Design Novel Fuzzy Robust Feedback Linearization Control with Application to Robot Manipulator

Автор: Farzin Piltan, MohammadHossain Yarmahmoudi, Mina Mirzaie, Sara Emamzadeh, Zahra Hivand

Журнал: International Journal of Intelligent Systems and Applications(IJISA) @ijisa

Статья в выпуске: 5 vol.5, 2013 года.

Бесплатный доступ

First three degree of six degree of freedom robotic manipulator is controlled by a new fuzzy sliding feedback linearization controller. The robot arm has six revolute joints allowing the corresponding links to move horizontally. When developing a controller using conventional control methodology (e.g., feedback linearization methodology), a design scheme has to be produced, usually based on a system’s dynamic model. The work outline in this research utilizes soft computing applied to new conventional controller to address these methodology issues. Feedback linearization controller (FLC) is influential nonlinear controllers to certain systems which this method is based on compute the required arm torque using nonlinear feedback control law. When all dynamic and physical parameters are known FLC works superbly; practically a large amount of systems have uncertainties and fuzzy feedback linearization controller (FFLC) reduce this kind of limitation. Fuzzy logic provides functional capability without the use of a system dynamic model and has the characteristics suitable for capturing the approximate, varying values found in a MATLAB based area. To increase the stability and robustness new mathematical switching sliding mode methodology is applied to FFLC. Based on this research model free mathematical tunable gain new sliding switching feedback linearization controller applied to robot manipulator is presented to have a stable and robust nonlinear controller and have a good result compared with conventional and pure fuzzy logic controllers.

Fuzzy Sliding Feedback Linearization Controller, Feedback Linearization Controller, Fuzzy Logic Methodology, Sliding Mode Method, Robot Manipulator

Короткий адрес: https://sciup.org/15010415

IDR: 15010415

Текст научной статьи Design Novel Fuzzy Robust Feedback Linearization Control with Application to Robot Manipulator

Published Online April 2013 in MECS

Robot manipulator is collection of links that connect by joints, these joints can be revolute and prismatic that revolute joint has rotary motion around an axis and prismatic joint has linear motion around an axis. Each joint provides one or more degrees of freedom (DOF).

One of the most important challenges in the field of robot manipulator is control of it; because this system is multi input multi output (MIMO), nonlinear, time variant parameter and some dynamic parameters are uncertainty [1-2]. Presently, robot arms are used in different (unknown and/or unstructured) situation consequently caused to provide complicated systems, as a result strong mathematical theory applied to new control methodology to design nonlinear robust methodology to guarantee the security in industrial factory. Classical and non-classical methods are two main categories of nonlinear plant control, where the conventional (classical) control theory uses the classical method and the non-classical control theory (e.g., fuzzy logic, neural network, and neuro fuzzy) uses the artificial intelligence methods. However both of conventional and artificial intelligence theories have applied effectively in many areas, but these methods also have some limitations to have an acceptable secure performance in unknown environment [1-10].

The main targets in designing control systems are stability, good disturbance rejection to reach the best performance (robustness), and small tracking error[11-29]. Based on structure and unstructured uncertainties strong mathematical tools used in new control methodologies to design nonlinear robust controller with an acceptable performance (e.g., minimum error, good trajectory, disturbance rejection). Feedback linearization controller (FLC) is one of the powerful nonlinear methodology, is used in nonlinear certain systems [30-53].This methodology is used in wide range areas such as in control access process, in aerospace applications, in robotic and in internal combustion (IC) engines, to solve some main challenging topics in control such as resistivity to the external disturbance and stability. Even though, this methodology is used in wide range areas but, pure FLC has an important drawbacks beside uncertain system and also in presence of external disturbance.

Artificial intelligence theory is used to solve this problem. Neural network, fuzzy logic, and neuro-fuzzy are synergically combined with nonlinear classical controller and resolved the conventional controller against to uncertainty [30-41]. Fuzzy logic theory (FLM) can be used to resolve the model base challenge in nonlinear, uncertain, and noisy systems. Conventional controllers often have many problems for modelling nonlinear dynamic system’s parameter. Conventional controllers require accurate information of dynamic model of robot arms. When the system model is unknown or when it is known but complicated, it is difficult or impossible to use conventional mathematics to process this model[32]. The main reasons to use fuzzy logic technology are able to give approximate recommended solution for unclear and complicated systems to easy understanding and flexible. Fuzzy logic provides a method which is able to model a controller for nonlinear plant with a set of IF-THEN rules, or it can identify the control actions and describe them by using fuzzy rules [32].

In various dynamic parameters systems to have stability and robustness, training on-line control methodology is used. Mathematical switching sliding mode methodology (MSM) is a significant nonlinear controller under condition of partly uncertain dynamic parameters of system. This method is used to control of highly nonlinear systems especially for robot manipulators, because this theory is a robust and stable. Switching sliding method is used to increase the stability and robustness based on LYAPUNOV base methodology. Conventional feedback linearization controller, fuzzy feedback linearization controller and switching sliding fuzzy feedback linearization controller have difficulty in handling unstructured model uncertainties. It is possible to solve this problem by proposed methodology and adaption law which this method can helps improve the system’s tracking performance by online tuning method. Mathematical error base methodology used to limitation tuning controller’s coefficient.

This paper is organized as follows; second part focuses on the modeling dynamic formulation based on Lagrange methodology, introducing to feedback linearization controller (computed torque controller), fuzzy logic methodology and sliding mode controller to have a robust control. Third part is focused on the methodology which can be used to reduce the error, increase the performance quality and increase the robustness and stability. Simulation result and discussion is illustrated in forth part which based on trajectory following and disturbance rejection. The last part focuses on the conclusion and compare between this method and the other one’s.

-

II. Theory2.1 Robot Manipulator’s Dynamic:

The equation of an n-DOF robot manipulator governed by the following equation [1, 4, 15-29, 41-53]:

M (q)q+N(q,q') = T (1)

Where τ is actuation torque, M (q) is a symmetric and positive define inertia matrix, N(q,q^ is the vector of nonlinearity term. This robot manipulator dynamic equation can also be written in a following form [1-29]:

т = M(q)q + S(q)[q q] + C(q)[q]2 + G(q) (2)

Where B(q) is the matrix of coriolios torques, C(q) is the matrix of centrifugal torques, and G(q) is the vector of gravity force. The dynamic terms in equation (2) are only manipulator position. This is a decoupled system with simple second order linear differential dynamics. In other words, the component q influences, with a double integrator relationship, only the joint variable q , , independently of the motion of the other joints.

Therefore, the angular acceleration is found as to be [3, 41-53]:

q = M-1(q). {т — N(q, q)} (3)

This technique is very attractive from a control point of view.

-

(4) and (5) the Brunousky canonical form can be written in terms of the state x = [ег er]r as [1]:

-

2.2 Feedback Linearization Method:

£ch ii-iei+[?i" (6)

With

U = qd+M-1(q).{N(q.q)-f} (7)

Feedback linearization method (FLC) is a powerful nonlinear controller which it widely used in control of robot manipulator. It is based on feedback linearization and computes the required arm torques using the nonlinear feedback control law. This controller works very well when all dynamic and physical parameters are known but when the robot manipulator has variation in dynamic parameters, in this situation the controller has no acceptable trajectory performance[14]. In practice, most of physical systems (e.g., robot manipulators) parameters are unknown or time variant, therefore, feedback linearization like controller used to compensate dynamic equation of robot manipulator[1, 6]. Research on FLC is significantly growing on robot manipulator application which has been reported in [1, 6, 15-16]. Vivas and Mosquera [8]have proposed a predictive functional controller and compare to FLC for tracking response in uncertain environment. However both controllers have been used in feedback linearization, but predictive strategy gives better result as a performance. A FLC with non parametric regression models have been presented for a robot arm[9]. This controller also has been problem in uncertain dynamic models. Based on [1, 6]and [8-9] FLC is a significant nonlinear controller to certain systems which it is based on feedback linearization and computes the required arm torques using the nonlinear feedback control law. When all dynamic and physical parameters are known, FLC works fantastically; practically a large amount of systems have uncertainties, therefore feedback linearization like controller is the best case to solve this challenge.

The central idea of FLC is feedback linearization so, originally this algorithm is called feedback linearization controller. It has assumed that the desired motion trajectory for the manipulator qd(t) , as determined, by a path planner. Based on tracking error definition;

e tt) = d att) - q att) (4)

Where e(t) is error of the plant, qd(t) is desired input variable, that in our system is desired displacement, q a(ts is actual displacement. If an alternative linear state-space equation in the form x = Ax + BU can be defined as

-

*=G 0b+[0Ju (5)

With U = -M-1 (q). N(q, q) + M-1 (q). т and this is known as the Brunousky canonical form. By equation

Then compute the required arm torques using inverse of equation (7), is;

т = M(q)(q d — U) + N(q, q) (8)

This is a nonlinear feedback control law that guarantees tracking of desired trajectory. Selecting proportional-plus-derivative (PD) feedback for U(t) results in the PD-FLC [6];

т = M ( q)(qd + Kve + Kpe) + N(q, q) (9)

and the resulting linear error dynamics are

(qd+ кРе + кре) = 0 (10)

According to the linear system theory, convergence of the tracking error to zero is guaranteed [6]. Where Kp and Kp are the controller gains.

-

2.3 Fuzzy Inference Engine:

The firs type of fuzzy systems is given by

м fto = 2

l=1

ElEl(x) = 9TE(x)

Where

9 = (91..... 9^)T,E(x) =

(E1(x), ..., Ем(x))T, and El(x) =

M,Z ( r;)

:ПГ=1^^Z?=1(ПГ=1^л/(xi)). 91.....9м are adjustable parameters in (11) . ^Ai(x1), -■, ^A^(xn) are given membership functions whose parameters will not change over time.

The second type of fuzzy systems is given by

E ?= , 9lln "= lexp(-(x^-3) )] яф = ехр ( ( .' '' 'I

Where , are all adjustable parameters. From the universal approximation theorem, we know that we can find a fuzzy system to estimate any continuous function. For the first type of fuzzy systems, we can only adjust 9l in (12). We define f (x|9) as the approximator of the real function ( ) .

f^(X|в)= 0T E(X)

We define 9 ∗ as the values for the minimum error:

9∗ =argmin[suр|f ^(x|9)- g(X)|]

∈£1 Lx∈ U-I

Where

|

Г 8i , 9i , |

, е^д |

|

|

⊖ T = ( 9i ,…, ) T = |

9^ , el , |

, 9? ⎥ |

|

⎣ 0L.02 .. , , |

AM …, |

Where /2 is a constraint set for в . For specific X , supx ∈ U | f ^ ( X | 0 ∗)- f ( X )| is the minimum approximation error we can get.

We used the first type of fuzzy systems (11) to estimate the nonlinear system (9) the fuzzy formulation can be write as below;

f ( X | 0 )= 0TE ( X )

∑ ^i9L [ gAi ( x )] (15) =∑?=i [ gAi ( X )]

Where 91 ,…, 9^ are adjusted by an adaptation law. The adaptation law is designed to minimize the parameter errors of 9 - 9 .

£( x )=(E1 ( X ),…, EM ( X )) I , E1( X )=∏ ^BA\ ( Xi )/ ∑ "1(∏ ^=Wt ( Xi )) , and gA\ ( Xi ) is defined in (15). To reduce the number of fuzzy rules, we divide the fuzzy system in to three parts:

F1 ( q , ̇)= ⊖1T £ ( q , ̇)

= 0 0fs ( q , ̇) ,…, 9m £ ( q , ̇) 1 (22)

F2 ( q , ̈ )= ⊖2? £ ( q , ̈ )

= 0 0ffi ( q , ̈ ) ,…, 9m £ ( q , ̈ ) 1

-

2.4 Switching Linear Sliding Methodology:

Based on switching linear sliding method discussion, the control law for a multi degrees of freedom robot manipulator is written as [18-24, 63-74]:

и = + Udis

Where, the model-based component UNonlinear is compensated the nominal dynamics of systems. A simple solution to get the switching linear sliding method condition when the dynamic parameters have uncertainty is the switching control law:

Udis = ( ⃗, t) ∙sgn(S)

where the switching function Sgn ( s ) is defined as

1s>0

sgn(s)={-1

and the К ( ⃗ ⃗, t ) is the positive constant.

-

III. Methodology

The general SISO if-then rules are given by

Rl : , x2 is A2,…,xn is ALn ,tℎen yjs ВД,…,Ут is Um

Where I =1,2,…, M are fuzzy if-then rules; = ( %1 ,…, Xn ) T and У =( У1 ,…, Уп ) T are the input and output vectors of the fuzzy system. The SISO fuzzy system is define as

f ( X )= ⊖ T E ( X ) (20)

F3 ( q , ̈)= ⊖ 3T E ( q , ̈)

= 0 03TE ( q , ̇) ,…, 9m £ ( q , ̈) 1 (24)

The control security input is given by

T = ̈ + В ( q ) ̇ ̇+ c ( q ) ̇2+

g ( q )+ F1 ( q , ̇)+ F2 ( q , ̈ )+ F3 ( q , ̈)- (25)

Kpe - Kyt ̇

Where M , В(q) ̇ ̇, C(q) ̇'2 ,g(q) are the estimations of M(q).

Based on feedback linearization formulation (9) and switching sliding methodology (17);

^New = ( q )( ̈ d + Kyt ̇+ Kpe )

And ^switch is obtained by

Uswitch =K(⃗х⃗, t) ∙sgn(SNew) =K(⃗х⃗, t)∙ sgn (M(q)(q̈d+K е̇+Kpе))

The Lyapunov function in this design is defined as

M

V= STMS+2∑ y~-^T․ Ф1(28)

where Vsj is a positive coefficient, Ф= ∗-в,в∗ is minimum error and 9 is adjustable parameter. Since ̇ -2 is skew-symetric matrix;

STMṠ+1STK̇ 'S = (Mi̇+vs)

If the dynamic formulation of robot manipulator defined by

Т= ( q ) ̈+ v ( q , ̇) ̇ + g ( q )

Based on Ф = ∗ - e → e = ∗ - Ф

the controller formulation is defined by

T = ̂ ̈ + ̂ ̇ + ̂ - AS - К

V̇ =

∑J=1 [Sj (Δf j - θ∗ T ζ(Sj)+фтζ(Sj)]-STλS+

∑ r^ γ-Фт ․ ̇

γ

According to (29) and (30)

M ( q ) ̈+ v ( q , ̇) ̇ + G ( q )= ̂ ̈ + ̂ ̇ +

̂- -

Since ̇ = ̇ - and ̈ = ̈ - ̇

̇ +( V + A ) s =∆ f - к

M ̇= M - к - vs - AS

The derivation of V is defined

„ 1 „ . .

̇= STM^ ̇ + 1 sт^ ̇ ’S +∑ 1 -фт ․q ̇

2 Tsi j=lrsJ

M

∑ —фт ․ ̇

7=1Ysj

Based on (32) and (33)

̇ =∑[Sj (Mi-(e ∗) 4( Sj)]-STAS l=i ∑ ■ _

— Фу [ Ysj ․ Sj ․ ^j ( Sj )+ ̇ >j ])

j=i Ysj where ̇ 'j = ( Sj ) is adaption law, ∅̇ , =- ̇ =

- YsjSj^j ( Sj )

̇ is considered by

V̇ =ST( Δ f-K

∑J^l γL*T․ ̇ γ where

∑ 7=^4 ( X )

M

-VS- λ S+VS)+

∆ f =[ M ( q ) ̈+ v ( q , ̇) ̇ + g ( q )]-

̇ =∑[ Sj ( Mi - Ki )]- STAS + /=1

suppose Лу is defined as follows

К = ∑ м [ ЦА ( Sj )] = ( s )

Kj =∑Г.,[ Цд ( Sj )] = 6,^ ( S, )

M

∑ Ysj^ ․ ̇

/=1 1

( Wh ) e = re [ ( ), ( ), ( ),…․․, ( )]

( 5 )= "(*); (5)

( )=∑ tn ( A ) ' ( Sj )

where Ц ( xi ) is membership function.

The fuzzy system is defined as

∑

9Tf ( X )= Ф ( e , t ̇)

1=1

where e =(s1, e2, e3 ,……․, 9м ) is adjustable parameter in (36)

according to 33, 34 and 36;

̇=∑ 7-i [ Sj ( Δ fi - 9T^ ( Sj )]- STAS +

∑ 7=1^ФТ ․ <1 ̇

Ysj

̇ =∑[Sj ∆ fj -.(e ∗) T^j ( Sj)/]-STAS(41)

i=i

The minimum error is defined by

=∆fj-.(e ∗) Tfj ( Sj )/

Therefore ̇ is computed as

̇ =∑[Sj emj]-STAS(43)

i=i

≤∑ T=i | Sj || |- STAS

=∑| Sj || |- AjSj2

i=i

=∑| Sj |(| |- AjSj ) (44)

i=i

For continuous function 9 ( x ) , and suppose £ >0 it is defined the fuzzy logic system in form of

SuPx ∈ и | f ( X )- g ( X )|< 6 (45)

the minimum approximation error ( ) is very small.

if ''-j = ℎ at a | Sj |> ( Sj ≠

0) t ℎ en ̇<0 for ( Sj ≠0)

This method has two main controller’s coefficients, Kp and Kv . To tune and optimize these parameters mathematical formulation is used

U = + Gswitch

U=Ufuzzy+Uswitch = K(⃗х⃗, t) ∙ sgn .M(q)(q̈d+Kv—new е̇ + Kp-newе)/ +

|

∑1=1 θ |

*∏'Ll exp ( ( δ α 5 ))+ |

|

∑1=1* |

∏ [L^xp( ( δ , α 1))+ |

Kp—new = × Kc (49)

^V—new = × Kc (50)

( t ̇( t )- t ̇( t -1))

-

IV. Results and Discussion

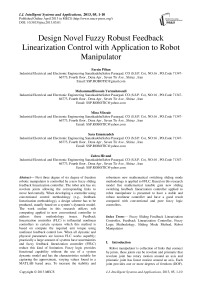

Trajectory following: Based on simulation results the Steady State and RMS error in proposed method (Steady State error =1e-6 and RMS error=1.2e-6) are fairly lower than FCTC’s (Steady State error ≅ -3e -5 and RMS error=-1․ 34e -5) and CTC’s (Steady State error ≅ - 0․ 001 and RMS error=0.00652) .

TZ _ ( rv - ^v—min )

= - + (51)

1+| |

Fig. 1: Trajectory following (proposed method, FCTC, CTC)

Based on Figure 1, step trajectory performance is used for comparisons of above controllers in certain systems. In this state proposed method has better trajectory performance but FCTC has oscillation.

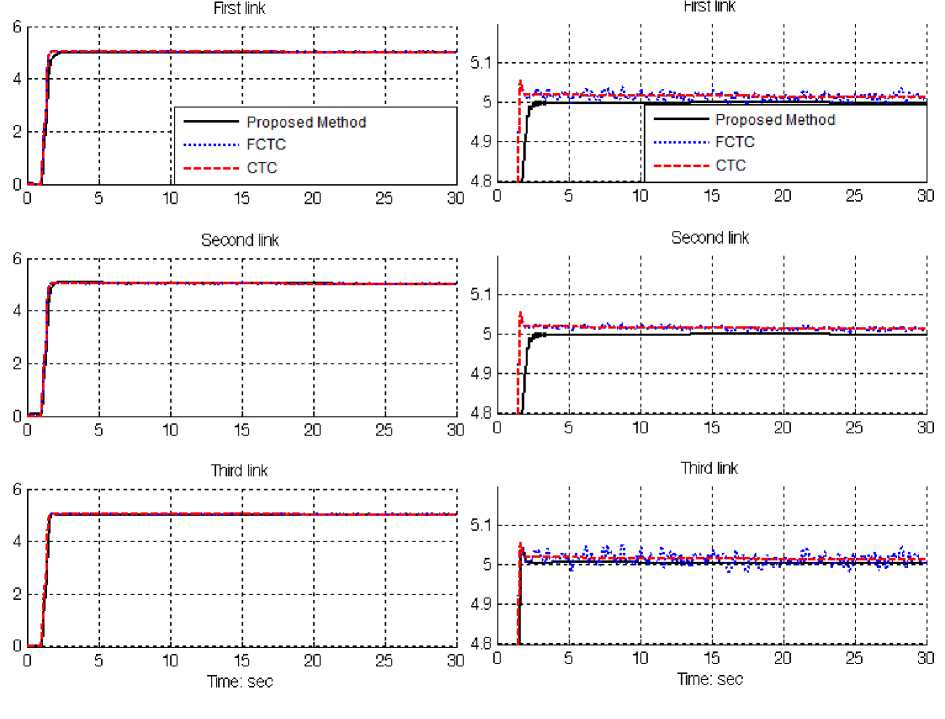

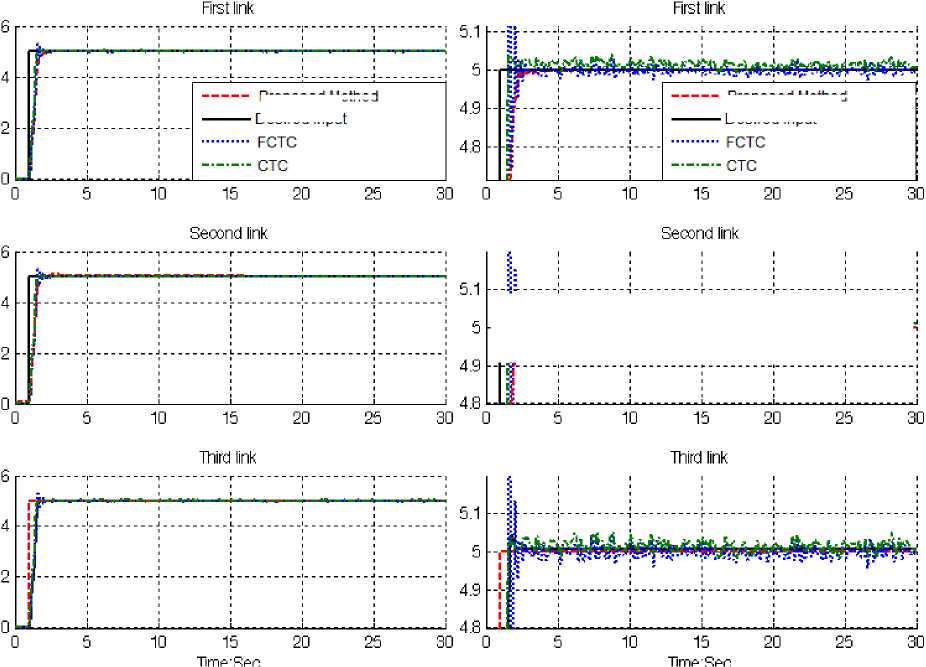

Disturbance rejection: Figure 2 illustrates the CTC, FCTC and proposed method. The disturbance rejection is used to test the robustness comparisons of these three controllers for step trajectory. A band limited white noise with predefined of 40% the power of input signal is applied to the step trajectory. It found fairly fluctuations in trajectory responses. Based on Figure 2; by comparing step response trajectory with 40% disturbance of relative to the input signal amplitude in CTC, FCTC and proposed method, proposed method’s overshoot about (1%) is lower than FCTC’s (8%)and CTC’s (9.1%). Besides the Steady State and RMS error in proposed method (Steady State error =1.6e-6 and RMS error=1.9e-6) are fairly lower than CTC’s

(Steady State error ≅ о․ 003 and RMS error= о․ 0048 ) and FCTC’s (Steady State error ≅-О․1 and RMS error=0. 652). Based on Figure 2, proposed method has fairly oscillation in trajectory response with regard to 40% of the input signal disturbance but this controller is more robust.

Proposed Method

Desired Input

Fig. 2: Disturbance rejection (proposed method, FCTC, CTC)

Proposed Method

Desired Input

|

SC*-»k |

||||

Disturbance rejection: steady state error is an important parameter to test the system’s performance. In system with 40% disturbance the comparison between steady state error is; (Steady State error =1.6e-6 and RMS error=1.9e-6) are fairly lower than CTC’s (Steady State error ≅ 0․ 003 and RMS error= 0․ 0048 ) and FCTC’s (Steady State error ≅-0․1 and RMS error=0. 652) .

-

V. Conclusion

Refer to this research, a mathematical tuning fuzzy switching sliding feedback linearization method with application to robot manipulator has proposed. Stability and robustness are two more important challenges to design high performance nonlinear controller in the presence of uncertainties and external disturbances. Regarding to the positive points in feedback linearization methodology, fuzzy inference system and sliding switching methodology, stability and robustness are resolve based on eliminate the nonlinear dynamic equations and LYAPUNOV based stability formulation. To have a wide band limitation robust against to structure and unstructured uncertainty mathematical performance based tuning is applied to proposed method. Regarding to this methodology the values of error reduce to 1.6 micro which in industry this value is equal to zero.

Acknowledgment

The authors would like to thank the anonymous reviewers for their careful reading of this paper and for their helpful comments. This work was supported by the SSP Research and Development Corporation Program of Iran under grant no. 2012-Persian Gulf-3C.

Список литературы Design Novel Fuzzy Robust Feedback Linearization Control with Application to Robot Manipulator

- T. R. Kurfess, Robotics and automation handbook: CRC, 2005.

- J. J. E. Slotine and W. Li, Applied nonlinear control vol. 461: Prentice hall Englewood Cliffs, NJ, 1991.

- K. Ogata, Modern control engineering: Prentice Hall, 2009.

- J. J. D'Azzo, C. H. Houpis and S. N. Sheldon, Linear control system analysis and design with MATLAB: CRC, 2003.

- B. Siciliano and O. Khatib, Springer handbook of robotics: Springer-Verlag New York Inc, 2008.

- F. T. Cheng, T. L. Hour, Y. Y. Sun and T. H. Chen, "Study and resolution of singularities for a 6-DOF PUMA manipulator," Systems, Man, and Cybernetics, Part B: Cybernetics, IEEE Transactions on, No. 2, vol. 27, pp. 332-343, 2002.

- M. W. Spong and M. Vidyasagar, Robot dynamics and control: Wiley-India, 2009.

- A. Vivas and V. Mosquera, "Predictive functional control of a PUMA robot," Conference Proceedings, 2005.

- D. Nguyen-Tuong, M. Seeger and J. Peters, "Computed torque control with nonparametric regression models," IEEE conference proceeding, 2008, pp. 212-217.

- Farzin Piltan , N. Sulaiman, Zahra Tajpaykar, Payman Ferdosali, Mehdi Rashidi, “Design Artificial Nonlinear Robust Controller Based on CTLC and FSMC with Tunable Gain,” International Journal of Robotic and Automation, 2 (3): 205-220, 2011.

- Farzin Piltan, A. R. Salehi and Nasri B Sulaiman.,” Design artificial robust control of second order system based on adaptive fuzzy gain scheduling,” world applied science journal (WASJ), 13 (5): 1085-1092, 2011.

- Farzin Piltan, N. Sulaiman, Atefeh Gavahian, Samira Soltani, Samaneh Roosta, “Design Mathematical Tunable Gain PID-Like Sliding Mode Fuzzy Controller with Minimum Rule Base,” International Journal of Robotic and Automation, 2 (3): 146-156, 2011.

- Farzin Piltan , A. Zare, Nasri B. Sulaiman, M. H. Marhaban and R. Ramli, , “A Model Free Robust Sliding Surface Slope Adjustment in Sliding Mode Control for Robot Manipulator,” World Applied Science Journal, 12 (12): 2330-2336, 2011.

- Farzin Piltan , A. H. Aryanfar, Nasri B. Sulaiman, M. H. Marhaban and R. Ramli “Design Adaptive Fuzzy Robust Controllers for Robot Manipulator,” World Applied Science Journal, 12 (12): 2317-2329, 2011.

- Farzin Piltan, N. Sulaiman , Arash Zargari, Mohammad Keshavarz, Ali Badri , “Design PID-Like Fuzzy Controller With Minimum Rule Base and Mathematical Proposed On-line Tunable Gain: Applied to Robot Manipulator,” International Journal of Artificial intelligence and expert system, 2 (4):184-195, 2011.

- Farzin Piltan, Nasri Sulaiman, M. H. Marhaban and R. Ramli, “Design On-Line Tunable Gain Artificial Nonlinear Controller,” Journal of Advances In Computer Research, 2 (4): 75-83, 2011.

- Farzin Piltan, N. Sulaiman, Payman Ferdosali, Iraj Assadi Talooki, “ Design Model Free Fuzzy Sliding Mode Control: Applied to Internal Combustion Engine,” International Journal of Engineering, 5 (4):302-312, 2011.

- Farzin Piltan, N. Sulaiman, Samaneh Roosta, M.H. Marhaban, R. Ramli, “Design a New Sliding Mode Adaptive Hybrid Fuzzy Controller,” Journal of Advanced Science & Engineering Research , 1 (1): 115-123, 2011.

- Farzin Piltan, Atefe Gavahian, N. Sulaiman, M.H. Marhaban, R. Ramli, “Novel Sliding Mode Controller for robot manipulator using FPGA,” Journal of Advanced Science & Engineering Research, 1 (1): 1-22, 2011.

- Farzin Piltan, N. Sulaiman, A. Jalali & F. Danesh Narouei, “Design of Model Free Adaptive Fuzzy Computed Torque Controller: Applied to Nonlinear Second Order System,” International Journal of Robotics and Automation, 2 (4):232-244, 2011.

- Farzin Piltan, N. Sulaiman, Iraj Asadi Talooki, Payman Ferdosali, “Control of IC Engine: Design a Novel MIMO Fuzzy Backstepping Adaptive Based Fuzzy Estimator Variable Structure Control ,” International Journal of Robotics and Automation, 2 (5):360-380, 2011.

- Farzin Piltan, N. Sulaiman, Payman Ferdosali, Mehdi Rashidi, Zahra Tajpeikar, “Adaptive MIMO Fuzzy Compensate Fuzzy Sliding Mode Algorithm: Applied to Second Order Nonlinear System,” International Journal of Engineering, 5 (5): 380-398, 2011.

- Farzin Piltan, N. Sulaiman, Hajar Nasiri, Sadeq Allahdadi, Mohammad A. Bairami, “Novel Robot Manipulator Adaptive Artificial Control: Design a Novel SISO Adaptive Fuzzy Sliding Algorithm Inverse Dynamic Like Method,” International Journal of Engineering, 5 (5): 399-418, 2011.

- Samira Soltani & Farzin Piltan, “Design Artificial Nonlinear Controller Based on Computed Torque like Controller with Tunable Gain”. World Applied Science Journal,14 (9): 1306-1312, 2011.

- Farzin Piltan, N. Sulaiman, Sadeq Allahdadi, Mohammadali Dialame, Abbas Zare, “Position Control of Robot Manipulator: Design a Novel SISO Adaptive Sliding Mode Fuzzy PD Fuzzy Sliding Mode Control,” International Journal of Artificial intelligence and Expert System, 2 (5):208-228, 2011.

- Farzin Piltan, SH. Tayebi HAGHIGHI, N. Sulaiman, Iman Nazari, Sobhan Siamak, “Artificial Control of PUMA Robot Manipulator: A-Review of Fuzzy Inference Engine And Application to Classical Controller ,” International Journal of Robotics and Automation, 2 (5):401-425, 2011.

- Farzin Piltan, N. Sulaiman, Abbas Zare, Sadeq Allahdadi, Mohammadali Dialame, “Design Adaptive Fuzzy Inference Sliding Mode Algorithm: Applied to Robot Arm,” International Journal of Robotics and Automation , 2 (5): 283-297, 2011.

- Farzin Piltan, Amin Jalali, N. Sulaiman, Atefeh Gavahian, Sobhan Siamak, “Novel Artificial Control of Nonlinear Uncertain System: Design a Novel Modified PSO SISO Lyapunov Based Fuzzy Sliding Mode Algorithm ,” International Journal of Robotics and Automation, 2 (5): 298-316, 2011.

- Farzin Piltan, N. Sulaiman, Amin Jalali, Koorosh Aslansefat, “Evolutionary Design of Mathematical tunable FPGA Based MIMO Fuzzy Estimator Sliding Mode Based Lyapunov Algorithm: Applied to Robot Manipulator,” International Journal of Robotics and Automation, 2 (5):317-343, 2011.

- Farzin Piltan, N. Sulaiman, Samaneh Roosta, Atefeh Gavahian, Samira Soltani, “Evolutionary Design of Backstepping Artificial Sliding Mode Based Position Algorithm: Applied to Robot Manipulator,” International Journal of Engineering, 5 (5):419-434, 2011.

- Farzin Piltan, N. Sulaiman, S.Soltani, M. H. Marhaban & R. Ramli, “An Adaptive sliding surface slope adjustment in PD Sliding Mode Fuzzy Control for Robot Manipulator,” International Journal of Control and Automation , 4 (3): 65-76, 2011.

- Farzin Piltan, N. Sulaiman, Mehdi Rashidi, Zahra Tajpaikar, Payman Ferdosali, “Design and Implementation of Sliding Mode Algorithm: Applied to Robot Manipulator-A Review ,” International Journal of Robotics and Automation, 2 (5):265-282, 2011.

- Farzin Piltan, N. Sulaiman, Amin Jalali, Sobhan Siamak, and Iman Nazari, “Control of Robot Manipulator: Design a Novel Tuning MIMO Fuzzy Backstepping Adaptive Based Fuzzy Estimator Variable Structure Control ,” International Journal of Control and Automation, 4 (4):91-110, 2011.

- Farzin Piltan, N. Sulaiman, Atefeh Gavahian, Samaneh Roosta, Samira Soltani, “On line Tuning Premise and Consequence FIS: Design Fuzzy Adaptive Fuzzy Sliding Mode Controller Based on Lyaponuv Theory,” International Journal of Robotics and Automation, 2 (5):381-400, 2011.

- Farzin Piltan, N. Sulaiman, Samaneh Roosta, Atefeh Gavahian, Samira Soltani, “Artificial Chattering Free on-line Fuzzy Sliding Mode Algorithm for Uncertain System: Applied in Robot Manipulator,” International Journal of Engineering, 5 (5):360-379, 2011.

- Farzin Piltan, N. Sulaiman and I.AsadiTalooki, “Evolutionary Design on-line Sliding Fuzzy Gain Scheduling Sliding Mode Algorithm: Applied to Internal Combustion Engine,” International Journal of Engineering Science and Technology, 3 (10):7301-7308, 2011.

- Farzin Piltan, Nasri B Sulaiman, Iraj Asadi Talooki and Payman Ferdosali.,” Designing On-Line Tunable Gain Fuzzy Sliding Mode Controller Using Sliding Mode Fuzzy Algorithm: Applied to Internal Combustion Engine,” world applied science journal (WASJ), 15 (3): 422-428, 2011.

- B. K. Yoo and W. C. Ham, "Adaptive control of robot manipulator using fuzzy compensator," Fuzzy Systems, IEEE Transactions on, No. 2, vol. 8, pp. 186-199, 2002.

- Y. S. Kung, C. S. Chen and G. S. Shu, "Design and Implementation of a Servo System for Robotic Manipulator," CACS, 2005.

- Farzin Piltan, N. Sulaiman, M. H. Marhaban, Adel Nowzary, Mostafa Tohidian,” “Design of FPGA based sliding mode controller for robot manipulator,” International Journal of Robotic and Automation, 2 (3): 183-204, 2011.

- Farzin Piltan, M. Mirzaie, F. Shahriyari, Iman Nazari & S. Emamzadeh.” Design Baseline Computed Torque Controller” International Journal of Engineering, 3(3): 2012.

- Farzin Piltan, H. Rezaie, B. Boroomand, Arman Jahed,” Design robust back stepping online tuning feedback linearization control applied to IC engine,” International Journal of Advance Science and Technology, 42: 183-204, 2012.

- Farzin Piltan, I. Nazari, S. Siamak, P. Ferdosali ,”Methodology of FPGA-based mathematical error-based tuning sliding mode controller” International Journal of Control and Automation, 5(1): 89-110, 2012.

- Farzin Piltan, M. A. Dialame, A. Zare, A. Badri ,”Design Novel Lookup table changed Auto Tuning FSMC: Applied to Robot Manipulator” International Journal of Engineering, 6(1): 25-40, 2012.

- Farzin Piltan, B. Boroomand, A. Jahed, H. Rezaie ,”Methodology of Mathematical Error-Based Tuning Sliding Mode Controller”International Journal of Engineering, 6(2): 96-112, 2012.

- Farzin Piltan, F. Aghayari, M. R. Rashidian, M. Shamsodini, ”A New Estimate Sliding Mode Fuzzy Controller for Robotic Manipulator” International Journal of Robotics and Automation, 3(1): 45-58, 2012.

- Farzin Piltan, M. Keshavarz, A. Badri, A. Zargari , ”Design novel nonlinear controller applied to robot manipulator: design new feedback linearization fuzzy controller with minimum rule base tuning method” International Journal of Robotics and Automation, 3(1): 1-18, 2012.

- Piltan, F., et al. "Design sliding mode controller for robot manipulator with artificial tunable gain". Canaidian Journal of pure and applied science, 5 (2), 1573-1579, 2011.

- Farzin Piltan, A. Hosainpour, E. Mazlomian, M.Shamsodini, M.H Yarmahmoudi. ”Online Tuning Chattering Free Sliding Mode Fuzzy Control Design: Lyapunov Approach” International Journal of Robotics and Automation, 3(3): 2012.

- Farzin Piltan , M.H. Yarmahmoudi, M. Shamsodini, E.Mazlomian, A.Hosainpour. ” PUMA-560 Robot Manipulator Position Computed Torque Control Methods Using MATLAB/SIMULINK and Their Integration into Graduate Nonlinear Control and MATLAB Courses” International Journal of Robotics and Automation, 3(3): 2012.

- Farzin Piltan, R. Bayat, F. Aghayari, B. Boroomand. “Design Error-Based Linear Model-Free Evaluation Performance Computed Torque Controller” International Journal of Robotics and Automation, 3(3): 2012.

- Farzin Piltan, S. Emamzadeh, Z. Hivand, F. Shahriyari & Mina Mirazaei . ” PUMA-560 Robot Manipulator Position Sliding Mode Control Methods Using MATLAB/SIMULINK and Their Integration into Graduate/Undergraduate Nonlinear Control, Robotics and MATLAB Courses” International Journal of Robotics and Automation, 3(3): 2012.

- Farzin Piltan, J. Meigolinedjad, S. Mehrara, S. Rahmdel. ” Evaluation Performance of 2nd Order Nonlinear System: Baseline Control Tunable Gain Sliding Mode Methodology” International Journal of Robotics and Automation, 3(3): 2012.