Composite building materials based on nanomodified cement systems

Автор: Natalia O. Kopanitsa, Olga V. Demyanenko, Anzhelika A. Kulikova, Alexander F. Buryanov, Nadezhda A. Lukyanova, Vadim G. Soloviev

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 5 Vol.15, 2023 года.

Бесплатный доступ

Introduction. This research work investigates the combined influence of nano-sized silicon dioxide (nano-SiO2), carbon nanotubes and surfactants on the structural and technological characteristics of cement compositions. Materials and research methods. The paper reveals the findings of a study on the effects of various dispersion techniques of carbon nanotubes (CNT) in surfactants, such as mechanical dispersion, ultrasonic treatment, and a combined method. It considers the uniformity of CNT distribution within the plasticizer and within the cement system, along with their impacts on the physical and mechanical properties of cement stone and concrete. Differential thermal and electron microscopic analysis of aqueous dispersions of carbon nanotubes and hardened activated nanomodified cement stone was carried out. Results and discussion. It has been experimentally proven that mixing nanotubes in dry cement does not allow them to be evenly distributed throughout the volume of the mixture. When using carbon nanotubes, the maximum effect is achieved when they are introduced into aqueous dispersions of plasticizers. The percentage of plasticizer was 1%, CNT 0,1% per 1 liter of water. The most effective method of dispersing carbon nanotubes in a plasticizer is a combined one. The results obtained were used in the preparation of cement stone and concrete compositions. Conclusion. The results show that complex additives consisting of nano-SiO2 and aqueous dispersions of carbon nanotubes have a positive effect on the physical-mechanical and structural-technological properties of cement stone and concrete. Graphic dependencies are shown indicating the effectiveness of using complex additives in the production of cement composites.

Cement systems, nanomodifiers, silicon dioxide, carbon nanotubes, composite materials

Короткий адрес: https://sciup.org/142238324

IDR: 142238324 | DOI: 10.15828/2075-8545-2023-15-5-443-452

Текст научной статьи Composite building materials based on nanomodified cement systems

Original article

R ussian and foreign scientists are actively conducting research in the field of production and use of ultrafine materials in the composition of concrete and mortar mixtures for various purposes. The use of nanotechnologies in the production of composite materials based on cement binders is relevant, since the introduction of primary nano-sized components into them will ensure the specified characteristics and significantly expand the functionality of composite materials through targeted control of the structure formation of the material [1–6].

From the literature, various types of nanomodifying additives are known (fullerenes, carbon nanotubes, oxide nanotubes and fibers, etc.), which can be used to regulate the properties of concrete, mortars, and dry construction mixtures. Analysis of the works of E.V. Korolev, V.I. Kalashnikov, G.P. Sakharov. and others [7-9], including our research [10-13], showed the promise of using nanoadditives similar in composition to cement hydration products such as: nano-SiO2, Al2O3, Fe2O3, CaO, which have excess internal energy and high chemical activity, which makes it possible to obtain binders and composite materials based on them with high physical and mechanical characteristics

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

-

[14] . A less studied nanomodifier for regulating the properties of cement systems is nanosized silicon dioxide [15]. Various methods for its preparation are known. S.P. Bar-dakhanov at the Institute of Theoretical and Applied Mechanics and the Institute of Nuclear Physics (Novosibirsk), a method for producing nanosilicon dioxide was tested [16]. Nano-sized silicon dioxide “Ts” was obtained by evaporating the substance under the action of an electron beam created by an electron accelerator. The second method of producing nano-silicon dioxide by the plasma-arc method, developed at TSUAB [17], was tested using diatomite (overburden rock) as a raw material.

Many scientists note the advantage of nanoparticles, which consists in the fact that their presence in composite building materials significantly improves their performance characteristics, or gives the materials new properties, but it is noted that the mechanism of their interaction with other components in cement and concrete requires careful study [8, 18, 19]. A promising modifier for concrete and mortars is carbon nanotubes (CNT). In works [1, 2, 20], the authors showed the possibility of using CNT as additional crystallization centers for cement hydration products. As well as activators of mixing water in the concrete mixture. It is noted that the efficiency of using CNT in composite materials can be increased by choosing the optimal technology for mixing CNT with binders in various states of aggregation (in solution, melt, emulsion, suspension, aerosol).

Despite the increased interest of Russian and foreign researchers in nanomodification technology, many experts express skepticism regarding the hypotheses that describe the mechanism of formation of the structure of cement stone in the presence of carbon nano-sized particles. One of the main reasons for conflicting data on the effect of carbon nanotubes on the structure and properties of the cement matrix is the heterogeneity of their distribution in the carrier medium. Due to their high surface energy, CNT during synthesis form globules, the sizes of which range from 400–900 microns. At the same time, nanotubes are difficult to distribute in an aqueous environment and require special techniques for their dispersion.

In this regard, the development of technology for dispersing carbon nanotubes in water and an aqueous solution of surfactants, in particular superplasticizer and other particles, for their subsequent modification of the cement matrix in order to improve the physical and technical characteristics of concrete is an urgent task.

MATERIALS AND RESEARCH METHODS

To prepare the samples, Portland cement CEM I 42,5N (Topkinsky Cement) was used.

Single-walled carbon nanotubes (CNT) were used as a nanomodifying additive. The characteristics of nanotubes are presented in Table 1.

Table 1

Characteristics of CNT

|

Parameter name |

Unit |

Result |

|

Average outer diameter |

nm |

1.97 |

|

Mass fraction of inorganic impurities |

%, m.p. |

11.102 |

|

Specific surface area |

m2/g |

546 |

|

G/D ratio |

– |

48 |

|

CNT content |

%, m.p |

83.347 |

Also, nano-sized silicon dioxide (nano-SiO2), developed at TSUAB, based on the use of the plasma-arc method, was used as a nanomodifier in concrete mixtures. Nanoparticles of the resulting powder have a size distribution in the range from 10 to 300 nm, but the largest number of them (82%) is in the range up to 100 nm. The peak of the distribution falls on particles with sizes of 11–20 nm (13%) [17]. The characteristics of nano-SiO2 are presented in Table 2.

Тable 2

Characteristics of the nanomodifier

|

Modifier |

Specific surface, m2/kg |

The average size particles, nm |

|

nano-SiO2 |

38 000 |

37.12 |

The following plasticizers were used:

– Superplasticizer “Steinberg F-10 Build” – a product based on the condensation of naphthalene sulfonic acid and formaldehyde;

– Superplasticizer “Steinberg GROS-63 MR” – a product based on polycarboxylate esters;

– HyperPlast 60 is a superplasticizing and superwaterreducing additive for concrete.

The paper presents the results of a study of the influence of various methods of dispersing carbon nanotubes in surfactants (mechanical dispersion, ultrasonic treatment, combined method) on the uniformity of distribution of carbon nanotubes in the plasticizer, as well as the introduction of carbon nanotubes in a dry state into a cement composition, on the physicomechanical characteristics of cement stone.

The features of phase transformations in the cement system and the change in the mass of chemically bound water were determined by derivatographic analysis using an STA 449 F3 Jupiter device.

Electron microscopic analysis was carried out using a JEOL JSM 6000 scanning electron microscope.

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

RESULTS AND DISCUSSION

It has been experimentally proven that mixing nanotubes in dry cement does not allow carbon nanotubes to be evenly distributed throughout the volume of the mixture.

When using carbon nanotubes, the maximum effect is achieved when they are introduced into aqueous dispersions of plasticizers. The percentage of plasticizer was 1%, CNT 0,1% per 1 liter of water. Water was added to the mixture of carbon nanotubes and plasticizer, then the resulting solution was mixed in three ways:

– ultrasonic treatment, using an ultrasonic dispersant, type UZDN-2T, for 2 hours;

– mixing in a high-speed bead mill for 2 hours;

– combined, including high-speed mixing in a bead mill for 2 hours, followed by ultrasonic treatment (UZDN-2T) for 2 hours.

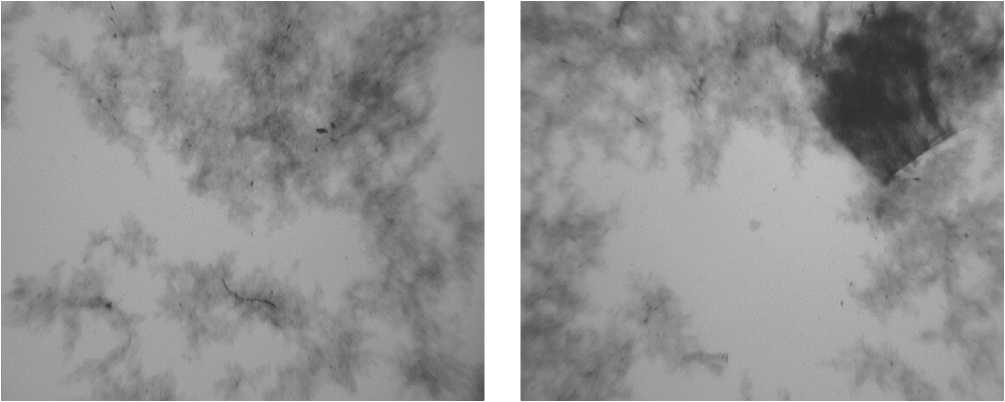

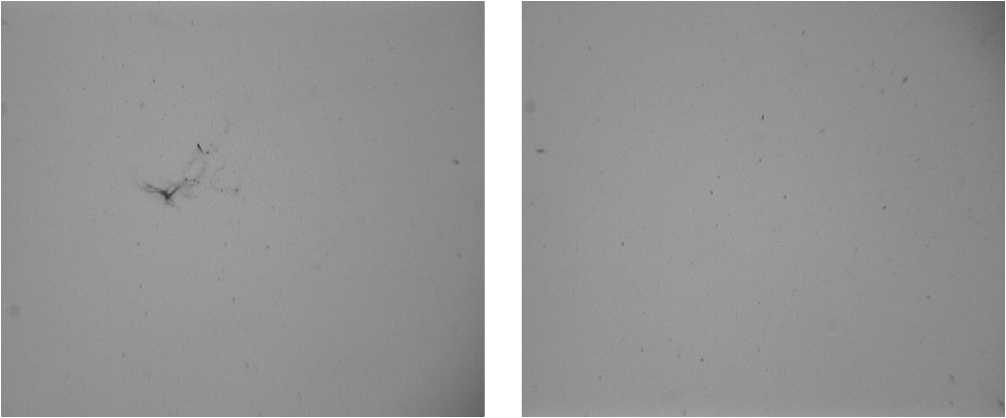

It has been established that the first two methods do not allow carbon nanotubes to be evenly distributed in the volume of an aqueous suspension. Figures 1–3 show micrographs of suspensions obtained using the combined method.

Studies of the microstructure of samples of aqueous suspensions with CNT using a scanning electron microscope showed the presence of areas with a relatively uniform distribution of nanotubes throughout the volume (Fig. 2–3), areas without them, and agglomerates with a diameter of about 10 µm. The micrographs (Fig. 1) clearly show agglomerates, which represent a significant

Fig. 1. Distribution of CNT in an aqueous dispersion of hyperplasticizer GP-60 (x5000)

Fig. 2. Distribution of CNT in an aqueous dispersion of plasticizer Steinberg GROS-63 MR (x5000)

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 3. Distribution of CNT in an aqueous dispersion of plasticizer Steinberg F-10 Build (x5000)

number of interconnected nanotubes, which may be characteristic of flexible single-walled nanotubes with the largest length-to-diameter ratio. The GP-60 plasticizer contains modified polycarboxylates, which do not allow nanotubes to mix and be evenly distributed throughout the mixture. Thus, the proposed method of mixing nanotubes in an aqueous suspension of a plasticizer is promising and two types of plasticizer were used for further research: Steinberg F-10 Build, Steinberg GROS-63 MR.

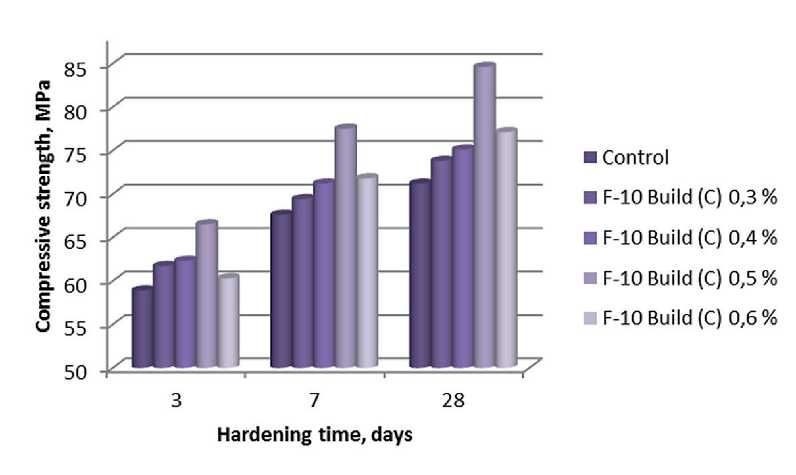

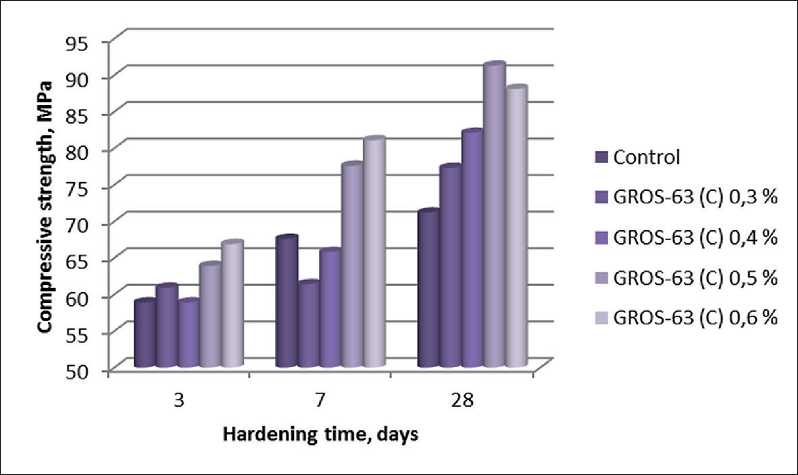

To study the effect of aqueous dispersions of carbon nanotubes on the physical and mechanical properties of cement systems, samples of cement stone were pre- pared with an additive content of 0.3; 0.4; 0.5; 0.6% by weight of cement. The addition of an aqueous dispersion was introduced into the cement system before the mixing water and mixed intensively. Cube samples measuring 20×20×20 mm were prepared from dough of normal density, which were stored in air-humid conditions. The compressive strength of the samples was assessed at 3, 7, 28 days of hardening. The test results are presented in Figures 4–5.

The research results obtained allow us to conclude that aqueous dispersions of carbon nanotubes increase the strength of cement stone at all stages of hardening.

Fig. 4. Compressive strength of cement stone with the addition of aqueous dispersion F-10 Build (C)

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 5. Compressive strength of cement stone with the addition of aqueous dispersion GROS-63 MR (C)

The maximum increase in the strength of cement stone with the addition of aqueous CNT dispersions with the introduction of 0.5% for GROS-63 MR is 28%, for F-10 Build – 18%. The introduction of a dispersion of carbon nanotubes leads to structural changes in cement stone associated with the formation of a dense shell over the surface of solid phases, including cement particles. In this case, spatial frame cells are formed in a modified cement matrix with dense layers of crystalline hydrates, which leads to a general strengthening of the matrix. Further studies were carried out with an additive percentage of 0.5%.

During the research, it was found that when adding an aqueous dispersion of carbon nanotubes to the cement system, the rheological characteristics of the cement mortar change. The tests were carried out using the “Spreadability Cone KR-1”. The test results are presented in Table 3.

Table 3

Results of determining the spreadability of cement mortar with aqueous dispersions of carbon nanotubes

|

No. |

Composition |

W/C |

Spreadability (mm) |

|

1 |

Control |

0.295 |

180 |

|

2 |

C+F-10 Build |

0.275 |

195 |

|

3 |

C+GROS-63 МR |

0.27 |

200 |

|

4 |

C+F-10 Build (С) |

0.27 |

205 |

|

5 |

C+GROS-63 МR (С) |

0.26 |

220 |

Analysis of the results obtained allows us to draw a conclusion about the effectiveness of plasticizing complex additives. Composition 5 has greater spread with lower water demand, which also confirms the rational composition of the resulting modifying additive.

Experience in the use of multifunctional modifying additives in concrete mixtures shows that complex additives are more effective than single-component additives, which, along with improving any properties of concrete or concrete mixture, can significantly reduce other technological indicators. The use of such additives makes it possible to more effectively influence the processes of cement hydration, specifically regulating the structure of cement stone and concrete, slow down its aging and increase durability, which will ensure high performance qualities of concrete products and structures. Previous studies have proven the effectiveness of using oxide nanoparticles in concrete mixtures. Analysis of the results of assessing the influence of the characteristics of nano-SiO2, methods of their preparation and introduction into cement paste, as well as the content of additives on the properties of the binder made it possible to determine a rational ratio of nano-sized additives in the cement matrix, equal to 0.03% by weight of cement (strength increase is 32%). The results obtained are consistent with the data of other researchers [14], in the works of which it was noted that an excessively high dosage, for example, of nano-sized silica particles can lead to “poisoning” of the system, a significant slowdown in the processes of hydration and hardening. This can be explained by the high reactivity of their surface area, high chemical activity, which creates conditions for the chemical binding of mixing water with silica into poorly soluble crystalline hydrates, and,

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Table 4

Determination of physical and mechanical properties of cement stone

To assess the joint effect of a complex modifying additive on the physical and mechanical properties of cement stone, cube samples were made with a ratio of additives nano-SiO2 0.03%, GROS-63 MR, F-10 Build 0.5% by weight of cement. The test results are shown in Table 4.

Analysis of the data given in the table made it possible to select a rational composition of cement stone (№ 5), the increase in strength of which is 57.4%. This may be due to processes occurring at the nanoscale in the combined presence of CNT and nano-SiO2 components in the cement composition. Polycarboxylates, which are the basis for the uniform distribution of nanotubes, serve as both a plasticizer and the basis for the effective interaction of nano-SiO2 and nanotubes, the formation of frame cells in a modified cement matrix with dense layers of crystalline hydrates. According to the table, the beginning of setting of the control sample is 1 hour 40 minutes, and the end is 3 hours 20 minutes. For modified cement paste samples, setting times are accelerated by 10 minutes (beginning of setting) and 15 minutes (end of setting) using an aqueous dispersion of carbon nanotubes F-10 Build (C), by 20 minutes (beginning of setting) and 30 minutes (end of setting). setting) with an aqueous dispersion of carbon nanotubes GROS-63 MR (С).

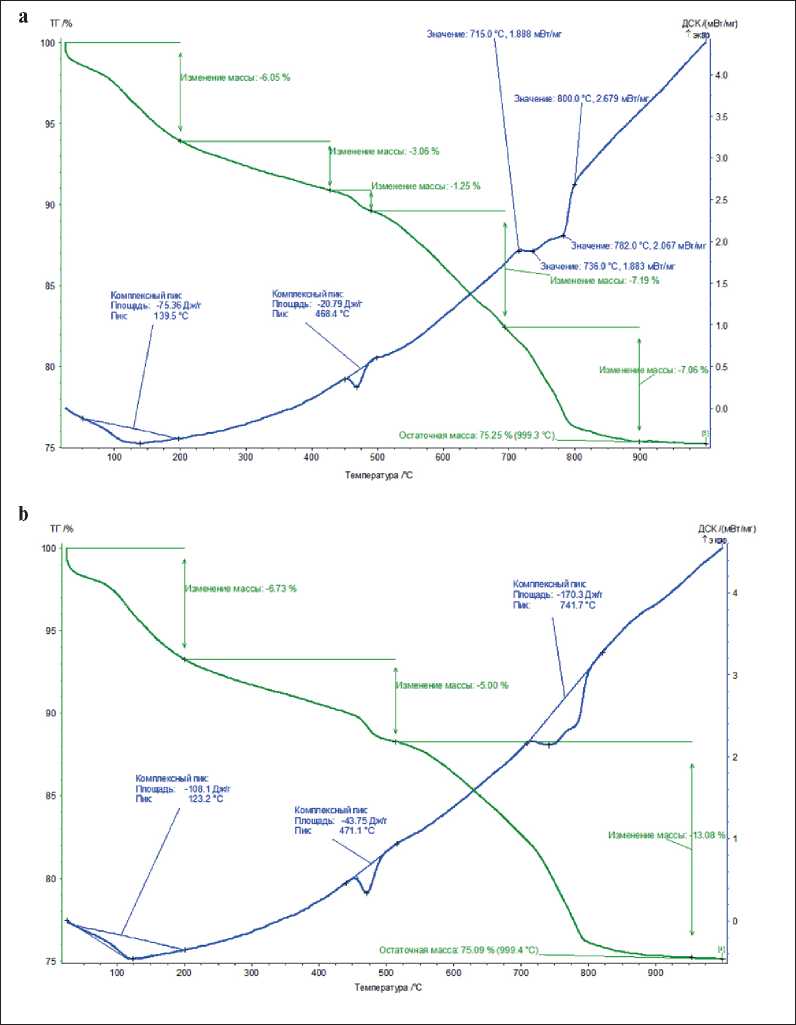

To explain the results obtained and establish the patterns of formation of the composition, structure and properties of cement stone, a derivatographic analysis of cement stone composition (№ 5) was carried out. The features of phase transformations in the cement system and the change in the mass of chemically bound water are determined in the temperature range from 20 to 1000оС. Figure 6 shows comparative thermograms of the control and modified cement stone samples.

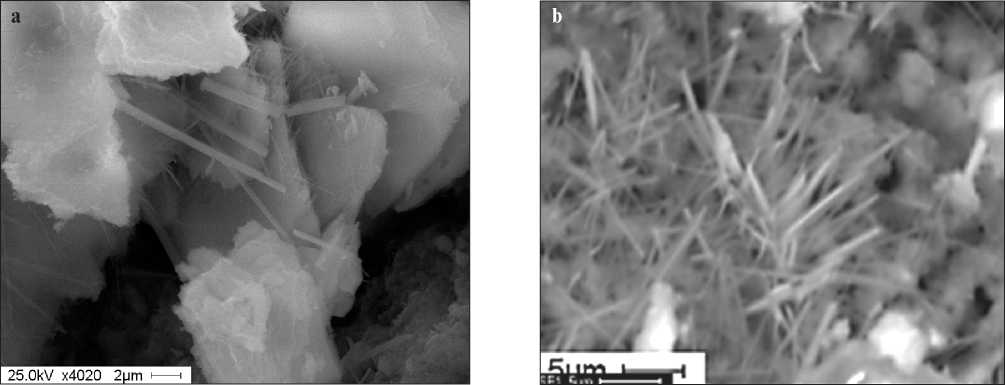

It was found that in the thermograms of the control cement stone and with the complex additive, the en-do-effects corresponding to the dissociation of calcite formed as a result of partial carbonization of Ca(OH)2 differ significantly in area. In the thermogram of cement stone with a complex additive, the peak area is twice as large, which may be due to the superposition of thermal effects of dehydration of additionally formed hydrosilicates. To confirm the obtained results of the influence of the additive on the formation of the structure of cement stone, an electron microscopic analysis of the samples was carried out (Fig. 7).

Analysis of the data presented in the photographs shows that the introduction of a complex additive into the cement matrix ensures the formation of low-basic calcium hydrosilicates, stable high-basic calcium hydrosulfoaluminates with an overgrown needle-like structure that tightens the pores.

It is known that one of the properties inherent in composite materials is multi-scale. This property allows us to conditionally consider any composite building material as a multilayer formation at the micro-, meso- and macro levels of interaction. Processes occurring at each large-scale level can be characterized by both a high degree of autonomy and interconnectedness, subordinate to one goal – to ensure the required operational characteristics. Modern synergetics also includes other principles, the application of which in construction materials science has not been sufficiently studied. To study the influence of complex additives with CNT and nanos, studies were carried out to assess their influence on the properties of concrete mixtures.

The composition of concrete was calculated by the intergranular voids method [21, 22]. Ratio Cement:Sand (crushed stone) – 1:3.63. All additives were introduced as a percentage of the cement mass. The optimal percentages of additives were previously determined. The nano-SiO2 additive was pre-mixed with Portland cement and introduced with the dry components of the mixture. Aqueous dispersions of carbon nanotubes were introduced into a concrete mixture with mixing water. The tests were carried out in accordance with GOST 26633-2015 “Heavy and fine-grained concrete. Technical conditions”. Frost resistance was determined in accordance with GOST

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 6. Thermograms of control (a) and modified (b) with an aqueous dispersion of carbon nanotubes GROS-63 MR (C) + nano-SiO2 cement stone samples

10060-2012 “Concrete. Methods for determining frost resistance. General requirements. Heavy, fine-grained, light and dense silicate concrete.” Water tightness and open porosity according to GOST 12730.5 on the device for determining air tightness – AGAMA-2R.

The physical and mechanical characteristics of the control fine-grained concrete and that modified with additives were determined at the design age of hardening. The table 5 shows the physical and mechanical characteristics of concrete.

Analysis of the data given in the table showed that all additives used in the work increase the rheological and performance properties of concrete mixtures. Compositions 2 and 4 significantly increase the grade’s frost resistance to 600 and 800, respectively, which is explained by the composition of the plasticizing additive F-10. The strength of concrete at the design age of hardening increases by 19% (composition 2) and by 44% (composition 4) in comparison with the control composition. Compressive strength for compositions 3 and 5 increases to 47 and 69%, compared

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 7. Electron microscopic image of a control sample of cement stone (a) (x4020) and a modified sample with the addition of GROS-63 MR (C) + nano-SiO2 (b) (x4000)

Table 5

Determination of physical and mechanical properties of concrete

CONCLUSION

The research outcomes delineated in this study demonstrate the feasibility of creating multi-functional additives, which incorporate nanocomponents of varied composition and production methods. Nevertheless, these disparate elements exhibit a synergistic effect.

The most effective method for distributing CNT nanoparticles in an aqueous environment and a cement matrix has been experimentally established, which consists of high-speed mixing of nanotubes with an aqueous solution of a plasticizer in a bead mill for 2 hours, followed by ultrasonic treatment (UZDN-2T) for 2 hours.

It has been shown that the efficiency of interaction between carbon nanotubes, aqueous dispersions of plasticizers and nano-SiO2 depends on the composition of surfactants. Plasticizers based on polycarboxylate esters interact better with nanotubes and nano-SiO2. Their effectiveness is confirmed by the results of physical and chemical studies, improvement of the rheological characteristics of concrete mixtures with complex additives and increase in the performance characteristics of hardened concrete. The introduction of complex additives makes it possible to specifically activate hydration processes, influence the structure of cement stone and concrete, phase composition and its porosity by increasing the degree of hydration of the main clinker minerals and the formation of more stable hydrate phases.

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Список литературы Composite building materials based on nanomodified cement systems

- 1. Beregovoi V.A., Snadin E.V., Inozemtsev A.S., Pilipenko A.S. Vysokofunktsional’nye betony dlya stankostroeniya s primeneniem nano- i mikromasshtabnykh syr’evykh komponentov. Nanotekhnologii v stroitel’stve. 2023;15(3):200–10. https://doi.org/10.15828/2075-8545-2023-15-3-200-210. – EDN: HGNZWR. (In Russ)

- Il’ina V.N., Il’in S.V., Gafarova V.A., Kuzeev I.R. Vliyanie nanouglerodnykh napolnitelei na svoistva kompozitsionnykh materialov. Nanotekhnologii v stroitel’stve. 2023;15(3):228–37. https://doi.org/10.15828/2075-8545-2023-15-3-228-237. – EDN: DMAYTS. (In Russ)

- Drexler K.E., Peterson C., Pergamit G. Unbounding the future: the nanotechnology revolution. New York: William Morrow; 1991.

- Scrivener K.L. Nanotechnology and cementitious materials. In: Bittnar Z, Bartos PJM, Nemecek J, Smilauer V, Zeman J, editors. Nanotechnology in construction: proceedings of the NICOM3 (3rd international symposium on nanotechnology in construction). Prague: Czech Republic; 2009: 37–42.

- Chong K.P., Garboczi E.J. Smart and designer structural material systems. Prog Struct Mat Eng. 2002;4:417-30.

- Garboczi E.J., Bentz D.P. Modelling of the microstructure and transport properties of concrete. Construct Build Mater. 1996;10(5):293–300.

- Sakharov G.P. O kratkosrochnoi perspektive nanotekhnologii v proizvodstve stroitel’nykh materialov i izdelii. Tekhnologii betonov. 2009;4(1):65–67.

- Bazhenov Y.M., Korolev E.V. Nanotekhnologiya i nanomodifitsirovanie v stroitel’nom materialovedenii. Zarubezhnyi i otechestvennyi opyt. Vestnik BGTU im. V. G. Shukhova. 2007;2:16–19.

- Kalashnikov V.I., Erofeev V.T., Moroz M.N., [et al.]. Nanogidrosilikatnye tekhnologii v proizvodstve betonov. Stroitel’nye materialy. 2014;5:88–91.

- Kosmachev P.V., Vlasov V.A., Kopanitsa N.O., Skripnikova N.K., Dem’yanenko O.V. Kompozitsionnye materialy na osnove tsementa s nanodispersnym dioksidom kremniya. Vestnik Tomskogo gosudarstvennogo arkhitekturnostroitel’nogo universiteta. 2017;4:139–146.

- Kopanitsa N.O., Sarkisov Y.S., Dem’yanenko O.V., Gorshkova A.V. Tsementnye kompozitsii, modifitsirovannye kombinirovannymi nanodispersnymi dobavkami. Vestnik Tomskogo gosudarstvennogo arkhitekturno-stroitel’nogo universiteta. 2017;4:101–106.

- Abzaev Y.A., Kopanitsa N.O., Klimenov V.A., [et al.]. Modelirovanie strukturnogo sostoyaniya amorfnogo tarkosila. Vestnik Tomskogo gosudarstvennogo arkhitekturno-stroitel’nogo universiteta. 2015;3(50):121–133.

- Kopanitsa N.O., Demyanenko О.V., Kulikova А.А., Samchenko S.V., Kozlova I.V., Lukyanova N.A. Influence of Activation Methods on the Structural and Technological Characteristics of Nanomodified Cement Compositions. Nanotechnologies in Construction. 2022;14(6):481–492. https://doi.org/10.15828/2075-8545-2022-14-6-481-492. – EDN: PFYSQZ.

- Urukhanova LA, Lkhasaranov SA, Bardakhanov SP. Build Mater. 2014:852–55.

- Scrivener KL, Kirkpatrick RJ. Innovation in use and research on cementitious material. Cem Concr Res. 2008;38(2):128–36.

- Bardakhanov S.P., Korchagin A.I., Kuksanov N.K., [et al.]. Poluchenie nanoporoshkov ispareniem iskhodnykh veshchestv na uskoritele elektronov pri atmosfernom davlenii. Doklady Akademii Nauk. 2006;409(3):320–323.

- Kosmachev P.V. Poluchenie nanorazmernogo dioksida kremniya plazmenno-dugovym metodom iz vysokokremnezemistogo prirodnogo syr’ya: dissertatsiya kand. tekhn. nauk: 01.04.07. Tomsk; 2018.

- Kim H., Lee S., Moon H. Strength properties and durability aspects of high strength concrete using Korean metakaolin. Construction and Building Materials Journal. 2007;1:128 p.

- Ji T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem Concr Res. 2005;35:1943–1947.

- Sanchez F., Zhang L., Ince C. Multi-scale performance and durability of carbon nanofiber/cement composites. In: Bittnar Z, Bartos PJM, Nemecek J, editors. Nanotechnology in construction: proceedings of the NICOM3 (3rd international symposium on nanotechnology in construction). Prague: Czech Republic; 2009.

- Kudyakov A.I., Smirnov A.G., Petrov G.G., Dushenin N.P. Proektirovanie i ispol’zovanie zapolnitelya s optimal’noi mezhzernovoi pustotnost’yu v betone. Izv vuzov. Stroitel’stvo i arkhitektura. 1987; 7:135–138.

- Kudyakov A.I., Simakova A.S., Kondratenko V.A., Steshenko A.B., Latypov A.D. Vliyanie organicheskikh dobavok na svoistva tsementnogo testa i kamnya. Vestnik Tomskogo gosudarstvennogo arkhitekturno-stroitel’nogo universiteta. 2018;20(6):138–147.