Complementary improvement of technological characteristics of asphalt concrete road surfaces using macromolecular nanocomposites

Автор: Anton O. Glazachev, Olga V. Ivanova, Dmitry A. Sinitsin, Ranis M. Akhmetshin

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 5 Vol.15, 2023 года.

Бесплатный доступ

Introduction. The issue of enhancing the long-term performance of asphalt concrete pavement on highways is not entirely addressed by conventional solutions, such as improving the choice of material composition and refining the production process for bitumen binders and mineral filler compounds. One of the most promising ways to improve the performance and durability of asphalt concrete is the complementary modification of bitumen and road-concrete nanocompositions with thermoplastic and elastic polymers. Methods and materials. Bitumen binders are assessed employing suitable methodologies to determine the following technological parameters: extensibility, softening temperature, brittleness, elasticity, and so forth. Asphaltenes of bitumen binders are the most important structure-forming component and form associated nanoclusters with sizes of 15–200 nm. Thermoplastic block copolymers are introduced into the composition of bitumen binders in granular form (chips) or melted form. Additionally, compatibilizers are used to improve the compatibility of complementary copolymers in bitumen binders. The quality of the finished asphalt concrete composition is significantly affected by the characteristics of the main components: mineral powder, sand, crushed stone, bitumen binder and macromolecular nano-additives, as well as by optimal process modes: mixing temperature, etc. Results. The complementary interaction of supramolecular associations of asphaltenes and fragments of macromolecules of polymer nanocomposites ensures the formation of Van der Waals bonds due to spatial mutual correspondence. The introduction of polymer nanomodifiers leads to an increase in the softening temperature and a decrease in the brittleness temperature of bitumen binders due to the formation of sufficiently stable supramolecular complexes. Discussion. Synergistic nanoadditives of complementary macromolecules into the bitumen binder provides a fewfold increase in the adhesion of the bitumen composition and the mineral components, as well as a noticeable increase of the temperature range for plasticity and deformability. Asphalt concrete coatings with polymer-bitumen binders increase the operability of the roadway and resistance to the formation of plastic flow deformations (shifts, ruts) at high and low temperatures. Conclusion. Bitumen binders of asphalt road concrete, which have been modified with polymer nanocomposites, have higher adhesion, an extended range of thermoplasticity and water resistance.

Asphalt concrete coating, polymer nanocomposite, complementary interaction, quality management, polymer-bitumen binder, nanostructural modifier

Короткий адрес: https://sciup.org/142238325

IDR: 142238325 | DOI: 10.15828/2075-8545-2023-15-5-453-464

Текст научной статьи Complementary improvement of technological characteristics of asphalt concrete road surfaces using macromolecular nanocomposites

Original article

An increase in the intensity and load of automobile traffic on the main highways of Russia and Bashkortostan leads to rapid deformative destruction of asphalt concrete pavements. One of the significant reasons for the premature destruction of the upper layers of asphalt concrete road surfaces with sharp temperature fluctuations is the formation of microcracks with subsequent erosive peeling and the increasing formation of defects (potholes with a depth of more than 3 cm, etc.) [1–4]. A decrease in the water and frost resistance of asphalt concrete and, as a result, a reduction in the operating time is also due to a lessening in the adhesion of bitumen binders to the surface of mineral aggregates. The elaboration of new technological solutions for the multi-tonnage production

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION of bitumen nano-binding materials and the increase in their operational life are an urgent direction of the implementation of the national project “Safe and high-quality roads” of the Russian Federation.

To increase the service life of asphalt concrete road coverings, bitumen composite binders have been improvement, among which polymer-bitumen compositions should be especially distinguished [5, 6]. Asphalt concrete mixtures with polymer-bitumen binders increase the performance of roadway coatings and resistance to the formation of plastic deformations (shifts, ruts) at high and low temperatures. The optimal choice of asphalt concrete composition and the ability to effectively resist real operational loads without breaking the continuity of the coating depend on the category of the highway and the climatic conditions of the region.

The purpose of this article is to study the use of polymer nanocomposites for technologically enhancing the parameters of the operational resistance of asphalt concrete road surfaces.

METHODS AND MATERIALS

Asphalt concrete is an optimally selected and mixed in a heated state mixture of mineral materials and bitumen – road surfaces is classified according to a certain list of technological parameters, each of which affects the physical and mechanical characteristics, functional condition and durability [7]. Asphalt concrete road surfaces are divided according to the following main parameters: type of aggregate (multicomponent composition); temperature of manufacture and laying; porosity; brand, etc.

Petroleum bitumen is the most widely used binder in road construction, as it prevails over analogues in terms of availability, cost, and efficiency. The technological durability of bitumen binders in asphalt concrete is directly related to the nanodisperse microstructure, due to the quantitative ratio of the main components: oils (aromatic, naphthenic and paraffin hydrocarbons with a molar mass of ≈ 500–1500 g/mol), oligomeric resins and macrocyclic asphaltenes [8–10]. The chemical composition and ratio of oils, resins and asphaltenes in road bitumen varies quite a lot depending on the initial petroleum raw materials and the technology of vacuum oxidative processing of tar at petroleum refinery.

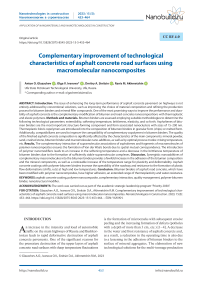

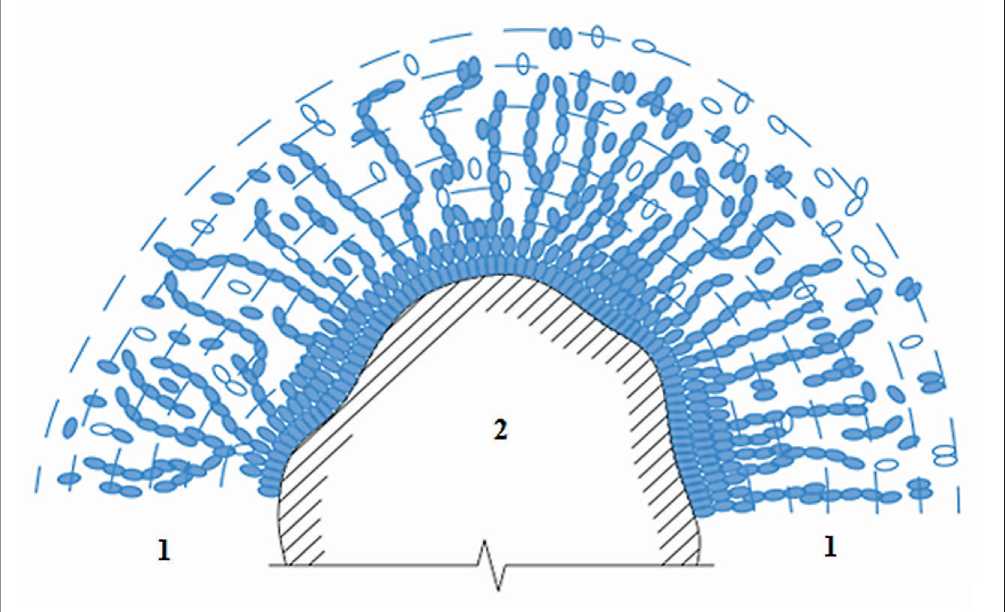

At temperatures of 120°C and above, asphaltenes are in a molecular dispersion state, and at lower temperatures they form associated supramolecular complexes (Fig. 1). Bituminous asphaltenes have an increased tendency to association due to intermolecular stacking π-π interactions and the formation of supramolecular liquid crystal nanostructures: aggregate fractal nanoclusters with sizes of 15–200 nm [11].

Asphaltenes of bitumen nano-binders due to their susceptibility to supramolecular complementary associations are the most important structure-forming component of asphalt concrete. Heterocyclic bitumen asphaltenes form supramolecular fractal nanostructures, which are a disc-

Fig. 1. Scheme of formation of associated complementary supramolecular complexes of bitumen asphaltenes: 1 – asphaltene; 2 – nanoaggregate cluster

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION shaped non-planar stack of polycyclic macromolecules with an interplane distance of ≈ 0.4 nm [12–15].

In building materials science, it is traditionally believed that the nanostructure of bitumen materials is a colloidal system in which fractal asphaltenes are dispersed, and the dispersion medium is oligomeric resins and hydrocarbon oils. Supramolecular bitumen asphaltenes are dispersed in the form of microparticles ranging in size from 18 to 20 microns, which are surrounded by molecular shells of heavy resins and oils with decreasing density.

Asphalt concrete road covering is a compacted composite material made by mixing mineral components (sand, crushed stone) of optimal dimensions, aggregated with bitumen (no more than 10–15% by mass). With an optimal ratio of bitumen and aggregates, the bitumen binder – complementary matrix is in an adsorbed state on the rough surface of the particles of finely ground mineral powders. Weak adhesion of bitumen binders to the surface of mineral fillers leads to premature destruction of asphalt concrete road covering.

The mineral frame of asphalt concrete forms a mixture of mineral powder (a material obtained by grinding carbonate – limestones and dolomites or non-carbonate rocks, or from solid industrial waste), sand and crushed stone with an appropriate granulometric composition according to GOST 32761-2014 “Public roads. Mineral powder. Technical requirements” and GOST 33029-2014 “Public roads. Crushed stone and gravel from rocks. Determination of granulometric composition”.

The basic requirements for mineral powder are normalized according to the following indicators: grain composition (smaller than 2 mm; 0.125 mm and 0.063 mm), porosity, etc. The grain (granulometric) composition of the mineral part of asphalt-concrete crushed stone-mastic mixtures is determined on sieves with nominal cell sizes: 0.063; 0.125; 0.25; 0.5; 1.0; 2.0; 4.0; 5.6; 8.0; 11.2; 16.0; 22.4; 31.5 mm. Mineral powder is made most often in the production of activated (with additives of surfactants) to enhance the complementary effect; activated mineral powders are predominantly hydrophobic. One of the methods of activation of mineral powders during technological grinding is the physico-chemical treatment of their surface, carried out by anion-active surfactants from fat processing waste [16].

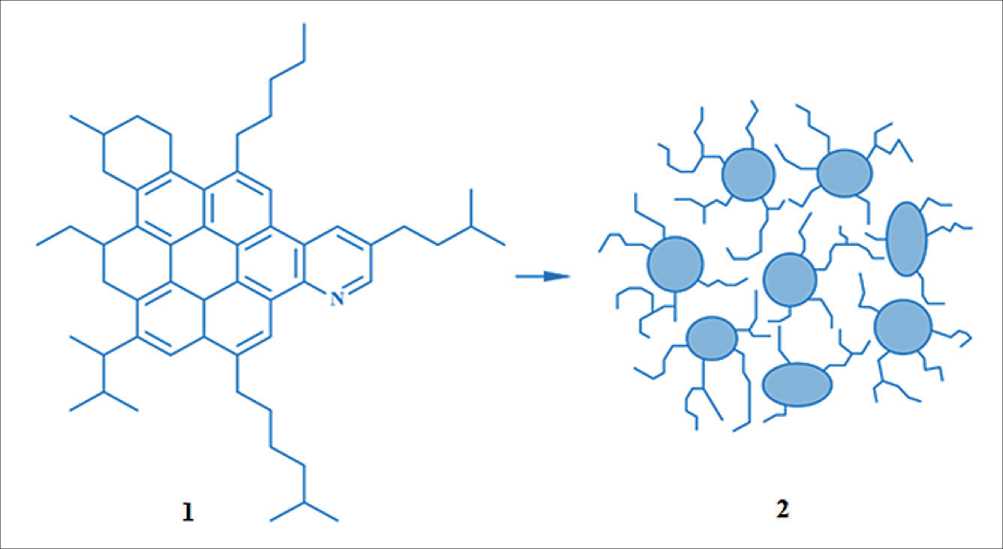

The calculation of the optimal ratio of mineral components: crushed stone (gravel), sand, mineral powder should provide the established grain content of large and small fractions in the total composition of aggregates, which ensures durability (at the same time strength, efficiency) of the road surface. The structure of the granulometric (grain) part is limited by the limiting curves (Fig. 2) of the permissible amount of the projected grain fraction; as a result, the performance indicators of the main characteristics of asphalt concrete of the corresponding brand will meet technical standards.

Asphalt concrete mixtures, depending on the filler, are divided into crushed stone, gravel, sand; by density – into high-density (residual porosity from 1.0% to 2.5%), dense (residual porosity over 2.5% to 5.0%), porous, highly porous. The main component of fine-grained asphalt concrete for the device of the upper layer of the road surface is crushed stone with a fraction of up to 20 mm. Crushed stone (gravel) dense asphalt concrete, depending on the content of crushed stone (gravel) in them, are divided into several types, for example, type B (crushed stone content from 40% to 50%). For mixtures of type B, the content of crushed stone grains of plate and needle shape should be no more than 25% by weight.

In accordance with GOST R 58406.1-2020 “Public roads. Mixtures of crushed stone-mastic asphalt concrete and asphalt concrete. Technical conditions” requirements for asphalt concrete are presented according to indicators characterizing the parameters of the structure (residual porosity, porosity of the mineral part, water saturation), physical and mechanical properties in terms of strength parameters (compression at temperatures of 20оC and 50оC and tensile strength when split at a temperature of 0оC) and shear stability (coefficient of internal friction and coupling during shear deformation).

Tests of asphalt concrete road covering include a number of methods that control the technological properties of bitumen-mineral compositions. The physical and mechanical characteristics of bitumen binders are evaluated using the following indicators: extensibility, softening temperature and brittleness, elasticity, as they determine most of the technological parameters of asphalt road concrete. The study of the rheological properties of bitumen (in particular, the dynamic viscosity at 60оC) with polymer nanoadditives allows us to evaluate their effect on the structure of the asphalt concrete mixture, choose the optimal combination and dosage, obtain asphalt concrete mixtures with the required characteristics: resistance of asphalt concrete road surfaces to rutting, increased compaction at low temperatures.

To expand the range of plasticity and temperature range of the use of bitumen binders, enhance adhesion and roughness in asphalt concrete, their modification is used, which consists in the introduction of various nanoadditives. Block copolymer styrene-butadiene-styrene, atactic polypropylene, isotactic polypropylene, etc. can be used as macromolecular improvers of technological characteristics of asphalt concrete road covering [17–20].

The operative addition of modifying polymer nanocomposites to the composition of bitumen compositions is an effective method of complementary improvement of the physical and mechanical characteristics of bitumen and increasing the durability of road surfaces. Complementary (mutually corresponding) interaction of fragments of macromolecules of polymer nanocomposites and supramolecular associations of asphaltenes ensures

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 2. Design of the granulometric composition of the mineral components of the upper layer of the road surface based on the limit curves of fine-grained asphalt concrete

the formation of Van der Waals bonds due to spatial mutual arrangement.

The scheme of the method of preparation of bitumen modified nano-binder: petroleum road bitumen (PRB) of the 70/100 brand was heated to 170–180оC while stirring in hydrodynamic mixers at a speed of 140–150 rota-tions/min. Next, a styrene-butadiene copolymer of 4% (by weight) was added; then the speed was increased to 700–800 rotations/min and mixed for 50–60 minutes until a homogeneous polymer-bitumen nanocomposition was obtained. The elasticity index of macromolecular-bitumen nanocompositions was determined using a ductilometer by finding the extensibility of a modified nano-binder at a temperature of +25оC and 0оC; elasticity at +25оC characterizes the technological characteristics of a three-dimensional nanoset, and at 0оC performance at low temperatures.

As macromolecular nanocomposites, often used to improve the frost resistance of thermoelastic characteristics of bitumen, it should be noted the use of complemen-tarily compatible styrene-butadiene rubber copolymers of a dendrimer branched structure [21]. Elastic butadiene and rigid styrene blocks can polymerize in the form of various copolymers, and rigid polystyrene domains with dimensions of 350–700 nm perform the function of vulcanization nanoset nodes in the macromolecule and enhance the synergistic effect.

Styrene-butadiene nanocomposite copolymers with a molar mass of ≈105 combine well enough with bitumen road binders due to the swelling of bitumen binder in naphthenic aromatic hydrocarbons and partial dissolution at a temperature of 175оC [22]. Thermoplastic block copolymers are introduced into the composition of bitumen binders in granular form (crumbs) or melt, and plasticizers are used to improve the compatibility of modifying copolymers and bitumen binders: industrial oils, oil tar, interfacial compatibilizers, etc. Optimal selection of the group chemical composition of compounded road bitumen ensures the formation of a nanodisperse structure of bitumen of the “sol-gel” type [23].

During the preparation of asphalt concrete improved with polymer nanomodifiers, the technological process is constantly monitored and samples of asphalt concrete coatings are tested. Effective digital control of parameters in the automated control system for the production of asphalt concrete mixture [24] allows us to develop the

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION optimal possibility for the operation of the technological line. The characteristics of the main components: sand, crushed stone, mineral powder, complementary bitumen binder and macromolecular nano-additives, as well as the parameters of the technological process are taken into account as criteria for managing the quality of the finished asphalt concrete mixture. Various types of asphalt concrete for the creation of road surfaces differ in the composition of complementary raw materials, manufacturing technology and physical and mechanical characteristics.

Vectors of complementary improvement of road asphalt concrete compositions with various additives are aimed at providing self-healing of microcracks of the pavement, self-cleaning of winter snow and ice deposits [25]. Temperature stability is characterized by the ability of asphalt concrete to withstand temperature changes: thermoplastic asphalt concrete transforms thermomechanical properties more smoothly from plastic (at high temperatures) to brittle (at low temperatures) and stability to shear deformations and cracking.

The most easily reproducible indicators of temperature stability are the values of the compressive strength of asphalt concrete at temperatures of +50оC, +20оC and 0оC. In accordance with the requirements of GOST 9128-2009 “Mixtures of asphalt road, airfield and asphalt concrete. Technical conditions” the minimum value of this indicator at +50оС not less than 0.9 MPa (characterizes the ability of asphalt concrete to withstand shear deformations), and the maximum is not more than 12 MPa at 0оC.

The bitumen binder is tested for adhesion to the surface of crushed stone – a complementary mineral component, with the adhesion of the bitumen binder below four points, an adhesive thermostable additive in the amount of 0.3–0.5% is additionally used. Granulated or nongranulated cellulose fiber is used as stabilizing nanoadditives and modifiers of crushed stone-mastic asphalt concrete.

RESULTS

The complementary supramolecular spatial grid formed in bitumen with the participation of styrene-bu-tadiene nanocomposite copolymers gives sufficiently high strength, heat resistance and the ability to highly elastic deformations [26] to asphalt concrete road surfaces in the temperature range from –80оC to +90оC; this is especially noticeable in conditions of increasing traffic intensity of heavy-duty vehicles. It should be noted that for the production of modified polymer-bitumen binders, it is necessary to increase the adhesion characteristics to the surface of complementary mineral fillers. High adhesion rates indicate the ability of modified bitumen to remain on the surface of filling materials under the destructive effect of water molecules on them.

In the dispersion medium of bitumen binders, macromolecular nanomodifiers form a three-dimensional nanoset and significantly dramatically increase elasticity, which characterizes the ability of the binder to reversible, elastic deformations; also, at the same time, the brittleness temperature decreases and the softening temperature increases. Road bitumen must have the necessary adhesion to the surface of fillers to ensure the required coefficient of long-term water resistance and long-term operation of asphalt concrete pavement without erosion [27]. The activation of the mineral powder of the asphalt concrete mixture affects the complementary factors of the structure formation of the road composition. When the bitumen binder is mixed with microparticles of mineral powder, fractal chemisorption of asphaltene nanoclusters occurs on the rough surface of the mineral component under the action of complementary intermolecular interactions.

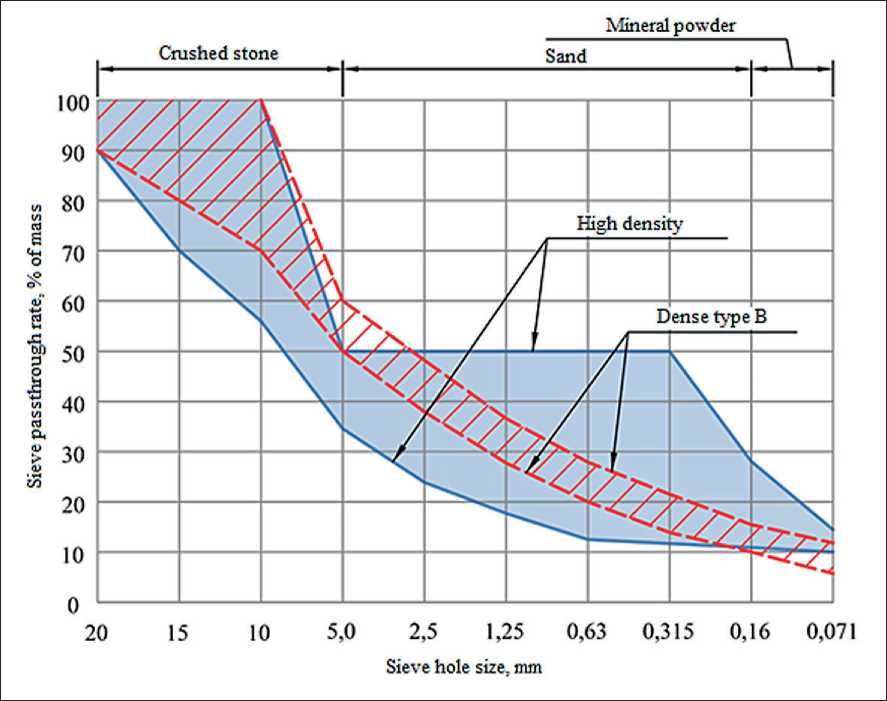

Complementary, spatially complementary macromolecules containing functional groups due to Van der Waals, hydrogen, hydrophobic, ion-dipole and electrostatic interactions leads to the emergence of a sufficiently large number of intermolecular bonds that determine the dynamism of supramolecular structure formation [28] of asphalt concrete coatings. For the technological production of the required bitumen-polymer nano-binder, 3–5% styrene-butadiene nanocomposite, 0.5–1% adhesive nano-additive – interfacial compatibilizer and 4–5% plasticizing component are introduced into bitumen (Fig. 3).

The crack resistance of asphalt concrete roadway significantly depends on the ability of bitumen nanobinders to be operated in the zone of reversible deformations. The most dominant factor in the appearance and growth of microcracks in the asphalt concrete coating under the combined action of mechanical loads, temperature fluctuations and aggressive media is the diffusion of destructive agents into the contact zone between the mineral filler and the film of the bitumen nanobinder.

As a result of the complementary modification of petroleum road bitumen by macromolecules, asphalt polymer concretes capable of resisting rutting, fatigue failure, crack resistance and thermal oxidation are produced. It should also be noted that glass fibers, polymer fibers and modified divinyl-styrene thermoplastics of tree-like structure are used as fillers to ensure increased resistance to shear and cracking of asphalt concrete coatings [29]. Adhesive polymer additives facilitate the formation of strong complementary bonds between bitumen binder and mechano-activated mineral fillers, reduce erosive peeling and enhance waterproofing characteristics.

The main disadvantages of bitumen are atmospheric thermooxidative aging and, more importantly, low deformation stability in the operating temperature range: glass formation and embrittlement in the autumn-winter period and flow (melting, rutting, etc.) in the summer season. The physico-chemical reasons for the technologi-

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 3. Microstructure diagram of bitumen binders modified with styrene-butadiene copolymers: 1 – bitumen nanoaggregate cluster; 2 – macromolecule of styrene-butadiene copolymer; 3 – polymer-bitumen nano-binder

cal defects of asphalt concrete coatings are the dispersed structure of bitumen: the practical absence of macromolecular compounds: asphaltenes are polycyclic solid products, and maltenes (resins and oils) are oligomers with a molecular weight of more than 2500–3000, which only predetermine the viscous deformations of bitumen nanobinders in a narrow temperature range. Widely used bitumen modifiers – butadiene-styrene block copolymers when introduced into a bitumen binder [30] do not completely solve the problem of its susceptibility to atmospheric aging due to the large number of double bonds in the macromolecule; a common disadvantage of such compositions is their delamination under the action of different densities of bitumen and polymers.

The initial petroleum bitumen of the PRB 60/90 brand does not fully meet the requirements of GOST: needle penetration depth (penetration), 0.1 mm (at 25оC) – 61 (requirement 61–90); softening temperature along the ring and ball, оC – 43 (requirement not lower than 47); extensibility, cm (at 25оC) – 124 (requirement at least 55); brittleness temperature, оC – minus 17 (the requirement is not higher than minus 15). Bitumen of the PRB 60/90 brand was modified by adding 1% crushed PET and 0.4% complementary nanoadditive, which made it possible to obtain a high-quality analogue of the PRB 130/200 brand that meets regulatory requirements: needle penetration depth, 0.1 mm (at 25оC) – 152 (when required. 131-200); softening temperature for the ring and ball, оC – 41.2 (when required. not lower than 40); extensibility, cm (at 25оC) – 94.7 (when required. at least 70); brittleness temperature, оC – minus 28 (if required. not higher than minus 18).

Another promising approach to complementary improvement of macromolecular nanocomposites technological characteristics of asphalt concrete road surfaces is the modification of bitumen with reactive additives: such modifiers can be introduced in smaller quantities, and the resulting compositions do not delaminate. For example, “Elvaloy” (produced by Du Pont) is a thermosetting copolymer of ethylene with butylacrylate and difunctional glycidyl methacrylate. As a result of the modifying use of “Elvaloy”, a physicochemical reaction occurs between

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION the epoxy group of glycidyl methacrylate and the carboxyl groups of asphaltenes [31]. The addition of a small amount of 1–1.5% “Elvaloy” to the bitumen binder PRB 90/130 increases elasticity from 60% to 90%, and also leads to an increase in the softening temperature of the bitumen binder, as well as significantly increases cohesion and increases adhesion with mineral components of asphalt concrete.

DISCUSSION

Asphalt concrete is a nanocomposite based on mineral particles of different sizes aggregated with bitumen (not exceeding 10% of the mass of the material), the properties of which determine the majority of physical and mechanical indicators of the road surface. Bitumen binders manifest themselves as typical petroleum nanodisperse systems, the adhesive characteristics of which are determined by nanostructured particles – asphaltenes of the dispersed phase. The content of the components of the asphalt concrete mixture is strictly regulated by the requirements of GOST, depending on the working conditions of the road surface.

The main binder component of road surfaces – bitumen has a number of significant disadvantages: too narrow plasticity interval and a low set of technological parameters necessary to create high-quality roads, especially at temperatures below zero [32]. Macromolecular complementary nanomodifiers of asphalt concrete compositions should also have a sufficiently high temperature resistance (above the flow temperature of bitumen) up to 180–200оC. Bitumen binders at all stages of the life cycle: in the process of manufacturing, storage, transportation and as part of asphalt concrete road surfaces are exposed to significant physico-chemical, mechanical and thermal oxidative effects [33].

Therefore, there is an urgent need to improve the properties of road bitumen by introducing modifying nano-additives, inhibitors of thermo-oxidative aging into it. Polymer-bituminous nano-binders (styrene-butadiene-styrene 2–3% by weight) simultaneously with a coagulation “frame” of supramacrocyclic asphaltenes contain an elastic nanoset of macromolecular block copolymers.

It should be noted that the adhesive interphase processes occurring on the surface of mineral powder grains during its interaction with bitumen have a decisive influence on the technological characteristics of asphalt concrete coatings (Fig. 4). Deformative destruction along the contact interphase zone often occurs due to the low cohesive strength of the macromolecular bitumen microfilm and insufficient adhesion of the bitumen material to the surface of the mineral components of asphalt con-

Fig. 4. Diagram of the interphase complementary interaction of the bitumen-polymer binder (1) with the surface of the mineral filler (2)

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION crete. The introduction of modifiers into bitumen should provide an increase in the complementary adhesion of the bitumen binder to the mineral components by several times, as well as a noticeable increase in the temperature range of plasticity and deformability.

A number of technical and economic requirements are imposed on polymer components used for the modification improvement of road bitumen: good compatibility with bitumen; a wide temperature range of high elasticity from –60оC to +100оC; low cost. Physico-mechanical and rheological characteristics of asphalt concrete road surfaces largely depend on the quality and ratio of bitumen and mineral components. During the preparation and transportation of asphalt concrete mixtures, in addition to the effect of elevated temperature (170–200оC), they are influenced by interphase surface phenomena in the boundary layers of the contact of the binder and mineral filler, and in the asphalt concrete of the modern roadbed, various climatic and physico–mechanical influences.

In case of violations of the manufacturing technology of asphalt concrete compositions, water molecules penetrate the interfacial surface between bitumen and mineral material and destroy the adhesive bonds in the laid road surfaces. The result of the action of encapsulated nanomodifiers [34] is a demanded increase in the technical and operational characteristics of asphalt concrete; the same effect is achieved when structuring a bitumen nanofacial at the interface. In this case, the complementary effect is achieved by reducing the bitumen content in the asphalt concrete mixture with an ordered arrangement of mineral powder particles. Unlike the modification of asphalt concrete, where the nanostructure self-organizes due to the introduction of modifiers, when structuring the asphalt binder, the ordering of the structure is realized by mechanical action on the particles of the filling material during the rolling of mineral granules.

The optimized mode of movement of ground vehicles and the technical category are the criteria for choosing a complementary type of asphalt concrete that provides shear stability and roughness of the road surface. The recommended applications of various asphalt concretes are the main factors in the use of permissible types and grades of asphalt concrete; the grade of asphalt concrete mixture rises with an increase in the road category and deterioration of road and climatic conditions. So, for sections of the highway with regular braking and stopping of vehicles, asphalt concrete mixtures with a high content of crushed stone and the use of crushed sand are chosen.

It should be noted that in the process of asphalt concrete roadway construction and during its formation, complementary quality management of road construction is very important: careful control of the alignment and density of the soil base; the correctness of the installation of side stones (curbs), lattices and manholes of wells of engineering and underground networks; unifor- mity of the thickness of the asphalt concrete layer taking into account the compaction coefficient; compliance of transverse and longitudinal slopes with the highway project, etc. So, for effective control of the assessment of the quality of asphalt concrete pavement, samples are taken: cuttings and cores are no closer than 1.5 m from the side stone; it should be noted that laboratory samples are taken no earlier than 3 days after the end of compaction and before the start of vehicle traffic at the rate of one sample per 3000 m2 [35]. The normative thickness of the laid layer of asphalt concrete roadway is instrumentally controlled during the laying process with a metal probe with divisions; the required uniformity of the distribution of the layer to be laid and the quality of the finishing of the joints of adjacent strips are carefully checked with special devices (Fig. 5).

It should also be noted that road bitumen according to the complex of technological, operational, technical and economic indicators, until the last 20 years, generally satisfied consumers, and low durability was compensated by low cost, justifying the repair of asphalt concrete pavements. However, with the increase in petroleum and energy prices, on the one hand, and with the increase in the intensity of impacts on road surfaces, on the other (an increase in the axial load of cars and an increase in the intensity of their movement on highways), the economically feasible service life of asphalt-ton coatings began to exceed their actual durability.

In comparison with asphalt concrete on traditional petroleum bitumen, complementary polymerasfalt concrete is characterized by less sensitivity to temperature changes, increased dynamic stability, shear resistance and track resistance, deformability at low temperatures, higher frost resistance. The service life of road surfaces using polymerasfalt concrete exceeds the service life of asphalt concrete coatings using bitumen by 2–3 times according to a specially developed scale, including requirements for heavy transport loads. In 2021, more than 1 million tons of polymer-modified bitumen binders were used throughout Russia in the construction of new expressways.

Fig. 5. Control of asphalt concrete roadway laying using polymer-bitumen nanocompositions

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Currently, the demanded advance of optimized formulations of bitumen nanoassemblers, adapted to the climatic conditions of the regions of the middle zone of Russia and the increasing intensity of motor traffic, is in demand. The uniform density of asphalt concrete mixtures, which is a complementary factor in enhancing the durability and stability of road surfaces, is achieved by continuously laying the composition in such a way that asphalt concrete does not segregate fractionally, and then is uniformly compacted by rollers [36].

Statistical analysis shows that in the Russian Federation, the volume of production of bitumen materials in 2022 amounted to about 7.7 million tons; at the same time, the technological capacities of Russian manufacturers already allow increasing production to 14.5 million tons. Traditional exporting partners and friendly countries of the Eurasian Economic Union continue to be interested in Russian bitumen. Within the framework of the Technical Regulations of the Customs Union (TR CU 014/2011), the construction of highways is carried out using innovative nanomaterials and technological control of road machinery and equipment [37, 38].

Digital nanotechnologies through the analysis of large databases make it possible to select the optimal composition of asphalt-concrete mixtures, artificial intelligence becomes a full-fledged participant in the creation of new formulations of bitumen nano-binders, the use of static sensing in 3D design of the construction of regional and federal highways, the management of road-building machines [39–41]. To solve the problem of abrasive wear and complementary improvement of macromolecular nanocomposites technological characteristics of asphalt concrete road surfaces, it is necessary to design compositions with large crushed stone (up to 60%) and the most dense microstructure. Innovative directions in the production of bitumen binders for complementary improvement of macromolecular nanocomposites technological characteristics of asphalt concrete drainage road surfaces is the transition to more voluminous and more dynamic tests.

In the ongoing projects of construction, reconstruction and maintenance of highways, it is necessary to work out the mechanism of import substitution of bitumen materials and the achievement of technological sovereignty in the renewal of road vehicles: graders, pavers, etc. It is planned in 2024 to put into effect GOST R “Public roads Petroleum bitumen binders. Brand selection rules”; the introduced standard will apply to the structural layers of asphalt concrete road surfaces, as well as establish a methodology for selecting bitumen binders acceptable for use in layers, taking into account the temperature conditions of asphalt concrete roadway operation and increasing transport loads.

In 2022, Russian enterprises produced more than 65 million tons of asphalt concrete mixtures; the Central

Federal District with a share of more than 28% became the leader in the production of asphalt concrete road and airfield mixtures in Russia in 2022; the Volga Federal District (over 18%) took the second place. The construction of domestic bitumen terminals in the Russian Federation for the complementary and stable functioning of asphalt concrete plants remains relevant. In the future, 2024– 2030, the bitumen terminal should not only store and ship high-quality bitumen, but also produce it, i.e. transform into a production and logistics complex [42].

Road construction is one of the key sectors of the Russian economy designed to stabilize the country’s forward movement in the face of aggressive sanctions and geopolitical turbulence. Sanctions restrictions that affected oil refining, supplies abroad to unfriendly countries, also affected the production of oil road bitumen. Vertically integrated companies “Rosneft”, “Gazprom” and others have technological capabilities to optimize the production technology of high-demand bitumen materials. In general, the implementation of the infrastructure transport strategy of Russia, within the framework of which the construction of trunk highways, for example, the M-12 Moscow-Nizhny Novgorod-Kazan with a subsequent extension to Yekaterinburg, will require an increase in the capacity of the domestic bitumen market: by 2033, according to an optimistic scenario, it will reach 8.5 million tons.

A general trend in the conditions of geopolitical retarding sanctions is the use of man-made waste in the production of asphalt concrete: slag, fly ash; various waste from the petroleum refining industry; artificial stone materials (expanded clay, and so on); used asphalt concrete, etc. [43, 44]. The recuperative use of bitumen-polymer recycled waste of soft roofs in the construction of highways is the optimal approach to solving environmental problems of our time [45]. Rubber-polymer-bitumen binders based on the use of rubber used tires are promising for nanostructural modification of bitumen and the construction of a draining asphalt concrete mixture [46, 47].

CONCLUSION

The addition of modifying polymer nanocomposites to bitumen compositions is an effective method of complementary synergetic improvement of the physical and mechanical characteristics of asphalt concrete. Bitumen with modifying macromolecular nanoadditives increase the durability of asphalt concrete coatings, the service life of roads increases by 2–3 times. Bitumen road asphalt concrete binders modified with polymer nanocomposites have higher adhesion and cohesion in the elastic-plastic state, a wide range of thermoplasticity, high elasticity from –60оC to +100оC.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Список литературы Complementary improvement of technological characteristics of asphalt concrete road surfaces using macromolecular nanocomposites

- Kalgin Yu.I. Road bitumen mineral materials based on modified bitumen. Voronezh: VSU Publishing House; 2006.

- Rudenskaya I.M., Rudensky A.V. Organic binders for road construction. Moscow: INFRA-M; 2010.

- Tyukilina P.M., Gureev A.A., Tyshchenko V.A. Production of petroleum road binders. Moscow: Nedra; 2021.

- Passek V.V., Velichko V.P., Andreev V.S. Prevention of longitudinal cracks in the asphalt concrete pavement of the roadway. Science and technology in the road industry. 2020; 1(91): 25-27.

- Kotenko N.P., Shcherba Yu.S., Evforitsky A.S. Effect of polymer and functional additives on the properties of bitumen and asphalt-concrete. Plastic masses. 2019; 11-12: 47-49. https://doi.org/10.35164/0554-2901-2019-11-12-47-49

- Porto M., Caputo P., Loise V., Rossi C.O., Eskandarsefat S, Teltayev B. Bitumen and bitumen modification: a review on latest advances. Applied Sciences. 2019: 9(4): 742. https://doi.org/10.3390/app9040742

- Kirillov A.M., Zavyalov M.A. Interpretation of asphalt concrete properties in the road surface. Construction materials. 2015; 4: 87-92.

- Grudnikov I.B. Petroleum bitumen. Processes and production technologies. Ufa: Publishing house SUE INHP RB; 2015.

- Yartsev V.P., Erofeev A.V. Operational properties and durability of bitumen-polymer composites. Tambov: Publishing house of TSTU, 2014.

- Usov B.A., Gorbunova T.N. Properties and modification of bitumen binders. System technologies. 2017; 22: 72-88.

- Hortal A.R., Martínez-Haya B., Lobato M.D., Pedrosa J.M., Lago S. On the determination of molecular weight distributions of asphaltenes and their aggregates in laser desorption ionization experiments. Journal of Mass Spectrometry. 2006; 41(7): 960-968. https://doi.org/10.1002/jms.1056

- Shutkova, S.A., Dolomatov, M.Y. Study of a supramolecular structure of continental type petroleum asphaltenes. J. Struct. Chem. 2017; 58(7): 1270-1274. https://doi.org/10.1134/S0022476617070022

- Hassanzadeh M., Abdouss M. Essential role of structure, architecture, and intermolecular interactions of asphaltene molecules on properties (self-association and surface activity). Heliyon. 2022; 8(12): e12170. https://doi.org/10.1016/j.heliyon.2022.e12170

- Shutkova S.A., Dolmatov M.Yu. Investigation of the electronic and supramolecular structure of petroleum asphaltenes // Russian electronic scientific journal. 2021; 2(40): 106-120. https://doi.org/10.31563/2308-9644-2021-40-2-106-120

- Khalikov R.M., Ivanova O.V., Glazachev A.O. Supramolecular improvement of technological parameters of asphalt concrete road surfaces by polymer nanocomposites. Actual problems of engineering, natural sciences. and human sciences: Materials of the international conf. Ufa: USPTU; 2022.

- Bochkov N.N., Algebraistova N.K., Shepelev I.I., Zhizhaev A.M. Investigation of hydrophobicity of activated mineral powder using foam flotation. Bulletin of Tomsk State University of Architecture and Civil Engineering. 2015; 2(49): 194-203.

- Haver S.V., Urcheva Yu.V., Syroezhko A.M., Vasiliev V.V. Influence of compatibility of petroleum bitumen and styrene-butadiene-styrene polymers on dispersion and performance characteristics of polymer-bitumen compositions // Bulletin SPbGTI (TU). 2016; 36: 68-71.

- Evdokimova N.G., Luneva N.N., Egorova N.A., Makhmutova A.R., Bayguzina Yu.A., Imangulova E.A. The selection of production technology of polymer-bitumen binders as an innovative nanobinders used in asphaltic concrete pavement. Nanotechnologies in Construction. 2018; 10(5): 20–37. https://doi.org/10.15828/2075-8545-2018-10-5-20-37

- Rusakov M.N., Ismailov A. Styrene-butadiene-styrene polymers for road construction in the Russian Federation. Construction of Unique Buildings and Structures. 2020; 2(87): 23-40. https://doi.org/10.18720/CUBS.87.3

- Khasanov M.F., Latypova Z.B., Khalikov R.M. Influence of thermodynamic factors on self-assembly of nanostructures of macromolecules. In the world of scientific discoveries. 2010; 4-10(10): 8-9.

- Polyakov I.V., Barannikov M.V., Polyakov V.S. Modification of road bitumen with additives based on degraded polymers. Chemical industry today. 2021; 2: 46-49.

- Nebratenko D.Yu., Lushnikov N.A. Polymer bitumen modifiers: styrene-butadiene thermoplastics and syndiotactic polybutadiene. Bulletin of VSGUT. 2022; 2(85): 78-86. https://doi.org/10.53980/24131997_2022_2_78

- Evdokimova N.G., Egorova N.A., Sultanova D.P., Kunakkulova E.M., Serezhkina N.G. The formation of the sol-gel nanostructures of road bitumen by selecting chemical group composition. Nanotechnologies in Construction. 2019; 11(5): 512–525. https://doi.org/10.15828/2075-8545-2019-11-5-512-525

- Pudovkin A.N., Khalikov R.M., Bulatov B.G., Sokolova V.V., Nedoseko I.V. Digital control of parameters in the automated control system for the production of asphalt concrete mixture. Electrical and information complexes and systems. 2021; 17(3-4): 103-113. https://doi.org/10.17122/1999-5458-2021-17-3-4-103-113

- Ignatiev A.A. Additives in asphalt concrete. Literature review. Bulletin of KGASU. 2023; 1(63): 14-30. https://doi.org/10.52409/20731523_2023_1_14

- Dong F., Yang P., Yu X., Jiang M., Wang S., Zu Y., Chen B., Wang J. Morphology, chemical reaction mechanism, and cross-linking degree of asphalt binder modified by SBS block co-polymer. Construction and Building Materials. 2023; 378: 131204. https://doi.org/10.1016/j.conbuildmat.2023.131204

- Crucho J., Picado-Santos L., Neves J., Capitão S. A review of nanomaterials’ effect on mechanical performance and aging of asphalt mixtures. Applied Sciences (Switzerland). 2019; 9(18): 3657. https://doi.org/10.3390/app9183657

- Khalikov R.M., Vedernikova T.G., Sharipov R.A., Rashidova S.T., Borisov I.M. Synergetic dynamism of the formation of supramolecular structures of polymers. Bulletin of higher educational institutions. Series: Chemistry and Chemical Technology. 2008; 51(11): 92-94.

- Kalgin Yu.I., Komarov E.V. Modified styrene-butadiene thermoplastic and polymer additives for road construction. News of universities. Construction. 2020; 9(741): 58-67.

- Kremenetskaya E.V., Goryachev M.V., Igoshin Yu.G., Korobitsyn A.Yu. Polymer-bitumen binder and method of its preparation. RU Patent No. 2412223. Publ. 20.02.2011.

- Ayupov D.A., Murafa A.V., Khakimullin Yu.N., Khozin V.G. Modified bitumen binders for construction purposes. Construction materials. 2009; 8: 50-51.

- Gorbatova V.N., Gordeeva I.V., Dudareva T.V., Krasotkina I.A., Nikol’skii V.G., Egorov V. M. Effect of the active powder of discretely devulcanized rubber on bitumen properties at low temperatures. Nanotechnologies in Construction. 2023; 15(1): 72-83. https://doi.org/10.15828/2075-8545-2023-15-1-72-83

- Mamulat S.L., Mamulat Y.S. Actual problems of modification of bitumen binders to increase the service life of road surfaces. Roads. Innovations in construction. 2019; 80: 70-74.

- Inozemtsev S.S., Korolev E.V., Including Self-healing of asphalt concrete using encapsulated modifier. Construction materials. 2022; 11: 58-69. https://doi.org/10.31659/0585-430X-2022-808-11-58-69

- Grinevich N.A. Designing the composition of road asphalt concrete. Yekaterinburg: UGLTU; 2016.

- Krupin N.V. Modern trends in asphalt concrete coating technologies. Roads. Innovations in construction. 2022; 100: 12-15.

- Stefan Yu.V., Bondarev B.A., Yankovsky L.V. The use of cuboid cast slag rubble for the construction and repair of trunk forest roads. Repair. Recovery. Modernization. 2016; 10: 11-16.

- Ivanova O.V., Khalikov R.M., Salov A.S., Nizamutdinov M.Kh., Zinnatullin V.V. Technological equipment management for 3D additive printing of building nanocomposites. Nanotechnologies in Construction. 2021; 13(2): 117–123. https://doi.org/10.15828/2075-8545-2021-13-2-117-123

- Borisenko Yu.G., Rudak S.V. Influence of the content and grain composition of light porous aggregates on the performance characteristics of bitumen mineral compositions. Construction and technogenic safety. 2019; 15(67): 101-110.

- Glazachev A.O., Sherstobitova T.M., Akhmetshin R.M. Advantages of using static sensing in construction. New science: theoretical and practical view: materials of the International. conf. Neftekamsk: SIC “World of Science”, 2020. Р. 58–66.

- Bobrova T.V. Updating parameters of an information model for road construction flow in work development project. The Russian Automobile and Highway Industry Journal. 2022; 19(6): 916-927. https://doi.org/10.26518/2071-7296-2022-19-6-916-927

- Gureev A.A., Tyukilina P.M., Nguyen T.T.I. On the problems of production and consumption of petroleum road binders in the Russian Federation. Proceedings of the Gubkin Russian State University of Petroleum and Gas. 2018; 1(290): 110-128.

- Polyakov I.V., Barannikov M.V., Polyakov V.S. Using polymer-containing waste from the production of thermoplastics for the modification of petroleum bitumen. Industrial production and use of elastomers. 2020; 2: 28-33. https://doi.org/10.24411/2071-8268-2020-10205

- Fomina N.N., Khozin V.G. Compatibilization of polymer mixtures during processing of waste products from thermoplastics. Nanotechnologies in Construction. 2021; 13(4): 229–236. https://doi.org/10.15828/2075-8545-2021-13-4-229-236

- Khalikov R.M., Ivanova O.V., Korotkova L.N., Salov A.S. Effective use of recycled polymer waste in the construction of road surfaces of highways. The Scientific Heritage. 2021; 68-1: 62-66. https://doi.org/10.24412/9215-0365-2021-68-1-62-66

- Krasnovskikh M.P., Chudinov S.Yu., Slyusar N.N., Pugin K.G., Vaisman Ya.I. Production of a nanostructured bitumen modifier in the reprocessing of automobile tires. Nanotechnologies in construction. 2022; 14(6): 501–509. https://doi.org/10.15828/2075-8545-2022-14-6-501-509

- Liu Z., Wang H., Gong X., Cui P., Wei H. Stiffening and toughening of asphalt mastic induced by bitumen–mineral selective molecular adsorption and nanostructural reconstruction // Sustainability. 2023. V. 15. No. 5. 4398. https://doi.org/10.3390/su15054398