Design Modified Sliding Mode Controller with Parallel Fuzzy Inference System Compensator to Control of Spherical Motor

Автор: Alireza Siahbazi, Ali Barzegar, Mahmood Vosoogh, Abdol Majid Mirshekaran, Samira Soltani

Журнал: International Journal of Intelligent Systems and Applications(IJISA) @ijisa

Статья в выпуске: 3 vol.6, 2014 года.

Бесплатный доступ

The increasing demand for multi-degree-of-freedom (DOF) actuators in a number of industries has motivated a flurry of research in the development of non-conventional actuators, spherical motor. This motor is capable of providing smooth and isotropic three-dimensional motion in a single joint. Not only can the spherical motor combine 3-DOF motion in a single joint, it has a large range of motion with no singularities in its workspace. The spherical motor, however, exhibits coupled, nonlinear and very complex dynamics that make the design and implementation of feedback controllers very challenging. The orientation-varying torque generated by the spherical motor also contributes to the challenges in controller design. This paper contributes to the on-going research effort by exploring alternate methods for nonlinear and robust controlling the motor. The robust sliding mode controller proposed in this paper is used to further demonstrate the appealing features exhibited by the spherical motor. In opposition, sliding mode controller is used in many applications especially to control of highly uncertain systems; it has two significant drawbacks namely; chattering phenomenon and nonlinear equivalent dynamic formulation in uncertain dynamic parameter. The nonlinear equivalent dynamic formulation problem and chattering phenomenon in uncertain system (e.g., spherical motor) can be solved by using artificial intelligence theorem and applied a modified linear controller to switching part of sliding mode controller. Using Lyapunov-type stability arguments, a robust modified linear fuzzy sliding mode controller is designed to achieve this objective. The controller developed in this paper is designed in a robust stabilizing torque is designed for the nominal spherical motor dynamics derived using the constrained Lagrangian formulation. The eventual stability of the controller depends on the torque generating capabilities of the spherical motor.

Fuzzy Sliding Mode Algorithm, Spherical Motor, Lyapunov Based, Chattering Phenomenon, Fuzzy Logic Controller

Короткий адрес: https://sciup.org/15010534

IDR: 15010534

Текст научной статьи Design Modified Sliding Mode Controller with Parallel Fuzzy Inference System Compensator to Control of Spherical Motor

Published Online February 2014 in MECS

Multi-degree-of-freedom (DOF) actuators are finding wide use in a number of Industries. Currently, a significant number of the existing robotic actuators that can realize multi-DOF motion are constructed using gear and linkages to connect several single-DOF motors in series and/or parallel. Not only do such actuators tend to be large in size and mass, but they also have a decreased positioning accuracy due to mechanical deformation, friction and backlash of the gears and linkages. A number of these systems also exhibit singularities in their workspaces, which makes it virtually impossible to obtain uniform, high-speed, and high-precision motion. For high precession trajectory planning and control, it is necessary to replace the actuator system made up of several single-DOF motors connected in series and/or parallel with a single multiDOF actuator. The need for such systems has motivated years of research in the development of unusual, yet high performance actuators that have the potential to realize multi-DOF motion in a single joint. One such actuator is the spherical motor. Compared to conventional robotic manipulators that offer the same motion capabilities, the spherical motor possesses several advantages. Not only can the motor combine 3-DOF motion in a single joint, it has a large range of motion with no singularities in its workspace. The spherical motor is much simpler and more compact in design than most multiple single-axis robotic manipulators. The motor is also relatively easy to manufacture. The spherical motor have potential contributions to a wide range of applications such as coordinate measuring, object tracking, material handling, automated assembling, welding, and laser cutting. All these applications require high precision motion and fast dynamic response, which the spherical motor is capable of delivering. Previous research efforts on the spherical motor have demonstrated most of these features. These, however, come with a number of challenges. The spherical motor exhibits coupled, nonlinear and very complex dynamics. The design and implementation of feedback controllers for the motor are complicated by these dynamics. The controller design is further complicated by the orientation-varying torque generated by the spherical motor. Some of these challenges have been the focus of previous and ongoing research [1-11].

In modern usage, the word of control has many meanings, this word is usually taken to mean regulate, direct or command. The word feedback plays a vital role in the advance engineering and science. The conceptual frame work in Feed-back theory has developed only since world war ІІ. In the twentieth century, there was a rapid growth in the application of feedback controllers in process industries. According to Ogata, to do the first significant work in three-term or PID controllers which Nicholas Minorsky worked on it by automatic controllers in 1922. In 1934, Stefen Black was invention of the feedback amplifiers to develop the negative feedback amplifier[12-28]. Negative feedback invited communications engineer Harold Black in 1928 and it occurs when the output is subtracted from the input. Automatic control has played an important role in advance science and engineering and its extreme importance in many industrial applications, i.e., aerospace, mechanical engineering and joint control. The first significant work in automatic control was James Watt’s centrifugal governor for the speed control in motor engine in eighteenth century[29-40]. There are several methods for controlling a spherical motor, which all of them follow two common goals, namely, hardware/software implementation and acceptable performance. However, the mechanical design of spherical motor is very important to select the best controller but in general two types schemes can be presented, namely, a joint space control schemes and an operation space control schemes[41-53]. Joint space and operational space control are closed loop controllers which they have been used to provide robustness and rejection of disturbance effect. The main target in joint space controller is to design a feedback controller which the actual motion ( qa(t) ) and desired motion ( qd(t) ) as closely as possible. This control problem is classified into two main groups. Firstly, transformation the desired motion Xd(t) to joint variable qd(t) by inverse kinematics of spherical motor[34-50]. This control includes simple PD control, PID control, inverse dynamic control, Lyapunov-based control, and passivity based control. The main target in operational space controller is to design a feedback controller to allow the actual end-effector motion Xa(t) to track the desired endeffector motion Xd(t). This control methodology requires a greater algorithmic complexity and the inverse kinematics used in the feedback control loop. Direct measurement of operational space variables are very expensive that caused to limitation used of this controller in spherical motor[50-53]. One of the simplest ways to analysis control of three DOF spherical motor are analyzed each joint separately such as SISO systems and design an independent joint controller for each joint. In this controller, inputs only depends on the velocity and displacement of the corresponding joint and the other parameters between joints such as coupling presented by disturbance input. Joint space controller has many advantages such as one type controllers design for all joints with the same formulation, low cost hardware, and simple structure. A nonlinear methodology is used for nonlinear uncertain systems (e.g., spherical motor) to have an acceptable performance. These controllers divided into six groups, namely, feedback linearization (computed-torque control), passivity-based control, sliding mode control (variable structure control), artificial intelligence control, lyapunov-based control and adaptive control[13-26]. Sliding mode controller (SMC) is a powerful nonlinear controller which has been analyzed by many researchers especially in recent years. This theory was first proposed in the early 1950 by Emelyanov and several co-workers and has been extensively developed since then with the invention of high speed control devices [12-18]. The main reason to opt for this controller is its acceptable control performance in wide range and solves two most important challenging topics in control which names, stability and robustness [24-53]. Sliding mode controller is divided into two main sub controllers: discontinues controller ( ) and equivalent controller ( ) . Discontinues controller causes an acceptable tracking performance at the expense of very fast switching. In the theory of infinity fast switching can provide a good tracking performance but it also can provide some problems (e.g., system instability and chattering phenomenon). After going toward the sliding surface by discontinues term, equivalent term help to the system dynamics match to the sliding surface[12-15]. However, this controller used in many applications but, pure sliding mode controller has following challenges: chattering phenomenon, and nonlinear equivalent dynamic formulation [20]. Chattering phenomenon can causes some problems such as saturation and heat the mechanical parts of spherical motor. To reduce or eliminate the chattering, various papers have been reported by many researchers which classified into two most important methods: boundary layer saturation method and estimated uncertainties method [22-36]. In boundary layer saturation method, the basic idea is the discontinuous method replacement by saturation (linear) method with small neighborhood of the switching surface. This replacement caused to increase the error performance against with the considerable chattering reduction. In recent years, artificial intelligence theory has been used in sliding mode control systems. Neural network, fuzzy logic and neuro-fuzzy are synergically combined with nonlinear classical controller and used in nonlinear, time variant and uncertain plant (e.g., spherical motor). Fuzzy logic controller (FLC) is one of the most important applications of fuzzy logic theory. This controller can be used to control nonlinear, uncertain, and noisy systems. This method is free of some model techniques as in model-based controllers. As mentioned that fuzzy logic application is not only limited to the modelling of nonlinear systems [31-36] but also this method can help engineers to design a model-free controller. Control spherical motor using model-based controllers are based on manipulator dynamic model. These controllers often have many problems for modelling. Conventional controllers require accurate information of dynamic model of spherical motor, but most of time these models are MIMO, nonlinear and partly uncertain therefore calculate accurate dynamic model is complicated [32]. The main reasons to use fuzzy logic methodology are able to give approximate recommended solution for uncertain and also certain complicated systems to easy understanding and flexible. Fuzzy logic provides a method to design a model-free controller for nonlinear plant with a set of IF-THEN rules [32]. This paper contributes to the research effort of alternate methods for modeling the torque generated by the spherical motor used in the fuzzy sliding modetype feedback controller design. The designed controller not only demonstrates the appealing features exhibited by the spherical motor, but also demonstrates some of the nice features of fuzzy sliding mode-type controllers as well. This paper is organized as follows; second part focuses on the modeling dynamic formulation based on Lagrange methodology, sliding mode controller to have a robust control, and design fuzzy logic compensator. Third part is focused on the methodology which can be used to reduce the error, increase the performance quality and increase the robustness and stability. Simulation result and discussion is illustrated in forth part which based on trajectory following and disturbance rejection. The last part focuses on the conclusion and compare between this method and the other ones.

-

II. Theorem

-

• Dynamic and Kinematics Formulation of Spherical

Motor

Dynamic modeling of spherical motors is used to describe the behavior of spherical motor such as linear or nonlinear dynamic behavior, design of model based controller such as pure sliding mode controller which design this controller is based on nonlinear dynamic equations, and for simulation. The dynamic modeling describes the relationship between motion, velocity, and accelerations to force/torque or current/voltage and also it can be used to describe the particular dynamic effects (e.g., inertia, coriolios, centrifugal, and the other parameters) to behavior of system[1-10]. Spherical motor has a nonlinear and uncertain dynamic parameters 3 degrees of freedom (DOF) motor.

The equation of a spherical motor governed by the following equation [1-10]:

[ al I" «рд I" а 21 ГТ X1 (1)

^(q) [P] + B(q) [ay] + C(q) [р2] = [ТУ]

Where τ is actuation torque, H (q) is a symmetric and positive define inertia matrix, B(q) is the matrix of coriolios torques, C(q) is the matrix of centrifugal torques.

This is a decoupled system with simple second order linear differential dynamics. In other words, the component q influences, with a double integrator relationship, only the variableq / , independently of the motion of the other parts. Therefore, the angular acceleration is found as to be [1-11]:

q = B-1(q). {t — [B + C}} (2)

This technique is very attractive from a control point of view.

Study of spherical motor is classified into two main groups: kinematics and dynamics. Calculate the relationship between rigid bodies and final part without any forces is called Kinematics. Study of this part is pivotal to design with an acceptable performance controller, and in real situations and practical applications. As expected the study of kinematics is divided into two main parts: forward and inverse kinematics. Forward kinematics has been used to find the position and orientation of task frame when angles of joints are known. Inverse kinematics has been used to find possible joints variable (angles) when all position and orientation of task frame be active [1].

The main target in forward kinematics is calculating the following function:

V(X,q) = 0 (3)

Where V(.)ERn is a nonlinear vector function, X = [X1,X2,......, Xt]T is the vector of task space variables which generally task frame has three task space variables, three orientation, q = [q1, q2, ...., qn]T is a vector of angles or displacement, and finally n is the number of actuated joints. The Denavit-Hartenberg (D-H) convention is a method of drawing spherical motor free body diagrams. Denvit-Hartenberg (D-H) convention study is necessary to calculate forward kinematics in this motor.

A systematic Forward Kinematics solution is the main target of this part. The first step to compute Forward Kinematics (F.K) is finding the standard D-H parameters. The following steps show the systematic derivation of the standard D-H parameters.

-

1. Locate the spherical motor

-

2. Label joints

-

3. Determine joint rotation (0 )

-

4. Setup base coordinate frames.

-

5. Setup joints coordinate frames.

-

6. Determine^, thata / , link twist, is the angle between

-

7. Determine dt and a , , that a, , link length, is the distance between Z , and Z , +г along X,. d , , offset, is the distance between X ,_г and X , along Z , axis.

-

8. Fill up the D-H parameters table. The second step to compute Forward kinematics is finding the rotation matrix (Д°). The rotation matrix from{FJ to {F, _-J is given by the following equation;

Z j and Z / +1 about an X / .

R Г1 = ul(9t )VKat)

Where U^i is given by the following equation [111];

Гс о s (e) -s in( e,) 01

ut (в. ) = lsi«( e а с о s( e aol

L о о and F^.) is given by the following equation [1-11];

V; (в ; ) = l° co s( a a Lo sin (a , )

- ( )l

COS (aa J

So (F ° ) is given by [8]

R R = (U 1 V 1 )(U 2 V2 )......... (UnVn) (7)

The final step to compute the forward kinematics is calculate the transformation by the following formulation [3]

0T _ 0T1T2T n- 1T _ [RR 01 (8)

n1 = 11 -21 ■ 31 ....... n1 = [ Q 1J

SLIDING MODE CONTROLLER : One of the significant challenges in control algorithms is a linear behavior controller design for nonlinear systems. When system works with various parameters and hard nonlinearities this technique is very useful in order to be implemented easily but it has some limitations such as working near the system operating point[12]. Some of nonlinear systems which work in industrial processes are controlled by linear PID controllers, but the design of linear controller for spherical motors are extremely difficult because they are nonlinear, uncertain and MIMO[33-55]. To reduce above challenges the nonlinear robust controllers is used to systems control. One of the powerful nonlinear robust controllers is sliding mode controller (SMC), although this controller has been analyzed by many researchers but the first proposed was in the 1950 [12-33].This controller is used in wide range areas such as in robotics, in control process, in aerospace applications and in power converters because it has an acceptable control performance and solve some main challenging topics in control such as resistivity to the external disturbance. The lyapunov formulation can be written as follows,

The derivation of can be determined as, y = 1sT.H.S + ST HS

The dynamic equation of spherical motor can be written based on the sliding surface as

HS = -VS + HS + VS - т

It is assumed that

ST (H -2 V )S = 0

by substituting (11) in (10)

y = 1STHS-ST VS + St(hS + VS - т) =

ST (HS + VS - т)

Suppose the control input is written as follows t = С, + т^ = [hF1 (F) + S]w +

К . sgn(S) + KPS

By replacing the equation (14) in (13)

V = ST(HS + VS - HS - FS - KS -

Ksgn (S) = ST .HS + FS - KS -

Ksgn (S)/

It is obvious that

|fs + Fs - ks| < |fS| + |Fs| + |kvs|(16)

The Lemma equation in spherical motor system can be written as follows

K = [|SS| + |FS|+ |K„S|+^, i = 1,2,3,4, _

The equation (12) can be written as

K > |[hS + vs-ks].| + 4i

Therefore, it can be shown that

<-<-j*,№l i=l

Based on above discussion, the control law for spherical motor is written as:

и= + Uswtth(20)

Where, the model-based component Ueq is the nominal dynamics of systems and U eq can be calculate as follows:

Ueq=[Н"1 (в+с)+ ̇]н(21)

USWITCH is computed as;

Uswitch = ∙ SGN (Ле + ̇)

by replace the formulation (22) in (20) the control output can be written as;

U= +К․ SGN (5)

By (23) and (21) the sliding mode control of spherical motor is calculated as;

U=[Н"1 (В+С)+ ̇]Н+К∙ SGN (5)

FUZZY LOGIC THEORY: This section provides a review about foundation of fuzzy logic based on [3253]. Supposed that и is the universe of discourse and х is the element of и , therefore, a crisp set can be defined as a set which consists of different elements ( х ) will all or no membership in a set. A fuzzy set is a set that each element has a membership grade, therefore it can be written by the following definition;

А ={ х , Ва ( х )| х ∈ X }; А ∈ U (25)

Where an element of universe of discourse is X , {Л А is the membership function (MF) of fuzzy set. The membership function ( {Л А ( X )) of fuzzy set А must have a value between zero and one. If the membership function {Лд ( X ) value equal to zero or one, this set change to a crisp set but if it has a value between zero and one, it is a fuzzy set. Defining membership function for fuzzy sets has divided into two main groups; namely; numerical and functional method, which in numerical method each number has different degrees of membership function and functional method used standard functions in fuzzy sets. The membership function which is often used in practical applications includes triangular form, trapezoidal form, bell-shaped form, and Gaussian form.

Linguistic variable can open a wide area to use of fuzzy logic theory in many applications (e.g., control and system identification). In a natural artificial language all numbers replaced by words or sentences.

If - t ℎ en Rule statements are used to formulate the condition statements in fuzzy logic. A single fuzzy If - t ℎ en rule can be written by

If х is A Then у is В (26)

where A and В are the Linguistic values that can be defined by fuzzy set, the If - part of the part of “xis A” is called the antecedent part and the t ℎ en - part of the part of “у is В ” is called the Consequent or Conclusion part. The antecedent of a fuzzy if-then rule can have multiple parts, which the following rules shows the multiple antecedent rules:

if e is NB and t ̇ is ML then T is LL (27)

where e is error, ṫ is change of error, NB is Negative Big, ML is Medium Left, T is torque and LL is Large Left. If - t ℎ en rules have three parts, namely, fuzzify inputs, apply fuzzy operator and apply implication method which in fuzzify inputs the fuzzy statements in the antecedent replaced by the degree of membership, apply fuzzy operator used when the antecedent has multiple parts and replaced by single number between 0 to 1, this part is a degree of support for the fuzzy rule, and apply implication method used in consequent of fuzzy rule to replaced by the degree of membership. The fuzzy inference engine offers a mechanism for transferring the rule base in fuzzy set which it is divided into two most important methods, namely, Mamdani method and Sugeno method. Mamdani method is one of the common fuzzy inference systems and he designed one of the first fuzzy controllers to control of system engine. Mamdani’s fuzzy inference system is divided into four major steps: fuzzification, rule evaluation, aggregation of the rule outputs and defuzzification. Michio Sugeno use a singleton as a membership function of the rule consequent part. The following definition shows the Mamdani and Sugeno fuzzy rule base

Mamdani F ․ R1 : (28)

у is В then z is C

Sugeno F ․ R1 :

у is В then f ( x , У ) is C

When X and У have crisp values fuzzification calculates the membership degrees for antecedent part. Rule evaluation focuses on fuzzy operation ( AND / OR ) in the antecedent of the fuzzy rules. The aggregation is used to calculate the output fuzzy set and several methodologies can be used in fuzzy logic controller aggregation, namely, Max-Min aggregation, Sum-Min aggregation, Max-bounded product, Max-drastic product, Max-bounded sum, Max-algebraic sum and Min-max. Two most common methods that used in fuzzy logic controllers are Max-min aggregation and Sum-min aggregation. Max-min aggregation defined as below

Bu ( xk , Ук , U )= в ⋃ LtFRi ( xk , Ук , U ) (29)

= 2 minr=1 0 BRpq ( Xk , Ук ), Bpm ( U )13

The Sum-min aggregation defined as below

Ии ( Хк , Ук , и )= и ⋃ Li™1 ( хк , Ук , и ) (30)

=∑minr=1 0 URpq ( Хк , Ук ), Нрт ( и )1

where г is the number of fuzzy rules activated by Xr and Ук and also fl и l=lFRi ( Хк , Ук , U ) is a fuzzy interpretation of i - t ℎ rule. Defuzzification is the last step in the fuzzy inference system which it is used to transform fuzzy set to crisp set. Consequently defuzzification’s input is the aggregate output and the defuzzification’s output is a crisp number. Centre of gravity method ( COG ) and Centre of area method ( СОА ) are two most common defuzzification methods, which COG method used the following equation to calculate the defuzzification

∑ iUi ∑ /=1 ․ Hu ( xk , Ук , Ui ) (31)

( хк , У«)=∑ ∑й․ Ии ( Хк , Ук , , ) ()

and СОА method used the following equation to calculate the defuzzification

СОА ( хк , Ук )

∑ jUj ․ Ни ( Хк , Ук , ^ ) ∑ tHu ․( хк , Ук , Ui )

Where COG ( хк , Ук ) and СОА ( Хк , Ук ) illustrates the crisp value of defuzzification output, U / ∈ U is discrete element of an output of the fuzzy set, Цу ․( Хк , ук , U /) is the fuzzy set membership function, and г is the number of fuzzy rules.

Based on foundation of fuzzy logic methodology; fuzzy logic controller has played important rule to design nonlinear controller for nonlinear and uncertain systems [53-66]. However the application area for fuzzy control is really wide, the basic form for all command types of controllers consists of;

-

• Input fuzzification (binary-to-fuzzy[B/F]conversion)

-

• Fuzzy rule base (knowledge base)

-

• Inference engine

-

• Output defuzzification (fuzzy-to-binary

[F/B]conversion).

Linear Controller: In the absence of spherical motor knowledge, proportional-integral-derivative (PID), proportional-integral (PI) and proportional -derivative (PD) may be the best controllers, because they are model-free, and they’re parameters can be adjusted easily and separately [1] and it is the most used in spherical motor. In order to remove steady-state error caused by uncertainties and noise, the integrator gain has to be increased. This leads to worse transient performance, even destroys the stability. The integrator in a PID controller also reduces the bandwidth of the closed-loop system. PD control guarantees stability only when the PD gains tend to infinity, the tracking error does not tend to zero when friction and gravity forces are included in the spherical motor dynamics [2]. Model-based compensation for PD control is an alternative method to substitute PID control [1], such as adaptive gravity compensation [3], desired gravity compensation [2], and PD+ with position measurement [4]. They all needed structure information of the spherical motor dynamic formulation. Some nonlinear PD controllers can also achieve asymptotic stability, for example PD control with time-varying gains [5], PD control with nonlinear gains [6], and PD control with feedback linearization compensation [8]. But these controllers are complex; many good properties of the linear PID control do not exist because these controllers do not have the same form as the industrial PID. Design of a linear methodology to control of spherical motor was very straight forward. Since there was an output from the torque model, this means that there would be two inputs into the PID controller. Similarly, the outputs of the controller result from the two control inputs of the torque signal. In a typical PID method, the controller corrects the error between the desired input value and the measured value. Since the actual position is the measured signal.

е ( t )= да ( t )- 9d ( t ) (33)

UpiD = + KVa ̇+ Ki ∑ e (34)

The model-free control strategy is based on the assumption that the orientation of the spherical motor are all independent and the system can be decoupled into a group of single-axis control systems [14-16]. Therefore, the kinematic control method always results in a group of individual controllers, each for an active rotation of the spherical. With the independent orientation assumption, no a priori knowledge of spherical motor dynamics is needed in the kinematic controller design, so the complex computation of its dynamics can be avoided and the controller design can be greatly simplified. This is suitable for real-time control applications when powerful processors, which can execute complex algorithms rapidly, are not accessible. However, since joints coupling is neglected, control performance degrades as operating speed increases and a spherical motor controlled in this way is only appropriate for relatively slow motion [13-16]. The fast motion requirement results in even higher dynamic coupling between the various spherical motor orientations, which cannot be compensated for by a standard motor controller such as PID [16], and hence model-based control becomes the alternative.

-

III. Methodology

Sliding mode controller (SMC) is an important nonlinear controller in a partly uncertain dynamic system’s parameters. This controller is used in several applications such as in robotics, process control, aerospace and power electronics. Sliding mode controller is used to control of nonlinear dynamic systems particularly for spherical motor, because it has a suitable control performance and it is a robust and stable. Conversely pure sliding mode controller is a high-quality nonlinear controller; it has two important problems; chattering phenomenon and nonlinear equivalent dynamic formulation in uncertain dynamic parameter. To reduce the chattering phenomenon and equivalent dynamic problems, this research is focused on applied parallel fuzzy logic theorem and modified linear methodology in sliding mode controller as a compensator. In a typical PD method, the controller corrects the error between the desired input value and the measured value. Since the actual position is the measured signal. The derivative part of PD methodology is worked based on change of error and the derivative coefficient. In this research the modified PD is used based on boundary derivative part. Based on the SMC controller;

тп^ls = K.sgn(S+ + KxS, S = Я e + e

_ , S

e(t) - О I S + Г X e(t)

UPD = Яe + e

This is suitable for real-time control applications when powerful processors, which can execute complex algorithms rapidly, are not accessible. The result of modified PD method shows the power of disturbance rejection in this methodology.

Fuzzy logic theory is used in parallel with sliding mode controller to compensate the limited uncertainty in system’s dynamic. In this method fuzzy logic theorem is applied to sliding mode controller to remove the nonlinear uncertainty part which it is based on nonlinear dynamic formulation. To achieve this goal, the dynamic equivalent part of pure sliding mode controller is modeled by Mamdani’s performance/ error-based fuzzy logic methodology. Another researcher’s method is based on applied fuzzy logic theorem in sliding mode controller to design a fuzzy model-based controller. This technique was employed to obtain the desired control behavior with a number of information about dynamic model of system and a fuzzy switching control was applied to reinforce system performance. Reduce or eliminate the chattering phenomenon and reduce the error are played important role, therefore switching method is used beside the artificial intelligence part to solve the chattering problem with respect to reduce the error. Equivalent part of sliding mode controller is based on nonlinear dynamic formulations of spherical motor. Spherical motor’s dynamic formulations are highly nonlinear and some of parameters are unknown therefore design a controller based on dynamic formulation is complicated. To solve this challenge parallel fuzzy logic methodology is applied to sliding mode controller. In this method fuzzy logic method is used to compensate some dynamic formulation that they are used in equivalent part. To solve the challenge of sliding mode controller based on nonlinear dynamic formulation this research is focused on compensate the nonlinear equivalent formulation by parallel fuzzy logic controller. In this method; dynamic nonlinear equivalent part is modeled by performance/error-based fuzzy logic controller. In this method; error based Mamdani’s fuzzy inference system has considered with two inputs, one output and totally 49 rules. For both sliding mode controller and parallel fuzzy inference system plus sliding mode controller applications the system performance is sensitive to the sliding surface slope coefficient (Я) . For instance, if large value of Я is chosen the response is very fast the system is unstable and conversely, if small value of Я is considered the response of system is very slow but system is stable. Therefore to have a good response, compute the best value sliding surface slope coefficient is very important. In parallel fuzzy inference system compensator of sliding mode controller the PD-sliding surface is defined as follows:

S = e + Я^(38)

where Я j = ^1а^[Я11,Я12,Я13]. The time derivative of S is computed;

S = qd+Я1e(39)

The parallel fuzzy error-based compensator of sliding mode controller’s output is written;

^ = Teq/uzzy + N NMMC

Based on fuzzy logic methodology f (x) = Ufuzzy = T.M=1OT^(^)(41)

where 0T is adjustable parameter (gain updating factor) and (Xх") is defined by;

_ ТлРХХ^^хл(42)

U } Yi^(Xi)

Design an error-based parallel fuzzy compensate of equivalent part based on Mamdani’s fuzzy inference method has four steps, namely, fuzzification, fuzzy rule base and rule evaluation, aggregation of the rule output (fuzzy inference system) and defuzzification.

Fuzzification: the first step in fuzzification is determine inputs and outputs which, it has two inputs (e, e) and one output (T^UZZY). The inputs are error (e) which measures the difference between desired and actual output, and the change of error (e) which measures the difference between desired and actual velocity and output is fuzzy equivalent torque. The second step is chosen an appropriate membership function for inputs and output which, to simplicity in implementation because it is a linear function with regard to acceptable performance triangular membership function is selected in this research. The third step is chosen the correct labels for each fuzzy set which, in this research namely as linguistic variable. Based on experience knowledge the linguistic variables for error (e) are; Negative Big (NB), Negative Medium (NM), Negative Small (NS), Zero (Z), Positive Small (PS), Positive Medium (PM), Positive Big (PB), and experience knowledge it is quantized into thirteen levels represented by: -1, -0.83, -0.66, -0.5, -0.33, -0.16, 0, 0.16, 0.33, 0.5, 0.66, 0.83, 1 the linguistic variables for change of error (e) are; Fast Left (FL), Medium Left (ML), Slow Left (SL),Zero (Z), Slow Right (SR), Medium Right (MR), Fast Right (FR), and it is quantized in to thirteen levels represented by: -6, -5, -0.4, -3, -2, -1, 0, 1, 2, 3, 4, 5, 6, and the linguistic variables to find the output are; Large Left (LL), Medium Left (ML), Small Left (SL), Zero (Z), Small Right (SR), Medium Right (MR), Large Right (LR) and it is quantized in to thirteen levels represented by: -85, -70.8, -56.7, -42.5, -28.3, -14.2, 0, 14.2, 28.3, 42.5, 56.7, 70.8, 85.

Fuzzy rule base and rule evaluation : the first step in rule base and evaluation is to provide a least structured method to derive the fuzzy rule base which, expert experience and control engineering knowledge is used because this method is the least structure of the other one and the researcher derivation the fuzzy rule base from the knowledge of system operate and/or the classical controller. Design the rule base of fuzzy inference system can play important role to design the best performance of parallel fuzzy plus sliding mode controller, that to calculate the fuzzy rule base the researcher is used to heuristic method which, it is based on the behavior of the control of robot manipulator. The complete rule base for this controller is shown in Table 1. Rule evaluation focuses on operation in the antecedent of the fuzzy rules in fuzzy sliding mode controller. This part is used AND / OR fuzzy operation in antecedent part which AND operation is used.

Aggregation of the rule output (Fuzzy inference): based on fuzzy methodology, Max-Min aggregation is used in this work (see table 1).

Table 1: Modified Fuzzy rule base table

Decrease the overshoot ё

|

—:-----------► J |

|||||||||

|

\e e\ |

FL |

ML |

SL |

Z |

SR |

MR |

FR |

Ш E C UI __t L |

|

|

NB |

LL |

LL |

LL |

ML |

SL |

SL |

Z |

||

|

NM |

LL |

ML |

ML |

ML |

SL |

Z |

SR |

||

|

NS |

LL |

ML |

SL |

SL |

Z |

SR |

MR |

||

|

Ш Ш U'l cc Ш u Ш О |

|||||||||

|

Z |

LL |

ML |

SL |

Z |

SR |

MR |

LR |

||

|

PS |

ML |

SL |

Z |

SR |

SR |

MR |

LR |

||

|

PM |

SL |

Z |

SR |

MR |

MR |

MR |

LR |

||

|

PB |

Z |

SR |

SR |

MR |

LR |

LR |

LR |

||

Defuzzification: The last step to design fuzzy inference in our parallel fuzzy compensator plus sliding mode controller is defuzzification. This part is used to transform fuzzy set to crisp set, therefore the input for defuzzification is the aggregate output and the output of it is a crisp number. Based on fuzzy methodology

Center of gravity method (COG) is used in this research. Table 2 shows the lookup table in parallel fuzzy compensator sliding mode controller which is computed by COG defuzzification method. Table 2 has 169 cells to shows the error-based fuzzy compensate of equivalent part behavior (see table 2).

Table 2: fuzzy performance: lookup table in parallel fuzzy compensate of sliding mode controller by COG

|

ё |

Membership Function (t fuzzv^ |

||||||||||||

|

e ' 1 |

-6 |

-5 |

-4 |

-3 |

-2 |

-1 |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

|

-i |

-85 |

-84.8 |

-84.8 |

-84 |

-82.1 |

-81 |

-79 |

-71 |

-68 |

-65 |

-62 |

-60 |

-54 |

|

-0.83 |

-84.8 |

-84 |

-82 |

-80 |

-78 |

-77 |

-74 |

-70 |

-64 |

-60 |

-56 |

-54 |

-47 |

|

-0.66 |

-78 |

-73 |

-70 |

-68 |

-64 |

-61 |

-60 |

-57 |

-55 |

-50 |

-47 |

-40 |

-38 |

|

-0.5 |

-70 |

-60 |

-58 |

51 |

-42 |

-38 |

-34 |

-33 |

-31 |

-29 |

-28.4 |

-28.1 |

-28 |

|

-0.33 |

-50 |

-48 |

-45 |

-40 |

-38 |

-34 |

-32 |

-30 |

-28 |

-26 |

-25 |

-21 |

-20 |

|

-0.16 |

-30 |

-25 |

-21 |

-18 |

-16 |

-14 |

-10 |

-9 |

-8 |

-7 |

-6.8 |

-6 |

-5 |

|

0 |

-10 |

-8 |

-6 |

-1 |

2 |

3 |

6 |

7 |

8 |

10 |

12 |

15 |

17 |

|

0.16 |

15 |

18 |

21 |

22 |

23 |

25 |

27 |

28 |

29 |

30 |

30.5 |

30.8 |

31 |

|

0.33 |

29 |

29.8 |

31 |

33 |

34 |

34.6 |

35 |

35.2 |

36 |

37 |

38 |

39 |

42 |

|

0.5 |

40 |

41 |

42 |

43 |

45 |

45 |

46 |

46.3 |

46.8 |

47 |

48 |

51 |

52 |

|

0.66 |

48 |

49 |

50 |

52 |

53 |

55 |

56 |

57 |

58 |

59 |

60 |

61 |

63 |

|

0.83 |

60 |

61 |

62 |

63 |

64 |

66 |

67 |

68 |

68.5 |

69 |

70 |

70.8 |

71 |

|

1 |

66 |

68.7 |

68.9 |

70 |

72 |

74 |

75 |

77 |

78 |

79 |

81 |

83 |

84 |

Proof of stability in modified PD fuzzy-based tuning error-based fuzzy sliding mode controller: The

Lyapunov function in this design is defined as

1 т 1V 1 т v= +2∑ Y^ ․ ф)

/=1

where Ysj is a positive coefficient, ф= ∗-в,в∗ is minimum error and 6 is adjustable parameter. Since ̇ -2 is skew-symetric matrix;

STḢ+ ^ST ̇ rs = (н̇+vs(44)

The controller formulation is defined by т= ̂ ̈ + ̂ ̇ - AS -К(45)

According to (44)

Н ( q ) ̈+ V ( q , ̇) ̇ = ̂ ̈ + ̂ ̇ - AS - К (46)

Since ̇ = ̇ - and ̈ = ̈ - ̇

Ḣ+(V+А)S=∆f-К(47)

̇= - --

The derivation of V is defined

1 V1 1 j j ^^

̇= STH ̇+ —ST ̇ IS +∑ — фт ․ ̇ ;=i ^si

̇= ST ( H ̇+ vs )+∑ —фт ․ ̇

I Ysi /=1

Based on (46) and (47)

̇= ST ( bf - К - VS - AS + VS )+ (49)

∑7=1^ФГ․ ̇ where ∆ f=[H(q) ̈+v(q, ̇) ̇]-∑Y=i94(x)

̇=∑7M=1[ si ( Mi - Kj )]- ST AS +

∑ Т^Ф1 ․ ̇

Ysj suppose Kj is defined as follows

∑ ihQj [ Ha ( Sj )]

J =∑ [ Ha ( si )]

= ( Sj )

Where Cj ( Sj )=[ ^j ( Sj ), cl ( Sj ), cl ( Sj ),

, , А Д( a ) ' ( Sj )

Cj ( Sj )=∑ ( I ( S -A

∑ () ( )

․, Cj ( Sj )] T

where ц ( xt ) is membership function. The fuzzy system is defined as

∑ eT;(X)= Ф(e, ̇)

where 0=(01, 02, 03,……․,0м) is adjustable parameter in (51)

̇=∑/м=1 [ Sj ( Mi - 94( sj)]-STAS +

∑ "^^ ․ ̇

Based on Ф= ∗-9→9=

̇=∑f=i [ Sj (Mi -e∗4( Sj)+

ФЧ ( Sj )]- STAS +∑ 7=Афт ․ ̇

̇=∑/M=l[ Sj ( Mi -( e ∗ ) 4 ( Sj )]- STAS +

∑ ”1 Ysj ^ [ Ysj ․ Sj ․ Hj ( Sj )+ ̇ b ])

where ̇ 'j = ( Sj ) is adaption law , ∅ ̇ J =- ̇ =

- YsjSj^j ( Sj )

̇ is considered by

̇=∑[ ∆ -.( ∗) ( )/]- i=^

The minimum error is defined by

^mj =∆ fj -.( 9 ∗ ) T^j ( Sj )/

Therefore is computed as

̇=∑[]-

≤∑ Г1 | Sj || ^mj |- S'AS

=∑| |||-

=∑| |(| |-)

For continuous function g ( x ), and suppose is defined the fuzzy logic system in form of

Supx ∈ и | f ( X )- 9 ( x )|<€

The minimum approximation error ( ^mj ) small.

if ^-i = | S: |> ( S: ≠

) ̇<0 ( ≠ )

г>0 it is very

-

IV. Results

Modified fuzzy compensator sliding mode controller is implemented in MATLAB/SIMULINK environment.

Tracking performance and disturbance rejection is compared for circle trajectory.

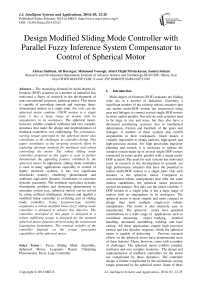

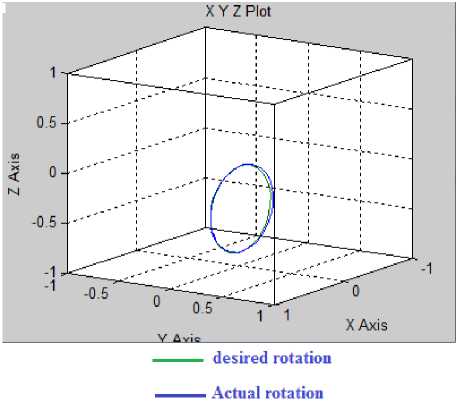

Tracking performances: From the simulation for first, second and third joints (spherical joints) without any disturbance, it was seen that proposed controller has a good trajectory performance, because this controller is adjusted and worked on certain environment. Figure 1 shows the tracking performance in certain system and without external disturbance this controller.

Fig. 1: Proposed Methodology applied to spherical motor without disturbance

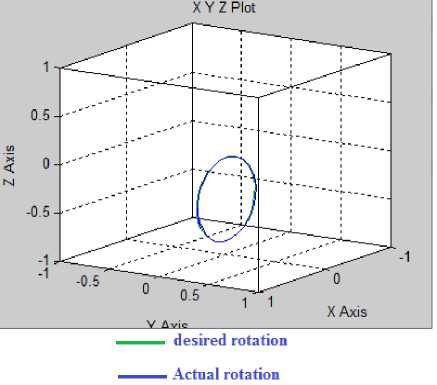

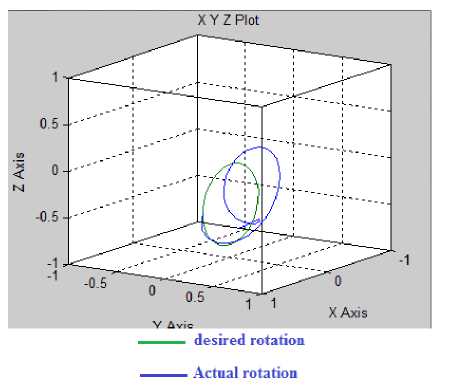

Disturbance rejection: Figures 2 and 3 show the power disturbance elimination in pure sliding mode controller and proposed method. The main targets in these controllers are disturbance rejection as well as the other responses. A band limited white noise with predefined of 40% the power of input signal is applied to controllers. It found fairly fluctuations in SMC trajectory responses. Among following graphs relating to trajectory following with external disturbance, SMC has fairly fluctuations.

Fig. 2: SMC in presence of uncertainty and external disturbance: applied to spherical motor

Fig. 3: Proposed method in presence of uncertainty and external disturbance: applied to spherical motor

-

V. Conclusion

Based on the dynamic formulation of spherical motor it is clear that; this system is highly nonlinear and uncertain dynamic parameters. Control of this system based on classical methodology is very complicated. The main contributions of this paper is compensating the nonlinear model base controller by nonlinear artificial intelligence model-free compensator and improve the stability based on modified PD methodology. The structure of modified PD compensator sliding mode controller with parallel fuzzy inference compensator is new. We propose parallel structure and chattering free compensator: parallel compensation and chattering free method is important challenge and to have the better performance modified PD and fuzzy logic method is introduced. The stability analysis of parallel fuzzy compensator plus sliding mode controller is test via Lyapunov methodology. The benefits of the proposed method; the chattering effects of parallel fuzzy inference compensator plus sliding mode controller, the slow convergence of the fuzzy and the chattering problem of sliding mode method are avoided effectively.

Acknowledgment

The authors would like to thank the anonymous reviewers for their careful reading of this paper and for their helpful comments. This work was supported by the Institute of Advanced Science and Technology (IRANSSP) Research and Development Corporation Program of Iran under grant no. 2013- Persian Gulf -2.B.

Список литературы Design Modified Sliding Mode Controller with Parallel Fuzzy Inference System Compensator to Control of Spherical Motor

- Vachtsevanos, G. I., Davey, K. and Lee, K. M., "Development of a Novel Intelligent Robotic Manipulator," IEEE Control System Magazine, 1987, pp.9-15.

- Davey, K., Vachtsevanos, G. I., and Powers, R., "An analysis of Fields and Torques in Spherical Induction Motors," lEE Transactions on Magnetics, Vol. MAG-23, 1987, pp. 273-282.

- Foggia, A., Oliver, E., Chappuis, F., "New Three Degrees of Freedom Electromagnetic Actuator," Conference Record -lAS Annual Meeting, Vol. 35, New York, 1988.

- Lee, K. M., Vachtsevanos, G. and Kwan, C-K., "Development of a Spherical Wrist Stepper Motor," Proceedings of the 1988 IEEE lntemational Conference on Robotics and Automation, Philadelphia, PA. April 26-29.

- Lee, K. M., Pei. I., "Kinematic Analysis of a Three Degree-of-Freedom Spherical Wrist Actuator," The Fifth International Conference on Advanced Robotics, Italy,1991.

- Wang, I., Jewel, G., Howe, D., "Modeling of a Novel Spherical Pennanent Magnet Actuator," Proceedings of IEEE International Conference on Robotics and Automation, Albuquerque, New Mexico, pp 1190-1195, 1997.

- Wang, I., Jewel, G., Howe, D., "Analysis, Design and Control of a Novel Spherical Pennanent Magnet Actuator," lEE Proceedings on Electrical Power Applications., vol. 154, no. 1, 1998.

- Chirikjian, G. S., and Stein, D., "Kinematic Design and Commutation of a Spherical Stepper Motor," IEEEIASME Transactions on Mechatronics, vol. 4, n 4, Piscataway, New Jersey, pp. 342-353, Dec. 1999.

- Kahlen, K., and De Doncker, R. W., "CW'l'ent Regulators for Multi-phase Pennanent Magnet Spherical Machines." Industry Applications Conference Record of the 2000 IEEE, vol. 3, 2000, pp. 2011-2016.

- Lee, K. M., Pei, I., and Gilboa, U., "On the Development of a Spherical Wrist Actuator," Proceedings of the 16th NSF Conference on Manufacturing Systems Research, Tempe AZ, January 8-12, 1990.

- Yang, C., Back, Y. S., "Design and Control of the 3-dcgn:es of freedom actuator by Controlling the Electromagnetic Force," IEEE Transactions on Magnetics, May, 1999, pp. 3607-3609.

- Samira Soltani & Farzin Piltan, “Design Artificial Nonlinear Controller Based on Computed Torque like Controller with Tunable Gain”, World Applied Science Journal (WASJ), 14 (9): 1306-1312, 2011.

- Farzin Piltan, Mohammadali Dialame, Abbas Zare & Ali Badri,“Design Novel Lookup Table Changed Auto Tuning FSMC:Applied to Robot Manipulator”, International Journal of Engineering, 6 (1):25-41, 2012

- Farzin Piltan, Mohammad Keshavarz, Ali Badri & Arash Zargari,“Design Novel Nonlinear Controller Applied to RobotManipulator: Design New Feedback Linearization Fuzzy Controller with Minimum Rule Base Tuning Method”, International Journal of Robotics and Automation,3 (1):1-12, 2012

- Farzin Piltan, Iman Nazari, Sobhan Siamak, Payman Ferdosali,“Methodology of FPGA-Based Mathematical error-Based Tuning Sliding Mode Controller”, International Journal of Control and Automation, 5(1), 89-118, 2012

- Farzin Piltan, Bamdad Boroomand, Arman Jahed & Hossein Rezaie, “Methodology of Mathematical Error-Based Tuning Sliding Mode Controller”, International Journal of Engineering, 6 (2):96-117, 2012

- Farzin Piltan, Sara Emamzadeh, Zahra Hivand, Fatemeh Shahriyari & Mina Mirazaei, ”PUMA-560 Robot Manipulator Position Sliding Mode Control Methods Using MATLAB/SIMULINK and Their Integration into Graduate/Undergraduate Nonlinear Control, Robotics and MATLAB Courses”, International Journal of Robotics and Automation, 3(3):106-150, 2012

- Farzin Piltan, Ali Hosainpour, Ebrahim Mazlomian, Mohammad Shamsodini, Mohammad H. Yarmahmoudi, ”Online Tuning Chattering Free Sliding Mode Fuzzy Control Design: Lyapunov Approach”, International Journal of Robotics and Automation, 3(3):77-105, 2012

- Farzin Piltan, Mina Mirzaei, Forouzan Shahriari, Iman Nazari, Sara Emamzadeh, “Design Baseline Computed Torque Controller”, International Journal of Engineering, 6(3): 129-141, 2012

- Farzin Piltan, Mohammad H. Yarmahmoudi, Mohammad Shamsodini, Ebrahim Mazlomian, Ali Hosainpour, ”PUMA-560 Robot Manipulator Position Computed Torque Control Methods Using MATLAB/SIMULINK and Their Integration into Graduate Nonlinear Control and MATLAB Courses”, International Journal of Robotics and Automation, 3(3): 167-191, 2012

- Farzin Piltan, Hossein Rezaie, Bamdad Boroomand, Arman Jahed, “Design Robust Backstepping on-line Tuning Feedback Linearization Control Applied to IC Engine”, International Journal of Advance Science and Technology, 11:40-22, 2012

- Farzin Piltan, Mohammad R. Rashidian, Mohammad Shamsodini and Sadeq Allahdadi, Effect of Rule Base on the Fuzzy-Based Tuning Fuzzy Sliding Mode Controller: Applied to 2nd Order Nonlinear System”, International Journal of Advanced Science and Technology, 46:39-70, 2012

- Farzin Piltan, Arman Jahed, Hossein Rezaie and Bamdad Boroomand, ”Methodology of Robust Linear On-line High Speed Tuning for Stable Sliding Mode Controller: Applied to Nonlinear System”, International Journal of Control and Automation, 5(3): 217-236, 2012

- Farzin Piltan, Bamdad Boroomand, Arman Jahed and Hossein Rezaie, ”Performance-Based Adaptive Gradient Descent Optimal Coefficient Fuzzy Sliding Mode Methodology”, International Journal of Intelligent Systems and Applications, , vol.4, no.11, pp.40-52, 2012.

- Farzin Piltan, Mehdi Akbari, Mojdeh Piran , Mansour Bazregar, ”Design Model Free Switching Gain Scheduling Baseline Controller with Application to Automotive Engine”, International Journal of Information Technology and Computer Science, vol.5, no.1, pp.65-73, 2013.DOI: 10.5815/ijitcs.2013.01.07.

- Farzin Piltan, Mojdeh Piran , Mansour Bazregar, Mehdi Akbari, “Design High Impact Fuzzy Baseline Variable Structure Methodology to Artificial Adjust Fuel Ratio”, International Journal of Intelligent Systems and Applications, vol.5, no.2, pp.59-70, 2013.DOI: 10.5815/ijisa.2013.02.0.

- Farzin Piltan, M. Bazregar, M. kamgari, M. Akbari and M. Piran, “Adjust the Fuel Ratio by High Impact Chattering Free Sliding Methodology with Application to Automotive Engine”, International Journal of Hybrid Information Technology, 6(1), 2013.

- Farzin Piltan, S. Zare , F. ShahryarZadeh, M. Mansoorzadeh, M. kamgari, “Supervised Optimization of Fuel Ratio in IC Engine Based on Design Baseline Computed Fuel Methodology”, International Journal of Information Technology and Computer Science , vol.5, no.4, pp.76-84, 2013.DOI: 10.5815/ijitcs.2013.04.09.

- Farzin Piltan, M. Mansoorzadeh, S. Zare, F.Shahryarzadeh, M. Akbari, “Artificial Tune of Fuel Ratio: Design a Novel SISO Fuzzy Backstepping Adaptive Variable Structure Control”, International Journal of Electrical and Computer Engineering, 3(2), 2013.

- M. Bazregar, Farzin Piltan, A. Nabaee and M.M. Ebrahimi, “Parallel Soft Computing Control Optimization Algorithm for Uncertainty Dynamic Systems”, International Journal of Advanced Science and Technology, 51, 2013.

- Farzin Piltan, M.H. Yarmahmoudi, M. Mirzaei, S. Emamzadeh, Z. Hivand, “Design Novel Fuzzy Robust Feedback Linearization Control with Application to Robot Manipulator”, International Journal of Intelligent Systems and Applications , vol.5, no.5, pp.1-10, 2013.DOI: 10.5815/ijisa.2013.05.01.

- Sh. Tayebi Haghighi, S. Soltani, Farzin Piltan, M. kamgari, S. Zare, “Evaluation Performance of IC Engine: Linear Tunable Gain Computed Torque Controller Vs. Sliding Mode Controller”, International Journal of Intelligent Systems and Applications, vol.5, no.6, pp.78-88, 2013.DOI: 10.5815/ijisa.2013.06.10.

- Amin Jalali, Farzin Piltan, M. Keshtgar, M. Jalali, “Colonial Competitive Optimization Sliding Mode Controller with Application to Robot Manipulator”, International Journal of Intelligent Systems and Applications, vol.5, no.7, pp.50-56, 2013. DOI: 10.5815/ijisa.2013.07.07.

- Salehi, Farzin Piltan, M. Mousavi, A. Khajeh, M. R. Rashidian, “Intelligent Robust Feed-forward Fuzzy Feedback Linearization Estimation of PID Control with Application to Continuum Robot”, International Journal of Information Engineering and Electronic Business, vol.5, no.1, pp.1-16, 2013. DOI: 10.5815/ijieeb.2013.01.01.

- Farzin Piltan, M.J. Rafaati, F. Khazaeni, A. Hosainpour, S. Soltani, “A Design High Impact Lyapunov Fuzzy PD-Plus-Gravity Controller with Application to Rigid Manipulator”, International Journal of Information Engineering and Electronic Business, vol.5, no.1, pp.17-25, 2013. DOI: 10.5815/ijieeb.2013.01.02.

- Amin Jalali, Farzin Piltan, A. Gavahian, M. Jalali, M. Adibi, “Model-Free Adaptive Fuzzy Sliding Mode Controller Optimized by Particle Swarm for Robot manipulator”, International Journal of Information Engineering and Electronic Business, vol.5, no.1, pp.68-78, 2013. DOI: 10.5815/ijieeb.2013.01.08.

- Farzin Piltan, F. ShahryarZadeh, M. Mansoorzadeh, M. kamgari, S. Zare, “Robust Fuzzy PD Method with Parallel Computed Fuel Ratio Estimation Applied to Automotive Engine“, International Journal of Intelligent Systems and Applications, vol.5, no.8, pp.83-92, 2013. DOI: 10.5815/ijisa.2013.08.10.

- Farzin Piltan, A. Nabaee, M.M. Ebrahimi, M. Bazregar, “Design Robust Fuzzy Sliding Mode Control Technique for Robot Manipulator Systems with Modeling Uncertainties”, International Journal of Information Technology and Computer Science, vol.5, no.8, pp.123-135, 2013. DOI: 10.5815/ijitcs.2013.08.12.

- Farzin Piltan, M. Mansoorzadeh, M. Akbari, S. Zare, F. ShahryarZadeh “Management of Environmental Pollution by Intelligent Control of Fuel in an Internal Combustion Engine“ Global Journal of Biodiversity Science And Management, 3(1), 2013.

- M. M. Ebrahimit Farzin Piltan, M. Bazregar and A.R. Nabaee, “Intelligent Robust Fuzzy-Parallel Optimization Control of a Continuum Robot Manipulator”, International Journal of Control and Automation, 6(3), 2013.

- O.R. Sadrnia, Farzin Piltan, M. Jafari, M. Eram and M. Shamsodini, “Design PID Estimator Fuzzy plus Backstepping to Control of Uncertain Continuum Robot”, International Journal of Hybrid Information Technology, 6(4), 2013.

- AminJalali, Farzin Piltan, H. Hashemzadeh, A. Hasiri, M.R Hashemzadeh, “Design Novel Soft Computing Backstepping Controller with Application to Nonlinear Dynamic Uncertain System”, International Journal of Intelligent Systems and Applications, vol.5, no.10, pp.93-105, 2013. DOI: 10.5815/ijisa.2013.10.12.

- M. Moosavi, M. Eram, A. Khajeh, O. Mahmoudi and Farzin Piltan, “Design New Artificial Intelligence Base Modified PID Hybrid Controller for Highly Nonlinear System”, International Journal of Advanced Science and Technology, 57, 2013.

- S. Zahmatkesh, Farzin Piltan, K. Heidari, M. Shamsodini, S. Heidari, “Artificial Error Tuning Based on Design a Novel SISO Fuzzy Backstepping Adaptive Variable Structure Control” International Journal of Intelligent Systems and Applications, vol.5, no.11, pp.34-46, 2013. DOI: 10.5815/ijisa.2013.11.04.

- S. Heidari, Farzin Piltan, M. Shamsodini, K. Heidari and S. Zahmatkesh, “Design New Nonlinear Controller with Parallel Fuzzy Inference System Compensator to Control of Continuum Robot Manipulator”,International Journal of Control and Automation, 6(4), 2013.

- FarzinPiltan, M. Kamgari, S. Zare, F. ShahryarZadeh, M. Mansoorzadeh, “Design Novel Model Reference Artificial Intelligence Based Methodology to Optimized Fuel Ratio in IC Engine”, International Journal of Information Engineering and Electronic Business, vol.5, no.2, pp.44-51, 2013. DOI: 10.5815/ijieeb.2013.02.07.

- Farzin Piltan, Mehdi Eram, Mohammad Taghavi, Omid Reza Sadrnia, Mahdi Jafari,"Nonlinear Fuzzy Model-base Technique to Compensate Highly Nonlinear Continuum Robot Manipulator", IJISA, vol.5, no.12, pp.135-148, 2013. DOI: 10.5815/ijisa.2013.12.12

- Amin Jalali, Farzin Piltan, Mohammadreza Hashemzadeh, Fatemeh BibakVaravi, Hossein Hashemzadeh,"Design Parallel Linear PD Compensation by Fuzzy Sliding Compensator for Continuum Robot", IJITCS, vol.5, no.12, pp.97-112, 2013. DOI: 10.5815/ijitcs.2013.12.12

- Farzin Piltan, A. Hosainpour, S. Emamzadeh, I. Nazari, M. Mirzaie, “Design Sliding Mode Controller of with Parallel Fuzzy Inference System Compensator to Control of Robot Manipulator”, International Journal of Robotics and Automation, Vol. 2, No. 4, December 2013, pp. 149~162.

- Farzin Piltan, Mahdi Jafari, Mehdi Eram, Omid Mahmoudi, Omid Reza Sadrnia, "Design Artificial Intelligence-Based Switching PD plus Gravity for Highly Nonlinear Second Order System", International Journal of Engineering and Manufacturing, vol.3, no.1, pp.38-57, 2013.DOI: 10.5815/ijem.2013.01.04

- Farzin Piltan, Sara Emamzadeh, Sara Heidari, Samaneh Zahmatkesh, Kamran Heidari, "Design Artificial Intelligent Parallel Feedback Linearization of PID Control with Application to Continuum Robot", International Journal of Engineering and Manufacturing, vol.3, no.2, pp.51-72, 2013.DOI: 10.5815/ijem.2013.02.04

- Mohammad Mahdi Ebrahimi, Farzin Piltan, Mansour Bazregar, AliReza Nabaee,"Artificial Chattering Free on-line Modified Sliding Mode Algorithm: Applied in Continuum Robot Manipulator", International Journal of Information Engineering and Electronic Business, vol.5, no.5, pp.57-69, 2013. DOI: 10.5815/ijieeb.2013.05.08

- Arman Jahed, Farzin Piltan, Hossein Rezaie, Bamdad Boroomand, "Design Computed Torque Controller with Parallel Fuzzy Inference System Compensator to Control of Robot Manipulator", International Journal of Information Engineering and Electronic Business, vol.5, no.3, pp.66-77, 2013. DOI: 10.5815/ijieeb.2013.03.08.