Cultural and technological characteristics of Russian forged iron tools from the Selkup cemetery Migalka in the Middle Ob basin

Автор: Chindina L.A., Zinyakov N.M.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.48, 2020 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145510

IDR: 145145510 | DOI: 10.17746/1563-0110.2020.48.3.090-098

Текст обзорной статьи Cultural and technological characteristics of Russian forged iron tools from the Selkup cemetery Migalka in the Middle Ob basin

The southern (central) group of the Selkups who belong to the Samoyedic people is the indigenous population of the Middle Ob region, where they settled compactly in the Narym region of the Ob and were scattered among the Turkic population in the Tomsk region of the Ob. These lands were included into the Russian State in the late 16th–early 17th century after the defeat of the military and political union of the southern (central) Selkups of the Skewbald Horde and building the Narym and Ket forts

(1596 and 1602). The Middle Ob (Narym) Selkups were obliged to pay the tribute (Selkupy…, 2011: 6–24; Pelikh, 1981: 8–11; Chindina, 2013: 91–94).

Archaeological studies of the Late Medieval sites in the Narym region of the Ob, carried out by A.P. Dulzon (1953, 1955), L.A. Chindina (1975, 2001, 2004), A.I. Bobrova (2007, 2016), L.M. Pletneva (1990), N.V. Berezovskaya (2010), and Y.I. Ozheredov (1998, 2001) yielded a wide range of iron objects, which have a great value in solving historical and cultural problems of the communities under research. Therefore, it is crucial

to study specific features of ferrous metallurgy and production of iron products in each case.

This article discusses the evidence from the Migalka cemetery located in the Narym part of the Middle Ob region, near the village of Yurty Inkiny, in the Kolpashevsky District of the Tomsk Region. L.A. Chindina investigated this site in 1989–1992. Seventy-four undisturbed burials and about thirty destroyed burials were identified. The complex of items found in the burials consisted of pottery, personal adornments, and household implements. The collection contains the objects not only of local production, but also those made by Russian and foreign artisans, including knives, axes, metal dishware, boots, personal ornaments, various fabrics, elements of horse harness, weaponry, coins from the reign of Tsars Mikhail Fedorovich, Alexei Mikhailovich, and Peter I, as well as counting tokens of the Nuremberg medalists. The site was dated to the last quarter of the 17th–first third of the 18th century (Chindina, 2004).

The Migalka cemetery is interesting for its originality and rich information. A relatively short period of its existence (60–70 years) makes it possible to order the chronology of long-term sites in the region and more reliably reveal the dynamics of historical and cultural processes. The Migalka site manifests the final stage of the Russian colonization of Siberia, which occurred under the influence of Peter I’s reforms, which makes it possible to establish the features and forms of cultural adaptation and integration of the Selkup society.

Analysis of knives and axes

This article explores the category of items—knives and axes—which are indicative of the social status and are indispensable to the life support system. Their technological study was carried out using metallographic and X-ray structural analyzes, the results of which have been partially published (Zinyakov, 2002: 142–147, fig. 14).

Knives were the most common finds at the cemetery after pottery and personal ornaments, and consisted of 32 items from 74 graves. They were absent in children’s burials (a ban up to 4–5 years of age). All knives were single-edged. The length of the blade varied from 9 to 15–16 cm; their width ranged from 1.5 to 2.7 cm, and thickness reached 0.4 cm. The knives were equipped with wooden, rarely burl handles, oval in cross-section. In eight cases, the wooden base had a metal frame. The handle was mounted on an iron wedge-shaped haft, sometimes with a tang. Two groups with variants can be distinguished according to their morphological features (shape of the blade and tang, specifics of their juncture). In the first group, blades have straight back and blade, converging at acute angle; sometimes, the blade bends smoothly or sharply at the end. The handle is coaxial to the blade. These knives have two ledges in the area of transition to the tang. In the second group, the back of the blade and tang form a single smooth arch. There is one ledge in the area of transition to the tang on the side of strictly straight blade.

Judging by visual morphological features, knives with the “humped” backs go back to the daggers of the Turkic period (Gryaznov, 1956: 101, pl. XXXII, 1 , 12 ; Molodin, Sobolev, Soloviev, 1990: 69, fig. 52). The Relka, Odintsovo (Upper Ob), Ulan-Koba, and other warriors of the Early Middle Ages used these knives as daggers in the forest Middle Ob region, forest-steppe Altai, and the Altai Mountains (Gorbunov, 2006: 210, fig. 45, 65; Chindina, 1977: 25, fig. 5, 6). The multifunctionality of “humpbacked” knives provided the warrior with a convenient weapon for hunting in everyday life, and this type became to be used for centuries in the working life of fishermen and hunters in the Middle Ob region.

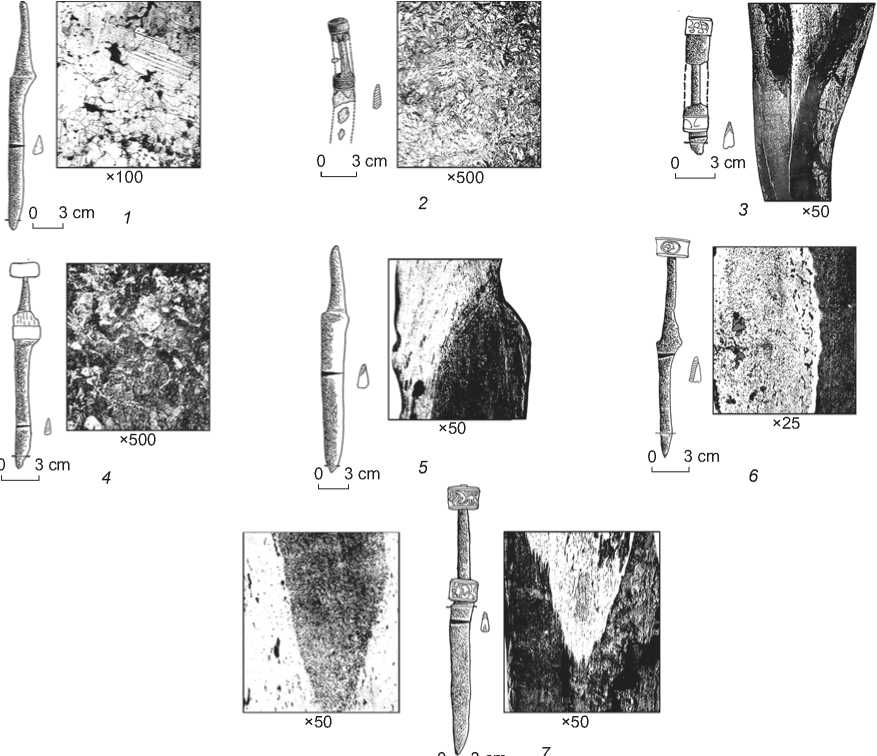

The seven best-preserved specimens were subjected to metallographic analysis. Two of them had solid wooden handles, and five were additionally equipped with lower hilt plates (bolsters) and pommels made of copper alloys. The bolster of the handle was located at its junction with the blade. The pommel fastened the end of the tang. They tightened all elements attached to the tang, strengthened the wooden parts, and generally ensured reliability of the knife’s structure. In addition, the bolster and pommel also had a decorative function. They had a smooth surface, sometimes with edging grooves or braids (Fig. 1, 1 ), or were decorated with engraving (Fig. 1, 2 , 3 , 7 ) and filigree enamel (Fig. 1, 6 ; 2). For obtaining the line of the needed width and depth, an engraving was carried out with different types of cutters. Professional carvers created complete and highly artistic images in the style of volute-like ornamental decor on each facing element of the handle.

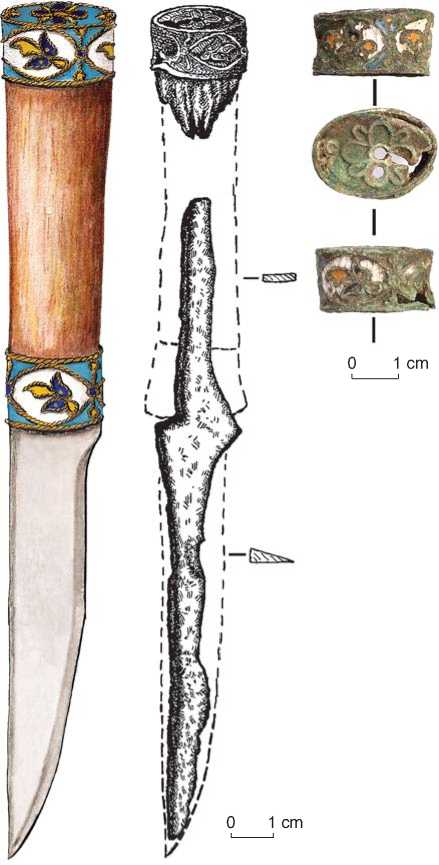

One of two knives with frames and handles decorated using the filigree-enamel technique, which were found in the cemetery, was metallographically analyzed. That knife was discovered in burial 69 (see Fig. 1, 6 ). The filigree was made by soldering very thin wire twisted in half on the surface of the bolster and pommel. The cells of the artistic composition were filled with colored enamel. Ornamentation consisted of three medallion-ovals against a blue enamel background along the entire ring of the hilt plate and pommel. The ovals are filled with white enamel; a three-petal lily is represented in the center; its side petals are blue; the central petal is yellow. The medallions are separated by a filigree vertical braids with three small circle buds filled with yellow and blue enamel. The composition is completed by two horizontal cord-edges (see Fig. 2). The lid of the pommel is decorated with a filigree pattern in the form of an oval with the eight-petal rosette in the center and two small lilies on its sides. The

3 cm

Fig. 1 . Knives: technological designs and microstructures.

1 – burial 10, analysis 1368; 2 – burial 9, analysis 1371; 3 – burial 19, analysis 1372; 4 – burial 13, analysis 1378; 5 – burial 48, analysis 1370; 6 – burial 69, analysis 1367; 7 – burial 10, analysis 1369.

enamel on the pattern has been severely crumbled and only a piece of the blue background has survived.

A significant number of items with enamel decoration were found at Migalka, including rings (and seal-rings), golubtsy (“dove-like”) earrings, as well as the abovementioned knives. The parallels to these knives occur in the materials from other burial sites of the Middle Ob region, including Mysovskoy site (late 13th–first third of the 18th century) on the same Shudelka River (left tributary of the Ob River) (Chindina, 1986) and Kolymukhta site (17th–20th centuries) (Berezovskaya, 2010) on the anabranch of the same name (on the right bank of the Ob River), near the village of Nazino and the town of Strezhevoy. The exact same knives have been found at the Kiki-Akki cemetery in the Upper Taz area (Poshekhonova et al., 2018). They are not inferior to the Migalka knife in terms of sophistication of their décor, and most importantly, they emphasize a wide geography of prestigious and expensive items similar in manufacturing technology and artistic decoration. According to customs books, in 1668–1670, similar knives cost 2 rubles 10 kopecks (Merzon, Tikhonov, 1960: 424). Notably, parallels to the knives with engraved patterns on the frames have been found at the cemeteries of Balagachevo (Dulzon, 1953) and Bergamak II (Tataurov, Tikhonov, 1996: 74, fig. 7).

Specific aspects of manufacture technology and artistic processing of the Migalka knife indicate that it belongs to the goods imported “from Rus’” to Siberia from the late 17th to 18th centuries (Chindina, 2004). In the period under study, there were a number of urban centers with long traditions in development of the applied art of filigree and enamel in the Russian State. Their products were distinguished by artistic features expressed in a specific composition of ornamentation, typology of motifs, and set of colors. A comparison of the enamel items from Migalka with Russian enamels directly indicates their belonging to the Solvychegodsk and Ustyug schools of filigree-

Fig. 2 . Remains of a knife with enamel hilt plates from burial 69, and its reconstruction by L.A. Chindina (drawings by E.V. Ryltseva and L.V. Chernaya, photographs by

E.V. Barsukov).

makers and enamelers, who typically used a special basic background color (white in Usolye, and blue or light blue is Ustyuzhye) and a variety of colors in the pattern. The palette changed over time: mainly blue, green, and light blue colors appeared in the enamels of the “Usolsk and Ustyug production” in the 16th century, while yellow and yellow-orange, borrowed from the German enamel-makers, became widespread in the 17th century (Postnikova-Loseva, 1959: 581–582; Postnikova-Loseva, Platonova, 1959: 52–54, 57, 59). The central motifs were always emphasized in the composition of the ornamental décor on the Ustyug enamels at the turn of the 17th– 18th centuries, and the secondary elements were subjected to the central motif (Mukhin, 1996: 90). The superposition of tiny contrasting dots on the main pattern is also typical of the Northern Russian and Moscow centers of enamel production.

Direct parallels to the knife from burial 69 at the Migalka cemetery are knives from a set of cutlery made by Ustyug craftsmen in the late 17th to first third of the 18th century, which belonged to merchants-entrepreneurs, later barons, the Stroganovs (State Historical Museum funds: OK 730, State Historical Museum, Inv. No. 43945). They are also distinguished by a special shape of the handle and specific technique for decorating its frame, including filigree enamel, lush flower rosettes, lilies, and multicolored enamels on a snow-white background*.

Metallographic analysis of a collection of knives from the Migalka cemetery has revealed the use of two technological patterns: production entirely of steel (3 spec.) (see Fig. 1, 1 , 2 , 4 ) and production of welded structures (4 spec.) (see Fig. 1, 3 , 5–7 ). Raw steel with an uneven distribution of carbon in the metal was used as the raw material for the products of the first technological group in two cases, and high-carbon steel in one case. Quenching was used for hardening (see Fig. 1, 2 , 4 ). The microstructure of the hardened metal is structureless martensite, martensite with bainite, and bainite. The microhardness of martensite was 659–713 kgf/mm2, that of bainite was 356 kgf/mm2. This group includes knives with the “humped” backs. Notably, such knife-daggers sometimes had expensive cladding (hilt plates) typical of the Russian-made products. This can be explained

in two ways: either local craftsmen used Russian décor in manufacturing traditional knives, or Russian craftsmen adopted a new type of products, popular in the local market, continuing to make prestigious and very expensive cladding. It is also curious that the hilt plates from the knives that went out of service were kept: in burial 29 they were placed in a box, while the hilt plates of the knife from the male burial (No. 9) were apparently reused.

Several versions have been observed in the second technological group: 1) side welding of iron and steel with subsequent quenching for martensite and troostite (see Fig. 1, 6); the microhardness of the metal was 286– 509 kgf/mm2; 2) a V-shaped welding of a steel blade on an iron base, and a similar hardening (see Fig. 1, 3); 3) a V-shaped welding of a steel blade on a ferrite base combined with the welding of a steel wedge from the side of the blade’s back (see Fig. 1, 7); the finished product was quenched in water; the metal microstructure is martensite with troostite (blade) and troostite (back); and 4) slanting welding of a steel blade (see Fig. 1, 5), followed by hard quenching of the metal to martensite.

Another important group of items from the Migalka cemetery, produced by Russian artisans, are shaft-hole axes. They were indispensable in woodworking (felling trees and hewing timber), and, if necessary, served as military weapons.

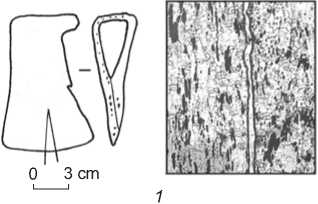

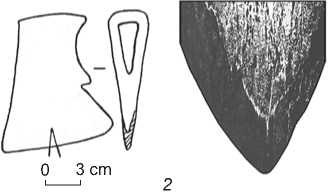

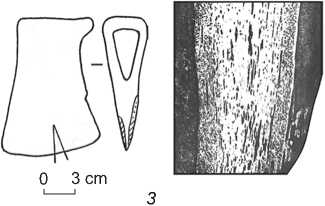

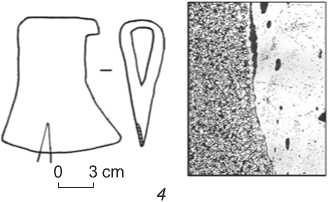

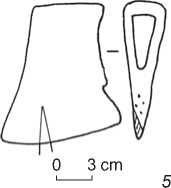

Five (of 12) shaft-hole axes have been metallographically examined. According to a well-known classification, they represent types III, IV, and V (Molodin, Sobolev, Soloviev, 1990: 38–43). Axe of type III (1 spec.) is distinguished by a wedge-shaped striking part with a triangular eye. The upper platform of the butt has a protrusion towards the handle. The axe beard is absent. The total length of the striking part is 12 cm; the width of the blade is 10.5 cm (Fig. 3, 4). Axes of type IV (3 spec.) have a similar striking part. Their only distinctive feature is the presence of a small beard on the butt. The total length of the items is 11.5–13.0 cm; the width of the blades is 7.8–10.7 cm (Fig. 3, 1, 3, 5). Axe of type V (1 spec.) has the shape described above and distinctive beard. The total length of the striking part is 12.5 cm; width of the blade is 10.8 cm (Fig. 3, 2).

A metallographic study of the thin sections taken from the cross-sections of the blades and one full section of the entire striking part has revealed two technological patterns followed in the production of shaft-hole axes. The first pattern welds a steel blade onto iron base (Fig. 3, 3 , 4 ) or low-carbon raw steel (Fig. 3, 2 , 5 ); the second pattern forges an entire axe of unevenly carburized metal, structurally representing ferrite and ferrite-pearlite (Fig. 3, 1 ). Welding technology was varied: narrowfaced, one-sided slanting lateral, and double-sided lateral (possibly V-shaped). Welded implements had better working properties. For increasing wear resistance, a solid steel blade was forged in a cold state. The heat treatment of the metal (quenching) has been observed as a hardening procedure. The microstructure of the hardened steels is martensite, troostomartensite, and troostite (Fig. 3, 2 , 3 , 5 ). Laboratory studies have not revealed any relationship between the types of the axes under consideration and the technology of their production.

The general technological pattern for manufacturing the body of shaft-hole axes in Medieval Rus has been

Fig. 3 . Axes: technological designs and microstructures (×20).

1 – burial 20, analysis 1365; 2 – burial 9, analysis 1377; 3 – burial 43, analysis 1376; 4 , 5 – space between the burials (analyses 1375 and 1366, respectively).

studied and reconstructed by B.A. Kolchin, using extensive archaeological materials from the 10th– 15th centuries (1953: 102–108). Judging from the results of structural analysis, Kolchin identified two technological methods, which are still used in the artisanal production of axes. The first pattern is as follows: a pre-forged strip was bent in the middle on a metal frame to obtain an eyelet and a butt. At the point of contact, strip halves were welded; the blade was expanded and the working edge was processed. The weld is clearly visible in the photograph of the microstructure of the axe (Fig. 3, 1 ). The second method of forming the eyelet and butt was to bend one end of the blank in the form of a loop and weld it to the strip at the point of contact. At the other end of the blank, the blade was expanded and the edge was processed (Ibid.: 104). Macro- and microstructural analysis of the Migalka axes indicate that the technological methods for producing the shaft-hole axes described above were used in the 16th– 17th centuries.

Metallographic study of the Migalka collection of ferrous metal products made by the Russian artisans makes it possible to conclude that modifications of two technological methods were widely used in their manufacturing. The first method was based on welding techniques, while the second method was based on solid steel processing. A certain pattern can be observed: there were not many more welded knives as compared to solid steel knives, but the vast majority of axes were welded products.

Judging by archaeological evidence, Russian axes were widespread among the Selkups. They were clearly more effective than the previously used socketed adzeaxes: their massiveness increased the impact of the tool; the wide blade and the long wedge-shaped striking part improved performance. A vivid expression of the advantages of the mechanical properties shown by the Russian axes is their efficiency. In the same work, it equals 0.71 for axe-adze, and 0.94 for shaft-hole axe of the 15th–18th centuries (Levashova, 1967: 70). Notably, only one adze-axe has been found at Migalka.

Local technology for producing adze-axes and knives is quite simple. Essentially, it consists of methods of metal plastic processing in a hot state. All operations were performed with hand hammers on an anvil. For example, at the Tiskino cemetery (70 km from Migalka), two burials of blacksmiths accompanied by their professional tool-sign (hammer) were found in the same burial mound (Chindina, 1975: Pl. 11, 13). Metallographic analysis of axes from this cemetery has revealed their low quality. For improving the working properties of the tools, the Selkup blacksmiths used hard and soft quenching (Paskal, Fedorishcheva, Chindina, 1983: 114; Zinyakov, 1997: 176–177).

Comparison of the results of metallographic studies into ferrous metal products from the Migalka cemetery and forged iron tools from the European towns of the Russian State (Zavyalov, Rozanova, Terekhova, 2007: 135–147) points to their significant similarity except for the ratio of structural designs. Generally, European Russia is characterized by the predominance of solid metal knives (59%) over welded knives (41%) (Ibid.: 140–142). This discrepancy can be explained. First, the metallographic data on blacksmith production of European Russian towns are averaged, since the initial evidence for research was taken from various regions of the state, while the items from the cemetery under study are associated with towns of only one region—the Russian North. It is known that the main bulk of Russian goods imported into Siberia in the 17th century was from Veliky Ustyug, Ustyuzhna Zhelezopolskaya, Solvychegodsk, etc. (Zinyakov, 2005), where the welding technology had long traditions in its various kinds. Secondly, in exchange transactions with the Selkup population, aimed at obtaining valuable Siberian furs, the Russians used primarily high-quality industrial products.

According to the sources, the flow of Russian goods into the environment of the autochthonous Siberian population was determined by three major factors: collection of the yasak tribute, industrial development of Siberia, and development of the all-Russian market. Yasak was a tax collected from the indigenous population of Siberia from the 17th to early 20th centuries. Until 1763, it was collected exclusively in kind (furs) (L.M. Dameshek, I.L. Dameshek, 1983: 161). A kind of remuneration— the “Tsar’s gift” granted for yasak payment—was the means of encouraging voluntary and timely payment of the tribute. The gifts consisted of goods that were in great demand among the Siberian population, such as small fresh-water pearls, copper rings and combs, tin in dishes and plates, copper in basins and cauldrons, iron “in bars” and iron products (axes, knives, “knife iron blanks”, and needles) (Bakhrushin, 1927: 22–32). The “Tsar’s gift” was an indispensable condition for receiving furs from the indigenous population, which quickly realized its benefits and tried to get it before submitting the yasak tribute. The governors complained: “They do not give the yasak without the Tsar’s gift—tin and beads” (Butsinsky, 1999: 26). Therefore, the central government was concerned about supplying Siberian towns with necessary reserves and creating a special “gift treasury”, which in the initial period of colonization of Siberia (17th century) was purchased in European Russia or abroad and was sent to the destination. Gifts as a prerequisite for submitting the yasak existed from the 17th to the late 19th century According to the observation of S.V. Bakhrushin, the distribution of gifts for the “yasak payment” looked more like an exchange trade than the fiscal duty (1927: 26).

The second factor that determined the flow of Russian goods into the environment of the indigenous population and their nomenclature, as well as qualitative and quantitative composition, was the industrial development of Siberia. Research shows that in the late 16th– 17th century, the Siberian region was in many respects economically dependent on European Russia with an established commodity artisanal and manufacturing production. The goods were supplied from Moscow, Kazan, and northern towns. Such trading and artisanal centers as Veliky Ustyug and Solvychegodsk played a particularly important role (Vilkov, 1967: 118–119).

Industry in Siberia and more specifically in the Middle Ob region was created in two ways. First, both written and archaeological evidence testify to a greater demand in the search for local raw material sources. One may confidently speak about specialized metallurgical sites based on siderite deposits in the interfluve of the Ob and Lower Tom Rivers (Shelomokskoye, Kizhirovskoye) (Pletneva, 1990: 102–109; Maloletko et al., 1983) and a number of sites on the Tagan River (Shaitansky, Mogilnitsky, Kireevsky). In the 17th century, this area became a part of Temerchinskaya Volost of Tomsk Uyezd, named after the ethnonym “Temertsi-yon” (“blacksmith-people”), which indicates this specific way of life of the local population (Barsukov, 2010: 13–16; 2015: 86–89; Konovalenko et al., 2010: 196–200). Archaeological evidence on the development of metallurgy and production of iron products in the Shaitansky microdistrict are not chronologically differentiated, however, scholars still distinguish the Late Medieval period (Barsukov, 2010: 13–16).

Second, the intentional training of professional personnel was carried out by relocating skilled artisans from the most developed urban centers of European Russia. In addition to blacksmiths, who possessed the sophisticated technical skills of processing iron and steel, representatives of the old-time servicemen were engaged in blacksmithing, and local craftsmen learned new technologies.

As a result, by the end of the 17th century, western Siberian towns increasingly acquired the features of trade and artisanal centers, and by the second quarter of the 18th century, some of them (Tobolsk and Tomsk) had already passed a significant path of development (Nikitin, 1983). According to archaeological and written sources, the processes of metallurgy and metalworking have been most clearly revealed using the example of Tomsk (Chernaya, 2015: 128–139). In addition to urban artisans, blacksmiths from the settlements on the vast territory of the Narym-Tomsk region of the Ob were also involved in the production of iron products using simple methods of forging and welding iron and steel (Zinyakov, 1997: 179).

The third factor that determined the turnover of Russian industrial goods in Siberia was the development of the all-Russian market, which started to emerge in the late 17th century. After Siberia had become a part of the Moscow State, trade in imported “Russian” goods in exchange for furs developed there. The demand for these goods fostered the engagement of the region into an emerging all-Russian market. Until the late 17th century, “goods from Rus’” occupied a dominant position in local trade. By the early 18th century, the supply volumes dropped sharply due to the emergence of Siberian industry (Vilkov, 1967: 86–87, pl. 10). The range of market goods consisted of several hundred items; the most important of which were the products made of ferrous and nonferrous metals, glass, and various fabrics, which is vividly demonstrated by the evidence from archaeological sites (Chernaya, 2016: 47–48). The Migalka cemetery stands out for its large range of Russian goods.

Conclusions

The results of analysis into category of iron objects in the system of burial rites at the Migalka cemetery unambiguously indicate important social points. The presence of extremely expensive knives with enamel, including those appearing in women’s burials, emphasized the high social and property status of those buried in them. The presence of axes only in male burials, in addition to the economic aspect, clearly marks gender specificity.

The study of ferrous household objects belonging to the Selkup population from the 17th–early 18th centuries shows the presence of a significant number of products made by the Russian artisans among them. Metallographic analysis of forged iron tools indicates that they were made according to the technological traditions of Russian ironworking and for the most part had high performance capacities. In general, imported Russian and foreign artisanal and manufactured goods which widely appear at the Migalka cemetery and other indigenous archaeological sites testify to the accelerated process of the engagement of the Middle Ob Selkups into commodity-money relations, their entry into all-Russian market, and the adoption of new values and standards of interaction between the two cultures.

Acknowledgments

This study was supported by the Competitiveness Improvement Program of Tomsk State University.