Colored grapes byproducts as the source for bio-active products

Автор: Gvinianidze T.N., Gvinianidze T.T., Chikovani P.M., Mindeli V.A., Djabnidze R.H.

Журнал: Juvenis scientia @jscientia

Рубрика: Технические науки

Статья в выпуске: 8, 2017 года.

Бесплатный доступ

The paper discusses grape peel as the source of biologically active materials and its canning methods. The research results confirmed that grape peel granules are characterized with great bacteriological stability and that the amount of phenolic complexes in it remains practically unchanged compared to the initial capacity. The technology of grape peel canning presented below is economically feasible and easy to realize. Granulated grape peel contains richest resources of biologically active substances for the food and pharmaceutical industry.

Drying, phenols, anthocyans, antioxidant activity, granules, grapes

Короткий адрес: https://sciup.org/14110313

IDR: 14110313 | УДК: 66.664

Текст научной статьи Colored grapes byproducts as the source for bio-active products

Финансирование: Работа выполнена при финансовой поддержке Национального научного фонда Шота Руставели [Грант N216752, разработка инновационной технологии сильного антиоксидантного полифенольного концентрата]

Owing to its unique chemical composition grape is traditional leader of the autotrophic organisms. It is rich in sugars (mainly in glucose and fructose), ferments, vitamins, and micro and macro elements, organic acids, nitrogenic compounds, phenolic substances and other important biologically active compounds, which are necessary for human body. In this context species of colored grapes, commonly spread in Racha-Lechkhumi and Imereti regions of Georgia are particularly remarkable. These breeds contain increased amount of antibiotic aromatic compounds. In addition, pectin substances of the grape skin bind up the radio-active metals in the form of insoluble salts and drive them out of the human body. Biologically active peel and seed extracts together with thermally processed concentrated juice has been widely applied as preventive means against anemia and nervous disorder. Grape peel and seed are rich in flavonoids, whose antioxidant, anti-radiant, and bactericidal properties has long been a subject of scientific interests.

After pressing grape it leaves marc, recyclable solid waste, about 15-27 % of the initial mass which with its chemical composition and bio-activity is no less valuable than the wine proper and other grape products [1, p. 57]. 60-70% of grape bunch phenolic compounds are found in the seed and 28-35% in the peel. Correspondingly, grape waste presents richest source of biologically active compounds. In this context peel and seed of colored grapes are of particular interests in as much as their biologically active substances composition is excellent raw material for the production of strong antioxidant polyphenol concentrates [2, p.82].

The object of study was peel of non-industrial and industrial colored grape species, cultivated in Imereti region, as rich in anthocyans a recyclable raw material.

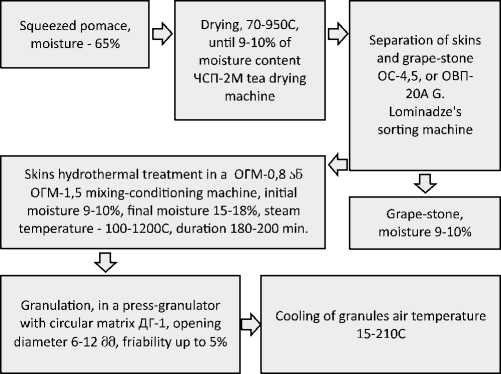

We have studied pomace of grapes (peel and seed), of Jvarisuli and Zeimberi ( Zeibeli 5455), 2016 yield, unsprayed with pesticides, cultivated in Imereti winery industry micro-zone, left after European method of grape processing. Technological scheme of sequence of processing is given below, see Fig. 1.

Extracts of peel and seed rich in polyphenols are widely applied in the production of food additives and concentrates as health-benefit and prevention [3, p.28].

The amount of anthocyan glucosides in grape peel and in produced from it granules was determined by high pressure liquid chromatographing method [Waters (UV/Visible Detector 2489, Binary HPLC Pump 1525), chromatographic column Symmetry C18, 3,5 µm 4,6×75 mm, detecting through 510 and 524 nm].

According to the content of sugar and alcohol grape waste product can be divided into two groups: non-vinified and vinified.

Fig.1. Technological scheme of storage of grape skins and stone

There are number of schemes of complex processing of these waste products. Only 20-30 % of product is subjected to immediate seasonal treatment and the rest of the mass can be processed after 120-180 days from the end of the season, which causes significant loss of biologically active compounds: namely, 20-45% of alcohol, 15-30% of sour salts etc. is lost [4, p.46]. In addition, processing of vinified waste compared to non-vinified costs 5-28% more and the expenses are mainly related to the drying and preservation modes and the time. Consequently, it is advisable to treat these recyclable resources with the method that grants maximum preservation of the biologically active compounds in the target product [5, p. 258].

Separated from stem pressed marc contains 65% of humidity and prior to canning / preservation it needs drying to the condition of 8-10%- humidity. In order to receive one ton peel 3 -5 ton of water should be evaporated [6, p.69]. High temperature drying is a costly process demanding 80% of the peel preservation-storage expanses. After drying we separate seeds from peels [7, p.65].

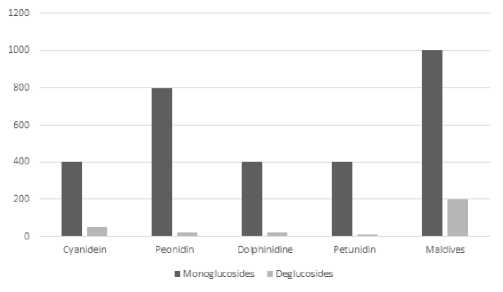

Fig.2. Content of anthocyanins in industrial grape varieties (mg/kg)

The analysis of the experiment revealed that expanses during marc drying, for the evaporation of one ton humidity is 2-3 times cheaper, if performed in the tea-drying machine ЧСП-2М – than the traditional drying method applied in the winery industry [8, p.15].

Grape peel hygroscopicity as of the complex chemical compound is significantly related to the particle surfaces are contained in pomace; humidity is adsorbed from the surface of these particles from the hydrophilic parts [9, p.258].

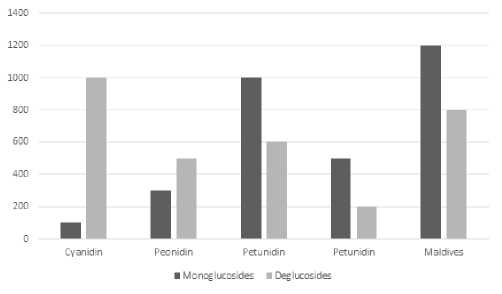

Humidity is adsorbed from the hydrophilic parts of the surface of the particles in the form of vapor and hydrophobic parts do not participate in the process [10, p.42]. As a result the crumbling of the desiccated peel augments hydrophilic properties of the particles which are negatively reflected on its technological data in the preservation process. For this reason the use of crumbled peel for feed is not recommended. The content of anthocyans in the Georgian vine, both in the local and introduced breeds fluctuates within the following bounds (see Fig. 2 and 3)[4].

Fig.3. Content of anthocyanins in clones and hybrids (mg/kg)

In general one of the methods of grape peel hydrophobiasation is granulation, which causes liquidation of active functional groups and improves the material preservation stability. Jvarisula and Zeimberi grape skin physical, chemical and bacteriological analysis results in the place where relative humidity measured 72-73 %, up to three month and after three month period is given in the Table 1. It was asserted that the aggregated bacteria quantity increases in both, dumped and granulated conditions. However, the active growth of bacteria quantity and fungus spores is higher in the dumped dried peel than in granulated one [11, p.83].

Hence, granulated grape peel is characterized with greater bacteriological stability than the stem removed and seedless dried marc preserved in the dumped condition [12, p.93].

Phenol compound quantity compared to the initial condition is almost unchanged.

Anthocyans in grapes are represented in the form of glucosides and are mainly located in the skin which develops complex essential (ethereal) bonds with sugars, particularly with glucose ruthinosas and sophorosas [6] and in cultural – industrial breeds it is mainly represented with malvidin monoglucose (30%), and in unsprayed colored clones and hybrids diglucoside forms prevail as is shown in pictures 2 and 3. Unsprayed clone grape skin is singled out as with summary, so the diglucoside form abundance. Many of winemaker farmers engaged in their own vineyards in Georgia do not give due respect to the astringent taste caused by the excess phenolic nature compounds as the wine produced in October is already consumed before February and by this time even the few parts of the phenolic compound are not matured oxidized and transferred into chinons.

Table 1

Results of physical, chemical and bacteorological analyses of Zeimberi grape peel

|

Peel content |

Crumbled condition |

Granulated condition |

|

Water soluble substances, Absolute dried substances, % |

20,2/17,4 |

19,6/19,0 |

|

Sugar, absolute dried substances, % |

12,9/10,4 |

12,8/11,2 |

|

Nitrogen compound on proteins, absolute dried substances, % |

12,0/9,8 |

12,0/11,2 |

|

Phenolic compounds g/kg |

2,0-7,0/1,8-6,3 |

2,0-7,0/1,9-6,7 |

|

Microorganisms in per 1 gr. product, one thousand bacteria |

400/2400 |

350/1200 |

|

Fungi one thousand unit |

3,0/11,8 |

2,8/4,8 |

|

humidity, % |

8,3/10,2 |

8,4/9,2 |

Note: numerator (before preservation)/denominator (after threemonth preservation).

Needless to speak about the importance of the proper conducting of maderization processes, which are practiced in the wine-producing European Countries.

Georgian scientists pioneered suggesting experimentally confirmed idea that quantitative content of anthocyans’ diglucoside forms cannot be considered as the grape genesis taxonomy sign [6, 7]. Among the multitude of examples to such conclusion we can quote Zeibel 5455 hybrid which does not contain anthocyan diglucoside forms.

Dried grape seed, together with the peel is a premium raw material for the production of biologically active food additives and medicines. The analysis of the work carried out by our team shows that implementing scientific and practical projects for the further study of the issue is actual and important.

CONCLUSIONS

-

1. The research has confirmed that cultivated clones and hybrid colored grape peel and seed is a rich source of the biologically active compound and the preservation method suggested by our team is cost-effective and easy to realize.

-

2. Granulated grape peel and seed present the richest source for the production of food additives and of the strong antioxidant polyphenolic concentrates.

-

3. It has been determined that long term preservation (9-12 months) has negligible effect on the change of phenolic compounds.

REFERENSES

-

1. Khvedelidze V.G., Gordeladze T.G., Gvinianidze T.N. Production of granulated tea enriched with sweet extracts // Food Industry. 1989 . № 11. Pp.56-59. (In Russian).

-

2. Nilov V.I., Skurikhin I.M. Chemistry of winemaking . PP, Moscow. 1967 . (In Russian).

-

3. Kishkovsky E.N., Skurikhin I.M Chemistry of wine , Food industry. Moscow. 1976 . (In Russian).

-

4. Gvinianidze T.N., Arzumanian A.N., Mamrikishvili L.G., Gvinianidze T.T. Storage of Wine-Making Secondary Resources as the Richest Source of Biologically Active Substances – Proccedings of National Polytechnic University of Armenia. Yerevan 2015 . Pp.40-47. (In Russian).

-

5. Gvinianidze T.N., Mamrikishvili L.M., Gvinianidze T.T. Study of phenolic compounds Georgian variety grape-stone and developing technology of food additive with radioprotective activity . Proceedings of I International Scientific Conference “Climate Change and its Impact on Sustainable and Safe Development of Rural Economy”. Academy of Agricultural Sciences of Georgia. 2014 . Pp.257-260. (in Georgian).

-

6. Kennedy J.A., Matthews M.A., Waterhouse A.L. Effect of Maturity and Vine Water Status on Grape Skin and Wine Flavonoids . Am. J. Enol. Vitic. 53 Pp.68-74.

-

7. Durmishidze S.V., Sopromadze A.N. Communications of the AN of the GSSR . 64, 3, 691. Tbilisi. 1971 . (In Russian).

-

8. Gelashvili N., Dzhmukhadze K. Methods for the determination of catechins of grapes-Zh, Winemaking and viticulture of the USSR . M. 1981 . p. 21. (In Russian).

-

9. Gvinianidze T. Liquid preparations technology sector catechins (Studies) . L&L Publishing. Titusville, FL, USA. 2012 . p. 41-44.

-

10. Gvinianize T., Mamrikisvili L., Fhutkaradze Z. Production of Liquer EcoWines with a High Terapeutic and Sensory Potential // BULLETIN of Akaki Tsereteli State University. 2014. No. 2(4). Pp. 83-93.

-

11. Gabidzashvili M.A., Gvinianidze T.T., Chokhonelidze V.A. The results of studying hydrophilic compounds of Saperavi variety grapestone . Proceedings of I International Scientific-Practical Conference. Stavropol, 2014 , pp. 91-93. (In Russian).

Список литературы Colored grapes byproducts as the source for bio-active products

- Khvedelidze V.G., Gordeladze T.G., Gvinianidze T.N. Production of granulated tea enriched with sweet extracts//Food Industry. 1989. № 11. Pp.56-59..

- Nilov V.I., Skurikhin I.M. Chemistry of winemaking. PP, Moscow. 1967..

- Kishkovsky E.N., Skurikhin I.M Chemistry of wine, Food industry. Moscow. 1976..

- Gvinianidze T.N., Arzumanian A.N., Mamrikishvili L.G., Gvinianidze T.T. Storage of Wine-Making Secondary Resources as the Richest Source of Biologically Active Substances -Proccedings of National Polytechnic University of Armenia. Yerevan 2015. Pp.40-47..

- Gvinianidze T.N., Mamrikishvili L.M., Gvinianidze T.T. Study of phenolic compounds Georgian variety grape-stone and developing technology of food additive with radioprotective activity. Proceedings of I International Scientific Conference "Climate Change and its Impact on Sustainable and Safe Development of Rural Economy". Academy of Agricultural Sciences of Georgia. 2014. Pp.257-260. (in Georgian).

- Kennedy J.A., Matthews M.A., Waterhouse A.L. Effect of Maturity and Vine Water Status on Grape Skin and Wine Flavonoids. Am. J. Enol. Vitic. 53 Pp.68-74.

- Durmishidze S.V., Sopromadze A.N. Communications of the AN of the GSSR. 64, 3, 691. Tbilisi. 1971..

- Gelashvili N., Dzhmukhadze K. Methods for the determination of catechins of grapes-Zh, Winemaking and viticulture of the USSR. M. 1981. p. 21..

- Gvinianidze T. Liquid preparations technology sector catechins (Studies). L&L Publishing. Titusville, FL, USA. 2012. p. 41-44.

- Gvinianize T., Mamrikisvili L., Fhutkaradze Z. Production of Liquer Eco-Wines with a High Terapeutic and Sensory Potential//BULLETIN of Akaki Tsereteli State University. 2014. No. 2(4). Pp. 83-93.

- Gabidzashvili M.A., Gvinianidze T.T., Chokhonelidze V.A. The results of studying hydrophilic compounds of Saperavi variety grape-stone. Proceedings of I International Scientific-Practical Conference. Stavropol, 2014, pp. 91-93..