites with fillers in the form of nanodispersed additives and other powdered substances are presented in the work [18]. Studies on inclusion of bio-additives to the PCM epoxy matrix are limited, but in the work [19] they improve such mechanical properties as rigidity, fracture toughness, and load-bearing capacity.

One of the promising fillers for the composite materials matrix is bio-additives based on collagen obtained from organic waste. They can be attributed to bioactive substances with optimal colloid-chemical properties. Organic wastes are secondary products derived from the processing of leather, fur, fish and meat raw materials. At the enterprises of the leather industry, a significant amount of solid organic waste is generated, which contains up to 50% of protein substances and can be actively used as biopolymers. Basic protein of such waste products is fibrillous protein-collagen, which forms the basis of the connective tissue and ensures its strength and elasticity.

Collagen makes up about 20–30% of the total amount of proteins in the body and has a unique structure, intra- and intermolecular bonds, and amino acid sequence [20–21]. In the collagen molecule three separate prolinerich polypeptide chains, containing glycine in every third position, twist one around the other, forming a triple helix. These molecules, in turn, are packaged into fibers, where neighboring molecules are held together by covalent crosslinks between neighboring leasing residues. Many rod-shaped collagen molecules cross-linked to- gether form strong, inextensible collagen fibrils, which have a tensile strength comparable to that of steel [21]. Collagen connective tissue consists of the fibers of collagen fibrils, characterized by a cross-banded structure. In tendons, collagen fibrils are arranged in cross-linked parallel bundles, which have very high tensile strength and are almost inextensible. Collagen fibrils can withstand loads that exceed their own weight by at least 10 000 times [22]. Although collagen has traditionally been used in the pharmaceutical and medical industries, it can also find wide application as a filler in composites.

The work is aimed at studying the effect of a bioactive collagen product obtained from organic waste of the leather industry on the strength of PCM.

Currently, there is a number of ways to obtain bioactive collagen products in the form of nanopowder from organic waste of the leather industry. Several methods have been developed for obtaining large volumes of nanosized powder from solid organic wastes of leather industry enterprises at a relatively low price. We presented a method for obtaining collagen from biological material based on the dissolution of charging feed in acetic acid and acetone [23]. In this technology for producing a biopolymer, a fermented milk composition is used as an acidic solvent. The fermented milk composition is a symbiosis of acid-tolerant prokaryotic microorganisms with their metabolic products and is used to reduce protein losses and preserve a greater number of intra- and intermolecular bonds in the collagen structure. A patent was obtained for the technology of collagen production [24]. The finished collagen product is a highly soluble in water brown powder with fractions up to 1 micron.

MATERIALS AND METHODS

We prepared the samples of fiberglass to carry out experimental work (grade T-10 (92) GOST 19170-2001). As a thermosetting matrix we used an uncured epoxy-diane resin ED-20 GOST 10587-84, as a curative for epoxy resin – polyethylenepolyamine TU 2413-357-0203447-99. For uniform distribution of dry collagen (1% or 2%) in the matrix, we used AG SONIC TC-150B ultrasonic bath

ab c d e

Fig. 1. Stages of processing PCM with collagen additives

CREATION OF NEW FUNCTIONAL MATERIALS with water heated to 45оC (Fig. 1c). The ultrasonic bath reduces the occurrence of air bubbles formed during the mechanical mixing, promotes uniform distribution of particles. It was noticed that a small amount of collagen up to 1 µm remains undissolved (Fig. 1b). We developed a special device for processing a prepreg for samples with nanoadditives (Fig. 1d).

The technological process of sample preparation involves the following operations. The reinforcing filler is cut to the required dimensions, and placed on the lower molding plate (Fig. 1e), the surface of the mold is covered with a smooth polyethylene film, the required number of layers of polymer material is laid on it, and a binder with different concentrations of collagen is placed between the layers (Fig. 1a, b, d). Then, the finished lay-up is evenly clamped with a hydraulic press (10 tons) to the stop and left pressed for 170 hours at a temperature of 30оC. The resulting sample is cut with a diamond disk into strips of the required dimensions.

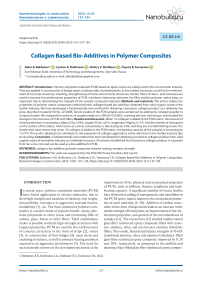

We made an analysis of the quantitative composition of collagen biopolymer particles in the composite matrix using a JSM-6510LVJEOL scanning electron microscope with an INCA microanalysis system installed in Centre of Collective Using “PROGRESS” at ESSUTM (Fig. 2).

We studied cutoffs of the samples sized 1 x 1 cm, cut out from the fractured areas after tensile tests. Cutoffs of the samples with collagen concentrations of 1%, 2%, and control samples without collagen (0%) with layers [90]2 were considered. It was found that when 1% or 2% collagen is added to PCM, the amount of chemical elements increases: carbon (C) by 2.93%, oxygen (O) by 1.61%, magnesium (Mg) by 0.11%. The results are presented in table 1.

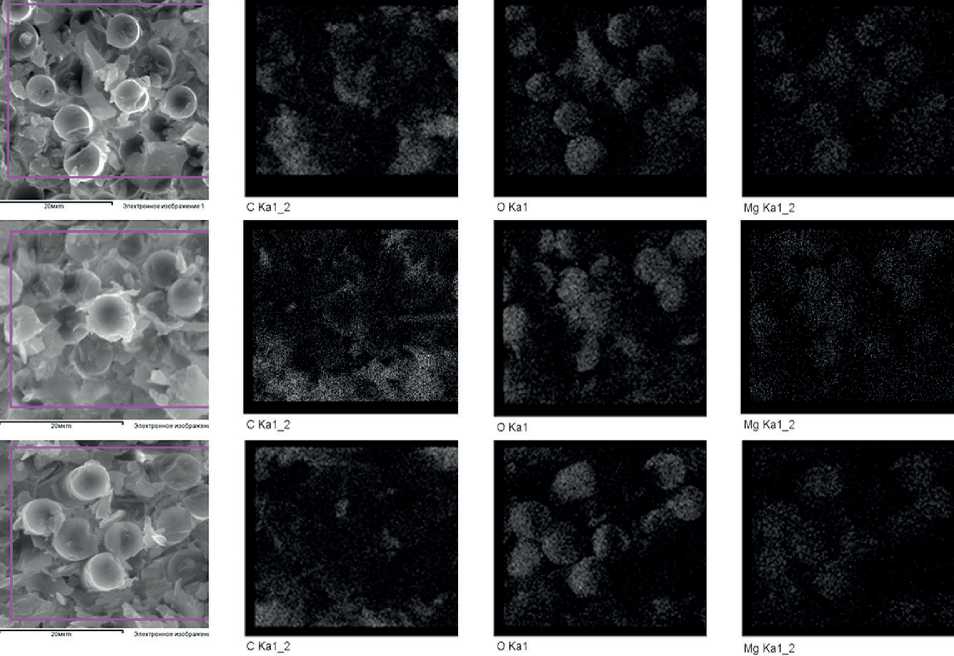

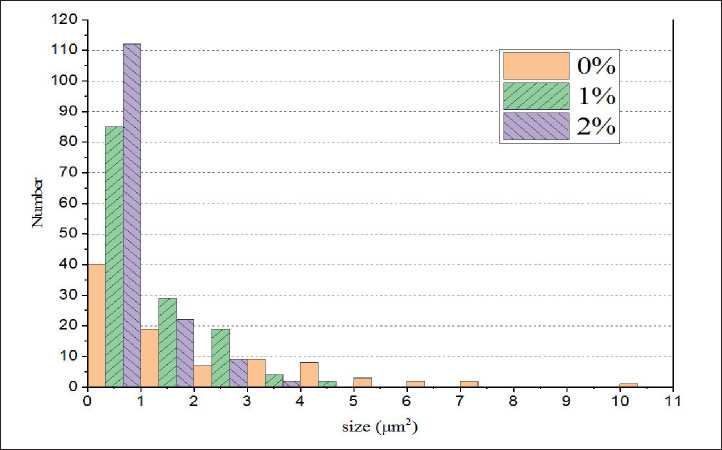

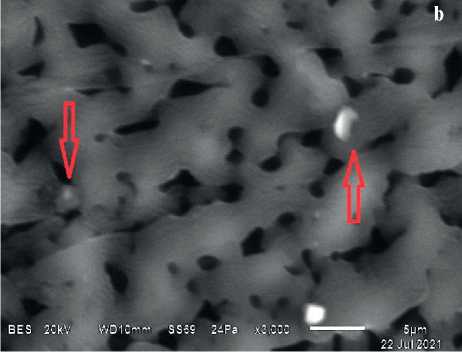

Studies of the surface of matrix with the addition of 1% and 2% collagen and matrix without the bioadditives (control samples) showed that with the addition of collagen the total number of micropores increases (up to 1 µm2), but the number of micropores sized more than 1 µm2 decreases (Fig. 3). The total area of micropores is reduced by an average of 3.57% with the addition of 1% collagen powder. The diagram in Figure 4 shows the areas of micropores in µm2 and their number depending on the percentage of collagen.

In dispersion-hardened materials, the particles act as a barrier to propagation of a crack in the matrix by strengthening the initial binder phase. Stress is concentrated in the area of matrix microinhomogeneities (micropores, grain boundaries, oversize non-equiaxed grains), carbon (С)

oxygen (О)

magnesium (Mg)

0%

1%

2%

Fig. 2. Analysis of the quantitative composition of collagen biopolymer particles in the composite matrix

CREATION OF NEW FUNCTIONAL MATERIALS

Table 1

Average amount of impurities in samples, %

|

% of biopolymer content |

C |

O |

Na |

Mg |

Si |

P |

S |

Cl |

K |

Ca |

|

|

100% |

In biopolymer |

47.65 |

47.97 |

0.18 |

0.08 |

0.13 |

0.85 |

0.67 |

0.43 |

0.07 |

1.54 |

|

0% |

In matrix |

34.07 |

36.5 |

0.08 |

1.32 |

14.33 |

0.11 |

0.08 |

0.11 |

0.24 |

9.13 |

|

1% |

In matrix |

36.78 |

38.6 |

0.1 |

1.46 |

13.34 |

0.09 |

0.1 |

0.13 |

0.2 |

9.1 |

|

2% |

In matrix |

39.94 |

39.72 |

0.08 |

1.54 |

13.78 |

0.1 |

0.11 |

0.17 |

0.24 |

9.3 |

|

Percentage of collagen |

0% – control sample |

1% |

2% |

|

Composite material surface at magnification |

|||

|

• |

|||

|

Micropores |

'aV |

^V"-'* "* 1. -.1 ^ч 5 Л; :А-- У ;-- • ж ^ ’ А 1* |

^.^? V.r< • ' Г ^ ■ „х*

>- ; . <<;> • |

|

Micropore area µm2 % |

187.269 14.03% |

140.5 10.52% |

91.93 6.89% |

Fig. 3. Analysis of the surface of composite material sized 38×34 µm2 at x1500 magnification where the rapid growth of cracks occurs. When collagen is added, the area of micropores decreases and the matrix is strengthening. During the crack propagation collagen particles serve as a barrier on its way: either the crack goes around the particle, and its growth time increases; or collagen particles at the crack tip are deformed, stretched and shred, and the resistance to crack development increases, since its edges are overlapped by “bond bridges” of collagen (Fig. 5).

RESULTS AND DISCUSSION

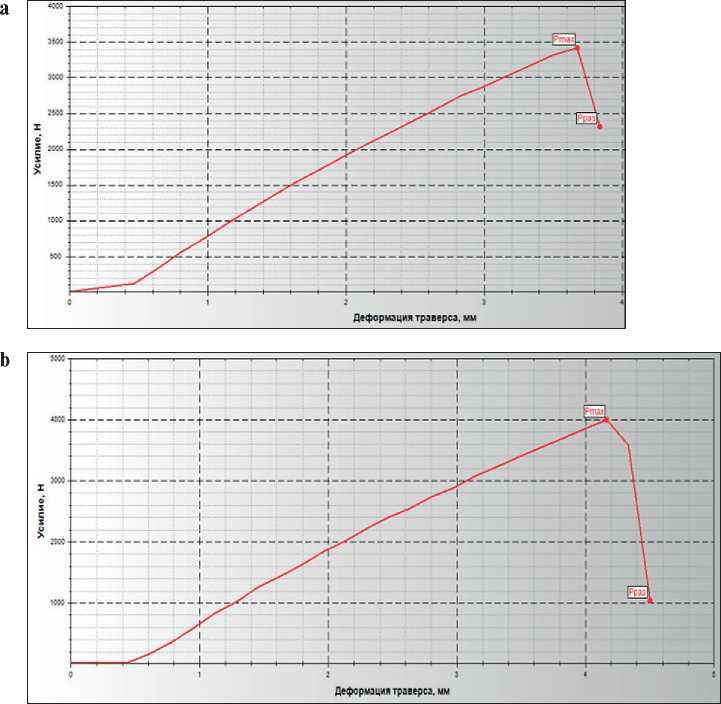

We carried out the tensile testing of the samples of PCM with the addition of 1% and 2% collagen and the angles of lay-up equal to [90]2 according to GOST 56785, (ASTM D3039) “Tensile Test Method for Flat Samples”. 10 samples were made from PCM with a collagen concentration of 1%; 10 samples – with a collagen concentration of 2%, 10 control samples – without bio-additives. Testing was carried out on a hydraulic machine IR5092-5 with a capacity of 0.5 tons (Fig. 6). We photographed the flat samples before and after testing (Fig. 6). The test results are presented in Table 2. Test diagrams of samples with collagen on Figure 7 shows the dependence of the compressive force on grip displacement. With the addition of 1% collagen in PCM, the samples withstand the load (PmaxН) more than the samples without bio-additives by 15.57%.

CREATION OF NEW FUNCTIONAL MATERIALS

Fig. 4. The number of voids of various sizes depending on the percentage of collagen

Fig. 5. The surface of polymer composite matrix: a – crack propagation on the matrix surface (2% collagen content); b – collagen at the crack front

Fig. 6. Samples after tensile tests

CREATION OF NEW FUNCTIONAL MATERIALS

Fig. 7. PCM tensile test diagrams: a – tensile test diagram, when adding 1% collagen to the matrix; b – tensile test diagram, when adding 2% collagen to the matrix

CONCLUSION

A fundamentally new method has been developed for obtaining a bioactive collagen product from solid organic waste of the leather industry at a relatively low price.

It has been established that a bioactive collagen product in a powder form has a low cost and can be used as a bioadditive for PCM. The studies of the PCM samples with the addition of dry collagen powder to the epoxy binder showed that the introduction of bio-additives leads to

Table 2

The results of tensile testing of the PCM samples

|

Названи е |

0% Control sample |

1% |

2% |

|

Pmax,Н |

2900 |

3433.333 |

4066.667 |

|

Pbreak, Н |

1350 |

1950 |

1066.667 |

|

Length of the region at break, mm |

94.206 |

94.184 |

94.635 |

|

Breaking elongation,% |

4.673 |

4.649 |

5.151 |

|

Length of the region at a given tensile stress, mm |

0.653 |

0.579 |

0.686 |

|

Elongation at a given tensile stress, % |

0.726 |

0.643 |

0.762 |

|

Uniform elongation, % |

–32.608 |

–32.690 |

–32.571 |

CREATION OF NEW FUNCTIONAL MATERIALS a change in the strength properties of the material. An analysis of the cut-offs of the samples, carried out on a JSM-6510LVJEOL scanning electron microscope, revealed a change in the PCM structure. When 1% or 2% collagen is added to the PCM matrix, the amount of chemical elements increases: carbon (C) – by 2.93%, oxygen (O) – by 1.61%, magnesium (Mg) – by 0.11%.

In PCM, collagen particles serve as a barrier to propagation of a crack in the matrix by strengthening the initial binder phase. The tensile tests have shown that when 1% collagen is added to the PCM matrix, the bearing capacity of the samples increases by 15.57%. The results obtained can contribute to the expansion of collagen application, waste reduction in the leather industry due to recycling.

Список литературы Collagen based bio-additives in polymer composites

- Chawla K.K. Composite materials science and engineering. Composites. 1989, 20 (3). DOI: 10.1016/0010-4361(89)90346-7.

- Chajes M.J., Thomson T.A., Januszka T.F., and Finch W.W. Flexural strengthening of concrete beams using externally bonded composite materials. Construction and Building Materials. 1994; 8(3): 191–201. DOI: 10.1016/S0950-0618(09)90034-4.

- Kustikova Y.O. Application FRP-rebar in the Manufacture of Reinforced Concrete Structures. Procedia Engineering. 2016; 153: 361–365. DOI: 10.1016/J.PROENG.2016.08.128.

- Tinkov D.V., and Safonov A.A. Design optimization of truss bridge structures of composite materials. Journal of Machinery Manufacture and Reliability. 2017; 46(1): 46–52. DOI: 10.3103/S1052618817010149.

- Fang H., Bai Y., Liu W., Qi Y. and Wang J. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments. Composites Part B: Engineering. 2019; 164: 129–143. DOI: 10.1016/J.COMPOSITESB.2018.11.047.

- Pokrovskii A.M., Chermoshentseva A.S., Bokhoeva L.A. Evaluation of crack resistance of a compressed composite plate with initial delamination. Journal of Machinery Manufacture and Reliability. 2021; 50(5): 446–454.

- Bonnaud L., Pascault J.P., Sautereau H., Zhao J.Q., and Jia D.M. Effect of reinforcing glass fibers on morphology and properties of thermoplastic modified epoxy-aromatic diamine matrix. Polymer Composites. 2004; 25(4). DOI: 10.1002/pc.20030.

- Awang Ngah S., and Taylor A.C. Fracture behaviour of rubber- and silica nanoparticle-toughened glass fibre composites under static and fatigue loading. Composites Part A: Applied Science and Manufacturing. 2018, 109. DOI: 10.1016/j.compositesa.2018.02.028.

- Bokhoeva L.A., Baldanov A.B., Rogov V.E., Chermoshentseva A.S., Ameen T. The effect of the addition of nanopowders on the strength of multilayer composite materials. Industrial laboratory. Diagnostics of materials. 2021; 87(8): 42-50. DOI: https://doi.org/10.26896/1028-6861-2021-87-8-42-50

- Chermoshentseva A.S., Pokrovskiy A.M., Bokhoeva L.A., Baldanov A.B., Rogov V.E. Influence of modification by nanodispersed powders on layered composite aerospace hulls and protective shields. IOP Conference Series: Materials Science and Engineering. Novosibirsk, 2019. P. 012178.

- 11.Abdrakhmanova L.A., Khozin V.G., Nizamov R.K. Nanomodification of epoxy binders. Nanotechnologies in Construction. 2019; 11(6): 686–695. DOI: 10.15828/2075-8545-2019-11-6-686-695.

- Manjunath M., Renukappa N.M., and Suresha B. Influence of micro and nanofillers on mechanical properties of pultruded unidirectional glass fiber reinforced epoxy composite systems. Journal of Composite Materials. 2016; 50(8). DOI: 10.1177/0021998315588623.

- Sprenger S. Improving mechanical properties of fiber-reinforced composites based on epoxy resins containing industrial surface-modified silica nanoparticles: Review and outlook. Journal of Composite Materials. 2015; 49(1): 53–63. DOI: 10.1177/0021998313514260.

- Uddin M. F., and Sun C. T. Strength of unidirectional glass/epoxy composite with silica nanoparticle-enhanced matrix. Composites Science and Technology. 2008; 68(7–8). DOI: 10.1016/j.compscitech.2008.02.026.

- Vaganova T.A., Brusentseva T.A., Filippov A.A., and Malykhin E.V. Synthesis and characterization of epoxyanhydride polymers modified by polyfluoroaromaticoligoimides. Journal of Polymer Research. 2014; 21(11). DOI: 10.1007/s10965-014-0588-z.

- Sprenger S. Improving mechanical properties of fiber-reinforced composites based on epoxy resins containing industrial surface-modified silica nanoparticles: Review and outlook. Journal of Composite Materials. 2015; 49(1). DOI: 10.1177/0021998313514260.

- Metal oxides account for 80% of the nanopowder market. Available at: http://www.abercade.ru/research/analysis/3974.html. [Accessed 01 December 2010].

- Lotfi A., Li H., Dao D.V., Prusty G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. Journal of Thermoplastic Composite Materials. 2021; 34(2). DOI: 10.1177/0892705719844546.

- Zhao X. et al. Applications of Biocompatible Scaffold Materials in Stem Cell-Based Cartilage Tissue Engineering. Frontiers in Bioengineering and Biotechnology. 2021; 9. DOI: 10.3389/fbioe.2021.603444.

- Silvipriya K.S., Krishna Kumar K., Bhat A.R., Dinesh Kumar B., John A., Lakshmanan P. Collagen: Animal sources and biomedical application. Journal of Applied Pharmaceutical Science. 2015; 5(3). DOI: 10.7324/JAPS.2015.50322.

- Trempe J.P. Molecular biology of the cell. 3rd edition. Trends in Endocrinology & Metabolism. 1995; 6(9–10). DOI: 10.1016/1043-2760(95)90011-x.

- Minihan S. Principles of biochemistry. Biochemical Education. 1983; 11(1). DOI: 10.1016/0307-4412(83)90020-1.

- Shalbuev D.V., Tumurova T.B. A method for obtaining a bioactive collagen product. Patent RF 2715639. Mar. 02, 2020.

- Anfimov P.E., Krasnova N.S. Method for obtaining collagen from biological material. Patent RF 2322249. Apr. 20, 2008.