Control of Switched Reluctance Motor and Noise Reduction Using Fuzzy Controller in Matlab/Simulink

Автор: B. Srilatha, Sheeba Kumari C., Tina Elizabeth Thomas

Журнал: International Journal of Engineering and Manufacturing @ijem

Статья в выпуске: 3 vol.14, 2024 года.

Бесплатный доступ

Switched Reluctance Motor (SRM) has been successfully used for its excessive efficiency and higher strength to torque ratio. However, the only demerit it has its radial pressure and acoustic noise. When SRM achieves higher speeds, it tends to generate more force between stator and as a result acoustic noise with higher decibels is a concern. In this paper, a layout is used for reduction of both radial force and acoustic noise for eight/6 SRM using the fuzzy logic controller by controlling the speed and current as a feedback loop. The mathematical models are framed to resolve glitches associated to radial pressure and acoustic noise. In this proposed method the SRM produces a very low noise level when it rotates at the speed of 1200 RPM. This method also has been implemented in MATLAB/Simulink platform mainly to reduce the acoustic noise at higher speed in SRM.

Switched Reluctance Motor (SRM), fuzzy logic controller, acoustic noise, radial force, MATLAB/Simulink

Короткий адрес: https://sciup.org/15019334

IDR: 15019334 | DOI: 10.5815/ijem.2024.03.04

Текст научной статьи Control of Switched Reluctance Motor and Noise Reduction Using Fuzzy Controller in Matlab/Simulink

An electrical machine is the fundamental part of any electrical drive with electromagnetic force-based operations. Nowadays, various speed drives are developed through the recent progressions in modern factory automation and industries, which can be utilized for meeting their required load constraints and conserving energy [1]. The usage of flexible speed drives is more emerging to manage their energy resources for upcoming years. The existing classification of motors is depended on the design of the electrical windings and magnetic system and also the category of supply [2]. DC motors are adopted and considered as a primary element of varied speed drive industries owing to the simpler control demands such as armature MMF and the area MMF are decoupled. As a result, it is a simpler work for controlling the torque through managing the field current by flux and by managing the armature current. Nevertheless, the existence of commutator segments and carbon brushes of DC motor requires proper maintenance, which is a possible challenge for maintaining the free drive and rugged system [3].

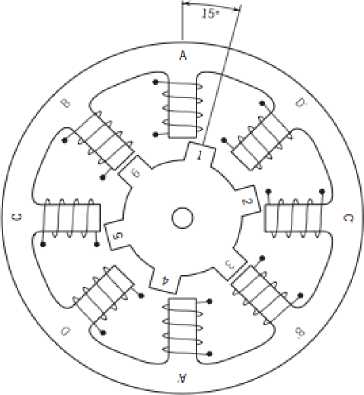

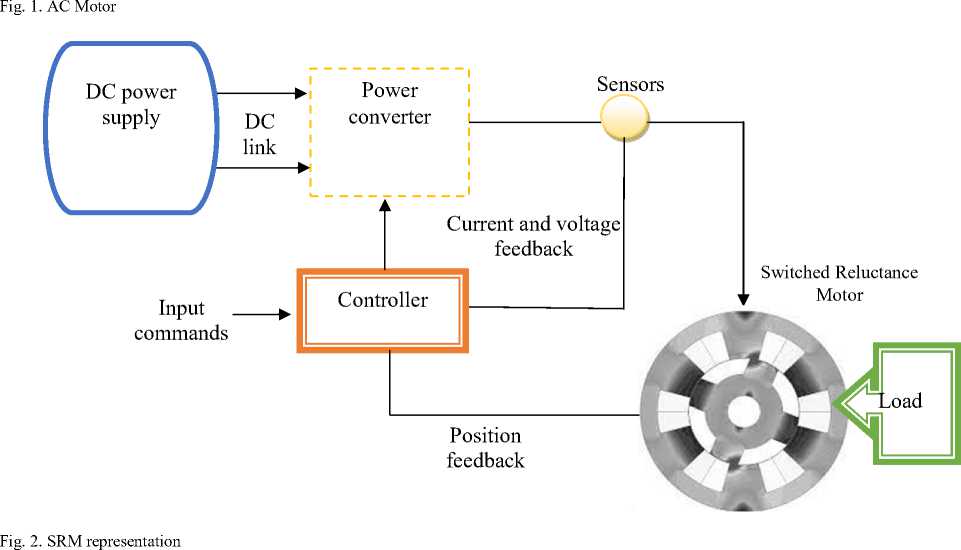

The AC motors like synchronous motors, induction motors, etc., are more rugged than DC motors and required comparatively low maintenance, which makes them more inspired in the electric drive field. The AC motors are initially employed for specific speed drives due to the lack of differentiable frequency in AC supply [4]. These AC motors are often employed for fluctuated speed drives through the enlightened power electronics technology and development of power electronic switching devices with high-speed power. Though, the traditional control mechanisms have not attained satisfactory performance due to many coupled multi-variable frameworks of the AC motors [5]. The AC motors are effectively controlled through the continuous enhancement in power electronics along with the application of recent control techniques for handling complex systems [6]. The vector control or field-oriented control technique is an elegant and popular technique of modern control methods. These control approaches are used for transforming the mathematical model of the AC motor to a simpler structure such as a DC motor, and so the entire set of control tools for DC motors permits to use for the AC motors. Thus, AC motors are now considered as the essential element of the industry [7]as shown in the Fig:1.

Special sorts of motors like BLDC motor, SRM and SRD are advanced in latest years, wherein BLDC motor is extensively used inside the statistics storage industry and low electricity programs whereas the high-electricity applications employ induction automobiles. [8]. Though, BLDC suffers from low starting torque and high cost. Therefore, a motor that can be utilized for both high and low power applications is more favourable. In addition, the SRD and SRM are more intensely employed [9]. Here, a reluctance machine is one of the categories of electric motor, which influences the non-permanent magnetic poles on the ferromagnetic rotor, where the torque is generated through the magnetic circuit of the motor for adopting the minimum reluctance configuration. It has also covered both synchronous and switched reluctance machines [9]. The SRM includes salient poles on both the stator and rotor with the operations such as "a variable-reluctance stepper motor except that the phase current is switched on and off when the rotor is at precise positions" that can be varied through the speed and torque. Moreover, these types of motors cannot perform without their electronic controller or drive, which are more suitable for both high and low power applications. This SRM is considered as an alternative solution for AC and DC motors in recent years due to the availability of microcontrollers, availability of high speed and high-power semiconductor switches for solving the complex control issues [9].

2. Literature Review

In 2023, Hayder Salim Hameed [10] has proposed fuzzy-logic approaches that revealed better effectiveness in various applications. The processing of speed control by a PI controller and a solution based on the usage of fuzzy adaptive systems was also defined. In 2022, F. Al-Amya [11] have developed the senseless speed control of 6/4 pole SRM drive based on the HO. It was composed of two modes such as the flux linkage sliding mode observer and the current sliding mode observer. A nonlinear method of SRM was implemented in Simulink/MATLAB. The position was estimated, and the speed errors were optimized using fuzzy-PID and ANFIS techniques. The experimental results were compared for three group speeds and the computed outcomes were differentiated with the simulated outcomes. The outcomes of electromagnetic torque ripple, position estimated error, and overall speed were differentiated, and its values were also defined in the table. It contained the benefits of high-precision speed control without any extra hardware and characteristics were enhanced.

In 2023, Pushparajesh et al. [12] have reduced the torque wave using Artificial Network Fuzzy Inference System because of direct torque conspires. The information bits were chosen for the testing and preparing process. The applicable energy and learning rate supported the weight variation. The Intelligent controller offered more power than the speed and motor torque and the rise time was minimized similar to the overshoot. The minimization in the blunder described that the voltage vector determination was precise and the results were better over a broad speed scope. The reenactment outcomes uncovered the fluctuation of torque swells for the changing drive speed and load torque. The experimental outcomes demonstrated that the torque ripple changed according to the speed. The equipment, as well as the recreation outcomes, delineated the controller efficiency.

In 2019, Mingyao Ma et al. [13] have proposed a new adaptive fuzzy control technique having segmented harmonic currents injection in the case of SRM. The conduction interval of every phase was divided into ‘n’ segments and the nth harmonic current was injected into the reference current of every phase. The harmonic current coefficient in every section was adjusted in an automatic manner using the fuzzy control scheme on the basis of the torque error. The present waveform could produce extra torque for dominating the torque ripple produced by the square wave reference current. Moreover, the new technique could attain adaptive control over a broad variety of angular velocities as well as load below the base speed. Additionally, the control technique was portable, flexible, and could be subjected to a majority of the SRM drive systems. The experimental, as well as the simulation outcomes, described that the torque ripple could be reduced efficiently using this technique in the real-time. In 2009, Gobbi et al. [2] have addressed a new technique known as the fuzzy iterative approach for modulating the phase current profile in reducing the torque ripples. The experimental outcomes demonstrated that the torque ripple was minimized among 5% of the desired steady torque in the dynamic functioning areas.

In 2003, Inanc and Ozbulur [1 4 ] have added a unique method for reducing the torque ripple of SRM that changed into dependent on the sum of the square of the phase currents with the assist of analog multipliers and two current sensors. Additionally, the SMC approach was subjected to the SRM speed control loop for compensating the low frequency oscillations. It adjusted the reference current value for maintaining steady motor speed. It became better than the fuzzy and PI controllers and turned into additionally sturdy to the outside disturbances. The outcomes described that the continuous sliding mode controller turned into efficient than the fuzzy or PI controllers in the torque ripple minimization of the motor that in turn compensated the nonlinear torque overall performance and made the drive insensitive to the parameter changes. As mutual inductances were composed of significant disturbance impact at the torque ripple, the proposed model was derived in their availability. It was used as an entire analog system for implementing the suggested algorithm. Further, the rotor position was sensed by a mechanical sensor. The experimental, as well as simulation outcomes, validated the suggested technique for the current measurements as well as the mutual and self-inductances.

The processing of speed control was done by a PI controller and a solution based on the fuzzy adaptive systems was also defined. In 2010, Liu et al. [4] have suggested a novel form of neural fuzzy controller for handling the conflict of minimizing the torque ripple in SRM that did not need the exact mathematical model and provided benefits over the existing PID control system. The simulation outcomes revealed that the neural fuzzy control scheme defined better performance in minimizing the torque dip and low frequency torque ripple and revealed the possibility and efficiency of the suggested strategy. In 2010, Sahoo et al. [15] have labelled a fundamental control problem in the SRM drives with the torque ripples. The reference phase current pattern was modulated using the fuzzy logic that compensated for the system nonlinearities such that the torque ripples were much decreased. The performance was validated using the computer simulation. In 2001, Rodrigues et al. [16] have developed a fuzzy-logic-oriented turn-off angle compensator for minimizing the torque ripple in an SRM. The turn-off angle was considered as a complex function of current and motor speed that was automatically varied for a broader motor speed range for the torque ripple minimization. The experimental outcomes demonstrated the ripple minimization when the turn-off angle compensator was employed. In 2000, Anwar M N, et al. [3] have addressed a novel technique for the motor current shaping for the torque ripple reduction by a neuro-fuzzy compensator. In the suggested technique, a compensating signal was included to the PI controller output. Numerical outcomes were described along with an investigation of the impacts of varying the membership function. In 2023, Pushparajesh et al. [12] have proposed an enhanced torque ripple reduction technique of an SRM with the help of TSF. In general, the TSF was subjected to the torque control. Yet, the traditional TSF could not follow the expected torque due to the nonlinear performance of the SRM. Further, the unexpected torque ripples were made by the tail current. It joined the FLC with the TSF. The benefit of this approach was that it could be handled at any conditions. Additionally, the controller tracked the torque below the wrong TSF. The efficiency was validated using the experiments and simulations.

PWM Based:

In 2001, Cai et al. [17] have proposed an optimized PWM control. Based on the motor running parameter information, the voltage ratio duty was forecasted precisely. Similarly, based on TSFs, the present profile was computed first and four different regions were described considering the referred current profiles.

The three different modes: freewheeling, non- magnetization and excitation were selected in a flexible manner based on the performance of the current profile. It was superior to the traditional PWM modulation with respect to the current ripple and the current searching performance was enhanced by not varying the hysteresis band or improving the switching frequency. The current ripple was described as the peak-to-peak value divided by the average value and this value was minimized by 40%. A comparison with respect to the copper loss and torque ripple was also proposed. The torque ripple was minimized through the introduced strategy below the saturation as well as the magnetic linear conditions. The copper loss and the torque ripple were minimized to an appropriate value. The efficiency and validity were checked using the experimental and simulation outcomes.

In 2002, Husain and Ehsani [18] have started with a detailed review of torque ripple minimization techniques and then labelled a novel scheme of PWM current control for the purpose of smoother drive operation. This technique involved a current control scheme during the process of commutation when the torque ripple reduction is of major significance.

3. Methodology

This effort has projected a new procedure to address the torque ripple, acoustic noise in SRM. The proposed research work has been implemented as below:

-

• The non-linearity or any change in the parameter of SRM is tackled by the FGS controller on the basis of the fuzzy rule-based scheme. The proposed method is developed in MATLAB/Simulink environment, in which controller selection of gain is significant in designing the phase that is carried out by trial-and-error method.

-

• A fuzzy logic controller is developed in MATLAB software to reduce the acoustic noise and radial force in SRM.

3.1. Proposed System

3.2. Srm Mathematical Model:

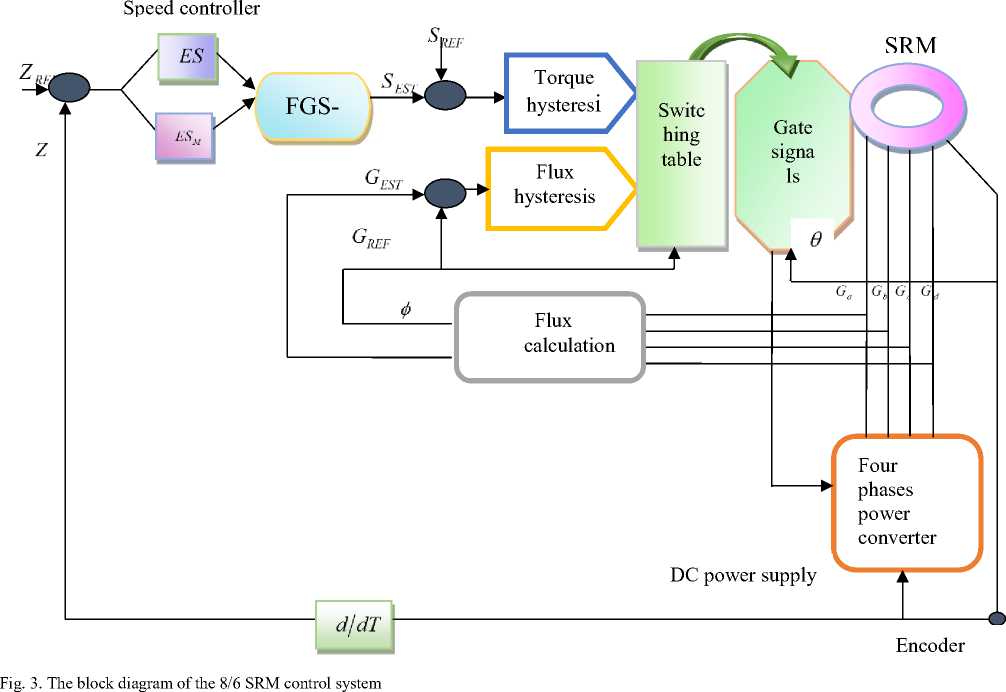

The overall performance of this system is enhanced, and the torque is evenly carried out by decreasing the torque ripple in the developed speed feedback system using DTS based FGS-PI controller. The proposed system has made the comparison between the actual speed and reference speed and then, the error signals are transferred to the speed controller. The estimated torque is generated in the proposed speed controller by employing the FGS-PI controller. Subsequently, the input parameters of the lookup table are considered as the flux linkages and estimated torque. The measurement of the current is required for evaluating the flux, and its respective torque is generated based on rotor position, flux linkages, and current. Both the torque and estimated flux are considered for comparison with their corresponding reference values. In addition, the encoder is employed to measure the rotor angle, which is correlated with the switch on and switch off angle for producing both on and off commands. This happens repetitively for three phases in a sequential order. The proposed system is influenced by the asymmetrical bridge converter, which helps in the excitation of phase separately by using the soft switching converter. The block diagram of the 8/6 SRM control system is diagrammatically represented in the Figure3 shown above.

The mathematical equation [1] for the SRM mentioned below is used for modelling of a controller. The torque of SRM with respect to flux linkages, rotor position, and current:

|

Tj - Torque of jth phase Wc - Co-Energy |

∂W c (i j ,l j ,L r ,θ) T j = ∂θ (1) T e = ∑ j n =1 T j (2) |

θ - Rotor position lj - Length of Air gap ij - Current of jth phase Lr - rotor Stack length Te - Electromagnetic torque

Finally the torques and the radial force is represented as

|

T e = 2μ0lgLrr. φ θ 2 2 (3) F = ∂Wc(ij.lj.Lr.θ) = K. ( -r . Lr .θ ) (4) n ∂L g 2μ 0 |

|

|

where, |

K = μ02.Np 2 h.ij2 (5) I g |

N ph – Turns per phase r – radius of rotor

3.3. Acoustic Noise of Srm

As circumferential difference is due to the acoustic noise, the result leads to radial force which is in N/m2. Therefore, the circumferential deflection is stated below: -

D circum(feXc) =

-^fcrMIm:)^ 2 2 2

if} 4 ^)

where,

D circum = Dynamic Deflection (m)

F n = Radial force (N/m2)

6 = Damping factor

Nrp = No. of rotor poles fp = Phase current’s Fundamental frequency (Hz)

fexc = Excitation frequency (Hz)

Rm = Stator yoke Radius hs = Height of Stator pole m, fm = Circumferential mode number and mode frequency

The sound radiated by the SRM in terms of power is stated below,

P — 4. Ure[. p. c. U . fexc . Dcircum’ Rout’ lstk where,

P = radiated sound power (w)

arel = Relative sound intensity k = Wave number

C = Speed of Sound (m/s) in the medium p.c = 415 N.s/m3 for air at 200C (p density of air)

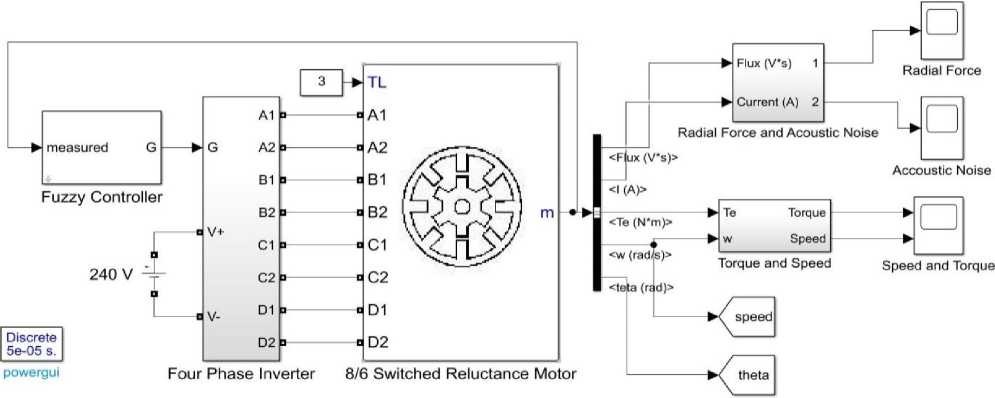

The software model using MATLAB/ Simulink for the proposed system is:

Fig. 4. MATALB/Simulink model

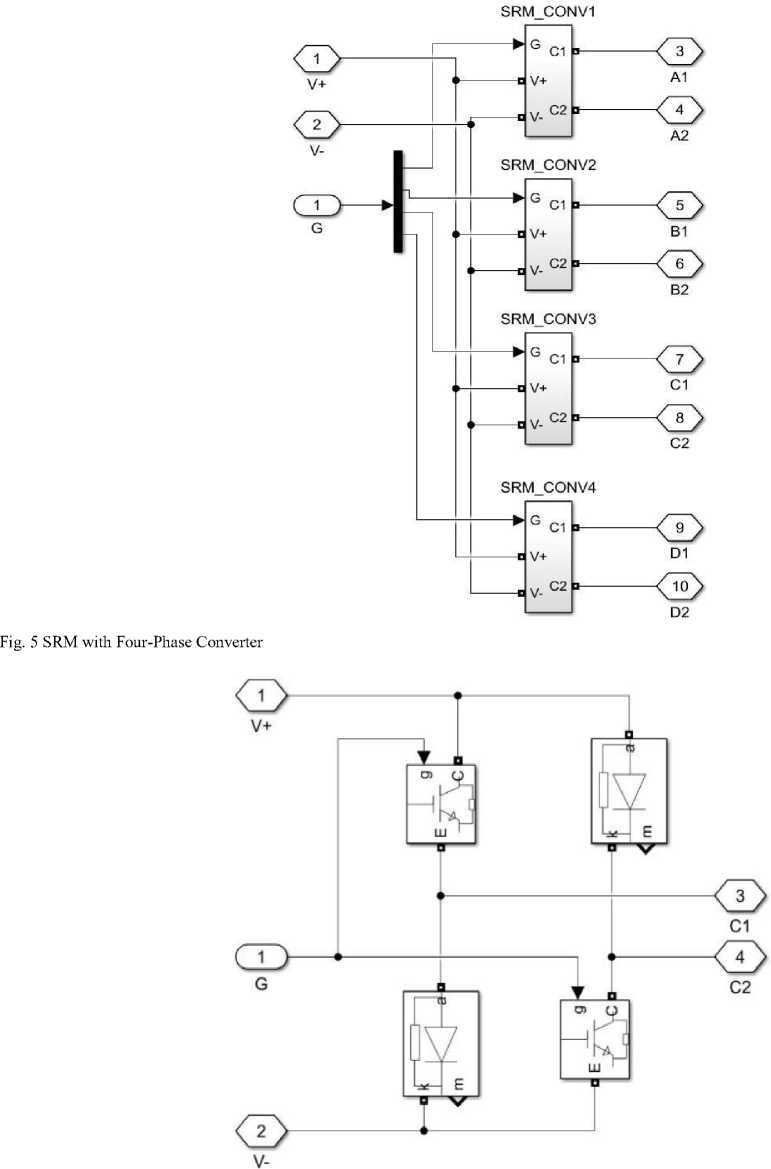

The 8/6 SRM version with 4-phase inverter that converts DC to four phases AC for the SRM is depicted. The already measured values are observed as feedback and fed to the fuzzy logic controller. The controller takes speed and current as input and correspondingly generates pulses to the SRM converter.

The freewheeling diodes using the four-phase converter:

Fig. 6. One phase of SRM using Single Phase Inverter

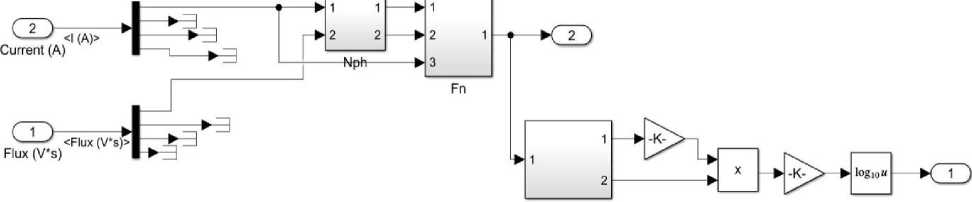

The pulses at the gate are given from the controller to the converter. the IGBT transistors are used as switches which can be useful for higher power applications. The freewheeling diodes protect the system from reverse current. The figure shown below is used for calculating and presenting acoustic noise and radial pressure. The model is constructed with the help of equations from (6) to (8). The Dcircum and the radial pressure power P and Fn are represented.

Dcircum

Fig. 7. Block diagram measuring radial force and acoustic noise.

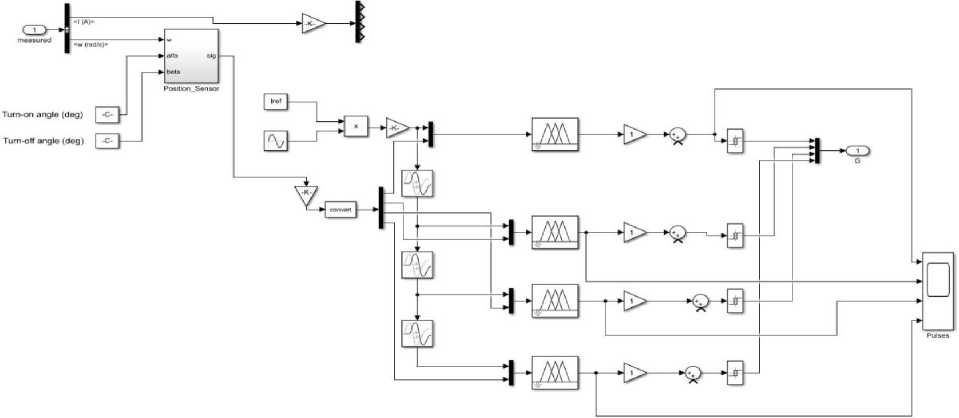

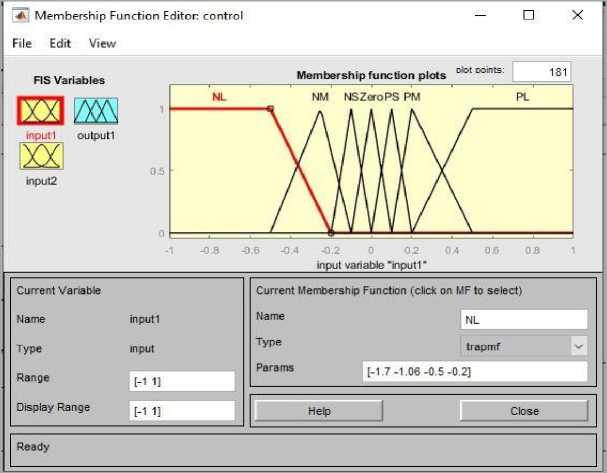

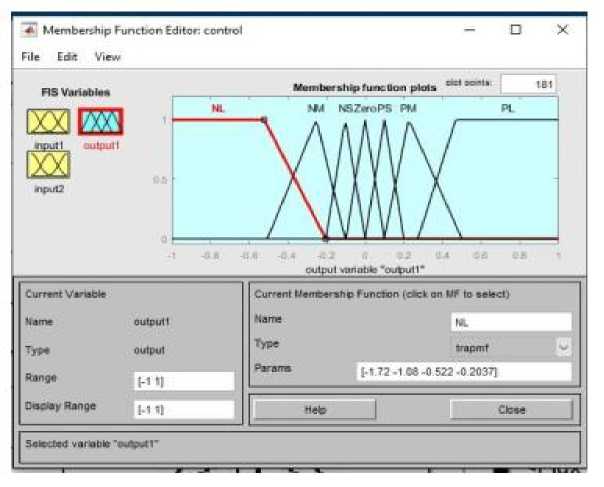

The controller using fuzzy logic method is shown underneath. The speed which is taken as input is converted to the current. The same current which is converted is compared with the actual current. This current will generate the gate pulses as input for the converted using fuzzy logic method. The output and the output of the fuzzy logic method shown below will generate the radial force and acoustic noise.

Fig. 8. Generation of pulses using Fuzzy controller

Fig. 9. Fuzzy controller with input block

Fig. 10. Fuzzy controller with output block

4. Results and Discussions

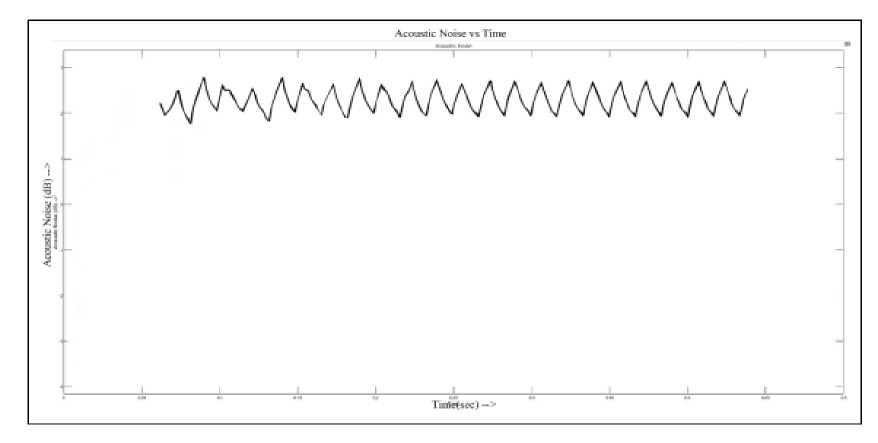

The SRM is an excellent motor because of its high efficiency and high power to torque ratio. But the demerit of the SRM is, it creates problems of high radial force and acoustic noise when it works in high speed. In this proposed method the SRM produces a very low noise level when it rotates at the speed of 1200 RPM. The outcomes and the comparisons with the existing methods are shown. The fuzzy logic parameter is chosen to increase the efficiency and accuracy.

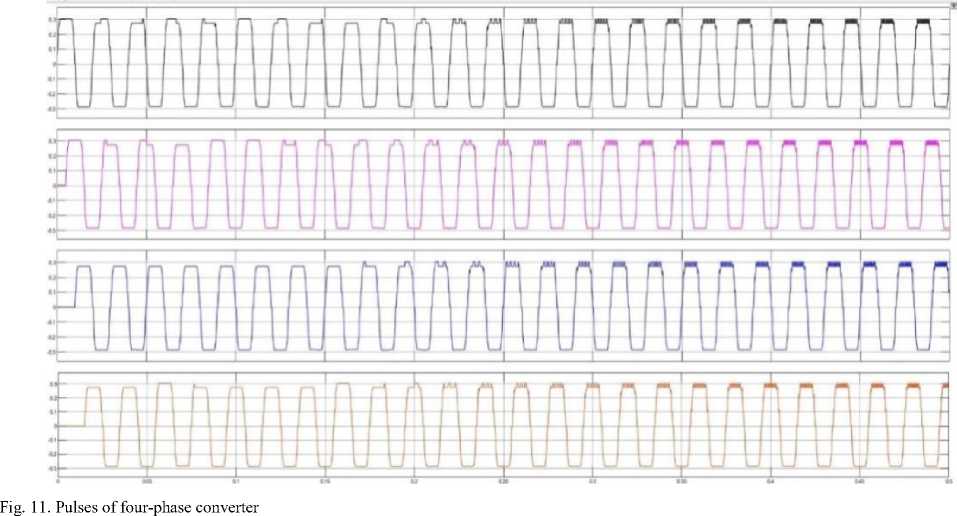

There is a shift of 60 degrees in the four phases. The gate pulses generated in this way are given to the converter to control the speed, torque ripple and the acoustic noise.

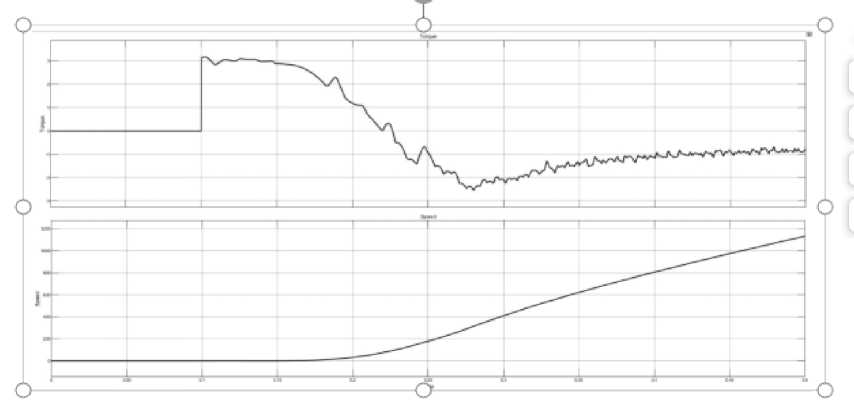

Fig. 12. SRM’s Torque and Speed

The graph represents the waveform for the torque and the speed at 1200 RPM. The torque attains the constant value as the speed also turns out to be constant. The SRM’s rotation is user predefined. The chosen value of load torque in the system is 3Nm.

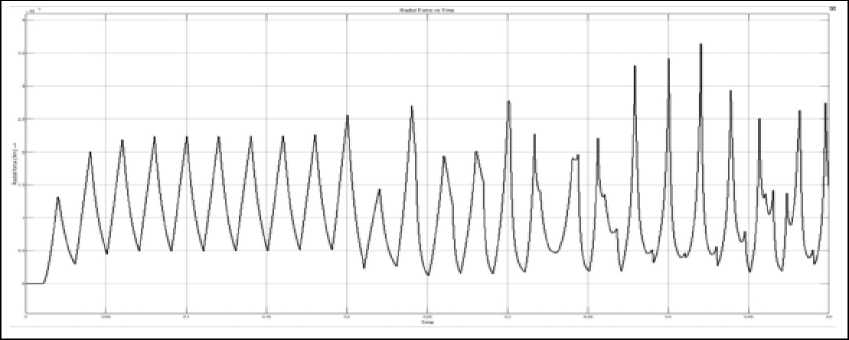

Fig. 13. SRM’s Radial force of 8/6

Fig. 14. SRMS’s Acoustic noise for 8/6

Table 1. Comparison table of Acoustic noise

|

Comparison |

Radial force |

Acoustic noise |

|

Existing paper [1] |

16x105 |

12 dB |

|

Existing paper [9] |

20x105 |

7.5 dB |

|

ProposedMethod |

3.5x105 |

2 dB |

From the comparison table of Acoustic noise, it is very well understood that the proposed method produces less radial force and acoustic noise. Hence it is stated, fuzzy logic controller minimizes the torque ripple by providing the speed at constant level with less acoustic noise and radial force.

5. Conclusion

The proposed method in this paper is an 8/6 SRM using MATLAB/Simulink for the minimization of acoustic noise and radial force is analyzed. The results in comparison with the existing controllers proved that the fuzzy logic controller which controls the speed and current of SRM has minimized the radial force and the acoustic noise. The simulation results proved that the high speed in SRM can be achieved with minimal acoustic noise.

Acknowledgment

The authors deeply appreciate the management of the oxford college of engineering for providing enabling environment to carry out this research.

Список литературы Control of Switched Reluctance Motor and Noise Reduction Using Fuzzy Controller in Matlab/Simulink

- “Acoustic Noise Reduction of Switched Reluctance Motor Drives”, by M Divandari, Middle East Journal of Scientific Research, ISSN 1990-9233, 2011

- Gobbi, R, 2009, “Fuzzy iterative Technique for Torque ripple minimization in SRM”, Electrical Power components and system, 982-1004.

- Anwar M N, 2000, “Radial force Calculation and acoustic noise reduction in SRM”, IEEE Transactions on Industry Applications, 1589-1597.

- Lin F C, “An approach to producing controlled radial force in SRM”, IEEE Transactions on Industrial Electronics, 2137-2146

- Cameron D E, 1992, “The origin and Reduction of Acoustic Noise in Doubly Salient Variable Reluctance Motor, IEEE Transactions on Industry Applications, 1250-1255

- Zhang J, 2009, “Nonlinear Radial force simulation of SRM based on finite element Model, IEEE International Conference 1678-1682

- Krishnan R, 2001, SRM Drives, Florida, CRC Press LLC

- Divandari M, 2007, “A Novel Sensor less SRM Drive via Hybrid Observer of current sliding Mode and Flux linkage”, IEEE International conference, 45-49

- Rekha P, 2021, “Torque ripple and noise control of SRM using adaptive fuzzy PI control with aid of AR algorithm”, International Journal of Power Electronics and Drive system, 1239-1251.

- Hayder Salim Hameed, Qasim Al Azze, Mohammed Saadi Hasan,2023, “Speed control of switched reluctance motors based on fuzzy logic controller and MATLAB/Simulink”,Indonesian Journal of Electrical Engineering and Computer Science Vol. 31, No. 2, August 2023, pp. 647~657 ISSN: 2502-4752, DOI: 10.11591/ijeecs.v31.i2.pp647-657.

- F. Al-Amyal, M. Hamouda, and L. Számel, “Performance improvement based on adaptive commutation strategy for switched reluctance motors using direct torque control,” Alexandria Engineering Journal, vol. 61, no. 11, pp. 9219–9233, 2022, doi: 10.1016/j.aej.2022.02.039.

- Pushparajesh et al,”Direct Torque Control Based Jelly Fish Algorithm For Torque Ripple Reduction in Permanent Magnet Synchronous Motor,Conference” 2023 International Conference on Network, Multimedia and Information Technology (NMITCON).

- Mingyao Ma et al,2020”Torque ripple suppression of switched reluctance motor by segmented harmonic currents injection based on adaptive fuzzy logic control”IET Electric Power Applications.

- Inanc, N., Ozbulur, V.: Torque Ripple Minimization of a Switched Reluctance Motor by using Continuous Sliding Mode Control Technique. Electric Power Systems Research 66(3), 241–251 (2003).

- Sahoo, S.K., Panda, S.K., Xu, J.-X.: Indirect Torque Control of Switched Reluctance Motors using Iterative Learning Control. IEEE Transaction on Power Electronics 20(1) (January 2005).

- W. Cai, P. Pillay, and Z. Tang, “Impact of Stator Windings and End-Bells on Resonant Frequencies and Mode Shapes of Switched Reluctance Motors”, IEEE Trans. on Industry Applications 38, 2002.

- Y. Cai and C. Gao, “Torque ripple minimization in switched reluctance motor based on BP neural network,” in 2nd IEEE Conference on Industrial Electrics and Applications, pp.1198-1202, 2007.

- Husain, I.: Minimization of Torque Ripple in SRM Drives. IEEE Transactions on Industrial Electronics 49(1) (February 2002).