Controlling the structural formation of porized cement composites in the production of thermally efficient enclosure structures of enhanced quality

Автор: Aleksei B. Steshenko, Aleksander I. Kudyakov, Aleksandr S. Inozemtcev, Sergei S. Inozemtcev

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 5 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Research to improve the quality of foam concrete products through targeted control of technological processes of structure formation of cement-based compositions is relevant. The strength of foam concrete is significantly influenced by the adhesion strength of the hardened cement paste to the aggregate. This article discusses methods of chemical and mechanochemical activation of foam concrete filler with glyoxal-containing additives, interaction with hydration products of binders and increasing the strength of the contact zone. The quality of foam concrete can be improved by controlling the properties of the contact zone. Materials and methods. The study was conducted using standard test procedures specified in national standards. Results. With preliminary chemical and mechano-chemical exposure of the sand surface to glyoxal-containing additives and its subsequent introduction into the foam concrete mixture the grade of strength of foam concrete increases to B1 while maintaining the average density grade D500 in comparison with foam concrete of the control composition, while the shrinkage value decreases by 20–38.5% and thermal conductivity coefficient by 37%. Conclusion. The use of glyoxal-based additives in foam concrete mixtures by pre-activating the sand surface can improve the quality of cement foam concrete.

Cement-based foam concrete, glyoxal-containing additives, structure formation, plastic shrinkage, porosity, compressive strength, average density, thermal conductivity coefficient

Короткий адрес: https://sciup.org/142238320

IDR: 142238320 | DOI: 10.15828/2075-8545-2023-15-5-408-417

Текст научной статьи Controlling the structural formation of porized cement composites in the production of thermally efficient enclosure structures of enhanced quality

Original article

In accordance with the concept for the development of the Russian construction industry until 2030, important tasks are the effective resource provision of housing facilities, including individual construction, with the maximum use of local raw materials, as well as reducing energy costs in the production of building materials and building maintenance. The optimal solution to the tasks set is to increase the thermal properties of enclosing structures, reduce the cost of construction, provide a comfortable and safe environment for living by using high-quality heat-insulating foam concrete for the construction of buildings. Heat-insulating foam concrete in wall structures provides good thermal protection of housing, the required load-bearing capacity and durability [1].

When producing non-autoclaved foam concrete with low average density, effective in terms of thermophysical parameters, problems arise in controlling the processes of ensuring a stable cellular structure, high strength, reducing drying shrinkage and thermal conductivity [2, 3]. It is necessary to scientifically substantiate and develop innovative ways to control structure formation in order to improve its quality for the widespread use of non-auto-

CONSTRUCTION MATERIALS SCIENCE claved foam concrete in the production of products and in monolithic construction [4].

Improving the physical and mechanical properties of foam concrete is achieved through the improvement or development of new technological methods that make it possible to regulate volumetric structure-forming processes at different scale levels, namely: at the micro level – the cement matrix; at the contact of interacting components, cement stone – aggregate; at the macro level – a durable frame made of fine aggregate (sand) [5].

Al components of foam concrete, regardless of the state of aggregation, participate in mechanical and physicochemical interaction during structure formation. The chemical activity of the surface of the grains increases and the process of interaction with the cement matrix at the phase interface is accelerated with controlled pre-activation of the filler. Chemical or mechanochemical activation of the foam concrete mixture filler using a structural-phenomenological analysis of the relationship between microstructural indicators and physical and mechanical properties allows us to predict the improvement of the main technological and technical parameters of the quality of foam concrete.

It has been established that treating the aggregate with aqueous solutions of acids leads to an increase in the chemical activity of the surface, the interaction of hydrate compounds of hardened cement paste with aggregate grains, and an increase in the microhardness of the contact zone and the strength of foam concrete [6, 7].

Currently, the issue of using modifying additives that affect the rheological properties of the cement matrix and the structure formation of the foam concrete mixture has been studied quite well [8–12]. Using modern modifying additives, they control the workability and setting time of the foam concrete mixture, reduce shrinkage, increase the homogeneity, and the strength of foam concrete up to 25% [9,13], reduce cement consumption by

10–15% [14–16]. The surface of the aggregate should be pre-activated to obtain the greatest effect from the action of modifying additives. The adhesion strength of the cement stone to the aggregate has a significant influence on the strength of foam concrete. [17]. The contact zone is the most important structural element of foam concrete, by controlling which it is possible to ensure the required quality parameters of the designed concrete.

In this work it is proposed to use crystalline glyoxal and a 40% aqueous solution of glyoxal for chemical and mechanochemical activation of the surface of quartzfeldspar sand. In the alkaline environment of hydrating cement, the glyoxal additive interacts with calcium hydroxide, which is formed as a result of the hydrolysis of alite, a cement mineral, with the formation of calcium glycolate (HO–CH2–COO)2Ca, increasing the volume of neoplasms and the foam concrete matrix [18–21]. Calcium glycolate is adsorbed on needle-shaped ettringite crystals, reducing the volume of pore space in the hardened cement paste and increasing strength [22, 23]. Based on this, it is assumed that by pre-activating the surface of aggregate grains with glyoxal additives and introducing them into the foam concrete mixture, it is possible to reduce porosity and increase the strength of hardened cement paste in contact areas with aggregate grains, which will improve the physical and mechanical parameters of the quality of foam concrete.

The purpose of the study is to establish the patterns of chemical and mechanochemical activation of filler with glyoxal additives on the structure formation and properties of cement foam concrete.

MARERIALS AND METHODS

The materials presented in table 1 were used carrying out the research.

Technical characteristics of glyoxal additives are presented in [1].

Table 1

Raw materials for foam concrete mixture

|

Material |

Compliance with the requirements of the regulatory document |

|

Portland cement CEM I 42.5N from Topkinsky plant |

Russian State Standards GOST 31108-2020 |

|

Quartz-feldspathic sand from the Kudrovskoye deposit in the Tomsk region with a fineness modulus of 1.8 |

Russian State Standards GOST 8736-2014 |

|

Foaming agent PB-2000 |

Technical Specifications 2481-185-05744685-01; Russian State Standards GOST 24211-2008 |

|

Tap water |

Russian State Standards GOST 23732-2011 |

|

40% aqueous solution of glyoxal (TH «Novokhim», Tomsk) |

Technical Specifications 2633-003-67017122-2011 |

|

Glyoxal crystalline (TH «Novokhim», Tomsk) |

Technical Specifications 2633-004-67017122-2011 |

CONSTRUCTION MATERIALS SCIENCE

Table 2

The basic composition of foam concrete for 1 m3

|

Consumption of raw materials per 1 m3 |

||||

|

cement, kg |

quartz-feldspathic sand, kg |

tap water, l |

foaming agent, l |

|

|

Basic composition D500 |

270 |

135 |

202 |

1.3 |

The physical and mechanical properties of foam concrete were determined in accordance with the requirements of national standards:

– testing and quality assessment of foam concrete (Russian State Standards GOST 25485–2019);

– average density (Russian State Standards GOST 12730.1-2020);

– compressive strength and quality assessment of a series of 6 samples (Russian State Standards GOST 101802012 and GOST 18105-2018);

– thermal conductivity using the ITS-1 thermal conductivity meter (Russian State Standards GOST 7076-99). The determination of plastic shrinkage was carried out according to the author’s method presented in [8].

The structure of pore volume of foam concretes was investigated using Quanta 200 3D Two-beam Scanning Electron Microscope. The images were obtained within the low vacuum mode at the stable accelerating voltage up to 20kV. In order to study porous structure of foam concrete mercury injection method was applied using Quantachrome 33 Porosimeter.

The basic composition of the foam concrete mixture was developed taking into account the requirements of Russian Standard SN 277-80 “Instructions for the production of cellular concrete products” (table 2).

The foam concrete mixture was prepared according to one-stage technology using a laboratory foam concrete mixer.

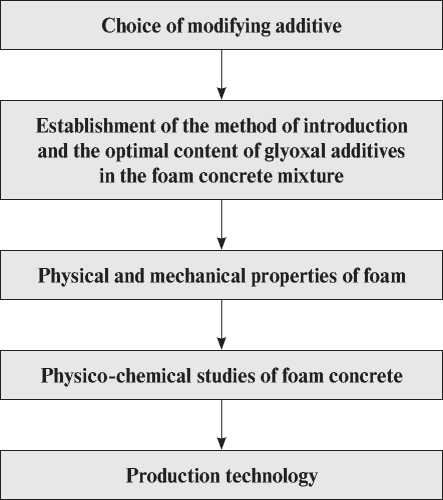

A block diagram of studies of improved quality thermal insulating cement based foam concrete modified with glyoxal additives was developed using the results of previous studies (fig. 1).

Scientific substantiation and choice of modifying additive

A positive effect was established when controlling the water demand, the kinetics of early structure formation and hardening of cement paste with a glyoxal additive according to the results of previous studies [1, 19, 23, 24]. That was the basis for choosing the additive to achieve this goal.

Establishment of the method of introduction and the optimal content of glyoxal additives in the foam concrete mixture

As a result of the analysis of various methods of preparation (activation) and the sequence of introducing components in the process of preparing a foam concrete mix-

Fig. 1. Block diagram of foam concrete research ture, taking into account the interaction of hardened cement paste with aggregate, it is accepted that the methods of separate or joint mechanical and chemical activation of the surface of the components are promising.

Two technological methods for the preparation and introduction of glyoxal-containing additives into the foam concrete mixture were scientifically substantiated to conduct experimental studies to establish the patterns of structure formation during the activation of the components:

– preliminary application of a 40% aqueous solution of glyoxal to the surface of the filler by spraying. Quartz sand was treated with a 40% aqueous solution of glyoxal by spraying with a spray gun and then introduced into the concrete mixer;

– dry quartz-feldspathic sand was ground in a mill together with crystalline glyoxal. Activation of the sand surface is carried out due to simultaneous compressive and shear deformation (abrasion), as well as the chemical interaction of the glyoxal additive with the surface of the filler.

CONSTRUCTION MATERIALS SCIENCE

RESULTS AND DISCUSSION

A foam concrete mixture with a mobility of 11–14 cm (the diameter of the flow on the Suttard device) and a W/T ratio equal to 0.5 was used during the research [8, 9, 25].

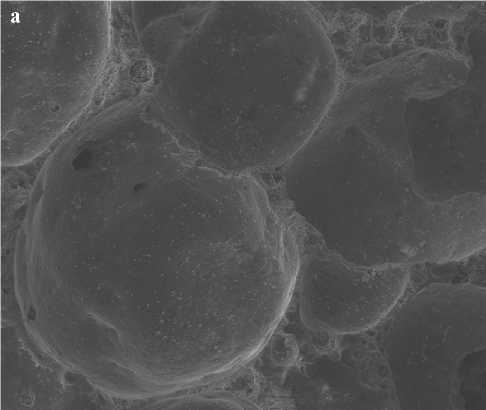

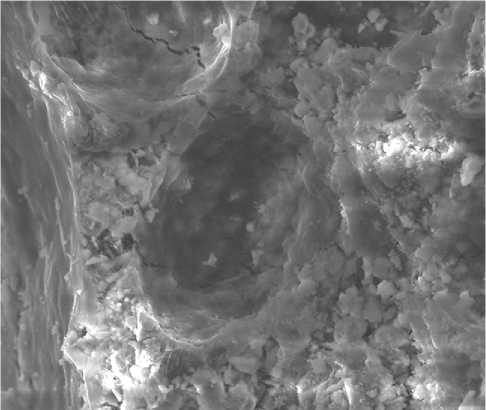

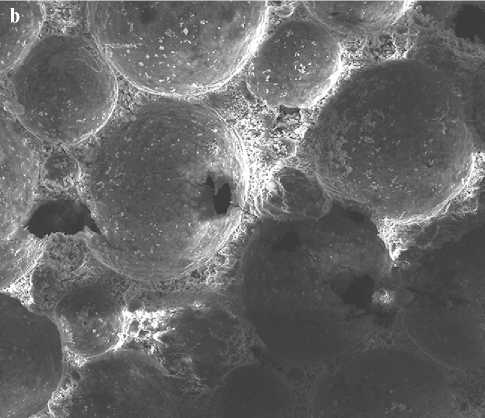

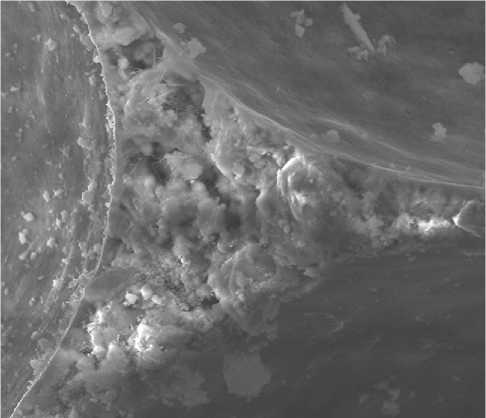

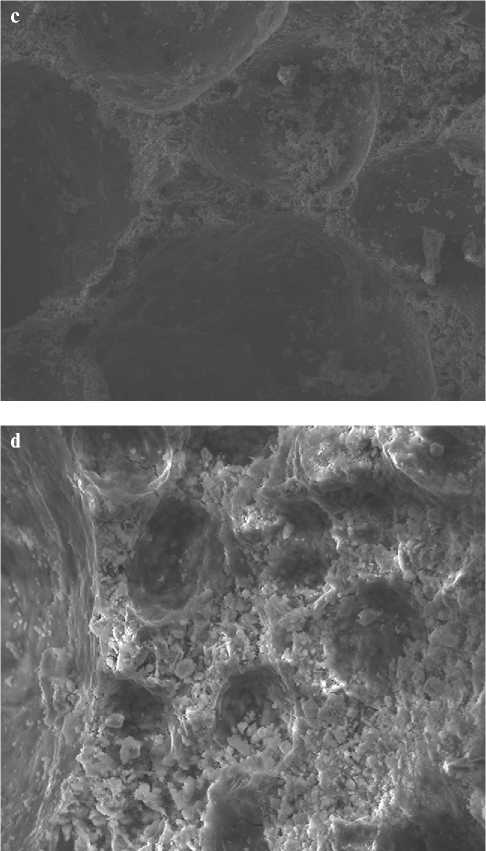

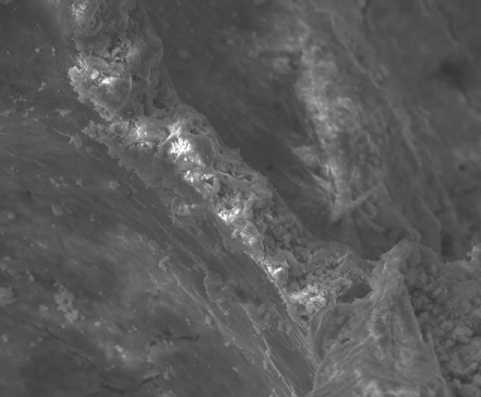

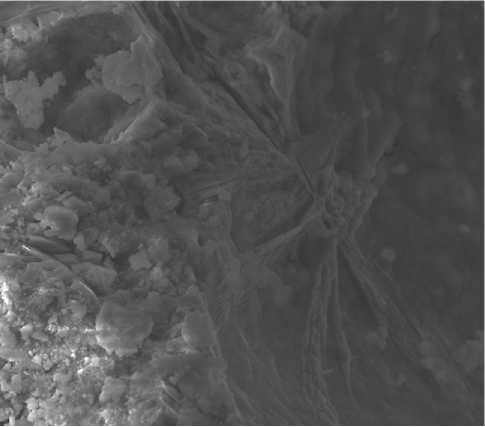

The results of the study of the structure of foam concrete, dried to a constant weight, with activated and nonactivated filler are shown in fig. 2.

A perforation and intensive destruction of the pore walls, as well as their association, are observed in the basic sample. It contributes to the development of the sedimentation process, a decrease in the homogeneity of the microstructure. It was found that foam concrete with chemical and mechanochemical activation has a more uniform structure, the pores evenly fill the entire volume of the material the, contact area of the cement matrix increases. Preliminary activation of sand contributes to the formation of a stable structure of foam concrete with closed fine pores.

The results of studying the structure of foam concrete with an activated sand surface are given in table 3.

According to the research results, it was established that the mechanochemical activation of sand by grinding with crystalline glyoxal leads to decrease the average pore diameter of foam concrete from 45.8 to 36.9 microns, the standard deviation of the average diameter from 23.6 to 12.1, and to increase the content of conditionally closed pores of foam concrete from 25.6% to 35.8% compared to samples without additives. It was also established that an increase in the polydisperse pore size distribution corresponds to a decrease in the quality of foam concrete.

The results of studies to determine the values of compressive strength and average density of foam concrete

Fig. 2. The structure of cement based foam concrete. On the left – zoom x250, on the right – zoom x2000: a) basic (reference) b) grinding sand with crystalline glyoxal 0.01%

CONSTRUCTION MATERIALS SCIENCE

Fig. 2. The structure of cement based foam concrete. On the left – zoom x250, on the right – zoom x2000: c) sand treatment with 40% glyoxal solution d) grinding sand with crystalline glyoxal 0.05%

Table 3

Porosity of foam concrete samples

|

Foam concrete with activated sand |

l^3 |

у 8 о a S 8 < 13 |

У о a о ю |

о OJ о |

'о 8 2 >> Н “ |

о й 9 о |

О § |

|

Basic (reference) D500 |

470 |

45.8 |

23.6 |

79.57 |

21.5 |

25.57 |

0.04 |

|

Sand treatment with 40% glyoxal solution |

480 |

40.1 |

22.5 |

77.89 |

15.6 |

25.17 |

0.03 |

|

Grinding sand with crystalline glyoxal 0.01% |

480 |

36.9 |

12.1 |

6.99 |

10.1 |

35.80 |

0.03 |

|

Grinding sand with crystalline glyoxal 0.05% |

487 |

39.2 |

18.9 |

77.06 |

13.7 |

28.80 |

0.03 |

Table 4

Statistical data on the average density of foam concrete

|

Type of foam concrete |

Average value, kg/m3 |

Concrete grade by average density |

Standard deviation |

The coefficient of variation, % |

|

Basic (reference) D500 |

470 |

D500 |

9.9 |

3.40 |

|

Sand treatment with 40% glyoxal solution |

480 |

D500 |

3.3 |

0.67 |

|

Grinding sand with crystalline glyoxal 0.01% |

480 |

D500 |

2.6 |

0.54 |

|

Grinding sand with crystalline glyoxal 0.05% |

487 |

D500 |

4.6 |

1.30 |

CONSTRUCTION MATERIALS SCIENCE and mechanochemical activation of sand with glyoxal additive.

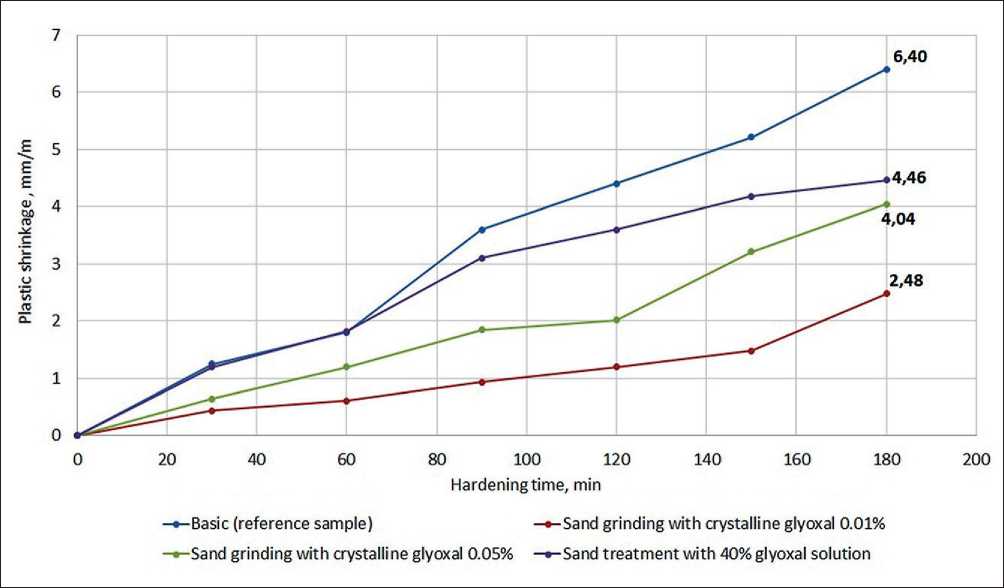

At an early age, when the mixture is still plastic, evaporation of free water from the surface of concrete and plastic shrinkage are the main factors of crack formation. Plastic shrinkage measurements were carried out over 3 hours.

The plastic shrinkage of the foam concrete mixture is reduced by 61% compared to the control sample (fig. 4) with the combined mechanochemical activation of sand with crystalline glyoxal in an amount of 0.01% by weight of cement. The reason for the higher shrinkage of the samples is the perforation of the walls and increased heterogeneity of the pores.

A significant reduction in shrinkage deformations during natural hardening of foam concrete makes it possible to predict a reduced level of stress formation during structure formation in the volume of foam concrete and, as a result, increased operational reliability of products made from this material [2, 16, 25].

The thermal insulation properties of foam concrete are affected by the total volume, size and uniformity of pore distribution in the foam concrete. According to the results of studies of the structure and average density, foam concrete with sand activated by glyoxal additives has a more uniform structure. According to the test results given in table 6, the values of the thermal conductivity coefficient change in accordance with the grade of average density of

Fig. 4. Influence of the method of sand activation using glyoxal additives on plastic shrinkage of foam concrete mix

Table 5

Statistical data on the compressive strength of foam concrete

|

Type of foam concrete |

Average value, MPa |

Compressive strength grade |

Standard deviation |

The coefficient of variation, % |

|

Basic (reference) D500 |

0.9 |

В0.5 |

0.055 |

10.5 |

|

Sand treatment with 40% glyoxal solution |

1.28 |

В1 |

0.120 |

9.2 |

|

Grinding sand with crystalline glyoxal 0.01% |

1.5 |

В1 |

0.048 |

7.1 |

|

Grinding sand with crystalline glyoxal 0.05% |

1.0 |

В1 |

0.056 |

7.6 |

CONSTRUCTION MATERIALS SCIENCE foam concrete, which is explained for the foam concrete matrix by the homogeneity of the porous structure.

As follows from the table 6 that the lowest thermal conductivity coefficient (0.063 W/m•oC) has foam concrete on sand activated by joint grinding of sand with crystalline glyoxal in an amount of 0.01% by weight of cement.

Preliminary activation of the sand surface with glyoxal additives makes it possible to produce cement foam concrete with improved quality parameters.

CONCLUSION

1. Electron microscopic studies have established that the average pore diameter in foam concrete with the preliminary activation of the surface of sand with crystalline

glyoxal decreases from 45.8 to 36.9 µm, the standard deviation of the average diameter decreases from 23.6 to 12.1, and the content of conditionally closed pores increases from 25.6% to 35.8% compared to samples without additives.

-

2. The shrinkage of the foam concrete with a preliminary physical and chemical effect of additives on the surface of the filler and its subsequent introduction into the foam concrete mixture decreases by 30–61%.

-

3. The coefficient of variation of the average density of foam concrete decreases from 3.4 to 0.6% and the compressive strength of foam concrete from 10.5 to 7.1% in foam concrete with glyoxal additives, as a result the grade of strength of foam concrete increased to B1 while maintaining the grade of average density D500.

Table 6

The values of the coefficient of thermal conductivity of foam concrete samples

|

Type of foam concrete |

Thermal conductivity coefficient, W/m • oС |

|

|

at a humidity of 25% |

in dry condition |

|

|

Basic (reference) D500 |

0.20 |

0.100 |

|

Sand treatment with 40% glyoxal solution |

0.17 |

0.081 |

|

Grinding sand with crystalline glyoxal 0.05% |

0.17 |

0.070 |

|

Grinding sand with crystalline glyoxal 0.01% |

0.16 |

0.063 |

Список литературы Controlling the structural formation of porized cement composites in the production of thermally efficient enclosure structures of enhanced quality

- Kudyakov A.I., Simakova A.S., Steshenko A.B. Сement based compositions with complex modifying additives based on glyoxal. The Russian Automobile and Highway Industry Journal. 2021; 18(6): 760-771. https://doi.org/10.26518/2071-7296-2021-18-6-760-771

- Klemczak, B., Gołaszewski, J., Cygan, G., Smolana, A., Gołaszewska, M. Analysis of methods reducing early age shrinkage of ultra-light foam concrete with phase change material. International RILEM conference on synergizing expertise towards sustainability and robustness of cement-based materials and concrete structures. SynerCrete. 2023; 43. https://doi.org/10.1007/978-3-031-33211-1_102

- Guanzheng Zh., Ray Kai L.S. A review on durability of foam concrete. Buildings. 2023; 13: 1880. https://doi.org/10.3390/buildings13071880

- Markin V., Nerella V.N., Schröfl C., Guseynova G. and Mechtcherine V. Material design and performance evaluation of foam concrete for digital fabrication. Materials. 2019; 12: 2433. https://doi.org/10.3390/ma12152433

- Korolev E.V., Grishina A.N., Inozemtcev A.S., Ayzenshtadt A.M. Study of the kinetics structure formation of cement dispersed systems. Part I.. Nanotechnologies in Construction: A Scientific Internet-Journal. 2022; 14(3): 176-189. https://doi.org/10.15828/2075-8545-2022-14-3-176-189

- Gencel O., Bilir T., Bademler Z., Ozbakkaloglu T. A detailed review on foam concrete composites: ingredients, properties, and microstructure. Appl. Sci. 2022; 12: 5752. https://doi.org/10.3390/app12115752

- Eliseeva, N., Eliseev, N. Regulation of foam stability for non-autoclave foam concrete with additives of colloidal nature. International Scientific Siberian Transport Forum TransSiberia. Lecture Notes in Networks and System. 2021; Vol. 402. https://doi.org/10.1007/978-3-030-96380-4_15

- Steshenko A.B., Kudyakov A.I., Ryabtseva N.E. Cement based foam concrete with hardening accelerators. IOP Conf. Ser.: Mater. Sci. Eng. 2020; 911: 012003. https://doi.org/10.1088/1757-899X/911/1/012003

- Steshenko A.B., Kudyakov A.I., Lukyanchikov S.A., Nasyrov V.A. Construction and heat-insulating foam concrete with the use of drilling sludge. AIP Conf. Proc. 2022; 2696: 020008-1–020008-5. https://doi.org/10.1063/5.0117016

- Song N., Li Zh., Yi W., Wang Sh. Properties of foam concrete with hydrophobic starch nanoparticles as foam stabilizer. Journal of Building Engineering. 2022; 56: 104811. https://doi.org/10.1016/j.jobe.2022.104811

- Hao Y., Yang G., Liang K. Development of fly ash and slag based high-strength alkali-activated foam concrete. Cement and Concrete Composites. 2022; 128: 104447. https://doi.org/10.1016/j.cemconcomp.2022.104447

- Kim D.V., Bazhenova S.I., Nguyen T.Ch., Tang V.L., Do M.Ch., Le V.L., Hoang M.Th. Insulation properties and performance of foam concrete using blast furnace slag. Structural integrity and life. 2022; 22 (1): 48–56.

- Dien V.K., Ly N.C., Lam T.V., Bazhenova S.I. Foamed concrete containing various amounts of organicmineral additives. IOP Conf. Series: Journal of Physics: Conf. Series. 2019; 1425: 012199. https://doi.org/10.1088/1742-6596/1425/1/012199

- Xiong Y., Pang B., Liu Zh., Liu Ch., Hu Zh, Liguo Ma L. Effect of foam temperature on foam stability of foamed concrete and stabilization mechanisms. Journal of Building Engineering. 2023; 77(6):107492. https://doi.org/10.1016/j.jobe.2023.107492

- Gökçe M., Toklu K. Ultra-low density foam concrete production using electrolyzed water. Journal of Testing and Evaluation. 2022; 50: 2. https://doi.org/10.1520/JTE20210224

- Mansyur, Tjaronge M.W., Irmawaty R., Amiruddin A.A. Early age of volume weight, indirect tensile strength and tensile elastic modulus of foam concrete containing blended cement. IOP Conf. Ser.: Earth Environ. Sci. 2022; 1117: 012025. https://doi.org/10.1088/1755-1315/1117/1/012025

- Кудяков В.А., Кудяков А.И., Лукьянчиков С.А., Кудяков К.Л. Управление технологическими процессами производства модифицированных бетонов. Вестник Томского государственного архитектурно-строительного университета. 2017. №6 (63). С. 147–157. [Kudyakov V.A., Kudyakov A.I., Lukyanchikov S.A., Kudyakov K.L. Control of technological processes for the production of modified concrete. Vestnik of Tomsk State University of Architecture and Building. 2017; 6(63): 147–157. (In Russian)].

- Gorlenko N.P., Sarkisov Yu.S., Volkova V.A. Kul’chenko K. Structurization processes in the system cement–water with chemical addition of glyoxal. Russian Physics Journal. 2014; 57 (2): 278-284. https://doi.org/10.1007/s11182-014-0236-4

- Simakova A., Kudyakov A., Efremova V., Latypov A. The effects of complex glyoxal based modifiers on properties of cement paste and hardened cement paste. AIP Conference Proceedings. 2017; 1800: 020006. https://doi.org/10.1063/1.4973022

- Fratzke A.R., Reilly P.J. Kinetic analysis of the disproportionation of aqueous glyoxal. IJCK. 1986;18757–773.

- Kudyakov A.I., Steshenko A.B. Study of hardened cement paste with crystalline glyoxal. Key Engineering Materials: Multifunctional Materials: Development and Application. 2016; 683: 113–117. https://doi.org/10.4028/www.scientific.net/KEM.683.113

- Salomaa P. The kinetics of the Cannizzaro reaction of glyoxal. Acta Chemica Scandinavica. 1956;10(2): 311–319.

- Кудяков А.И., Симакова А.С., Кондратенко В.А., Стешенко А.Б., Латыпов А.Д. Влияние органических добавок на свойства цементного теста и камня. Вестник Томского государственного архитектурно- строительного университета. – 2018. – Т. 20 (6): 138–147. [Kudyakov A.I., Simakova A.S., Kondratenko V.A., Steshenko A.B., Latypov A.D. Cement paste and brick properties modified by organic additives. Vestnik of Tomsk State University of Architecture and Building. 2018; 20(6): 138–147. (In Russian)].

- Sokolova Y., Ayzenshtadt A.M., Strokova V.V. Evaluation of dispersion interaction in glyoxal/silica organomineral system. Journal of Physics Conference Series. 2017; 929(1): 012110. https://doi.org/10.1088/1742-6596/929/1/012110

- Steshenko A.B., Latypov A.D., Ryabtseva N.E. The deformation characteristics of the modified heat-insulating foam concrete. J. Phys.: Conf. Ser. 2020; 1611: 012046. https://doi.org/10.1088/1742-6596/1611/1/012046