Designing a Decision Making Support Information System for the Operational Control of Industrial Technological Processes

Автор: Adelina Faradian, Teimuraz Manjafarashvili, Nikoloz Ivanauri

Журнал: International Journal of Information Technology and Computer Science(IJITCS) @ijitcs

Статья в выпуске: 9 Vol. 7, 2015 года.

Бесплатный доступ

Fuzzy logic is a new and innovative technology that was used in order to develop a realization of engineering control. In recent years, fuzzy logic proved its great potential especially applied to automatization of industrial process control, where it enables the control design to be formed based on experience of experts and results of experiments. The projects that have been realized reveal that the application of fuzzy logic in the technological process control has already provided us with better decisions compared to that of standard control technique. Fuzzy logic provides an opportunity to design an advisory system for decision-making based on operator experience and results of experiments not taking a mathematical model as a basis. The present work deals with a specific technological process ─ designing a support decision making information system for the operational control of the lime kiln with the use of fuzzy logic based on creation of the relevant expert-objective knowledge base.

Fuzzy-Logic, Information Systems, Lime Kiln, Knowledge Base, Expert Knowledge, Linguistic Variables, Fuzzy Rules

Короткий адрес: https://sciup.org/15012362

IDR: 15012362

Текст научной статьи Designing a Decision Making Support Information System for the Operational Control of Industrial Technological Processes

Published Online August 2015 in MECS DOI: 10.5815/ijitcs.2015.09.01

Industrial technological processes is a complex process and it is impossible to solve the management problem traditionally by using an accurate mathematical model. This is due to the fact that the management of industrial processes carried out by the use of information obtained by mixing the subjective (it is given in the normative and technical documentation of process) and objective (it is given in expert information about a particular enterprise, about the enterprise approach to emergency mode, etc.) information. That’s why the technological processes are observed by a man-operator. So, the control of the majority of the lime kiln is done partly manually. The best means of formalizing such a mixed information is building a knowledge base in the form of fuzzy logic rules and after its use in the process management. The burning pro- cess has non-linear character and causes a lot of problems. In an ordinary control system, the only way to control is heuristic methods. In order to implement the control strategy on the basis of expert knowledge were given individual components of the structure, with the use of linguistic variables and fuzzy rules [1] [2] [3].

In their paper [4] Dr. Jörg Gebhardt and Constantin von Altrock review eight (8) recent applications of fuzzy logic in industrial automation:

-

1. Anti-Sway Control of Cranes

-

2. Fire Zone Control in Waste Incineration Plants

-

3. Dosing Control in Waste Water Treatment Plants

-

4. Control of Tunnel Inspection Robots

-

5. Positioning in Presses

-

6. Temperature Control in Plastic Molding Machines

-

7. Climate Control and Building Automation

-

8. Wind Energy Converter Control

All applications used the so-called "fuzzyPLC", an innovative hardware platform that merges fuzzy logic and traditional automation techniques. Following a quick overview on the fuzzyPLC, they discuss this eight (8) applications and focus on how fuzzy logic enabled a superior solution compared to conventional techniques. Whenever possible, they quantify the benefit in cost saving or quality improvement. They note, that “in recent years, fuzzy logic has proven well its broad potential in industrial automation applications. In this application area, engineers primarily rely on proven concepts. Real potential of fuzzy logic in industrial automation lies in the straightforward way fuzzy logic renders possible the design of multi-variable systems… many practitioners do not have the background required for rigorous mathematical modeling. Thus, the general observation in industry is that single process variables are controlled by simple control models such as PID or bang-bang, while supervisory control is done by human operators. This is where fuzzy logic provides an elegant and highly efficient solution to the problem. Fuzzy logic lets engineers design supervisory multi-variable controllers from operator experience and experimental results rather than from mathematical models"…” Thus, the major potential for fuzzy logic lies in the implementation of supervisory control loops”.

The present article considers the construction of such type multi - variable Decision Making Support Information System for control technological process of burning lime process, however, this approach can be used to control any other real technological process.

-

II. Description Of The Lime Burn Technological Process

Air lime called quicklime, which is obtained by annealing carbonate rocks that contain a small admixture of clay. Airy lime may be the following species: a) quicklime - carbonate rocks roasting product, b) milled quicklime - the milled quicklime product, c) quicklime hydration powder product. For the production of lime usually use rocks, which are composed of calcium carbonate. Calcium carbonate is found in nature in two crystalline forms, calcite, and aragonite Calcium carbonate is found in nature in two crystalline forms, calcite, and aragonite. The technical process of making lime is roasting limestone. Depends on it the quality of the final product. According to the reaction

Ca ( hard ) + 3 0 ( gas ) + C ( hard ) = CaCO^ (1)

Heat power of formation of the elements of CaCO is 289000 cal/mol. Lime is widely used in construction [5].

American scientist Boitman in the early 20th century, proved both theoretically and practically, that kilns for lime burning need to use a fraction of stone from 50 mm to 150 mm. Besides that, the specialists' attention should be paid to a small number of compounds in the lime. It can cause abnormal situations during operation, therefore not desirable scheme for obtaining stone from unverified quarry.

Boitman’s research shows that dosing of fuel and limestone is the most important point for the normal functioning, after production of fuel quality and limestone. One of the responsibilities of the operator of the kiln takes into account it all. Quality of lime is an important indicator for the kiln. Degree of annealing should be such that the result obtained qualitative lime [6]. For normal functioning of the kiln must:

-

1. Providing continuous operation downloadable instruments, necessary to constantly monitor the work of these devices.

-

2. Save gas kiln temperature in the range 100-120 Co.

-

3. Dose of fuel must be properly. Minimum once a

week is necessary to check the dose of fuel.

Uniform kiln load and ensure the mix level throughout the entire work.

Control of the kiln consists of the following items:

-

1. Quality control limestone.

-

2. Fuel control.

-

3. The fuel metering mixtures.

-

4. Control the mixing of fuel and lime.

-

5. Temperature control gas kiln.

-

6. Quality control its temperature quenching lime and blanking time.

-

7. Control of the gas composition in the kiln.

-

8. Performance improvement process results.

-

9. Promptly reporting inoperative kiln emergency.

-

10. During the slaking constantly monitor the quality of heat cost.

-

11. The decrease of poisonous gas emissions into the atmosphere control.

Analysis of the gasses in the kiln is thus very important for the successful operation of lime [7] [8].

Specific enterprise, where was implemented a learning of technological process, has been built and tested Decision Making Support Information System, which characterized by the following activities:

Enterprise represent lime factory, which produces quicklime for different areas and delivers to other factories. The main raw materials are local origin limestone and coal in particular anthracite that we cannot find in Georgia and imported from abroad. In the case of emergency, you can use local coal, but it has poor quality and difficult to work on the kiln, and it is impossible to produce high quality products.

In the upper part of the kiln is continuously fed a mixture of limestone and anthracite.

Limestone burning occurs in the middle of the kiln, which is called the core that should be 1000 -1100° C degrees for qualitative burning lime. The lower part of the kiln is also constantly being burnt lime speech, which is automatically replenished transporter on the list, through which he meets in storage bunkers. From the bunker, supplier can automatically get into trucks to be delivered to the user. The factory can be operated with different capacities, which depends on the supply of raw materials and the number of requests from summary customers, appropriately factory income will be different. The result is also conditioned by lime quality, which depends on the quality of the feedstock, kiln operating, weather and other. Thus, the mode of operation of the kiln depends on various factors of uncertainty, and a serious management requires that instantly engaged in the manufacture of kiln operators based on instructions from the chief and technology [9]. The additional condition is that the cost of entry is made only for goods supplied to customers from the end of the total, therefore, future management measures necessary for the implementation of the greater part of the decision-making process has at this time. In different parts of speech are mounted gauges, their parameters are displayed on the control panel, where the operator according to the parameters controls the kiln. A list of these parameters is as follows:

-

1. Temperature kiln core.

-

2. Pressure exhaust miles.

-

3. Speed section located in a lower portion of the kiln.

-

4. Proportionality raw limestone and anthracite which is determined by metering.

-

5. Operating status of all mechanisms and instruments.

-

6. Index of burned lime or not.

-

7. Location firing zone kiln.

These parameters are measured every second and the operator must respond firmly, when leaving them out of a certain range, otherwise can receive low-quality products and the kiln to start working incorrectly and in the worst case it will stop. This last condition is not completely reasonable as to bring into operation the kiln needs 2 months. There are parameters whose values are fed to the factory 24 hours once, and that should be considered by the operator. These parameters are:

-

1. Activity lime which was sold to a customer

-

2. Lime released during the day, which will be calculated in every 24 hours.

-

3. The amount of lime used in the kiln for 24 hours, which is considered using dispensers.

-

4. Number of anthracite used within 24 hours, which was calculated using dispensers.

-

5. Number of limestone imported railroad tonnage.

-

6. Number of limestone in the territory of the factory in tons.

-

7. Number anthracites at the factory in tons.

The factory employs 4 shifts that have 4 different kiln operators have different qualifications and different operating condition of the kiln. Decision-making system would give them stable recommendation on relevant actions. Also would improve the quality and quantity of production which is main goal of factory. Operator has to know how to manage kiln for emergency and nonemergency mode. When there is non-emergency mode, a main task of management system is to get maximum performance.

If the kiln has not the best performance, it is necessary to bring her to this state, otherwise keep it. In emergency mode, the main task of management to withdraw from this mode kiln, and its return to the non-emergency mode and then, must work management system for nonemergency mode.

The aim of our work is to create a management system for burning lime, for emergency and for non-emergency mode.

-

III. Fuzzification Of The Parameters

-

A. Instantly Variable Parameters

For example, let's give the fuzzification of one of constantly changing parameter, which is the temperature A of the active zone of the kiln. The temperature of the active zone of the kiln considering the normal state and the deviation from this condition is ranging from 600 °C to 1400 C. At temperatures less than 600 C limestone burning does not occur, and at a temperature of more than 1400C burns upper part of the kiln and the kiln fails. We use the proper linguistic variable called "temperature of the active zone of the kiln". This linguistic variable has 5 therms:

A1- "very undesirable, low temperature", in the next temperature interval: from 600 C to 850 C . In this temperature, interval is burned only lime of magnesite type. Carbonate type lime in this interval almost is not burning. Lime from quarry of Dedoplistskaro nearly 3% contains magnesite lime, which is taken into account in this temperature interval. This temperature range is mainly taken into account by heating and preparation lime for firing. (With the interval fuzzification 600 C ^ 800 C)

A2- "undesirable low temperature", in the next interval from 800 C to 950 C. In this temperature, interval is burned lime with a mixture of clay and soft lime. Solid lime in this interval is not incinerated. Lime from quarry of Dedoplistskaro is mostly solid lime, so does not burn in this interval. Lime quarry of Dedoplistskaro contains up to 5% of a mixture of clay and lime, which is considered by this temperature interval. (With the interval fuzzification 800 C ^ 950 C)

A3- "desired optimum temperature", in the next interval from 900 C to 1150 C . In this temperature, interval is burned the bulk of the solid lime, which is a big part of lime of Dedoplistskaro quarry. This is the main temperature range for lime burning. (With the interval fuzzification 900 C ^ 1150 C)

A4- "undesirable high temperature", the next interval from 1100 C to 1250 C. In this temperature interval burnt lime with a touch of metal. For burning simple lime, this is already high temperature, it already causes the "asteroids", to contend with them, we must move lattice of kiln. If in the burning zone temperature is in the range - A4, the kiln becomes to the abnormal working mode. Therefore, this interval is not desirable for the normal mode. (With the interval fuzzification 1100 C ^ 1250 C)

A5- "very undesirable high temperature" at the next interval from 1200 C to 1400 C. In this temperature interval the kiln operates in abnormal mode, because it is, on the one hand, most of the output lime are asteroids, which are unsuitable for use, it is defective products, on the other hand, the device upper parts of the kiln are burned loadable and the kiln is completely failed, if you do not take immediate action. At these temperatures, a lime completely receive a bad influence of metal impurities (Al and Fe) on kiln operation and on the process of lime burning. At 1400 C and more metal parts kiln begin to deform and melt. (With the interval fuzzification 1200 C ^ 1400 C). Analysis, membership function are defined as follows [10] [11] [12]:

'1, x e [600,800]

M(x) = J -0.02x +17,x e (800,850]

0,x e (850,1400]

0, x e [ 0,800 ]

0.02 x - 16, x e ( 800,850 ]

M 1 ( x ) = < 1, x e ( 850,900 ]

- 0.02 x + 19, x e ( 900,950 ] 0, x e ( 950,1400 ]

0, x e [ 0,900 ]

0.02 x - 18, x e ( 900,950 ]

mK x ) = J 1, x e ( 950,1100 ]

- 0.02 x + 23, x e ( 1100,1150 ]

0, x e ( 1150,1400 ]

0, x e [ 0,1100 ]

0.02 x - 22, x e ( 1100,1150 ]

m 1 ( x ) = J 1, x e ( 1150,1200 ]

- 0.02 x + 25, x e ( 1200,1250 ] 0, x e ( 1250,1400 ]

0, x e [0,1200]

М1(x) = < 0.02x - 24, x e (1200,1250]

1, x e (1250, +w]

Similarly happens the classification of other instantly varying parameters, what are: temperature of the gases coming out of the kiln -B; gas pressure emanating from suction tube of the kiln -C, which is called the extension; temperature lime discharged from the bottom of the kiln-D; speed of table located in the lower portion of the kiln-E. Control the movements of this table can adjust the amount of products coming out of the kiln; the ratio of raw materials - lime and anthracite which is determined using the dosing -F; indicator that determines whether or not burned lime-G;

-

B. Fuzzification 24 Hours Changing Parameters

Active of lime production - H; Number of lime released during the day - I, this figure is also calculated, in the same way, produce fuzzification of parameters changing 24 hours. Within 24 hours, the amount of lime loaded into the kiln in tonnes - J, which is calculated in terms of the dispenser; Within 24 hours, the amount loaded into the kiln expressed in kilograms - K, which is calculated in therms of the dispenser; The amount of limestone received during the day from the railway station in tonnes - L; Number of stock of limestone in the factory - M; Number of stock of anthracite in the factory - N; Quality anthracite stock – O, with is measured in kilocalorie/kilogramme. All these linguistic variables have own therms [13] [14] [15] [16].

-

C. Output Variable

Fuzzification output variable "Change in condition of the kiln" is possible like this: Checking the values of the above parameters control system will occur every half hour, and on the basis of the obtained values develop recommendations on whether the state of kiln should remain the same or change to maximum performance. The output variable to be characterized as 3 variables, such as A rarity change, an ash velocity change and amount of downloadable anthracite. The first linguistic variable is characterized by three terms: sharpening up to 50 units; not change the value of an existing rarity; soften up to 50 units. The second linguistic variable can be characterized by three terms: the speed increases by 2 units; does not change the speed; decrease speed by 2 points; The third linguistic variable consists of 3 therm: increasing anthracite 2 pounds; not change the amount of anthracite; decrease values of anthracite to 2 pounds.

Thus, the first therms of the linguistic variable are defined as:

R1 – sharpening to 50 units;

R2- not change the value of the existing scarcity;

R3- soften up to 50 units;

Thus, the second therm of the linguistic variable is defined as:

-

V1 – increase the rate of ash into 2 units;

-

V2- not to change the speed of ash;

-

V3- a decrease in the rate of ash into 2 units;

Thus, the third terms of the linguistic variable are defined as:

Q1 – increase of values atrocity 2 pounds;

Q2 - do not change the amount anthracite;

Q3 - a decrease of values atrocity 2 pounds;

Once again, we note that the purpose of the control system kiln is lead a kiln to a state of maximum performance, along the dimension of parameters performing every half hour. Maximum performance mode is the mode in which, the kiln produces monthly and more than 3,000 tons of lime, and average weighted activity of lime is more than 60%. And in an emergency mode the purpose of management system of the kiln is, as quickly as possible return the kiln to the non-emergency mode, taking into account the inertness of the kiln.

-

D. Logical Rules

On the basis of information about this particular process, based on the specifications and technical information about the enterprise and its devices, also on the basis of expert information collected by surveys, using fuzzy logic´s “IF … THAN …” type rules is constructed and adjusted knowledge database [17] [18] [19], which consists of terms of the constantly changing and within 24 hours of changing linguistic variables, that are composed of logical rules, also of the weights established by expert, which are set for these two types of rules separately. For example, we present a small fragment of the rules because in the system there are the hundreds of numbers of such rules:

№1

IF H=(H5) AND I=(I1 OR I2 OR I3) AND J=(J1 OR J2 OR J3 OR J4) AND K=(K4) AND L=(L1 OR L2 OR L3 OR L4) AND M=(M1 OR M2 OR M3 OR M4 OR M5) AND N=(N1 OR N2 OR N3 OR N4 OR N5) AND O=(O2 OR O3) THEN R=(R1) AND V =(V1) AND Q=(Q3); [0,9]

№ 2

IF H=(H5) AND I=(I3 OR I4) AND J=(J1 OR J2 OR J3 OR J4) AND K=(K4) AND L=(L1 OR L2 OR L3 OR L4) AND M=(M1 OR M2 OR M3 OR M4 OR M5) AND N=( N2 OR N3 OR N4 OR N5) AND O=(O2 OR O3) THEN R=(R2) AND V=(V2) AND Q=(Q3); [0,9]

It is a small fragment of rule cluster of knowledge base for non-emergency mode, separately exists in the same database rule clusters for different types of emergency regime. In this way, full knowledge base contains all the possible impact on the stove for all possible combinations of incoming terms of linguistic variables On the basis of these knowledge databases running general algorithm of system, which is described below.

-

E. The General Algorithm

The following steps of the algorithm are:

-

1. After receiving new values of parameters every half hour we fuzzification it in accordance their membership functions and obtain fuzzification values. Then define mode: check the condition B5 AND G2 AND (H1 OR H2).

-

2. Checking the condition occurs, so we take the values of membership functions of these therms and by using the operations AND = MIN OR = MAX calculates the value of condition membership function, it will be number between 0 and 1. If this value is greater than or equal to 0.3 then the system asks the operator to corroborate an emergency mode and after a confirmation go to the second emergency mode rule cluster of knowledge base. Check the condition of the implementation of each right to choose the rules that match show existing variable of each rule, and we believe the value of the membership function of these variables onto, i.e. we obtain the result fuzzy set of kiln status changes.

-

3. If the value of the membership function conditions less than 0.3 the condition is very low i.e. not executed and to verify the second emergency mode condition B5 AND (D3 OR D4).

-

4. If not satisfied no one condition fallback mode which means one is an emergency and goes to the nowemergency mode rule cluster of knowledge base (in the regulations) checked up all the rules get their output variables and compute the membership function, we obtain the result fuzzy set of kiln status changes.

-

5. Defining the membership function of an output variable is made by traditional methods. Clearly that the measured parameter value is always a distinct number. Fuzzification parameters occur so that the number we are looking for those therms of this parameter in determining the precise meaning of that parameter. Then we insert distinct value into the membership function argument, as a result of which we obtain fuzzification value i.e. obtain a distinct value for its membership function. This is done for each parameter. The result is one or more of the therm of the output variable with the appropriate membership functions. Then we take the maximum of the output variable of the same therms. After all this, we will have for each output variable fuzzy set appropriate. In our case, it will be separate for R, for V, for Q.

-

6. The resulting impact on the kiln defuzzification fuzzy sets, using the maximum principle whereby we obtain three influences on the stove or four in the emergency case mode, which must be realized for the operator manipulated stove.

Then, same, using the AND = MIN OR = MAX value is calculated from the conditions of membership functions. If this value is greater than 0.3, then the system asks the operator to corroborate emergency mode and after a confirmation go to first emergency mode rule cluster of knowledge base and check the performance of each rule assert those rules whose conditions are satisfied, after choose exiting each variable conditions and consider we obtain the membership function of these variables.

If it turned out, that after evaluating the function of the output variables have two terms with the same membership functions such R2/0.6 and R3/0.6, then proceed as: for the R-find input value C in which therm it is.

If the therm is C3, C4 or C5 then choose R2 and for the other therms choose R3. Proceed similarly with V only look at the value of the term variable incoming E. In E1 therm case we choose V1, if there are E2 and E3 we choose V2, and we choose V3 if there is E4. For variable Q, we look at the therms of variables F and H.

In the case F1, we choose Q1, in the case Q2, choose F2, and in the F3 or H5 case we choose Q3.

Impact due to the following four parameters: rarity replacement, replacement ash speed, anthracite amount replacement, the unloaded lime amount from the line by hand. As a result, the operator receives appropriate advice.

Designed a Decision Making Support Information System that provides regular data reception, the implementation of the general algorithm, and gives advice to the operator for optimum production management [20] [21]. The system has been tested in enterprise as in emergency and not emergency mode. Testing has shown, that the system is working properly.

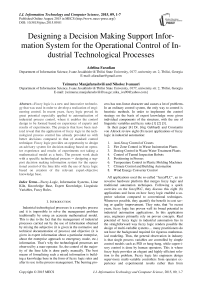

Table 1. The comparison of the predicted results by actual and the advisor system.

|

Expansion change (+50/0/–50) |

Sieve speed change (+2/0/–2) |

The change of amount of anthracite in the mix (+ 2/0 / -2) kg |

|

R1 |

V1 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V1 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q3 |

|

R3 |

V3 |

Q3 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R3 |

V3 |

Q2 |

|

R3 |

V3 |

Q2 |

|

R3 |

V3 |

Q2 |

|

R3 |

V3 |

Q2 |

|

R3 |

V3 |

Q2 |

|

R1 |

V1 |

Q2 |

|

R1 |

V1 |

Q2 |

|

R1 |

V1 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

|

R2 |

V2 |

Q2 |

The table 1 below shows a comparison of some of the test results: predicted output variables of system are marked in red, which do not match the historical data which is taken from the actual values, while the blue - it's a coincidence. As can be seen from a comparison of these colors match almost complete, which indicates the correctness of the database logical rules and the correct operation of the system in terms of control.

If we pay attention to the red cell of comparison, becomes clear, that the difference between the actual and the predicted displacement is caused due to the fact that the system carries out operation of the furnace by using a "conservative" algorithm, that is, if the system is in maximize performance or approximate thereto state the output variables are stay the same.

Whereas at the appropriate time historical data operation of the furnace operators can be realized "maximalist" algorithm, i.e. the value of any variable output can be increased slightly.

In the existing literature on the management of the shaft furnace indicated that due to the high inertia of the furnace and a large influence of small change on the course of chemical process is desirable to control the furnace by using a "conservative" approach, respectively, in our system, this approach has been used in the theory of recommendations respectively that the response of the system in the red zone shows a more than adequate response to the last period of the furnace operator.

Thus, advisor system can be used for furnace operator training using historical data.

Use of this system could help to avoid the transition of the kiln into emergency mode, and costs caused by the production, which were caused by inadequate solution of the operator.

-

IV. Conclusion

In this paper, we consider the construction of an information system to support operational decision-making using fuzzy logic for the entire cycle, for emergency and non-emergency case, based on the creation of the expertobjective knowledge. Specifically examined the work of the lime annealing kiln with all parameters. Operational support system gives solutions to operators to make a decision, considering both groups of factors that were listed above, which greatly improves the operation of the kiln the quantity and quality of output, that is helping to achieve the main goal of production to maximize profits. In the decision-making system embedded not only scientific knowledge about the production, but also the knowledge of qualified staff, that gives the possibility, that the recommendations for the operators will be good for any change in the system was tested on the basis of previous years. Finally, we can conclude that the construction of the Designing a Decision Making Support Information System should be considered as a knowledge of the process, existing in the production of objective knowledge and the expert knowledge (subjective knowledge) qualified staff. In addition to this must be taken into account the specific features of production (volume warehouses, volume of receiving raw materials and shipping products, the structure of enterprise, etc., these parameters conditionally we have called the changing parameters within 24 hours). The importance of taking them into account and stipulates that in industries with a similar technological process parameterization of technological process and fuzzification of parameters may be different and must be made individually for a particular enterprise. Accordingly, software for implementing an information system should comprise the possibility of modifying and adjusting to the specific production.

Список литературы Designing a Decision Making Support Information System for the Operational Control of Industrial Technological Processes

- Barnabas, B. (2013). Mathematics of Fuzzy Sets and Fuzzy Logic.

- Ganesh, M. (2006). Introduction to fuzzy sets and fuzzy logic.

- Deepa, S. N., Sivanandam, S. N., & Sumathi, S. (2007). Introduction to Fuzzy Logic.

- Gebhardt J., Von Altrock C. (1996). Proceedings of the Fifth IEEE International Conference on Fuzzy Systems.

- Chandra, S. (2013).Waste Materials Used in Concrete Manufacturing.

- Pascenco, A.A., Serbin, V.L., & Starchevsky, E.A. (1975). Cementing materials. Publisher Association "Vitsa School”.

- Fraps, G. S. (1917). Effects of lime and carbonate of lime on acid phosphate.

- Naumenko, A.V., Naumenko, V.D., & Naumenko, I.V. (2004). Production of lime, limestone milk and the car-bonation gas in sugar factories.

- Oates, J. A. H. (2008). Lime and Limestone.

- Siddique, R., & Khan, M.I. (2011). Supplementary Ce-menting Materials. Springer.

- Ambrosio, B. (1989). Qualitative process theory using linguistic variables.

- Hanss, M. (2005). Applied Fuzzy Arithmetic.

- Kaufman, A., Madan, M.G., & Esposito, B. (1991). “Introduction to Fuzzy Arithmetic”.

- Zadeh, L. A. Linguistic Variables and Approximate Reasoning.

- Zadeh, L. A. The concept of a linguistic variable and its application to approximate reasoning.

- Lieb, H. H. (1993). Linguistic Variables.

- Klir, G. J., & Yuan, B. (1995). Fuzzy Sets and Fuzzy Logic.

- Leonenkov, A. (2005). Fuzzy modeling in MATLAB and fuzzyTECH.

- Ruan, D., & Kerre, E. (2000). Fuzzy If-Then Rules in Computational Intelligence Using MATLAB”. Springer-Verlag Berlin Heidelberg (pp. 157-367).

- Wang, L.X., & Jerry, M. Mendel, J.M. (1991).Generating Fuzzy Rules from Numerical Data, with Applications.

- Ross, J.T. (2004). Fuzzy Logic with Engineering Applications.

- Bernadette, B.M., Yager, R.R., & Lotfi, A.Z. (1995). Fuzzy Logic and Soft Computing.